Preparing the surface for applying liquid thermal insulation ASTRATEK metal

The insulated surface must be cleaned of rust, scale, and contamination mechanically or manually with metal brushes and dust-free. If there are untreated grease stains, degrease it with solvent 646, 647. In case of severe corrosion, treat the surface with a rust converter based on orthophosphoric acid (15% solution of water and orthophosphoric acid). When a phosphate “whitish” film forms on a metal surface, wash off the remaining acid with water, this will form a protective layer of a “whitish” surface. When applying ultra-thin thermal insulation ASTRATEK metal

on a previously painted surface, it is necessary to remove the old paint in places of peeling and peeling. If necessary, sand with medium to coarse sandpaper.

Padding

To improve adhesion and increase the service life of ASTRATEK metal

It is recommended to prime metal surfaces before applying the coating.

When covering “cold” metal surfaces (at least +5°C) with ultra-thin thermal insulation, it is recommended to use GROSS metal primer (1-2 layers) or another high-quality acrylic primer for metal. For non-ferrous metal surfaces, it is necessary to use a special primer for non-ferrous metals, type VL-023.

When covering hot (more than +80°C) metal surfaces with ultra-thin thermal insulation, it is recommended to use a 20-25% aqueous solution of ASTRATEK metal

as a primer layer.

Thermal insulating polymer coating ASTRATEK facade for thermal insulation of building structures

Price from 430 rub. per liter

ASTRATEK façade is an energy-saving thermal insulation coating that can replace traditional thermal insulation systems. The use of thermal insulation coating ASTRATEK facade allows you to reduce energy consumption for heating and air conditioning. In a private house or apartment, subject to additional energy saving conditions (economical electrical appliances, modern windows, etc.), the use of ASTRATEK facade coating can achieve a significant reduction in heat loss.

The thermal insulation coating ASTRATEK façade helps maintain a comfortable temperature in the room due to the highly filled microporous structure of the material, which reflects, dissipates and restrains heat flow. Thanks to its unique thermophysical properties, ASTRATEK coating significantly increases the thermal resistance of insulated enclosing structures. The walls of buildings are more stable in maintaining relative constant temperatures, i.e. have greater heat resistance. Thus, in the summer, excessive heating of the walls by solar radiation and high ambient temperatures is reduced, and in winter, heat loss in the premises is significantly reduced.

Liquid thermal insulation coating ASTRATEK façade is characterized by excellent adhesion, increased weather resistance, durability and vapor permeability, which, combined with high water-repellent properties, provides long-term protection to almost any façade.

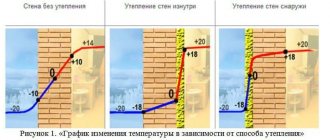

Thermal insulation of building structures using ASTRATEK façade coating can be performed:

- outside the building envelope

- indoors

- indoors and outside the building envelope

Liquid thermal insulation coating ASTRATEK façade is used for thermal insulation of residential, public and industrial buildings during new construction, reconstruction or restoration, and during renovations of private houses and apartments. The finished energy-saving ASTRATEK facade coating can be decorated at your discretion; it can be puttyed, plastered, covered with wallpaper, ceramic tiles, or painted with acrylic paints.

Liquid coating ASTRATEK façade is applied in layers. The thickness of one technological layer is 0.4 mm (when applied to highly absorbent plastered, brick and concrete surfaces, the thermal insulation coating ASTRATEK façade can be applied with a spatula in layers 0.8 - 1.2 mm thick). The material consumption rate for a single-layer coating (0.4 mm) is 1 liter per 1.5-2 sq.m. The labor intensity of application is similar to the complexity of painting work. The service life of ASTRATEK thermal insulation is 15 - 25 years (depending on operating conditions).

The manufacturer guarantees the stable quality of the thermal insulation coating for at least 1 year when transported and stored under proper conditions.

Hazard class (chemical composition) 4 (GOST 12.1.007-76). The material is a safe cargo for transportation.

Advantages of liquid thermal insulation coating ASTRATEK façade:

- the possibility of continuous covering of the object with the elimination of “cold bridges”, which provides increased thermal protection of the walls of buildings and structures;

- the possibility of thermal insulation of walls without reducing the internal usable area of the room;

- the possibility of thermal insulation of walls without increasing the load on the foundation and other building structures;

- the possibility of thermal insulation of objects without changing the external shape of all facade elements, which is indispensable during the restoration of architectural monuments;

- prevents temperature deformations of building structures;

- has hydrophobic properties, does not accumulate moisture and is not destroyed under the influence of atmospheric phenomena;

- does not support combustion, reduces smoke formation and fire spread;

- non-toxic, environmentally friendly;

- low labor and resource costs during operation and repair.

Application of liquid thermal insulation ASTRATEK metal

3.1. Work on applying liquid thermal insulation ASTRATEK metal

It is recommended to carry out at a temperature of the insulated surface ranging from +5°C to + 120°C.

3.2. ASTRATEK metal liquid thermal insulation

on a surface with a residual humidity of more than 8%, in strong wind, rain, fog, frost.

3.3. When applying ultra-thin thermal insulation coating ASTRATEK metal

You should pay attention to the following points:

Application of thermal insulation ASTRATEK metal

It is recommended to apply to “cold” metal surfaces at an ambient temperature of +5°C and a humidity of no more than 65%. The lower the relative air humidity, the faster the material dries and, accordingly, the higher the humidity, the longer the drying time.

On clean, polished metal surfaces, steam condenses into moisture at humidity levels greater than 90%. On rough or uncleaned surfaces, condensation occurs already at a humidity of 65-70%. In addition, condensation can settle on the surface even at low humidity if the metal temperature is lower than the air temperature. Therefore, before applying liquid ultra-thin thermal insulation ASTRATEK metal

the surface must be dried naturally or by force.

It should be remembered that when the temperature drops below +20°C and the humidity rises to 85%, the drying time of liquid thermal insulation increases. Therefore, it is necessary to increase the time between applying layers of ASTRATEK metal

no less than 2-3 times. For example, a material dried at low temperatures seems ready after the formation of a film, although the film will become completely strong only after all the water has evaporated and the film formation of the liquid thermal insulation is complete.

High ambient temperatures significantly accelerate the evaporation of water and the curing of ultra-thin thermal insulation. In this case, only the top layer can dry out and “preserve” the water vapor inside, which, in turn, will worsen the thermal insulation and performance characteristics of the finished coating. When the ambient air and surface temperatures are equally high, this, as a rule, does not happen, so in summer it is recommended to carry out thermal insulation work only in the morning in order to avoid a significant difference in the temperatures of the metal and air. Drying the applied layer ASTRATEK metal

a directed jet of heated air onto the surface of the coating is also unacceptable.

Before using liquid thermal insulation ASTRATEK metal

It is necessary to mix thoroughly until a homogeneous mass is obtained. When mechanically mixing, the speed of rotation should not exceed 300 rpm. If necessary, dilution with clean water is allowed 3 - 7% of the total volume. The resulting composition must be stirred periodically during operation.

3.4. ASTRATEK metal coating

applied in layers with a brush, air or airless spray, subject to interlayer drying technology, at a temperature of t = 20 ± 2 ° C and above and a relative humidity of no more than 65%.

The thickness of the applied layer should not exceed 0.5 mm; the final thickness of ASTRATEK metal

is determined by the method of thermal engineering calculation.

The complete drying time for each applied layer with a thickness of 0.3-0.5 mm is 24 hours. The time for complete drying of ultra-thin thermal insulation depends on the number of layers, temperature and humidity of the surrounding air. If necessary, the interlayer drying time of ASTRATEK metal

should be increased by 2-3 times. The thermal insulation coating is resistant to rain after 24 hours.

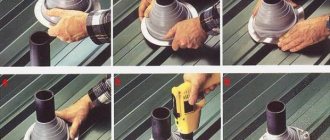

3.5. Applying liquid thermal insulation with a brush.

It is recommended to use a non-natural bristle brush for applying interior or exterior paints, as well as for painting small surfaces and correcting paint imperfections. Immediately before applying liquid insulation, wet the brush with water. When applying ASTRATEK metal

To obtain a high-quality coating with a brush, movements should be directed in one direction.

Recommendations for applying liquid thermal insulation ASTRATEK metal

air or airless sprayer, as well as the necessary advice on selecting the necessary equipment, can be obtained from our technical specialists by calling +7 (8442) 47-70-30.

After application, rinse working tools with water.

You can apply GROSS façade acrylic paint or other high-quality acrylic paints to the finished coating.

For additional protection of the finished thermal insulation coating from constant contact with aggressive media, we recommend applying a polyurethane coating UREPLEN®

Liquid ceramic thermal insulation ASTRATEK

Applies like paint, acts as a thermal barrier!

ASTRATEK heat insulator is a homogeneous white suspension that contains special lightweight ceramic fillers and modifying components based on a polymer dispersion. The material is applied with a brush or spray to walls or other surfaces that need insulation. When dried, the liquid insulation forms an elastic coating characterized by strength, microporous structure and low thermal conductivity. The film has flexibility and elasticity, durability and wear resistance. Absorbing into the surface being treated, ASTRATEK fills its micropores, thereby reducing the level of interaction of the surface with the environment, protecting it from adverse influences. ASTRATEK liquid thermal insulation is used on a wide variety of surfaces:

- concrete;

- wood;

- metal;

- PVC;

- cold and hot water supply pipelines.

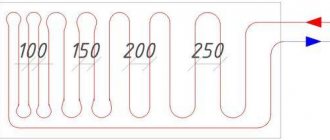

And also the use of ASTRATEK material has become widespread:

- for “warm floors”;

- for steam pipelines and air conditioning systems;

- for insulating various containers;

- for insulating building facades and interior walls;

- for insulation of roofs, basements, window and door openings.

An ultra-thin layer of 0.5 mm makes the material almost invisible. It is possible to apply the material in several layers, the total thickness of which does not exceed 3 mm. Multilayer coating is used mainly for thermal insulation of buildings.

Advantages of ultra-thin thermal insulation ASTRATEK Like all new building materials, ASTRATEK was created taking into account previous experience in the production of thermal insulation materials. Suffice it to say that such ultra-thin thermal insulation was initially developed for spaceships, and after testing, it began to be used not only in the aerospace field, but also in construction. The obvious advantages of the material are:

- preventing walls from freezing, eliminating “cold bridges”;

- eliminating the formation of condensation;

- the ability to apply the material to the surface of any configuration and in hard-to-reach places;

- high adhesion of the material;

- significant reduction in the labor intensity of insulation work;

- low specific gravity of the material, no additional load on the treated surfaces;

- ability to withstand high and low temperatures, from -60 to +(150-200) °C;

- the formation of a very thin coating – up to 3 mm, which saves space;

- anti-corrosion properties of the material, which allows it to be used on metal surfaces;

- high resistance of the material to ultraviolet rays and precipitation;

- fireproof properties of the material;

- long service life - up to 30 years;

- the possibility of subsequent application of any coating and any finishing material to the liquid thermal insulation;

- high environmental friendliness of the material, complete harmlessness to human health;

- The efficiency of liquid thermal insulation is high - its 1 mm layer gives the same results as a 50 mm thick layer of rolled insulation!

All high technical, operational and environmental qualities of ASTRATEK liquid insulation for walls are confirmed by relevant certificates and approvals for use. ASTRATEK is a high-quality original, new thermal insulation material, the use of which provides significant economic and practical benefits, which ultimately determines its choice.

Excellent liquid thermal insulation gives ASTRATEK wide application for coating various materials and any shape of surfaces:

Precautions and disposal

Thermal insulating polymer coating ASTRATEK metal

fireproof and explosion-proof, does not contain solvents, does not require special precautions when handling it.

In case of contact with eyes, rinse them immediately with water. Do not allow material to enter wastewater. Keep out of the reach of children. Carry out work in a ventilated area. Remains of ASTRATEK metal

after drying should be disposed of as household waste. The material is water-soluble; the addition of organic solvents is not allowed.

Structure and composition of Asstratek heat insulator

The thermal insulation coating Asstratek is a high-tech material, the structure of which is a homogeneous suspension or mastic. The composition of liquid thermal insulation includes the following components: • acrylic binder - polymers • special fillers - expanded perlite • pigmenting, inhibitory and fire-retardant additives (titanium dioxide, zinc oxide, quartz, styrene-butadiene latex).

The consistency of the astratek coating resembles thick paint, which can be applied to the surface with your own hands using a brush, sprayer or spatula. After Asstratek thermal insulation dries, a reliable elastic coating is formed that has heat-protective and anti-corrosion qualities. For reference: a 1 mm layer of insulation coating can provide similar thermal insulation properties of 60 mm mineral wool insulation or brickwork up to 380 mm thick.

Moreover, the microporosity of the insulation structure can be considered ideal. Liquid insulation coating is characterized by stable adhesion, weather resistance and vapor permeability. Naturally, if there are so many positive qualities, the choice of liquid insulation will be made in favor of Astratek thermal insulation.

Manufacturer's Warranty

The manufacturer guarantees the compliance of thermal insulating polymer coatings ASTRATEK metal

technical characteristics when following the rules of transportation, storage, preparation and application, which are given in these recommendations and technical descriptions for each specific type of coating.

Shelf life in original, unopened packaging is 12 months from the date of production.

The manufacturer is not responsible for the incorrect use of liquid thermal insulation, as well as for the use of ASTRATEK metal

for other purposes and conditions not provided for in technical documents.

ASTRATEK metal heat-insulating polymer coating

can be obtained from technical support specialists by phone.