The need for thermal protection and requirements for insulation

If a person is told that something needs to be done, he has every right to know why it is needed. If a house has insufficient thermal insulation of its structures, serious problems arise during operation.

The insulation performs the following functions:

- preventing freezing of the ground floor floor and penetration of cold into the premises;

- protection against condensation, which leads to the formation of mold, mildew and rotting of wooden house structures;

- the house will require lower heating costs during the cold period;

- increasing sound insulation characteristics.

The following requirements apply to the insulation used in the floor pie:

- good strength characteristics;

- resistance to moisture;

- resistance to rotting and molding;

- safety for humans;

- non-flammability;

- ease of installation.

All these requirements are met by extruded polystyrene foam, which can be used to insulate structures of concrete, wood, brick and frame buildings.

Choosing polystyrene foam is not a choice at all for the sake of budget

And you do everything with your own hands, using this foam plastic for floor insulation

The main thing is to get your bearings with the variety of materials that the construction market offers.

There is the following classification of foam plates:

- PSB-S-15 - a numerical indicator is used to determine the density of slabs; these have a minimum density and are used for thermal insulation of places where mechanical strength is not the main factor of insulation. This is quite suitable for insulating attics, roofs without an attic, and spaces between rafters.

- PSB-S-25 is the most common brand for insulating walls and floors of wooden houses.

- PSB-S-35 - can be recommended for insulating floors on the first floors of private houses, although its main areas of application are insulation of foundations and underground communications. 35 is often used to protect against uplift in swimming pools and sports fields.

- PSB-S-50 - from the point of view of mechanical strength, this is the most reliable foam plastic and its place is where mechanics come to the fore - the arrangement of floors in high-rise buildings and roads in difficult terrain.

In addition, classification according to production method is possible:

- polystyrene - pressed and unpressed, it is they who are marked PS, the letter “B” means “unpressed”;

- polyurethane (PPU) - this is a well-known foam rubber;

- polyethylene (PPE);

- polyvinyl chloride (PVC) - a material that has been conquering the world recently; Some types of PVC foams are recognized as self-extinguishing.

When insulating, polystyrene foam labeled PS / PSB is more often used.

Try to avoid gaps between the slabs and wooden joists, as in the photo. In any case, the cracks will need to be covered with adhesive plaster or elastic mastic. That is why, first the foam, and then the overlap on top

This letter “B” forces us to introduce another division of foam plastics into 2 types:

- Pressless - made from granules by sintering them at high temperatures, the granules are not so tightly adhered to each other, and are easily separated simply by hand;

- Pressed - here there is much more pressure during sintering with the addition of a special foaming agent, this one cannot be broken by hand, a knife is required.

In the end, for our purposes, insulation, we will introduce one more qualification:

- polystyrene foam in the form of slabs and providing the ease of insulation work for which the described material is famous;

- in the form of granules - essentially the primary material from which the slabs are created; if you need to fill the entire insulation space as tightly as possible and not use all kinds of putties to eliminate cracks, then we advise you to take a closer look at this “intermediate” phase of the material in question, which is not used so often.

Advantages of polystyrene foam

The widespread use of polystyrene foam for insulation purposes is due to its following advantages:

- Firstly, it has very low thermal conductivity. According to this characteristic, only some types of mineral wool can compete with foam plastics.

- Secondly, the material is very easy to use, it cuts perfectly and sometimes one sharp knife is enough to work with it.

- Thirdly, high sound insulation. This property mainly applies to porous foam.

- Fourthly, high chemical and biological resistance. There is practically no interest in rotting, and, in any case, it does not serve as an object of attention as a breeding ground for microbes.

- Fifthly, very good moisture resistance. They even determine the percentage of moisture absorption, which for polystyrene foam is only from 0.5 to 1.5%.

- Well, and sixthly, polystyrene foam is very common, you can buy it at very affordable prices everywhere.

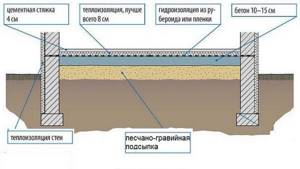

Insulating floors with foam plastic necessarily involves the use of insulating material according to the proposed scheme. Pay attention to the presence of insulation along the vertical wall

Flaws

It must be borne in mind that polystyrene foam, as a material for insulation, also has disadvantages, which in the eyes of many are very serious:

- Firstly, the point is not even that it is flammable, over time this has been dealt with and there are technologies and widely used samples that even suppress fire. The fact is that when exposed to fire, polystyrene foam emits very dangerous smoke. And in case of a fire, the most dangerous thing for a person is not the fire, oddly enough, but the combustion products, it is the smoke that kills. In fact, this drawback discourages many from using polystyrene foam for insulation.

- Secondly, you will not be able to control the degree of insulation using foam plastic boards, as you could with expanded clay or cotton wool.

Helpful advice! If you are working on the floor on the ground floor, we recommend choosing thicker foam plastic slabs - at least 10 cm thick. In all other cases, standard 5 cm thick slabs are quite suitable. Well, and, of course, it is necessary to keep in mind that the maximum temperature at which the foam retains its characteristics is 180 degrees.

Insulating a wooden floor with polystyrene foam does not require the use of a fastening solution with the material; usually the foam is laid directly on top of the insulation

What is expanded polystyrene

Expanded polystyrene consists of styrene granules filled with gas. Air is the most effective insulation, so a large number of cavities allows the material to have good heat-protective properties. Currently, two types of expanded polystyrene are widely used in construction: polystyrene foam and extruded material. The second one is preferable to use.

These two materials look similar in appearance, but differ in their characteristics and manufacturing method. Polystyrene foam is made from polystyrene foam balls by sintering. In the production of extruded polystyrene foam, granules are mixed with a foamed reagent and pressed through an extruder.

What's better? Polystyrene foam or extruded polystyrene foam?

Polystyrene foam has only one advantage compared to extruded material: low cost.

If a house is being built without severe cash constraints, it is better to choose the second option.

If we conduct a comparative analysis, we can come to the following conclusions:

- extruded polystyrene foam has high strength and works better in floor construction;

- polystyrene foam is characterized by higher water absorption (about two times);

- in the presence of moisture and exposure to low temperatures, the foam may crumble into individual balls;

- polystyrene foam is a medium- and low-flammable material and, when exposed to high temperatures, releases substances hazardous to humans;

- Thanks to special additives, extruded polystyrene foam becomes fire resistant.

For insulating the floor of a wooden house, extruded polystyrene foam .

To reduce construction costs, you can apply floor insulation with two types of polystyrene foam at the same time. The lower thick layer of greater thickness is made of polystyrene foam, and the upper one is made of a more durable material 3-5 cm thick. This method allows you to achieve a compromise between price and quality.

What is expanded polystyrene

This is gas-filled polystyrene, which belongs to the category of foam plastics. The production technology is simple - a viscous mass of polystyrene is filled with gas, which dissolves, forming bubbles. Then the polymer mass is heated with steam, causing it to expand many times, and the granules filled with gas are sintered together. Expansion is carried out until the mass fills the form in which it was placed.

It was the hollow structure of the material that made it possess low thermal conductivity. By the way, for expanded polystyrene it is equal to 0.034-0.044 W/m K. This is one of the best indicators among all thermal insulation materials present on the market.

But it is necessary to point out that there are several types of polystyrene foam boards, which are based on their density. This characteristic varies from 15 to 50 kg/m3. And the denser the material, the worse its heat-protective qualities. In our case, to insulate the floor with expanded polystyrene boards, you will need a material with a density of 25-35 kg/m3. The thing is that floors are a structure that is constantly subject to loads. This means that durable material must be used here.

Other insulation characteristics:

- the material is flammable and belongs to class G3;

- service life – 20 years;

- environmental friendliness - high, that is, with changing humidity and temperature, it does not emit toxic and other substances harmful to humans;

- ease of installation.

It was the flammability with the release of acrid, toxic smoke that repelled many consumers from polystyrene foam boards when the task was to insulate the premises from the inside. Preference was given to mineral wool. Today, manufacturers offer self-extinguishing polystyrene foam, which contains fire retardants. That is, under the influence of fire it melts, but does not burn. It is produced by extrusion. This is exactly what it is recommended to purchase today when the task is to insulate floors.

Self-extinguishing polystyrene foam boards

*

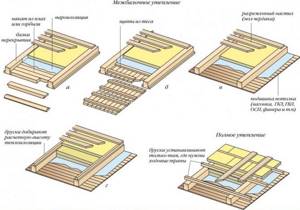

Wooden house floor pie

Depending on the strength, the material can be laid in two ways: without logs and with their help. In the first case, the weight of the entire structure of the finished floor falls on the insulation, so a cement-sand screed is made on top of it. Previously, we have already examined in detail the technology of floor insulation under screed. Most often, this method is used for the floors of brick and concrete buildings.

For a wooden house, insulation is carried out between wooden joists. It is important to take into account the location of the insulation in the building - the thermal protection of the attic floor differs from the insulation of the floor above a cold basement or underground.

Please note that the process of insulating the floor in a house on screw piles is slightly different from the above method.

In the first case, the layers are laid in the following order:

- wooden floor;

- vapor barrier;

- insulation.

When used in the construction of the ground floor floor, the installation order is as follows:

- wooden floor;

- waterproofing;

- insulation;

- vapor barrier.

When using extruded polystyrene foam, a vapor barrier need not be installed.

For polystyrene foam, it is important to remember that protection from steam is located on the warm air side, and protection from moisture is located on the cold air side. Only in this case will the house be reliably protected from the penetration of cold air. As a vapor barrier and waterproofing, you can use ordinary durable polyethylene film.

Installation process

Depending on the installation method, work can be carried out in different ways.

The minimum layer of insulation depends on the climate in which the house is located, but on average it is 10 cm.

Laying insulation without joists (under screed)

The work process begins with cleaning the base from dirt and dust. Next, if necessary, perform alignment. After preparing the base, the slabs are laid out, taking into account the gap for thermal expansion. These gaps are filled with fiberglass or polyurethane foam. With this installation method, a cement-sand screed is placed on top of the insulation. For fragile foam, it must be additionally reinforced.

The link describes in detail the technology of insulation with polystyrene foam under the screed.

Laying between joists

The process begins with the installation of logs , the pitch of which is selected depending on the size of the insulation boards.

This method does not require high strength, so you can safely use polystyrene foam.

Between the logs, depending on the structure being protected, a vapor barrier or waterproofing . The plates are mounted in the same way as in the previous case, with a small gap. of the finished floor structure begins .

Schemes for constructing a floor pie are given in this article above ↑.

Floor insulation with expanded polystyrene can significantly reduce the load on the building structure. This is especially important if the house is being built on unstable soils with poor characteristics, since it allows you to avoid overloading the foundations.

Eps thickness for ground flooring. Calculator for calculating the thickness of floor insulation on the ground

The floors of the first floor of a private house require a special approach to insulation. And especially those that are installed directly on the ground. Its heat capacity is enormous, and with insufficient thermal insulation, the soil can literally pull out all the accumulated heat from the premises, even if the weather outside is not the coldest.

Calculator for calculating the thickness of floor insulation on the ground

For thermal insulation to be truly effective, high-quality materials must be used and the calculated thicknesses of the insulation layers must be observed. How to carry out these calculations yourself? You can arm yourself with thermotechnical formulas - they are easy to find on the Internet. But it’s easier to take advantage of the opportunity offered - this is a calculator for calculating the thickness of floor insulation on the ground.

Below are some important recommendations for its use.

Calculator for calculating the thickness of floor insulation on the ground

Explanations for calculations

So, we proceed from the fact that the building structure (the floor in this case) must have a certain resistance to heat transfer so as not to serve as a heat loss pipeline. For each of the regions of Russia, these values are calculated taking into account climatic features. They are called normalized heat transfer resistance values and are measured in m²×K/W.

You can find out the value for your region of residence at any local construction organization. Or follow the map diagram below:

Map-scheme of normalized values of heat transfer resistance for building structures

What immediately attracts attention is that three such values are indicated for each area. In this case, we are interested in only one thing - for floors. It is highlighted with blue numbers. It is this value that should be entered into the corresponding field of the calculator.

Now let’s move on to the insulation scheme itself.

The total value of thermal resistance is made up of the resistances of each layer of the insulated structure. If the planned structure of the insulated floor on the ground and the materials used for these purposes are known, then there is no big problem in calculating what thickness of insulation will be sufficient to achieve the standardized value.

When applied to a floor on the ground, it makes sense to take into account only the insulation itself (or a combination of several materials) and the floor covering, if it has any significant thermal insulation qualities. This includes, for example, plank covering or cladding with thick plywood. There is no point in taking into account concrete screeds or ceramic cladding - their thermal conductivity is very high. And thin floor coverings (laminate, linoleum and the like) will not have a significant effect on the thickness of the insulation simply due to their small thickness.

So, in the calculator you can calculate using two options. Moreover, the second option is divided into two more “subspecies”.

- The first option is to use only expanded clay for insulation. The backfill is covered with a reinforced screed, over which the finishing floor covering is subsequently laid.

When calculating along this path, you only need to indicate the parameters of the finishing flooring. If there is no point in taking them into account, the layer thickness value is left at the default value of zero.

The final value will be shown in millimeters. This is the required thickness of expanded clay backfill.

- The second option is to use the insulation selected from the list for thermal insulation. It can, for example, be laid under a reinforced finishing screed. Or, logs for the plank floor are mounted on top of the screed, between which the thermal insulation material will be placed. This difference does not particularly affect the calculation.

But here, too, two approaches are possible.

— The insulation is used in combination with an expanded clay “cushion.” This is often useful - it allows you to reduce the thickness of the material used. This means that in the additional data entry fields that open, you will need to indicate the thickness of this expanded clay backfill, and then select an insulation material from the proposed list. With the final floor covering, the approach does not change - as described above.

— Only one insulation is used. Everything is the same, but only the thickness of the expanded clay backfill is left equal to zero by default.

The result in both last cases will show the thickness of the selected insulation in millimeters. This is the minimum value, which, if necessary, is increased to the standard thickness of thermal insulation materials.

What is USP?

Among the most energy-efficient structures is the insulated Swedish slab (USP), which is both a reliable foundation and a well-insulated floor of the first floor, immediately equipped with a water heating system. Read more about the technology of constructing an insulated Swedish slab in a special publication on our portal.

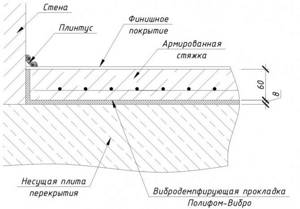

How to lay polystyrene foam under a screed

The more expensive energy resources become, the more often the question of installing thermal insulation is raised, both in private houses and in apartment buildings. When carrying out repair or construction work, they try to insulate almost all premises, including non-residential ones. The availability of modern thermal insulation materials makes it possible to cope with this task without any problems.

Installation of polystyrene foam for floor insulation

Expanded polystyrene for flooring is a functional and cheap insulation material, the installation of which is not particularly difficult; even a person who does not have experience or professional skills can do it with their own hands. Thermal insulation of the floor with polystyrene foam can be carried out at the stage of building construction, this will reduce the cost of construction work, or during operation of the house.

Floor insulation with foam plastic is a simple way to reduce home heating costs

If floors that are located above the basement are insulated, there is no need to install waterproofing, since the foam boards are laid on the floor itself. But if flooring is laid on the ground, then a vapor barrier layer will be necessary.

Under the screed, floor insulation is done in the following sequence:

- The surface of the ceiling is leveled with a layer of cement screed.

- Thermoacoustic tape is laid along the perimeter of the walls to the height of the floor.

- The laid foam plastic boards are covered with a layer of waterproofing, 0.2 mm thick. At the joints, the film is laid with an overlap (the overlap width is about 10 cm).

- A cement screed (at least 5cm thick) is applied on top of the thermal insulation layer.

- After the screed has dried, the floor covering is laid.

You can insulate the floor without a screed; in this case, the floor covering is laid directly on the foam boards. The sequence of thermal insulation work is as follows: a vapor barrier layer is laid on the floors, and foam boards are placed on top. There is no need to lay waterproofing on polystyrene foam; you can immediately install the floor covering.

You can use polystyrene foam for floor insulation in a private house, cottage, or apartment. Expanded polystyrene is often used as a heat insulator when installing heated floors.

Expanded polystyrene and its advantages

As a result of the thermal swelling of polystyrene molecules, it was possible to obtain a fairly cheap, modern, heat-insulating material with unique heat transfer characteristics that help maintain temperature in rooms. This material is called “expanded polystyrene”. The material is quite light, since 97% consists of voids filled with air.

The origin of polystyrene foam can be as follows:

- autoclave;

- pressed;

- extruded-autoclave;

- extruded;

- not pressed.

For floors in residential premises located on the ground floor, non-pressed polystyrene foam of the PBS-S-35 brand is mainly used. If the premises are expected to have heavy loads, for example in a garage, then expanded polystyrene grade PBS-S-50 should be used. Such brands have a number of advantages, including the property of self-extinguishing, since they are treated with a special composition.

Expanded polystyrene has a number of advantages, which include:

- low thermal conductivity coefficient (10 cm of this material can replace 50 cm of wood or 2 m of brick);

- long service life;

- excellent sound insulation characteristics;

- environmental cleanliness;

- relative strength;

- resistance to temperature changes;

- moisture resistance;

- does not lose its properties under the influence of various household chemicals.

This material has one drawback: it can dissolve upon contact with any organic resins. If you plan to lay polystyrene foam under the screed, then measures should be taken to ensure that no organic resins can get on the insulation.

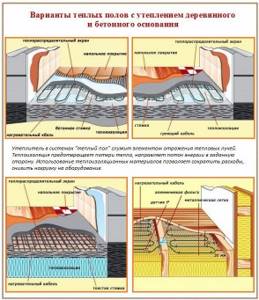

Use with underfloor heating system

When installing a heated floor system with your own hands on the ground floor, it is also rational to use polystyrene foam or expanded polystyrene. The floor pipes are laid in the thickness of the cement layer, which in this case is made thicker than 80 mm. To increase strength, reinforcing mesh is used. A layer of polystyrene foam under the insulation ensures maximum system efficiency.

Options for underfloor heating

This video discusses all the technical details of installing a semi-dry screed on polystyrene foam:

The use of polystyrene foam for floor insulation

To increase the thermal insulation properties of the floor, the screed should be insulated with polystyrene foam.

Warming can be done:

The technology for laying polystyrene foam, regardless of the base, is almost identical. The method of screeding the floor with polystyrene foam insulation has become widespread. This method is especially justified when it is not possible to raise the floor level, but high-quality insulation is simply necessary.

In apartment buildings, screeds are made using extruded polystyrene foam, although the technology is not much different. The fact is that EPS under a screed is a more rational solution, since it is stronger than ordinary polystyrene foam and has better thermal conductivity characteristics (read: “Which warm floor to choose for tiles”).

This means that thinner sheets can be used, which will save living space. Insulating the floor with extruded polystyrene foam under the screed gives excellent results in terms of the mechanical strength of the floor. It is recommended for use in conditions where significant load is applied to the floor.

When working with expanded polystyrene, you must adhere to the following rules:

- The material lends itself well to processing. To ensure accurate cutting, measurements should be taken carefully.

- For perfect cutting, use a special cutter with a hot wire.

- In places where there are gaps larger than required, mineral wool is laid.

- You should not resort to the use of organic mastics and resins.

- At the junctions of the floor and the walls, it is necessary to leave gaps about 1 cm wide.

- When laying polystyrene foam in the bathroom or kitchen, damper tape is glued over the slabs at the junction of the floor and walls.

- If you plan to lay laminate flooring, you should provide additional sheathing on the floor.

- If it is linoleum or carpet, then the floor is additionally reinforced with sheets of chipboard plywood or OSB boards so that the base does not bend.

If the floor is laid on a foundation made of soil, serious preparatory work must be carried out.

Penoplex thickness for floor insulation. How to choose penoplex for a balcony?

There is a sufficient range of brands on the market, but it is this diversity that makes it somewhat difficult to find the best candidate for insulating the floor on the balcony. When choosing, you need to start from:

- properties of a certain class of penoplex;

- specific area for insulation;

- balcony functionality;

- material thickness.

There are the following brands of EPS:

- 31, 31С. These products are characterized by low strength and low density - its maximum value is 30.5 kg/m³. Therefore, they are not suitable for insulating the floors of balconies.

- 35 - universal penoplex. It has sufficient density (up to 38 kg/m³) and compressive strength (83 kPa). It is used widely.

- 45, 45C. These brands are even stronger, their density ranges from 35 to 40 kg/m³. The materials are suitable for insulating foundations, so they are used to insulate balconies under screed.

Penoplex series - the second topic for familiarization:

- “C” - “wall” - for external walls;

- “K” - “roof” - for thermal insulation of attics and roofs;

- “F” - “foundation” - for bases, plinths;

- “Comfort” - for indoor work, these include balconies and loggias;

- "Geo" - for road and industrial construction.

If we talk about the optimal choice for a “semi-outdoor” room, then the leader will be the material marked with the letter “C”. The alternative is a series called “comfort”. Impregnation with fire retardants is a requirement already mentioned.

The optimal thickness of penoplex slabs for insulating a balcony is 20-50 mm. If the house is located in a region where winters are harsh, then choose thicker material. The thickness also depends on what effect the owners want to achieve.

- If the balcony is used as a room for drying clothes and is not heated, then the thermal insulation layer in this case can be 20-30 mm.

- When they plan to make a full-fledged room out of it, which will be visited regularly, they purchase penoplex with a thickness of at least 50 mm.

If all the characteristics have been considered, evaluated, and a suitable option has been found, then you can go shopping and then begin to prepare for the upcoming work.

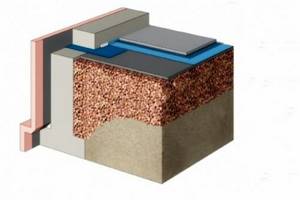

Installation of expanded polystyrene on a base of soil

This option is great for home owners.

Construction of a floor from scratch requires the following work:

- The soil is thoroughly leveled and compacted.

- Crushed stone is poured onto the ground and leveled. The layer thickness should be within 10 cm.

- A small layer of sand is poured on top of the crushed stone, which will serve as a kind of pillow. The layer is carefully leveled and compacted.

- After this, sheets of expanded polystyrene are mounted on the sand cushion. Sheets should be stacked as tightly as possible. If cutting sheets to size is required, this operation is performed as carefully and accurately as possible.

- A vapor barrier layer is laid on top of the insulation layer. The film is laid in half a sheet and secured with tape.

- For greater strength and durability, a layer of reinforcement is laid before pouring.

- The next stage is pouring the floor with cement-sand mortar. The surface is carefully leveled and smoothed with a grater. The screed should be calculated in such a way that the thickness of the concrete is within 5 cm, which will provide the floor with the required strength.

- After the screed has set, the base is finally leveled, after which the floor covering can be laid.

Features of foam screed

Insulation with various materials requires the installation of different cement-sand screeds. Foam plastic has low strength, so the coating in this case must be additionally reinforced. For flooring, mesh made from rods with a diameter of 4-6 mm is sufficient. The cell size is 50x50 mm or 100x100 mm, depending on the expected load, screed thickness and reinforcement diameter.

When insulating with stronger polystyrene foam, reinforcement is not required. A layer of cement mortar 30-80 mm thick will be sufficient. In this case, doing the work yourself is not at all difficult.

Approximate calculation of the cost of work for a room of 40 m 2

To calculate the cost of the work, let’s take the installation of polystyrene foam in 2 layers, with sheet dimensions of 1250x600x30 mm.

The volume of required building material is (taking into account 10% of the stock) - 9 packages, at a price of 1200 rubles / pack. = 10800 rub.

Coating waterproofing (a bag of dry mixture 40–50 kg, at a consumption of 2 kg/m2) - 1000 rubles.

Consumables - construction knives, hardware, steel mesh, etc. - 2000 rubles.

Delivery of material - 1000 rubles.

Total: 14800 rub.

Labor costs when working 2 people - 1 shift, 16 people/hour.

Screed made on a base made of polystyrene foam, with a thickness of 7–10 cm - 450 rubles/m 2 = 18,000 rubles.

That is, a subfloor with excellent characteristics costs 32,800 rubles.

What's good about the material?

In terms of their structure, insulating boards are granular material filled with gas. Its granules are tightly connected to each other under the influence of high temperature, which gives it unique qualities.

Basic qualities

- Low thermal conductivity . The high heat-saving property is due to the fact that air has low heat conductivity.

- Moisture resistance . Due to its structure, the material does not absorb water and moisture. This quality, and especially the floors with polystyrene foam, will be appreciated by residents of the first floors.

- Resistance to biological influences (microorganisms, fungi) and various chemicals (salt solutions, chlorides, acids, etc.).

- Durability . Plates of material can withstand enormous loads of up to 450 kg per square meter.

Note! The density directly depends on the correct installation of insulation on the floor.

- Excellent sound insulation . Due to its structure, polystyrene foam is able to absorb noise.

- Durability . This insulation is able to retain its properties and shape for a long time, depending on correct operation.

- High temperature resistance . In case of fire, the material does not support combustion and, when removed from an open flame, dies out instantly.

Types of material

High-quality insulation of a wooden floor with polystyrene foam can be done only after choosing the appropriate brand. It is best to use the PSB-S model as a heat insulator. They are self-extinguishing - they do not support the combustion process. This is important if high fire safety requirements are imposed.

You should also pay attention to a number of technical parameters. They will affect the original performance of the insulation. The thickness of this polymer surface for thermal insulation of the base directly depends on its density and brand. For construction work, it is recommended to use models of at least class 40.

Recommendations for selection:

- The optimal density should be from 28 to 40 kg/m³. This indicator affects mechanical strength;

- Find out the production method. To form a dense structure, an extrusion method must be used. Otherwise, the density of the material will not exceed 17 kg/m³. It's actually foam;

- Edge structure. At the cut site it represents regular polyhedra. If there are small balls there, this indicates poor workmanship.

One of the determining parameters is price. If you need to insulate the first floor with polymer sheets, you should choose a high-quality heat insulator. It a priori cannot be cheap.

Advice

During installation, protection from direct exposure to sunlight is required. They can have a destructive effect on the structure of the insulation.

Types of insulation from this material

The retail chain offers a choice of two types of polystyrene foam insulation:

- Styrofoam. This type of insulation, due to its structure and production technique, has good sound insulation. Polystyrene foam is a foamed gas-filled material. Expanded polystyrene granules are tightly connected to each other under the influence of thermal treatment. Available in slabs that are lightweight and durable.

- The next type of floor insulation is extruded polystyrene foam. The product is produced by forcing material in a liquid state through an extrusion head to give it a specific shape. The material has a finely porous sponge-like structure and differs from polystyrene foam in its strength and price.

Features of insulation

There are two main types of insulation of the floor base: the technique of insulation over logs and over a concrete base.

Before starting installation work, you should prepare the necessary set of tools:

- Screwdriver;

- Drills with drill bits of different sizes;

- Construction mixer (for preparing the mixture);

- Plane;

- Jigsaw;

- Saw;

- Stationery and mounting knife;

- Hammer;

- Hammer;

- Hydraulic level;

- Pencil;

- Dowels and screws;

- Polyurethane foam;

- Distance pads;

- Putty knife.

Insulation of floors with joists

Let's consider the sequence of work when insulating a floor with joists with your own hands:

- The old coating must first be dismantled.

- Wooden logs are laid on the subfloor at a distance of 0.6-1 m from each other.

Advice! Gaps along the walls and between the joists and the product should be filled with polyurethane foam.

- The recess between the joists is covered with a vapor barrier film and fixed to the slats using a stapler.

- Expanded polystyrene sheets are cut to size and placed between the joists.

- The insulated floor is covered with a waterproofing layer of polymer film.

- Lay the floorboard and install the decorative covering.

Insulation by joists

Tip: Before laying insulation boards on wooden structures, be sure to treat them with special solutions against fungi and microorganisms, as well as moisture-proofing substances.

Do not forget that the choice of insulation scheme for the subfloor depends on the type of floor itself. The photo below shows how to lay polystyrene foam flooring on a soil and wood base.

Laying on compacted soil in a wooden house.

Insulation of floors on a concrete base

Expanded polystyrene is laid on a concrete screed after preparing the base.

The brief instructions below will show you how to do this work on your own without the help of specialists:

- We compact the soil, fill it with a layer of crushed stone and cover it with a layer of sand.

- Expanded polystyrene is laid evenly without gaps along the entire perimeter from the corner of the room towards the door. The maximum gap between sheets laid end to end is no more than 2-3 mm.

Note! All joints should be carefully glued or filled with polyurethane foam, since if proper thermal insulation and installation of the material is carried out, the polystyrene foam under the heated floor will perform its main function and the optimal room temperature will be maintained.

- A waterproofing film layer is laid.

- A reinforced mesh with a cell size of 100x100 mm is laid on top. The edges of the mesh, cut into strips, should extend onto the surface of the polystyrene foam approximately 8-11 cm from the edge.

- Then the entire surface is filled with a screed solution based on sand and cement, the layer thickness is approximately 4 cm. The floor screed with polystyrene foam is ready.

- At the finishing stage, any decorative coating is applied (linoleum, laminate, tile, etc.)

Note! Extruded polystyrene foam floors are ideal for subgrades.

How to insulate a concrete floor with polystyrene foam

Initially, you will need to decide on the final flooring option. If you plan to make a protective screed on top of the installed insulation, lay plywood under laminate or parquet floors, then, in principle, you can use foam plastic with a density of at least 35 kg/m3. If a concrete screed is poured over the insulation without further finishing, then only extruded polystyrene foam should be used.

Important! In any case, low-density foam cannot be used, otherwise, even with screed reinforcement, cracks and breaks will appear. The surface of the foam sheet can be easily deformed even with your fingers.

Floor insulation scheme for concrete in an unheated room

Preparing the site for insulation

It is impossible to lay thermal insulation sheets directly on concrete without preparation. Firstly, the foamed polystyrene should fit as tightly as possible to the concrete surface, without any cracks or gaps. Otherwise, the thermal insulation will “play” under load and deform. As a result, the finishing screed, which will be laid on top of the polystyrene foam, will become covered with cracks.

Secondly, moisture will accumulate in the gaps between the base and the insulation, which at low temperatures will turn into ice and tear the polystyrene foam away from the surface with all the ensuing consequences.

Therefore, a little preparation is required:

- We dilute a small amount of dry plaster to level concrete walls; on average, no more than a liter of mixture is required per 1 m2;

- We sweep the concrete floor, use a spatula to fill in small cavities and depressions;

- We check the condition of the surface using the usual rule or a steel bench ruler.

After cleaning and leveling, leave the surface for five to six hours to harden and set the repaired areas. For old floors, it is sometimes more convenient to fill one common screed. In any case, there should be no voids, otherwise polystyrene foam will be ineffective as insulation for concrete.

Laying polystyrene foam

If thermal insulation is laid in a non-residential area, then the process of laying out sheets is noticeably simplified:

- We lay a row of expanded polystyrene slabs from wall to wall;

- We cut with a knife or cutter - we adjust the dimensions and geometry so that the ends of the sheets are adjacent to each other with a minimum gap;

- We number the sheets, disassemble the row, apply a small amount of tile adhesive to the back side, carefully and evenly rub it over the surface of the polystyrene foam;

- We lay the thermal insulation, load it with a small load, about 2-3 kg for each square meter.

After a few hours, we seal the joints with tape and move on to laying the next row. If there is a slight difference or step left on the seams, it’s okay; subsequent filling with screed will hide the defects.

If the insulation of a concrete floor is carried out in a residential, constantly heated room, then the seams on the glued slabs are cut at an angle or cut and additionally blown with foam.

Floor insulation can also be made from extruded polystyrene foam. For this purpose, sheets with tongue-and-groove type end locks are used. It is enough to lay the panels on the floor, even without any glue, connect the locks and secure the insulation to the concrete using fungi. It is clear that the joints also need to be foamed.

It is better to reinforce a concrete screed with at least one layer of mesh

Final sealing of insulation

The insulation laid on the floor should be checked for any raised areas. If there are any, then we attach the polystyrene foam to the concrete using a dowel-fungus.

Attaching thermal insulation to concrete using fungi

The next step is to carefully trim the remaining foam and treat the insulation surface with a deep-penetrating acrylic primer. After a couple of hours, you can pour the concrete screed or glue the plywood. Of course, you will need to lay a waterproofing film under the screed. If reinforcement is used in the future concrete floor, then the mesh will need to be raised above the film, otherwise the metal will tear the waterproofing to shreds under load.