Technological pipelines of enterprises and life support systems of populated areas transport various media with different parameters. These parameters, in particular temperature, must be maintained regardless of the influence of environmental conditions, and for this thermal insulation is necessary. Its thickness is determined by calculation, which is based on the requirements of regulatory documents.

Thermal insulation of the pipeline must maintain the temperature in the pipe regardless of the influence of environmental conditions on it.

Characteristics of network laying and standard calculation methods

Carrying out calculations to determine the thickness of the heat-insulating layer of cylindrical surfaces is a rather labor-intensive and complex process. If you are not ready to entrust it to specialists, you should be careful and patient to get the right result. The most common way to calculate the thermal insulation of pipes is based on standardized heat loss indicators. The fact is that SNiP establishes the values of heat loss by pipelines of different diameters and with different methods of laying them:

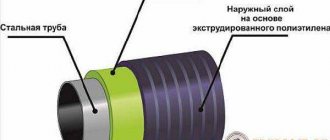

Pipe insulation diagram.

- open method on the street;

- open in a room or tunnel;

- channelless method;

- in impassable channels.

The essence of the calculation is to select the heat-insulating material and its thickness in such a way that the amount of heat loss does not exceed the values prescribed in SNiP. The calculation methodology is also regulated by regulatory documents, namely the relevant Code of Rules. The latter offers a slightly more simplified methodology than most existing technical reference books. Simplifications include the following points:

- Heat losses when the pipe walls are heated by the medium transported in it are negligible compared to the losses that are lost in the layer of external insulation. For this reason, they can be ignored.

- The vast majority of all process and network pipelines are made of steel; its heat transfer resistance is extremely low. Especially when compared with the same insulation indicator. Therefore, it is recommended not to take into account the heat transfer resistance of the metal pipe wall.

Is it necessary to insulate pipes in the basement of a house?

Is it necessary to insulate polypropylene pipes in the basement? If you did not insulate the strip foundation during construction. then it is simply necessary to protect communications from heat loss. If a country house is rarely used in winter, then communications may freeze, regardless of what material is used for the water supply pipe - metal-plastic, HDPE pipe or galvanized steel.

When a cold water pipe enters a warm room, condensation will always form on it. If the pipe is insulated, you will protect the room from possible dampness. Heating pipes in the basement also need thermal insulation so as not to waste excess heat in this room, but to redirect it as much as possible to the living quarters, reducing your heating costs.

Methodology for calculating a single-layer thermal insulation structure

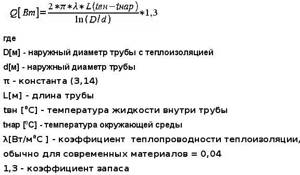

The basic formula for calculating the thermal insulation of pipelines shows the relationship between the amount of heat flow from an existing pipe covered with a layer of insulation and its thickness. The formula applies if the pipe diameter is less than 2 m:

Formula for calculating thermal insulation of pipes.

ln B = 2πλ [K(tт - to) / qL - Rн]

In this formula:

- λ — thermal conductivity coefficient of insulation, W/(m ⁰C);

- K is the dimensionless coefficient of additional heat loss through fasteners or supports, some values of K can be taken from Table 1;

- tt is the temperature in degrees of the transported medium or coolant;

- to—outside air temperature, ⁰C;

- qL—heat flow value, W/m2;

- Rн - heat transfer resistance on the outer surface of the insulation, (m2 ⁰C) / W.

Table 1

| Pipe laying conditions | K coefficient value |

| Steel pipelines are open along the street, through channels, tunnels, open indoors on sliding supports with a nominal diameter of up to 150 mm. | 1.2 |

| Steel pipelines are open along the street, through channels, tunnels, open indoors on sliding supports with a nominal diameter of 150 mm or more. | 1.15 |

| Steel pipelines are open along the street, through canals, tunnels, and open indoors on suspended supports. | 1.05 |

| Non-metallic pipelines laid on suspended or sliding supports. | 1.7 |

| Channelless installation method. | 1.15 |

The thermal conductivity value of the insulation λ is a reference value, depending on the selected thermal insulation material. It is recommended to take the temperature of the transported medium tt as the average throughout the year, and the temperature of the outside air tto as the average annual temperature. If the insulated pipeline runs indoors, then the ambient temperature is set by the technical specifications for the design, and in its absence it is taken equal to +20°C. The indicator of heat transfer resistance on the surface of a heat-insulating structure Rн for outdoor installation conditions can be taken from Table 2.

table 2

| Rн,(m2 ⁰C) /W | DN32 | DN40 | DN50 | DN100 | DN125 | DN150 | DN200 | DN250 | DN300 | DN350 | DN400 | DN500 | DN600 | DN700 |

| tt = 100 ⁰C | 0.12 | 0.10 | 0.09 | 0.07 | 0.05 | 0.05 | 0.04 | 0.03 | 0.03 | 0.03 | 0.02 | 0.02 | 0.017 | 0.015 |

| tt = 300 ⁰C | 0.09 | 0.07 | 0.06 | 0.05 | 0.04 | 0.04 | 0.03 | 0.03 | 0.02 | 0.02 | 0.02 | 0.02 | 0.015 | 0.013 |

| tt = 500 ⁰C | 0.07 | 0.05 | 0.04 | 0.04 | 0.03 | 0.03 | 0.03 | 0.02 | 0.02 | 0.02 | 0.02 | 0.016 | 0.014 | 0.012 |

Note: the value of Rн at intermediate values of coolant temperature is calculated by interpolation. If the temperature is below 100 ⁰C, the value of Rн is taken as for 100 ⁰C.

Indicator B should be calculated separately:

Table of heat losses for different pipe thicknesses and thermal insulation.

B = (diz + 2δ) / dtr, here:

- diz - outer diameter of the heat-insulating structure, m;

- dtr — outer diameter of the protected pipe, m;

- δ—thickness of the thermal insulation structure, m.

Calculation of the thickness of pipeline insulation begins with determining the indicator ln B, substituting into the formula the values of the outer diameters of the pipe and thermal insulation structure, as well as the thickness of the layer, after which the parameter ln B is found using the table of natural logarithms. It is substituted into the main formula along with the indicator of the normalized heat flow qL and make a calculation. That is, the thickness of the pipeline insulation must be such that the right and left sides of the equation become identical. This thickness value should be taken for further development.

The considered calculation method applied to pipelines with a diameter of less than 2 m. For pipes of larger diameter, the calculation of insulation is somewhat simpler and is carried out both for a flat surface and using a different formula:

δ = [K(tт - to) / qF - Rн]

In this formula:

- δ—thickness of the thermal insulation structure, m;

- qF is the value of the normalized heat flow, W/m2;

- other parameters are the same as in the calculation formula for a cylindrical surface.

Thermal insulation of pipelines and its essence

By using thermal insulation, manufacturers make it easier for themselves to carry out certain technological processes. This solution is widely used in many industries:

- Metallurgical.

- Food.

- Oil refining.

- Chemical.

But insulation receives more attention from energy representatives. In this case, the thermal insulation objects have the form:

- Smoke pipes.

- Heat exchange devices.

- Accumulator tanks where hot water is stored.

- Turbines with gas and steam.

Thermal insulation of pipelines is used on devices that are located in both vertical and horizontal planes. This is a current solution for thermal insulation of equipment, such as tanks in which water is stored along with coolants. A number of stringent requirements are imposed on the effectiveness of insulating coatings.

Methodology for calculating a multilayer thermal insulation structure

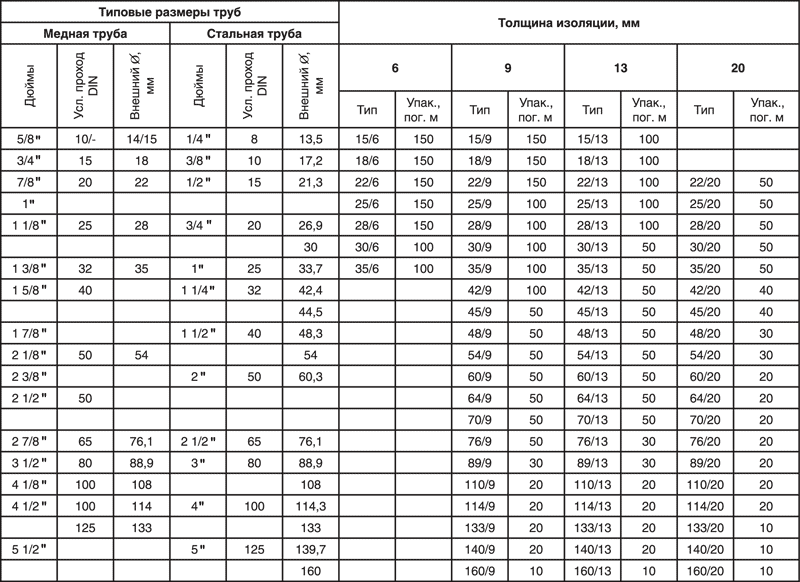

Copper and steel pipe insulation chart.

Some transported media have a fairly high temperature, which is transferred to the outer surface of the metal pipe almost unchanged. When choosing a material for thermal insulation of such an object, they are faced with the following problem: not every material is able to withstand high temperatures, for example, 500-600⁰C. Products capable of contact with such a hot surface, in turn, do not have sufficiently high thermal insulation properties, and the thickness of the structure will be unacceptably large. The solution is to use two layers of different materials, each of which performs its own function: the first layer protects the hot surface from the second, which protects the pipeline from the effects of low outside air temperatures. The main condition for such thermal protection is that the temperature at the boundary of the layers t1,2 be acceptable for the material of the outer insulating coating.

To calculate the thickness of the insulation of the first layer, use the formula already given above:

δ = [K(tт - to) / qF - Rн]

The second layer is calculated using the same formula, substituting instead of the pipeline surface temperature tt the temperature at the boundary of two heat-insulating layers t1.2. To calculate the thickness of the first layer of insulation for cylindrical surfaces of pipes with a diameter of less than 2 m, a formula of the same type is used as for a single-layer structure:

ln B1 = 2πλ [K(tt - t1.2) / qL - Rn]

Substituting instead of the ambient temperature the heating value of the boundary of two layers t1,2 and the normalized value of the heat flux density qL, the value ln B1 is found. After determining the numerical value of parameter B1, the thickness of the first layer of insulation is calculated using the table of natural logarithms using the formula:

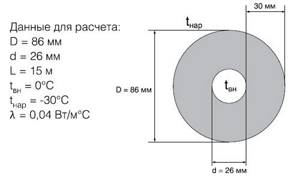

Data for calculating thermal insulation.

δ1 = diz1 (B1 - 1) / 2

The thickness of the second layer is calculated using the same equation, only now the temperature of the boundary of the two layers t1,2 acts instead of the coolant temperature tt:

ln B2 = 2πλ [K(t1.2 - t0) / qL - Rн]

Calculations are made in a similar way, and the thickness of the second thermal insulation layer is calculated using the same formula:

δ2 = diz2 (B2 - 1) / 2

It is very difficult to carry out such complex calculations manually, and a lot of time is lost, because along the entire pipeline route its diameters can change several times. Therefore, in order to save labor and time on calculating the insulation thickness of process and network pipelines, it is recommended to use a personal computer and specialized software. If there is none, the calculation algorithm can be entered into the Microsoft Excel program, and results will be quickly and successfully obtained.

Types of insulation

Let's consider the most popular and frequently used materials for thermal insulation:

- Fiberglass. Glass fiber materials are often used for above-ground piping because they have a long service life. Fiberglass has a low application temperature and is characterized by low density. High-quality fiberglass has high vibration, chemical and biological resistance.

- Mineral wool. Insulation of pipelines with mineral wool is a very effective heat insulator. This insulating material is used in different conditions. Unlike fiberglass, which has a low application temperature (up to 180ºC), mineral wool can withstand temperatures up to 650ºC. At the same time, its heat-insulating and mechanical properties are preserved. Mineral wool does not lose its shape and is highly resistant to chemicals and acid. This material is non-toxic and has a low degree of moisture absorption.

In turn, mineral wool comes in two forms: stone and glass.

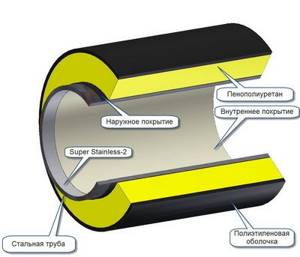

- Polyurethane foam has a wide range of applications, but is a fairly expensive material. According to SNiP standards, thermal insulation of pipelines is environmentally friendly and does not affect human health. Polyurethane foam is resistant to external factors, non-toxic and quite durable.

- Expanded polystyrene. In some areas of industry, foam plastic is an indispensable material, as it has low thermal conductivity and moisture absorption and a long service life. Expanded polystyrene is difficult to ignite and is an excellent sound insulator.

- In addition to the above materials, pipeline insulation can be carried out using other less well-known, but no less practical insulation materials, such as foam glass and penoizol. These materials are durable, safe and are close relatives of polystyrene foam.

Thermal insulating paint can also provide protection against corrosion and high thermal insulation of pipes.

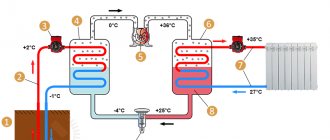

Method for determining by a given value the reduction in coolant temperature

Materials for thermal insulation of pipes according to SNiP.

A problem of this kind is often posed when the transported medium must reach its final destination through pipelines at a certain temperature. Therefore, the determination of the insulation thickness is required to be made by a given temperature reduction value. For example, from point A the coolant leaves through a pipe with a temperature of 150⁰C, and to point B it must be delivered with a temperature of at least 100⁰C, the difference should not exceed 50⁰C. For this calculation, the length l of the pipeline in meters is entered into the formulas.

First, you should find the total heat transfer resistance Rп of the entire thermal insulation of the object. The parameter is calculated in two different ways depending on the following condition:

If the value (tt.start - tо) / (tt.fin - tо) is greater than or equal to the number 2, then the value of Rп is calculated using the formula:

Rп = 3.6Kl / GC ln [(tt.start - to) / (tt.end - to)]

In the given formulas:

- K is the dimensionless coefficient of additional heat loss through fasteners or supports (Table 1);

- tt.init - initial temperature in degrees of the transported medium or coolant;

- to—ambient temperature, ⁰C;

- tt.kon is the final temperature in degrees of the transported medium;

- Rп - total thermal resistance of insulation, (m2 ⁰C) / W

- l is the length of the pipeline route, m;

- G—consumption of transported medium, kg/h;

- C is the specific heat capacity of this medium, kJ/(kg ⁰C).

Thermal insulation of steel pipe made of basalt fiber.

Otherwise, the expression (tt.start - to) / (tt.end - to) is less than the number 2, the value of Rp is calculated as follows:

Rп = 3.6Kl [(tt.start - tt.end) / 2 - tо ] : GC (tt.start - tt.end)

The parameter designations are the same as in the previous formula. The found value of thermal resistance Rп is substituted into the equation:

ln B = 2πλ (Rп - Rн), where:

- λ — thermal conductivity coefficient of insulation, W/(m ⁰C);

- Rн - heat transfer resistance on the outer surface of the insulation, (m2 ⁰C) / W.

Then they find the numerical value of B and calculate the insulation using the familiar formula:

δ = diz (B - 1) / 2

In this method for calculating pipeline insulation, the ambient temperature t should be taken based on the average temperature of the coldest five-day period. Parameters K and Rn - according to tables 1 and 2 above. More detailed tables for these values are available in the regulatory documentation (SNiP 41-03-2003, Code of Rules 41-103-2000).

Method for determining the surface temperature of an insulating layer based on a given temperature

This requirement is relevant in industrial enterprises where various pipelines run inside rooms and workshops where people work. In this case, the temperature of any heated surface is normalized in accordance with labor protection rules in order to avoid burns. Calculation of the thickness of the thermal insulation structure for pipes with a diameter over 2 m is carried out in accordance with the formula:

Formula for determining the thickness of thermal insulation.

δ = λ (tt - tp) / ɑ (tp - t0), here:

- ɑ — heat transfer coefficient, taken from reference tables, W/(m2 ⁰C);

- tп – normalized temperature of the surface of the heat-insulating layer, ⁰C;

- other parameters are as in the previous formulas.

The thickness of the insulation on a cylindrical surface is calculated using the equation:

ln B =(diz + 2δ) / dtr = 2πλ Rн (tt - tp) / (tp - t0)

Designations of all parameters are as in the previous formulas. According to the algorithm, this calculation is similar to calculating the thickness of insulation based on a given heat flow. Therefore, it is then carried out in exactly the same way; the final value of the thickness of the heat-insulating layer δ is found as follows:

δ = diz (B - 1) / 2

The proposed method has some error, although it is quite acceptable for preliminary determination of the parameters of the insulating layer. A more accurate calculation is performed by the method of successive approximations using a personal computer and specialized software.

Types of insulation materials

Thermal insulation of heating pipes is carried out after purchasing the material, but before this moment it is necessary to learn about the characteristics and advantages of the insulation, as well as its scope. After this data, you will be able to select the most suitable and effective option.

Polyurethane foam

This insulation consists of ribs and walls that form a solid solid structure. It creates a heat-insulating shell that has a high level of strength, while quite effectively retaining heat inside the heating network. Polyurethane foam has the following positive qualities:

- odorless and non-toxic;

- does not rot;

- it is environmentally harmless to the human body;

- has excellent dielectric properties;

- the material is resistant to various types of climatic influences, favorably suitable for outdoor use;

- sufficiently strong insulation, eliminating the possibility of pipeline breakdowns under the influence of mechanical loads from the outside.

Its only noticeable drawback is its high cost.

Minvata

Possessing a significant level of efficiency, it is quite popular among heat insulators. It consists of mineral wool and has a number of its own features:

- cotton wool has low moisture absorption due to treatment with special compounds during the manufacturing process;

- high degree of thermal stability, which, when heated, ensures the preservation of thermal insulation and mechanical parameters at the primary level;

- is environmentally friendly and does not contain toxic substances;

- it is not afraid of exposure to acids, solvents and other chemical solutions.

Mineral wool is excellent for use as a heat insulator for heating pipes. It is quite often installed on pipelines that are subject to continuous heating of great force.

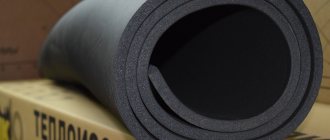

Foamed polyethylene

Does not harm the human body. It is not afraid of significant temperature changes and is resistant to moisture. The insulation is quite popular among buyers. It has the shape of a tube with a specific thickness in which an incision is made. It is used as a heat-insulating material for heating network pipes, and also for insulating warm and cold water pipes.

It retains its properties when used together with other building materials, including concrete, lime and others.

Penofol

This insulation for heating pipes has appeared on the market quite recently, being a reflective heat insulator, which consists of aluminum foil and cellular polyethylene. Thanks to 2 layers, the material has excellent thermal performance, which is why it is quite in demand among buyers. Folgoizol has a number of features:

- fairly easy installation that does not require special protective equipment;

- it is environmentally friendly and does not emit toxic substances;

- has a long service life;

- has a wide range of uses, suitable for both indoor and outdoor use.

Penofol is distributed in rolls with varying levels of density of the polyethylene layer. When choosing thickness, you should take into account the future conditions of use of the heat insulator. The double layer helps retain heat in a closed space, achieving the maximum permissible efficiency.