Material orientation

When starting serious work - choosing an option for joining sewer pipes, it is important to find out in advance what material you will have to deal with.

Today the following products are used in drainage systems:

- made of PVC (polymer);

- cast iron;

- become;

- concrete;

- ceramics;

- asbestos cement;

- corrugations.

The first two types of material are most often used, while the others are quite rare. Corrugated pipes are in demand in external pipelines of private buildings or as components of networks of large production facilities.

Cast iron pipes are used in external drainage systems. Compared to steel ones, they are quite heavy, so they are not suitable for internal sewerage, especially if they are installed by one person. But at the same time, cast iron pipes are not afraid of corrosion, like steel ones, and have a long service life, and are also in demand in heating systems, in particular, when installing risers. Although not every person will connect complex elements in cast iron pipes. The disadvantage of such products is the regular adhesion of waste inside the pipe due to the uneven surface. In winter, during the heating season, they are more susceptible to clogging. Compared to them, polymer products are more practical.

Question details

Basic information

Why is sealing required?

At first it may seem that if you screw the fitting onto the pipe, it will hold tightly and nothing should leak. In fact, this is deceptive, since the thread is always made with a small allowance - the outer one towards a decrease in diameter, and the inner one towards an increase. Otherwise, there is a chance that the fitting will not be screwed on. The thread can be made very precise, but the cost will be very expensive, and therefore a gap is made. In imported expensive fittings, such a gap can be several hundredths of a centimeter, and in domestic cast iron fittings, especially if they have a large diameter, there can be a gap of 0.1 cm and more. Through such connections, water will not only drip, but flow in a stream. It is impossible to do without a seal to ensure the reliability of the threaded connection of pipes.

But there are also conical pipe threads that do not need to be sealed. They will help ensure tightness in the metal-to-metal pair by compressing the threads while tightening the connection. During disassembly of this type of connection and reassembly, it will no longer be possible to ensure tightness, therefore such threads are not used for pipe connections in the domestic gas and water supply system.

How and with what to seal

One of the easiest ways to seal a pipe connection is to use union nuts and gaskets. They are often used to connect various appliances to pipes, for example, geysers or a plumbing mixer. The pipe of the device will be unthreaded and flared. The union nut will be located on it, and the gasket will be placed under the pipe and pipe, and then the union nut will be tightened. The main thing is that you do not overdo it, as otherwise the gasket can be damaged by the edge of the pipe or even squeezed out. In this case, tightness will not be achieved, and the gasket will have to be replaced and rearranged again.

The main advantage is that in such a reliable threaded pipe connection, the surface of the thread will not come into contact with water flowing in the pipes and will not be subject to corrosion. The connection with union nuts can always be disassembled, and the only consumable element will be a cheap gasket. Unfortunately, it is not possible to completely switch to such connections, since during installation a complex flaring operation would have to be performed. For steel pipes at home this is almost impossible.

For conventional threaded connections, several types of sealants are used, for example, flax on lead lead, flax with pastes and sealants, FUM tape, non-drying and drying sealants, as well as anaerobic gels.

Plastic pipes: advantageous connection

Recently, products made from polyvinyl chloride are at the peak of popularity, displacing metal analogues, which in their technical parameters are significantly inferior to plastic ones. The main feature of plastic pipes is softening at elevated temperatures and returning to their original state at low temperatures (read: “Options for connecting sewer plastic pipes - advantages and disadvantages of methods”).

To understand how to connect plastic sewer pipes, you need to consider the positive arguments in their favor:

- anti-corrosion properties, thanks to which PVC products can be safely laid underground without additional insulation and at the same time save significantly;

- chemical resistance to substances and aggressive environments;

- low weight of plastic pipes;

- excellent throughput due to the smooth internal surface;

- service life, which can reach 100 years;

- easy installation that allows you to build any type of drainage system.

The downside to using PVC pipes is limited throughput. Although this drawback can be completely resolved if you choose a larger pipe. Knowing the diameter and length of the product, it is easy to select parts for the plastic sewer network. Knowing theoretically how to connect two pipes of different diameters, you can begin practical actions.

This type of pipe is also successfully used for external sewer networks. At the same time, in bitter frosts, you need to pay attention to thermal insulation, for example, purchasing soft insulation.

Advantages of polymers

As noted earlier, polymers are most often used in the pipe production process. The main advantage of this material lies in its ability to soften. That is, under the influence of high temperatures, the polymer becomes soft. As soon as cooling occurs, it returns to its original state. Other advantages of polymers are worth noting:

- Resistance to corrosive processes.

- There is no need to insulate the pipe that will be laid in the ground.

- Resistant to aggressive environments and chemicals.

- Smooth inner surface to prevent clogging.

- Low weight.

- The ability to arrange engineering communications of almost any complexity due to convenient installation.

- Long service life.

example

The only disadvantage of polymer is considered to be limited throughput. However, this unpleasant moment can be eliminated by selecting a pipe with a larger diameter.

Fittings play an important role in connections. With the help of these connectors, the system is sealed and does not allow unpleasant odors to enter.

Joining of PVC pipes for sewerage, fittings

Often at home, plastic pipes are joined together using fittings. These are a kind of connectors that ensure the tightness of the structure, eliminating the penetration of dampness and unpleasant odors from the system. Thanks to the wide range of these products, repair work is facilitated and worn-out elements are replaced with new ones.

Let's look at how to connect sewer pipes using fittings.

The latter are classified into types that differ in:

- functions (intermediate or connecting fittings);

- structures (couplings, tees, turn signals, extensions, etc.);

- shape (straight, T- and L-shaped).

Using this classification, you can easily select the appropriate pipe material and explain to the store which fitting models you are interested in.

When inserting the pipe into the fitting, do not forget to first butt the rubber gasket.

How to connect plastic pipes with cast iron

I never break the golden rule: plastic pipes can be cut into cast iron ones, but vice versa - under no circumstances.

If you need just this option, it is best to use the connection:

- flange;

- threaded;

- Gebo fitting;

- using part of a rubber hose, but a good seal is needed here.

Preliminary steps before connecting

How to connect sewer pipes that are components of a large system? The answer to this question involves several sequential actions.

First of all, you need:

- Prepare a drawing of the system. It is important to take into account the existing objects in the house or apartment to which it is planned to lay drainage pipes, for example, a shower room, a bathtub, a toilet.

- Determine where the pipes join the central riser, and this is where the fittings will be needed.

- Remember that pipes for private sector sewerage are classified into two types according to cross-sectional size: 110.50 mm. It is the latter option that will be the ideal solution for laying pipes for a shower stall, bathtub, sink, or washing machine.

Before purchasing drainage pipes, you need to calculate in advance the required footage of the material so as not to waste money on excess plastic. After all, these products cannot be damaged.

Among the connectors, the turning fitting is of great importance, designed for joining a siphon (a hose from a plumbing fixture) and a drainage pipe made of PVC or metal. Some specialists neglect this connecting element, and in vain. After all, its absence can break the tightness of the system, and the joint will constantly let water through.

In order to ensure the longevity of the functioning of the drainage system, it is necessary to note certain nuances:

- Provide a specific slope of the pipes, which is calculated taking into account the amount of reduction - no more than 2-3 cm/m of the product. This indicator is needed for rapid removal of liquid.

- When arranging the pipeline, start from the plumbing to the central riser so that in the future the joints do not interfere with the flow of liquid in the system.

Knowing how to connect sewer pipes at the initial stages, you can protect the system from possible leaks in advance.

Requirements for sewer pipe joints and connection angles

When creating a sewer system yourself, you should remember the rules for laying the pipeline. It is laid at a slight slope. This is necessary to prevent water from stagnating in the system. The slope must be at least 2 cm for each meter laid. The correct installation of pipes is checked by level.

Installed sewerage system in the floor on a slope

The weak point when laying a sewer system is the joints. Therefore, their sealing is of particular importance. After completing the assembly of the structure, the system is checked for leaks. To do this, the drain is completely filled with water. During testing, temporary plugs are placed in the revision. There shouldn't be any leakage.

The main subtleties of laying external sewerage

Fittings are used when arranging intra-house or intra-apartment sewerage. The situation is completely different with the external system, which is installed on the site near the house. In this case, it is necessary to start with the construction of wells intended for water purification.

Having understood how to join drainage pipes, it becomes clear that the external system requires products of larger diameter.

It is imperative to take into account the fact that the diameter of the outer pipe should be slightly larger than the size of the sewer pipe. It is better to take material with a “reserve” than to change the entire drainage system when there is a desire to connect new plumbing fixtures.

Having completed the preparatory steps, you can begin the serious business of connecting sewer pipes. According to the types and joints of pipes, two connection options are distinguished: detachable and permanent.

Sewage pipelines made of cast iron and PVC simultaneously

In the housing and communal services sector, work on replacing old cast iron pipes with plastic ones has not been completed 100%. Housing office workers often use a more economical technique - connecting PVC sewer pipes to cast iron structures. This procedure is carried out using the socket method, just like joining purely cast iron pipes, and is identical to joining plastic products (read: “How to connect cast iron pipes to each other and to plastic or steel pipes”).

Next, the joints are sealed:

- Insert the end of the pipe into the socket and center it with stops made of wood or metal, which must be driven into the free space between the pipes.

- Screw a turn of oiled rope onto the connection and push the fibers into it. The latter should drop to approximately 75% of the depth of the socket.

- Make another turn of the seal and push it deeper into the socket.

- Repeat the winding of the rope at the joint until the rope comes completely to the joint surface.

The sealing work is completed by applying a cement patch on top of the pressed fibers. You can replace cement with silicone sealant or bitumen mastic. The result is a highly reliable connection. Do not forget that after time has passed, the sequence of sealing actions must be repeated.

Joining of pipes using the detachable method

Such connections are classified into flange and coupling. For plastic pipes it is better to use the first option. To achieve excellent tightness, it is better to use cast iron fasteners and rubber gaskets in detachable connections.

Let's look at how to properly connect sewer pipes using flanges step by step:

- Cut the pipe very smoothly, without chamfers.

- Place the loose flange over the cut.

- Insert a spacer protruding 10 cm from the cut line.

- Place a flange on it and connect it to the mating fittings.

- Secure with bolts.

During repairs or installation of pressure/non-pressure systems, coupling connections are used.

For the system to function trouble-free, you need to:

- Before connecting the pipes to each other, cut off their ends at 90°.

- Attach the coupling to the joint so that it is located exactly in the middle of the connector.

- Make a mark on the pipes indicating the location of the coupling.

- Treat the ends of the pipes and the fitting from the inside with a special lubricant.

- Insert one of the pipes into the coupling until it stops.

- Join the pipes without distortion to form a single axis.

- Push the coupling onto the second pipe up to the previously made mark.

This detachable method is very convenient for disassembling the pipeline if necessary. When assembly is performed, great attention is paid to sealing the joint.

General rules

If you are deciding how to connect PVC sewer pipes to each other, you need to study the installation recommendations. The rules are developed taking into account the intricacies of communications operation. They are common for pipes made of different materials:

When installing internal sewerage, products with a socket are installed so that the widening at one end is directed in the direction opposite to the water flow. This is done to avoid the formation of blockages. When laying the pipeline, ensure a slight slope. The value of this parameter depends on the size of the communications. For example, for products with a diameter of 50 mm, a slope of 0.035 is provided. The larger the size of communications, the smaller the slope. Thus, for pipes with a diameter of 100 and 150 mm, the value of this parameter will decrease, respectively, to 0.02, 0.008. To connect pipeline sections, shaped elements are used. Thanks to them, it becomes possible to change the direction of communications, tilt or turn. If pipes made of polyvinyl chloride are selected, installation with tension or bends is prohibited. When heated, this will lead to deformation of the products. If you need to make a turn, use oblique tees and half-bends. The outlet elements in these fittings are located at an angle of 30-45°, which eliminates the formation of blockages, overflow and deformation of the pipe during a volley discharge. Cleaning communications in these areas is also carried out without unnecessary difficulties. This is due to the fact that when inserted into the pipe, the sewer cable will move only in the direction of movement of the drains. In areas where various fittings are installed, clamps are used. They increase the reliability of fastening connecting elements in places where the load on communications is increased. When laying a horizontal pipeline, which is characterized by a large length, additional fastening elements are used: clamps, hangers, supports. They are installed in increments equal to 8-10 diameters of communications. If this is not done, soon after the start of operation the pipeline will sag. In this area, the likelihood of blockages will increase. When installing a vertically oriented pipeline, additional fastening elements should also be used. In this case, only clamps are used

It is important to ensure reliable fixation, so the fasteners must cover the entire circumference of the pipe. Moreover, it is necessary to install clamps in the area of the socket connection

The step is not followed in this case. If you need to connect sections of pipeline made of different materials, for example PVC and cast iron, differences in strength and ring stiffness should be taken into account. For this purpose, special fittings are used. It is prohibited to carry out installation using the chasing method. If the room has a complex configuration or it is not possible to lay a straight pipeline, you need to remember that the number of turns should be minimal, especially if a rectangular elbow is used. This will increase the likelihood of blockages and lead to destruction of the pipeline.

To avoid mistakes, you can first watch a video about the sewer pipe connection diagram.

One-piece types: nuances

Now let's figure out how to join sewer pipes using the one-piece method.

There are different methods, but here are the most common:

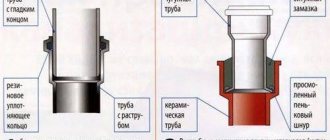

- "Into the bell" . According to the theory, a socket with a rubber ring is connected to the straight end of the pipe. Before starting work, all surfaces are cleaned and degreased, and the flat end of the pipe product must be chamfered. Before joining, both surfaces are treated with silicone grease, and if it is absent, with liquid soap or detergent, and then joined. In this case, the longitudinal axes of both products must coincide. The flat part is inserted into the socket no deeper than the previously made mark.

- Welding: socket or butt . According to the theory of the first option, using moderate pressure welding, the following are melted: the inner side of the socket of one pipe and the outer side of the smooth end of the other. If butt welding is done, then the ends of both pipes and the joint itself are melted. The latest technique allows you to understand how to connect pipes of the same diameter.

- Gluing . According to this method, the connecting ends are coated with a special glue. It is selected depending on the material of the pipes. For example, BF-2 is suitable for metal and plastic, epoxy adhesive is suitable for polymers and metal, grade 88N is suitable for rubber and metal.

Benefits of switching from cast iron to plastic

Polypropylene sanitary products have a number of operational advantages:

- withstand temperature changes;

- resistant to aggressive environments;

- deposits do not accumulate in them and blockages do not form, since the inner surface of the products is smooth;

- are light in weight;

- easy to install;

- affordable.

Fittings have a service life of up to 50 years.

We suggest ordering transitions from cast iron to plastic using the catalogue, contact us by phone. Orders are formed promptly, delivery is made throughout Moscow and Russia on favorable terms. All products are provided with quality certificates. The TERMA-MSK online store accepts retail and wholesale orders, offers convenient payment options and favorable prices for shaped fittings for the installation of internal sewerage.

Which connection method is considered the most reliable?

The simplest and most effective is the bell technology. Even a beginner can easily perform this assembly. The tightness in this case depends on the rubber ring with which the socket is equipped. It should be directed opposite to the flow of water.

If there is no lubrication, you can use liquid soap or detergent.

Welding pipe ends is considered a difficult method. To perform such work it is necessary to have special expensive equipment. However, the reliability and tightness of the docking always remain at the highest level.

The adhesive connection allows you to get a fairly strong joint. Before starting work, you need to thoroughly clean the parts from dirt and degrease the surfaces. All actions are performed quickly and carefully, before the glue has time to harden.

O-rings are used to secure the fittings. This installation can be done by yourself without the assistance of an assistant. This method is suitable for combining small diameter products.

The fastening must be done so that the connection point has free access to remove blockages.

To fix PVC sewer pipes, no special preparation is required, which cannot be said about metal analogues.

What to consider when choosing a method: which is better?

The choice of technology for connecting pipelines made of different materials directly depends on the integrity and general condition of the cast iron socket.

To insert into a cast iron sewer pipeline and switch from plastic to cast iron or vice versa, several methods can be successfully used, but the use of a fitting in the form of a compensating pipe is considered optimal.

Such a plumbing fixture quite easily compensates for deformation and failure of the sewer network as a result of linear thermal expansion or contraction, and also helps to give the drainage areas the required level of inclination.

It is advisable to use pipes along with corrugated pipes if it is necessary to adjust the height of the cross to create an optimal angle for installing the toilet.