The basement, like other rooms in the house, must be insulated. Most residential buildings have a basement located between the first floor ceiling and the ground. Its height depends on the same parameter of the base and can vary within 0.5-2 m or more. Insulation of the basement ceiling and comprehensive insulation measures make it possible to more efficiently use the internal space located under the first floor. Properly selected materials and technologies make it possible to create a comfortable microclimate in the basement.

Purpose of thermal insulation

Lack of insulation and damage to the waterproofing layer allow moisture and cold air to penetrate. This is especially noticeable in the basement, where over time mold appears due to dampness and there is a risk of fungus spreading along the surface of the walls. Insulating the basement ceiling will prevent the negative effects of moisture and low temperatures on concrete and preserve load-bearing structures from destruction. In addition, effective thermal insulation will provide:

- reduction in heat loss by approximately 20%;

- comfortable floor temperature in the rooms on the first floor.

Thanks to ceiling insulation and other insulation options, the basement can be equipped with a laundry room, utility rooms or recreation rooms. In some cases, a cellar, gym or swimming pool is installed under the ceilings of the first floor.

The final stage

By installing a thermal insulation layer on the ceiling in the cellar, its owner will solve the problem of cold and water entering the room. But moisture can still form in this part of the house. And the reason for this is that the material is not able to remove it from the cellar. At any moment, condensation will appear, which will cause the spread of unpleasant mold and rot. All this will provoke active reproduction of the pathogenic fungus, which should not be allowed in cellars. A special hole that will perform the functions of standard ventilation can solve the problem. Air circulation will help quickly remove steam from the cellar.

0 0 vote

Article rating

Choice of insulation

The variety of materials used for insulation allows you to find the best option for different areas of use. When choosing a certain type of insulation, you need to pay attention to the following parameters:

- coefficient of thermal conductivity;

- moisture permeability;

- reasonable cost.

An important criterion for assessing insulation is its resistance to fire. To avoid accidents, thermal insulation should not ignite or release poisonous and toxic substances in the event of a fire.

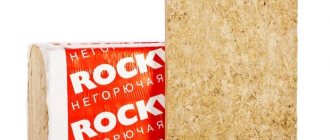

Mineral wool and fiberglass

Another popular building material is mineral wool. It is accessible to many consumers due to its low price. Mineral wool is distinguished by fire resistance, vapor permeability, environmental friendliness, thermal conductivity and a high degree of sound insulation. In addition, it is non-hygroscopic. This insulation is strong and durable, it is easy to install on any surfaces of different configurations.

When working with mineral wool, the home craftsman must provide respiratory protection, since the smallest particles of this material rise into the air like dust. Inhaling them by humans can lead to health problems.

Also, this type of insulation emits such a harmful component as phenol. For this reason, it is necessary to work with it in a respirator, and cover the heat-insulated surface with a vapor-proof polyvinyl chloride film.

Glass wool is a type of mineral wool. It is an elastic and durable material consisting of fragile glass threads, which, when broken, dig into the skin and eyes. When working with glass wool, you should take precautions - wear long sleeves, a respirator, gloves, and goggles.

Types of thermal insulation materials

Insulation of the ceiling in the basement can be done using mineral wool, polystyrene foam or extruded polystyrene foam, which differ in technical characteristics and installation nuances.

Mineral wool

is compressed fibers of inorganic material, the layers of which are molten rocks, blast furnace slag and fiberglass. Mineral wool based on sedimentary rocks is used to insulate basement ceilings. It is different:

- good insulating properties;

- low thermal conductivity;

- resistance to fire and chemicals.

The lifespan of the material is about 30-40 years.

Polystyrene foam and extruded polystyrene foam

foam Insulation materials are made from polystyrene using different technologies, so some of their parameters have significant differences. Common benefits include:

- light weight;

- low thermal conductivity coefficient;

- ease of installation and maintenance.

Extruded polystyrene foam is more effective as thermal insulation than polystyrene foam, but is more expensive. The main disadvantage of these materials is the disruption of the natural balance of temperature and humidity in the premises, which occurs due to the lack of circulation of moisture and air. To maintain a comfortable microclimate, it is necessary to ensure good ventilation.

Why do this

The reasons for insulation may be different. Most homeowners do this to ensure that cold air from there does not enter the interior of the house. But this is not the only reason.

In these places, the house is often equipped with utility rooms, laundries and even billiard rooms. In these cases, the reason is obvious - it is necessary for it to become warm there.

In addition, quite humid air usually rises from here. This is due to the fact that colder air masses sink down, taking with them moisture, which gradually condenses in a colder place. To avoid this, you will need to install not only a layer of heat-saving coating, but also organize good ventilation of the room.

The effectiveness of the constructed heat-saving layer will directly depend on what insulation was chosen to create the heat-saving pillow.

Tools and materials

The list of tools and devices necessary for insulating basement ceilings depends on the method of its implementation. The minimum set should include:

- knife for cutting insulation;

- tape measure and building level;

- dry or ready-made mixtures for leveling the concrete surface;

- putty knife.

If polystyrene foam or extruded polystyrene foam is used as thermal insulation, you will need special glue and a fine-tooth comb to apply it. Insulation with mineral wool is carried out after installing the frame, which will require the following:

- metal profiles or wooden blocks;

- hacksaw for metal or wood;

- drill;

- screws and dowels.

To protect the insulation from moisture, a vapor barrier layer is required, and to treat the ceiling surface, a special impregnation is required, the composition of which is determined by the ceiling material.

Warming the cellar from freezing

Owners of private households and country houses have the opportunity to equip their own basement structure, designed for storing seasonal harvests of fruits and vegetables, preparations and various food supplies. In order for all internal and external surfaces in it to be reliably protected from moisture accumulation and freezing, you need to know how to insulate the ceiling, door and walls in the cellar.

It is possible to create an optimal microclimate in such a storage facility if it is properly constructed and insulated. A well-equipped cellar guarantees that the harvest will be completely preserved, regardless of the weather outside.

When deciding how to insulate a basement, you should take into account its type, which can be:

- ground;

- underground;

- buried.

It is easiest to insulate a ground-based object, since in this case it is possible to install thermal insulation inside and outside it. In turn, a buried basement requires not only insulation, but also waterproofing of surfaces. The most successful option for arranging a cellar is underground or bulk, since then positive temperature conditions are constantly maintained.

Despite the differences in storage types described above, their design has a roof, floor and ceiling. Therefore, when performing insulation, all these surfaces should be insulated in accordance with the operating characteristics of the building.

For example, when building a ground-based structure, special attention is paid to insulating the cellar - the ceiling, roof and walls in it, and for external work they use expanded polystyrene and polystyrene. Before thermal insulation of a buried storage facility, waterproofing is carried out, since there is a high probability of flooding.

The process of arranging an underground facility is considered the most labor-intensive - it involves partial excavation of the soil that surrounds the walls and roof, with the subsequent construction of a protective barrier that prevents the penetration of moisture.

Preparatory work

Before starting insulation work, you should inspect the surface of the ceiling, clean it of dust and identify irregularities, cracks and other defects. In addition, you will need to check for height differences in different areas of the floor. If there are significant discrepancies, it is advisable to choose the frame method for installing thermal insulation.

After cleaning the ceiling from dust and dirt, repair any detected damage using wood putty or cement-based leveling mixtures. After drying, the surface is sanded and treated with special compounds to protect against fungus and mold. Preparatory work is carried out especially carefully when using the adhesive method of fixing the insulation.

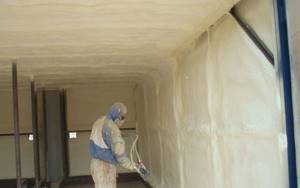

Polyurethane foam

A frequently used thermal insulation material is polyurethane foam (abbreviated PUF). Its popularity is explained by such advantages as biological neutrality, ensuring the tightness of the furnished premises, and high-quality protection from moisture.

Since polyurethane foam is applied to the surface in a monolithic layer, the resulting coating hardens quickly and has no visible joints or seams. Even in the case of direct contact with moisture, this insulation does not succumb to mold and is resistant to rotting processes.

Polyurethane foam can be used for interior and exterior work. PU foam has one drawback, which is the method of its application. The fact is that its installation requires expensive equipment operating under high pressure. Construction companies can afford to purchase it. But this minus is insignificant compared to the effective result obtained.

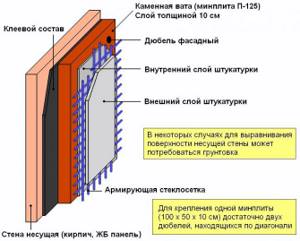

Mineral wool insulation

When using mineral wool to insulate a ceiling, you must first make a frame from metal guides or wooden blocks. They are fixed to the ceiling in increments of 50 cm using dowels or self-tapping screws, constructing cells of a certain size. Then a vapor barrier layer is laid using a membrane film, and the following types of work are performed:

- cut the insulation into pieces of the required sizes, coinciding with the dimensions of the frame cells;

- lay mineral wool slabs in cells, additionally securing them with dowels with wide heads;

- fix a layer of vapor barrier material.

Various types of panels, siding and other types of finishing are used as the finishing layer, the choice of which depends on the purpose of the basement.

Insulating the basement from freezing from the inside

In order for the internal space of the object to be protected from freezing, the cellar should be insulated - the ceiling, walls, floor and all other structural elements through which heat usually leaks. To do this, use roofing felt, expanded clay or rigid thermal insulation materials. The process of insulating various internal surfaces of a building has its own characteristics.

In the cellar it will be necessary to insulate:

- floor;

- ceiling plane;

- walls;

- door.

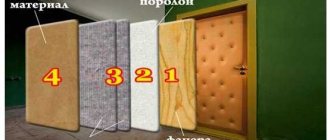

Foam insulation

Installation of thermal insulation using polystyrene foam or extruded polystyrene foam can be done using a special adhesive composition. Ceiling insulation measures include the following steps:

- carrying out markings that are necessary for orientation during laying of the material;

- preparation of glue, the composition of which depends on the type of flooring;

- rolling one side of the insulation with a needle roller to increase adhesion;

- applying glue to the thermal insulation plates using a fine-tooth comb;

- gluing sheets of foam plastic or extruded polystyrene foam to the ceiling surface from the middle in a checkerboard pattern;

- additional fastening of the insulation with special dowels, which are placed in the middle and along the edges of the slabs.

During installation, the thermal insulation sheets are placed close to each other, trying to avoid gaps. The joints between the sheets can be closed with construction tape. If finishing is necessary, after the glue has dried, a reinforcing mesh is attached to the insulation. Then the surface of the ceiling is puttied, eliminating unevenness. For utility basements, it is enough to paint the layer of plaster after it has dried, but in rest rooms and similar rooms the finishing is carried out taking into account the general design concept.

How to get rid of condensation in the garage

Insulating the ceiling in the basement

Insulating the ceiling is a mandatory procedure that includes arranging a cellar. It is especially relevant in cases where this building is not located under the house, but in a separate area. Therefore, water can easily penetrate into it from the top. The problem can only be prevented by creating an insulating layer. Typically, underground rooms are constructed from concrete slabs. They are also used for foundations and various floors. This material by its nature is not able to prevent moisture from penetrating into the building. And it is also not a guarantee that cold will not get into the cellar. The insulation of concrete slabs will allow you to create a favorable atmosphere in the room for food storage and preservation. It wouldn’t hurt to additionally treat the ceiling and other parts of the cellar with a high-quality moisture-proofing compound.

The procedure for insulating a cellar includes a number of sequential works:

- Before starting insulation, it is recommended to impregnate the concrete slab with a waterproofing compound that can penetrate into the material. This substance will fill the cracks in concrete that have appeared over the years of operation, as well as internal capillaries. It is through them that moisture can penetrate into the room.

- It is necessary to wait until the treated slabs dry completely.

- Foam boards are attached to a dry surface.

- The insulating material must be carefully secured with dowels.

- Now you need to attach the mounting mesh to the material.

- The entire treated area of the cellar is covered with a layer of plaster.

To insulate a cellar with mineral wool, you will have to do a little different work:

- Wooden blocks are attached to the ceiling.

- Between the bars and the surface of the cellar, laid out mineral wool mats are placed.

- Additionally, it is worth laying the insulation with a vapor-proof film. It will not let the cotton get wet.

Just like the ceiling, you can insulate the walls of the underground room.

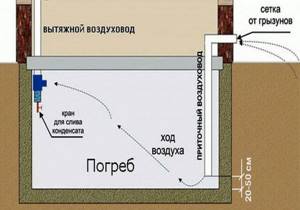

Creating ventilation in an insulated cellar

Home storage of harvest and winter preparations certainly requires a reliable ventilation system. It is especially necessary for an insulated cellar, since due to the constant above-zero temperature, air humidity increases in it, as a result of which mold appears.

To prevent this, it is necessary to create ventilation openings during the construction stage of the storage facility. They are closed in winter and kept open at other times of the year.

For example, supply and exhaust ventilation ensures the inflow and outflow of fresh air masses, and normal temperature is ensured in other ways. You can insulate the ventilation duct with mineral wool and cover it with waterproofing material. As a result, the ventilation system will function smoothly and efficiently, and the temperature in the cellar will always be comfortable.

Ceiling insulation options

When insulating the ceiling with sawdust, you should be careful not to miss the cracks that are always present on the surfaces. To eliminate them, polyurethane foam is used.

There are several options for arranging thermal insulation of the ceiling using sawdust, both using pure wood raw materials and by adding additional additives to it, such as clay, lime, etc.

The most popular methods are:

- use of sawdust in its pure form;

- the use of additives - cement and lime;

- the use of additional components - clay and lime.

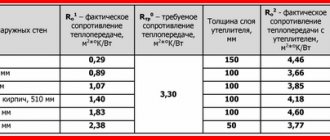

Waterproofing basement walls and installing insulation

The first stage is waterproofing the basement walls with penoplex installed on it (waterproofing layer). Insulation can be carried out earlier than 5-7 days after completion of waterproofing work. This time is more than enough for the evaporation of the solvents in their composition. Only in this case the waterproofing of the basement walls will not corrode the penoplex.

For water-saturated soils, experts recommend installing drainage to drain water away from the thermal insulation. Drainage pipes are laid slightly below floor level on a so-called gravel bed with a slope of 3-5%. Then they are covered with a layer of gravel. And only after completing the above steps, insulation is carried out on the basement soil using penoplex.

We determine the cause of dampness and eliminate it

Moisture in the basement can come from outside moisture or from condensation inside the basement.

Influx of dampness from outside

To rule out this cause, conduct a survey of the basement or cellar.

Moisture can seep into the outside of the basement through cracks or defects in the walls. Along poorly installed communications

Pay attention to the condition of the blind area. If large trees grow near the foundation, then water can also enter the basement through their roots.

High groundwater is one of the reasons for dampness in the basement.

Eliminating the causes

After inspecting and identifying large and small cracks, clear them and carefully seal them with cement mortar. Dry well. Treat with a concrete cleaner; it effectively destroys mosses, lichens, and fungi. After drying, coat with bitumen mastic.

The entry points of communications where leaks are possible should be sealed with alabaster mortar.

If moisture enters through cracks in the floor, then all cracks must be sealed with cement mortar.

After drying, pour about a 5-7 centimeter layer of sand or fine expanded clay.

Lay roofing material three millimeters thick on top of the sand or expanded clay. In this case, it is necessary to overlap the sheets on each other and on the walls by at least 10-15 cm. You can cover the sand with a special waterproofing film for floors.

The joints of roofing felt sheets are coated with bitumen mastic. Lay the reinforcing mesh and make a new screed.

You can lay logs and lay a wooden floor after the concrete has dried.

If the cellar has a clay floor, then waterproofing it is not at all difficult. To do this, you need to remove about 5-7 centimeters of clay. Level well and compact the base thoroughly. Spread two layers of thick plastic film, overlapping at least 10 cm on the floor and 12-15 cm on the walls.

Prepare a mixture of clay and sawdust, adding about 10% of the latter. Mix well, moisten a little. Place on top of the film in a layer of 12-15 cm, compact well.

During the drying process, small cracks will form on the floor. They are covered with the same composition.

After drying, apply a second similar layer, but with a rise of 25-30 cm on the walls.

When the floors dry well, the humidity in the basement will be much lower.

Increased humidity from an internal source

The appearance of condensation on the internal surfaces of a cellar or basement is an internal source of dampness. If condensation appears on the walls and ceiling in a cellar or basement, the culprit is poor ventilation or its absence.

The simplest ventilation device is shown in the figure.

For small basements and cellars, up to approximately 45-50 cubic meters. meters, two pipes installed at different ends of the basement are enough. Firstly, the supply air, which from below does not reach the floor by 10-15 cm, and from above rises above the ceiling by 30-35 cm. Secondly, the exhaust, which from below is located almost under the ceiling, and from above should be higher than the supply air at least than 60-70 cm. Be sure to install “fungi” on top of both pipes to protect them from rainwater. In addition, it is advisable to install a metal rodent mesh on the supply pipe, since it is located low above the ceiling.

If the basement area is larger, then it is advisable to install a fan on the exhaust pipe.

Do-it-yourself penoplex installation

To carry out proper installation of polystyrene foam boards on the ceiling surface, you will need to prepare a certain list of consumables and tools. In addition, the insulated surface must also be prepared. This will allow you to install the thermal insulation layer quickly, without downtime.

You will need:

- building level;

- construction or stationery knife;

- hammer;

- perforator;

- ladder or stepladder.

List of materials required for DIY installation:

- deep penetration primer with an antifungal component;

- dry adhesive composition compatible with polystyrene foam;

- foam for installation;

- fastening tools (so-called mushrooms).

Insulation of the ceiling base from the attic side

This method consists of the following sequence of actions:

- Cleaning the surface to be insulated from residues of various types of contaminants.

- Applying an adhesive mixture to the surface and laying insulation elements on the attic flooring.

- During the procedure, care must be taken to ensure that no serious gaps are formed;

- When the glue has completely set, it is necessary to seal the existing gaps between the insulator plates. This is done using polyurethane foam.

- After 24 hours, you need to trim off all excess foam for installation. If the attic space will be used for residential purposes, planks or other floor coverings are laid.

Insulation of the ceiling on the residential side

There are often objective circumstances according to which it is not possible to install insulation from the attic area. This happens in apartment buildings where upstairs neighbors live, or in buildings where there is no attic at all. In this case, all insulation work will be carried out from the side of the home, and the procedure will become somewhat more complicated.

The work algorithm looks like this:

- All debris must be removed from the surface to be insulated and visible gaps and cracks must be filled with putty;

- then apply a primer and a mixture that prevents the development of fungus;

- insulation boards are treated with an adhesive solution and then fixed to the surface;

- using a hammer drill, holes for the “fungi” are drilled on the surface of the glued slabs;

- the dowels must be driven into the holes made for them, so the plates will be securely fastened;

- places where joints do not fit tightly and all gaps are carefully foamed;

- after the polyurethane foam has hardened, remove its excess with a knife and begin to secure the reinforced mesh, which will be held in place by the adhesive solution;

- the surface treated with glue and reinforced with mesh must be cleaned and primed, after which a fine finish can be applied;

- The final stage of work consists of decorating the insulated area (you can use paint or any decorative coating).

It is not difficult to conclude that carrying out work inside to insulate a room is a much more labor-intensive and costly process. Because of this, the popularity of this procedure is low, and it is used only in situations where it is impossible to insulate the home from the outside.

Insulation of the attic ceiling

If the attic space is used as a residential attic, the question of insulating it using penoplex will be relevant. Its high qualities of thermal insulation and absorption of extraneous sounds will make staying in the attic more comfortable and suitable for living. But it is worth considering that the material will have to be secured differently in this area.

Independent work will consist of the following stages:

- Prepare the surface for attaching fragments of insulating material to it. The procedure is standard and described above.

- Assembling the sheathing frame and securing the polystyrene foam boards to it.

- Treat all joints with installation foam that has a minimum expansion rate.

- OSB, chipboard or plank flooring is fixed on top of the thermal insulator.

Installation of profiles and their fastening

Penoplex insulation of the basement basement and finishing with tiles are currently very often used. The first of them has all the necessary heat-saving functions and copes well with various loads. And the tiles perform a decorative function.

Work begins by determining the level of the edge. To do this, take a level, which consists of a tube and an ordinary hose (rubber). And in order to increase the effectiveness of the measures (especially for low basement areas), it is advisable to place a number of points in the corner areas of the structure. Its height should be approximately 1 meter from the level of the ground masses.

Next, you need to identify a horizontal line running along the edge of the wall structure. After this, the installation of profiles begins from the corner sections of the structure. Next, attach the top profile edge to the wall structure. Dowels are used as fastenings.

Types of cellars for a private home

When deciding how to insulate a cellar from the inside or outside, the type of cellar is first taken into account:

Above ground cellar

Above ground cellar

A separate room with a depth of up to 0.5 m into the soil. It can be free-standing or wall-mounted (one of the walls of the cellar is the wall of an outbuilding or garage). From the point of view of insulation, this is the simplest option, because It is possible to insulate the walls and roof from the outside and inside.

Deep cellar (semi-underground)

Deep cellar

The lowest point of the building is located at a depth of no more than 1.5 m from the ground surface. In this case, in addition to insulation, you should also think about neutralizing the effects of groundwater and frost heaving of the soil.

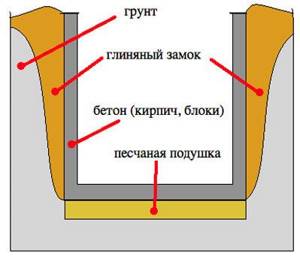

Underground cellar (bulk)

Underground (bulk) cellar

It is distinguished by the location of the floor at a level of 2-3 meters underground. With proper waterproofing, this is the most advantageous cellar from the point of view of operation, which perfectly maintains above-zero temperatures, approximately constant, throughout the year.

Despite the differences in construction, the design of the cellar is not diverse.

Standard cellar design:

- walls - if the soil is dense - soil, if the soil is moving - brick or stone;

- there is no floor, or rather it is dirt;

- ceiling - reinforced concrete or wood.

Accordingly, the ceiling, walls, and floor are insulated. Those. all cellar surfaces through which heat loss is possible.

How to insulate a ceiling correctly

Knowing how to insulate a cellar with maximum efficiency means understanding the principle of carrying out work, starting from the ceiling. It is its surface that is isolated first. Foamed polyurethane foam, resistant to mold and mildew, is suitable for the ceiling. Insulation with this insulation will prevent heat loss through the ceiling and prevent the penetration of cold from the outside.

The ceiling can be insulated from two sides: from above - from the side of the living space of a private house and from below - in the basement itself. The essence of the work practically does not depend on the choice of insulation method. They begin with preparing the surface, after which they install thermal insulation with an additional layer of hydro- and vapor barrier for insulation materials that exhibit insufficient resistance to moisture. The final stage is rough or decorative finishing.

They work in this sequence, insulating the ceiling both from the side of the living space of a private house and from the basement.

How to drain and drain water

Eliminating water penetration into the basement from the ground is either difficult or impossible. More often it is necessary to install a drainage system around the house or repair the existing one.

In this case, it is necessary to tear off the foundation from the outside. In this case, talking about internal insulation loses all meaning, since the foundation walls become free for external insulation and for additional waterproofing.

There may be other drying options. Sometimes the issue is resolved comprehensively for a group of houses or an entire village, by opening a drainage ditch.

Sometimes the basement can only be drained by installing a well with a pump. Although pumping out a spring under a house is an extremely thankless task, what should you do? This source of water can serve the purpose of water supply to the house, so not all the work of the pump will be “wasted”.

Thus, for a wet basement there is only one method of insulation left - external with preliminary drying of the soil.

Waterproofing the room

If during the operation of the premises leaks were noticed in the seams and joints between building materials, then it is necessary to cover the cellar with internal waterproofing to prevent condensation.

For this, three technologies are used: roll, membrane and penetrating, the latter of which is more efficient. For internal waterproofing, it is better to use the penetrating method, for which a mixture is prepared consisting of a dry base and water

The essence of the penetrating method is to introduce the product into microcracks in concrete, due to which they are filled. Thus, water in smaller quantities will pass through the pores of the material, thereby not affecting the humidity.

Wooden structures are most susceptible to problems with waterproofing. Condensation in the basement of a wooden house often appears due to damage to the primary layer of material, the condition of which requires constant monitoring.