In most cases, foam plastic is used to insulate private houses and industrial buildings. This material has excellent thermal insulation properties and a high level of environmental friendliness. In addition, it is resistant to bad weather conditions. Insulating a private home using polystyrene foam will cost 1.5-2 times less than insulating using other materials. Expanded polystyrene can be easily cut, drilled and glued.

Polystyrene foam is used to insulate private houses. It is a highly environmentally friendly material that remains resistant to temperature changes.

The material is made from polystyrene granules. It can be obtained by foaming with warm air. Polymer granules, which turn into thin capsules measuring 5-10 mm, are formed by extrusion into small blocks of the required thickness or designs in the form of various shapes. The ratio of polymer and air can be from 1:30 to 1:10. Thanks to this, it is possible to obtain materials of different densities.

The advantage of polystyrene foam is saving material consumption.

The advantages of polystyrene foam include the following:

- The material is chemical and moisture resistant.

- Does not swell in water.

- Not affected by mold and mildew.

- Durable.

- Resistant to temperature changes.

- Combusts only on contact with open flame.

Disadvantages of the material:

- Destroyed under the influence of carbon solvents.

- When ignited, produces a large amount of smoke.

- During combustion, it releases toxic substances.

Types of material

The product is one of the types of polystyrene foam, therefore it has many of its characteristics. This is a special polymer filled with gas. The composition of the material is foamed polystyrene, various additional substances that improve its structure, as well as a small amount of water. Manufacturing technology allows us to obtain a unique product with high thermal insulation properties. Expanded polystyrene also perfectly prevents sound transmission.

Floor insulation in the house Source masterskayapola.ru

The material is produced by various methods, depending on which it acquires certain characteristics. The result is products with different densities, so each type is used in a specific area. Also, the manufacturing method affects the final cost of the substance. Main production methods:

- Pressless. These are granules dried several times and then foamed. This material is very fragile and retains moisture well inside.

- The pressing method has low thermal conductivity. The granules are subjected to additional compression, due to which they close and change the structure of the product. The material turns out to be of higher quality, but the manufacturing technology takes longer, which increases the price of such foam.

- The autoclave method is used quite rarely, since its production requires a special device. This material is practically not used for home insulation, since its characteristics do not meet the task.

- The extrusion option provides for the production of household products. Various foams, packaging and other products for household needs are made from it. This polymer is not used for insulation.

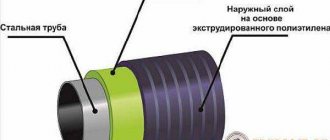

- The extruded method is most often used to produce materials that can then be used to insulate a home. This is a type of pressless manufacturing, but it must involve an extruder. The product retains heat well, since its pores are very small in diameter, they are maximally closed to external influences. Thanks to these indicators, this type has become widespread among craftsmen and users; it is presented in a large assortment on the construction market.

Work on insulating a wooden house Source rubankom.com

Penoplex - what is it?

Penoplex is a manufacturer’s trademark and at the same time a common name for extruded polystyrene foam as a type of insulation that relatively recently appeared on the Russian market, and they began to produce it under this brand. Penoplex is hydrophobic, has a low volumetric weight and practically zero vapor permeability, which allows it to be used without the use of hydro- and vapor barriers. We can say that this is the best insulation of all existing ones in terms of thermal conductivity, it is easily processed and mounted on all types of surfaces - vertical, horizontal and inclined.

Among the negative characteristics is that penoplex does not support combustion, but when exposed to fire, it melts, emitting caustic toxic smoke. In addition, it loses its properties and becomes unusable under the influence of prolonged exposure to the sun.

Advantages of insulating walls outside

The owner of a house always has a question: should he insulate his home with penoplex from the inside, or mount it from the outside? The option of placing the insulation on the facade side is more preferable - it allows you to transfer the dew point into the insulation (provided the thickness is calculated correctly) and thereby protect the walls from excessive moisture. It should also be remembered that the internal location of penoplex significantly reduces the area of the house, and also leads to the need to finish the walls, which is not entirely advisable - well-treated wood looks good in the interior of a home without any finishing. Therefore, it is better to insulate the surface of the walls with penoplex from the outside.

How to insulate a wooden house with foam plastic

To understand how to glue foam to wood, it is important to study its structure. The material is most often supplied in the form of lightweight but durable slabs, the thickness of which can vary significantly depending on the type and purpose. The structure of the substance allows it to work effectively in any weather and temperature conditions - it is not afraid of mechanical damage and natural factors.

Walls of a house with polystyrene foam Source otdelkaexp.ru

Due to its unique composition, expanded polystyrene is successfully used for both internal and external insulation of homes. The difference will only concern the method of fastening the material:

- The house can be insulated from the inside by placing sheets of polystyrene foam on wooden walls. This method is not used often because it has significant disadvantages. Expanded polystyrene for interior decoration has high heat-insulating properties; it also does not allow moisture and water vapor to pass through it. As a result, the walls will not warm up well, but they will be exposed to cold and wind from outside the room. This can lead to the formation of a dew point inside the room, which can lead to the accumulation of condensation between the wood and the insulation layer. Constant exposure to liquid is dangerous by the onset of putrefactive processes, the appearance of fungus and mold on the surface of the walls.

- The external method of insulation is increasingly used by craftsmen in the construction and renovation of houses. Its second name is a ventilated facade, which has special properties. When installing insulation, waterproofing is used to protect it from the effects of weather factors. Also, this method allows the sheets to be constantly ventilated, which has a good effect on the durability of such a coating. The only drawback of the solution is the high cost compared to the internal option.

A wooden floor can also be insulated using expanded polystyrene - in this case, sheets of material are laid between the floor joists. If the first floor is being finished, this method prevents cold air from entering from the ground, and in the case of intermediate floors, stabilization of the temperature regime is achieved. The heat is evenly distributed between the rooms, which avoids overheating of the upper rooms. Insulated floors help create a normal microclimate in the house if the upper floors are not heated in winter.

Foam adhesive - types, properties and methods of application

Paint guru➣Glue➣Glue for construction➣

Expanded polystyrene, or ordinary polystyrene, is a material widely used in construction and repair.

It has an environmentally friendly composition, is economical in price and easy to use. The service life of foam plastic thermal insulation is directly affected by the choice of means for fixing it.

The adhesive for polystyrene foam should securely attach the material and last for many years.

You can glue polystyrene foam to walls, ceilings or other surfaces for insulation with your own hands - the process is simple. A high-quality adhesive composition must meet a number of requirements. First of all, it should not contain harmful components that destroy the foam:

- ketone-based solvents, including acetone;

- nitrogen compounds – nitromethane, nitrobenzene and others;

- chlorine derivatives;

- petrochemical products – gasoline, white spirit, kerosene;

- alcohols and ethers;

- other flammable substances that disrupt the structure of the material.

Even a small percentage of such additives will, over time, negatively affect the quality of the lining of a house or other premises.

Also, when selecting glue, it is taken into account whether it will be used for exterior work or inside the building.

Houses covered with polystyrene on the outside are exposed to low temperatures, and the product must be frost-resistant.

The instructions for the adhesive mixture always indicate what types of substrates it is suitable for. It is necessary to clarify whether the product is suitable for application to concrete, wood, and metal surfaces.

If necessary, the glue must adhere securely to putty and other heat-insulating materials (isolon, EPS). To attach sheets of foam plastic to each other, you can use dry or “wet” glue.

We invite you to familiarize yourself with: Bathhouse made from vulture panels, DIY project video

The construction market is filled with different compositions for gluing foam plastic. Typically for this purpose it is recommended to use:

- foam, foam glue;

- liquid Nails;

- powder masses;

- adhesives-sealants, etc.

Dry mixes

Such materials are sold in large bags (up to 30 kg) and diluted with water. The powder looks like putty or plaster, but contains stronger binding components.

This method of wall insulation will be the most budget-friendly. Typically, mixtures are prepared based on cement, gypsum and a number of polymer additives. The reliability and durability of adhesives leaves no doubt.

Quality brands are considered:

- Ceresit ST-83;

- Knauf Perlfix;

- "Avangard-K";

- "Primus";

- "Volma";

- Armierungs-Gewebekleber.

Most mixtures are suitable for gluing foam plastic outside and inside the house - to concrete, wood and other materials.

From them you need to prepare an adhesive solution, adding the amount of water specified in the instructions. Consumption per 1 sq. m of surface – approximately 1.5-2 kg of finished mass.

To improve adhesion to the base, before starting work, the walls are cleaned, dried, and primed. The solution must be mixed thoroughly; there should be no lumps in it. The glue is applied with a spatula in strips or in a continuous layer - along the edges, in the center.

What is the best way to stick foam on the wall? Polyurethane composition is ideal for this purpose.

There are even special foams on sale labeled “for polystyrene foam.” They can be applied to vertical and horizontal substrates and used for interior and exterior work.

Well-known brands are Tytan Styro 753, Penosil, Ceresit ST-84 Express.

Polyurethane foam adhesive easily connects plastic and all its derivatives (including polystyrene foam) to any surface. It allows you to attach blocks to OSB boards, metal, concrete, plaster, wood, aerated concrete, and foam blocks. The advantages are obvious:

- high speed of installation of slabs;

- moisture resistance, frost resistance;

- ease of use;

- low consumption.

Bonding of materials with polystyrene foam will be reliable, the adhesion rate is maximum. There is no need to dilute the glue; it is sold in ready-made cans.

Consumption of one package is 10-15 sq. m slabs.

The polyurethane in the composition allows you to fix the materials within 20-30 minutes, and you need to hold the foam with your hands for no more than 20 seconds.

Is it allowed to glue polystyrene foam using PVA? The choice is popular due to the low cost of the product.

Unfortunately, the degree of fixation of this glue is not sufficient to create durable insulation.

But PVA can play a role: it will serve as a filler for voids in the wall, and the quality of fastening will be improved by dowels. The double technique will allow you to save money and get the job done without delay.

Some people practice gluing foam to metal using PVA. This can be done, but the consumption is very high, and burlap is used as a layer.

Polyurethane foam

Is it possible to glue polystyrene foam onto polyurethane foam? Professionals and beginners alike respect it due to its efficiency, excellent adhesion to the surface and reliability of the adhesive seam.

It is convenient to work with foam; it is easily sprayed from a container. And yet, the purpose of this tool is somewhat different. It is used to seal grooves, cracks, and strengthen concrete structures.

Of course, it is possible to attach polystyrene boards to iron, concrete, brick with foam, but there are a number of disadvantages:

- all operations will have to be performed very quickly, the material will soon harden;

- after hardening, it expands greatly in volume and can deform thin foam plastic and cause curvature of the homemade structure;

- due to uneven expansion, voids can form in some areas, which deteriorates the quality of thermal insulation;

- The material consumption per square meter is high, the cost of repairs will be far from budget.

Many polyurethane foams, moreover, contain components that corrode foam and are not suitable for it. Therefore, the correct procedure is:

- immediately determine whether the product is suitable for polystyrene foam;

- glue the blocks onto the walls using a different glue;

- Fill the joints between foam plastic boards with polyurethane foam.

You can reduce the consumption of foam material by using a glue gun; saving on its purchase is impractical.

Liquid Nails

What glue do professionals use most often? Craftsmen often prefer liquid nails “Moment Installation”, Dragon and a number of others.

All work involving this product will be completed quickly and efficiently, because the adhesion to the surface, hardening speed and service life are in an optimal ratio. In terms of bond strength, liquid nails are second only to polyurethane foam adhesives.

Therefore, for complex substrates (for example, metal sheets), experts advise using the two indicated products together.

To optimize adhesion, the surface should be cleaned, degreased and, if necessary, primed. This way you can glue polystyrene foam even to the ceiling. Due to their high cost, liquid nails are usually used in small areas.

In order to properly glue polystyrene foam, it is important to know the specifics and properties of the base material. There are a number of features that must be taken into account during installation.

Craftsmen often try to save money when insulating concrete walls with polystyrene foam without making lathing. Indeed, it is possible to glue the material directly to the wall. For this purpose you will need the following tools and consumables:

- primer;

- putty knife;

- cement;

- sand;

- glue;

- drill.

To improve the quality of the clutch, preparations are made. The surface is cleaned of dirt, dust and stains. Unstable areas will have to be puttyed again after removing the old coating. At the end of the preparatory work, the wall is primed.

Typically, dry adhesive mixtures are purchased to connect foam and concrete. They are diluted with water according to the instructions, the proportions are indicated in it. Mix using a drill with an attachment; a construction mixer is also suitable.

Next, wait the time indicated on the package to infuse the solution.

How to glue foam to concrete? The tips are:

- in the presence of small defects or minor irregularities, the glue is applied in continuous strips, 2 cm apart from the edges;

- if the wall unevenness is more than 2 cm, lubricate the foam in strips with gaps (this will remove excess air);

- Be sure to apply the product to the middle of each slab;

- Press the material against the wall, and immediately remove excess glue with a rag.

Additionally, it is recommended to fasten with dowels - in the center, in the corners. It is also possible to attach the material with sealant or liquid nails and dowels; the seam will also be reliable. Instead of these materials, special polyurethane glue, which is applied using a gun, is suitable.

How to properly attach heat-insulating material to an iron surface? Most of them have the same rules. Polystyrene foam, extruded polystyrene foam, and penoplex are attached to metal using burlap.

After joining with the latter there will be no problems with repairs; you can use almost any glue. If you need to seal small areas inside the house, you can even use double-sided tape.

Also an important nuance is the obligatory cleaning of the wall from rust - if this is not done, the adhesion of the glue will decrease.

Expanded polystyrene is attached to the metal base by the following means:

- aerosol adhesives;

- sealants with silicone;

- polyurethane and mounting foam;

- dry polymer mixtures.

An excellent option would be to work with one-component polyurethane glue, which is sold in cylinders. It can also be produced in the form of adhesive foam. If foam is attached to a sloping or uneven metal wall, this adhesive is the best choice for a craftsman.

It is also used without burlap in cases where it is impossible to attach the latter. There must be at least 5 dots of any glue on the foam sheet. After dilution, dry mixtures are applied in strips, as described above for concrete surfaces.

Tree

In general, the procedure for gluing foam plastic to wooden bases is similar. We are talking about fastening to plywood, OSB boards, lining, boards. Features of the work are as follows:

- Before pasting the walls, it is important to completely clean them of debris and dust, if necessary, wash and dry them;

- priming is mandatory, for old wood - 2-3 times;

- if the foam plastic is attached under the windows, a reinforcing mesh is first attached to the wood (using a construction stapler);

- voids in the walls and cracks are filled with polyurethane foam, after a day its excess is cut off;

- protruding areas, knots are cramped;

- The remnants of old varnish are completely removed from the wood, they destroy the foam.

Advantages and disadvantages of the product

The production of the material is possible only in production; polystyrene foam cannot be made at home. The substance contains styrene, which is a waste product from oil refining, so the product is not highly safe and environmentally friendly. Despite this circumstance, polystyrene foam has significant advantages:

- Low price, which is significantly inferior to other types of insulation.

- Good density, allowing you to effectively retain heat indoors.

- Low weight and excellent elasticity.

- Does not allow sounds to pass through walls.

- Easily tolerates interaction with liquids.

- Widely distributed in stores, you can find different types of products for specific tasks on sale.

- Large selection of structures and shades.

- High resistance to various adhesives and dyes, chemical inertness.

- It does not rot and is durable - the decomposition of the material can last for years.

- It is not subject to ignition, which allows you to protect a wooden house from fire.

- Long period of operation, which is more than 15 years.

- Easy to cut and install, they can be done even without the use of special equipment.

The negative aspects of the material are associated with its synthetic origin, as well as its complex structure, including many chemical compounds. Among the disadvantages of polystyrene foam are the following:

- Poor tolerance to sunlight, prolonged exposure to which leads to damage to the product. Also, the initial properties of a substance can change significantly.

- Flammable substances and solvents can damage the structure of the material. It is dangerous to use gasoline and fuel oil.

- Animals and insects can easily destroy or damage polystyrene foam.

- When ignited, a large amount of harmful substances are formed that are extremely dangerous to human health. Inhaling them can be fatal.

- The material should not be heated, as this results in the formation of toxic compounds. For this reason, it is prohibited to use polystyrene foam in baths and saunas.

Insulating a house from the inside Source stroyrem-nn.ru

Is foam plastic (polystyrene) good as insulation?

Scheme of thermal protection of various materials for insulation.

Due to its characteristics, polystyrene foam (polystyrene) has found very wide application in construction. It has low thermal conductivity, relatively good steam conductivity, and is also lightweight, which does not additionally load the building structure. In addition, it has the ability to withstand high mechanical loads while having low density.

Other positive qualities of polystyrene include its good interaction with other building materials, resistance to moisture, fairly low thermal conductivity (or high thermal resistance), low noise resistance, extraordinary ease of processing and relatively low price.

Today, many are arguing: will it be good if you insulate a wooden house from the outside with polystyrene foam? They pay attention to its low vapor conductivity, which supposedly leads to moisture and rotting of wooden walls. Therefore, it is not recommended to insulate with polystyrene foam, and when choosing insulation, it is recommended, if possible, to replace polystyrene with other insulation materials. But the approximate indicators of vapor permeability of materials they give show that expanded polystyrene has approximately the same vapor permeability as pine wood.

Therefore, the use of polystyrene as insulation for buildings with high internal humidity (for example, baths) is not recommended. And if the humidity inside a wooden house is normal and controlled, then the use of polystyrene foam as insulation will fully justify itself.

Scheme of foundation insulation with polystyrene foam.

There is an opinion that it is better to use penoplex as polystyrene insulation. Let's consider this question. Penoplex is extruded polystyrene foam. That is, most of its characteristics are similar to those of foam plastic (heat and sound insulation, resistance to aggressive substances, specific gravity, ease of processing, etc.). It is characterized by greater density, increased mechanical resistance to loads, and the ability to self-extinguish upon fire.

The disadvantage of penoplex is its low vapor and air conductivity; moreover, it has a higher cost compared to polystyrene foam. The disadvantages of polystyrene over penoplex are eliminated by working to protect the foam from fire using fire-resistant facing materials and putties. In addition, the vaunted fire safety of penoplex approaches zero during a fire itself, since the burning of the insulation will be supported by the burning of the wood of the walls. Thus, the use of polystyrene foam for insulating a wooden house is more profitable than penoplex.

For middle-class living, choose foam with a thickness of 5-8 cm.

Expanded polystyrene insulation

Any type of material is subject to environmental influences. Products are affected by temperature fluctuations, humidity changes, sunlight, precipitation and other natural factors. Therefore, to prevent the gradual deterioration of the foam, insulation is used to protect vulnerable areas. In the case of a wooden house, the fight against humidity, which provokes putrefactive processes, is especially important.

Arrangement of the frame on the building Source ultra-term.ru

Laying the material

In a private home, it is important not only to know how to attach polystyrene foam to a wooden wall, but also to understand the features of installation on the floor. In the latter case, the material is laid along the logs. Work begins by creating a foundation at the bottom of the structure.

Expanded polystyrene sheet on the floor Source beton-house.com

The easiest way to do this is by two methods. The first of them is to install boards under the joists, on which a layer of insulation is then laid. The second method involves installing slats on both sides of the joists, which serve as the basis for laying the material.

Laying polystyrene foam on the wall Source baurum.ru

Before installing insulation, it is necessary to lay waterproofing so that moisture from the ground or concrete does not penetrate deep into the material. This requirement is relevant even for monolithic types of foundation. After this, you can lay the polystyrene sheets themselves directly. It is best to install the slabs in layers, in a checkerboard pattern, so that the visible seams overlap.

Installation of foam plastic boards Source remoskop.ru

When placing insulation under the joists, it is necessary to leave a 2 cm gap for ventilation. If the installation was made too high, the structure will need to be raised using lathing.

Base insulation with polystyrene foam Source uteplix.com

To prevent steam from the room from penetrating the material during the heating season, a layer of vapor barrier is laid. Lastly, they begin to organize the subfloor. To do this, use a board, plywood or OSB board.

Insulation of the roof of a house Source svoidomstroim.ru

Fastening the material to the walls

Typically, insulation is laid on the facade using frames. This technology allows you to effectively hold the material and simplifies the installation of the entire structure. The procedure is performed gradually, step by step.

Preparatory work

Attaching expanded polystyrene to a wooden wall begins with preparing a reliable base. Since wood is very sensitive to external factors, it must be protected as much as possible from damage. Both old and new buildings are periodically insulated, so you need to pay close attention to the quality of the surface. It is important to remember that before starting the main work, the wood must be dry; remaining moisture can provoke putrefactive processes and even destruction of the structure of the material.

In painted rooms, all coating should be carefully removed, and the joints between the logs should be well sealed. All procedures must be completed before the start of insulation work. Damage is also eliminated; any remaining bark is removed, if there is any on the surface.

Scheme for attaching foam plastic Source masterfasada.ru

The prepared and dried wall is treated with antiseptic solutions. Particular attention is paid to this point, since after installing the insulation, this area will become inaccessible for viewing. As a result, it will not be possible to notice the formation of mold or the appearance of insects and fungi there.

Installation of sheathing

Installing the frame allows you to securely hold the insulation in place, prevents sliding and sagging, and also allows air to freely penetrate and ventilate the walls of the house.

Application of adhesive foam for installation Source opechkah.ru

Video description

How to glue foam plastic?

If you have a choice between glue and foam, then it is better to choose the first option, since the consumption of the product will be much less, and the quality of gluing will remain the same. The substance is applied between the wall and the insulation in a thin, uniform layer to securely attach the material to the surface. Before starting the procedure, it is important to thoroughly clean the area, remove traces of paint and varnish, repair potholes and damage, and dry the wood.

Applying glue to polystyrene foam Source balkon4life.ru

This method is well suited for timber buildings, but it makes no sense to use it for log buildings. This is due to the heterogeneous surface of the latter, which reduces the area of contact between the material and the glue. Differences in the size and shape of the logs will make it difficult to create an even and smooth area, so the results of the work may be far from ideal.

After glue or foam is applied to the foam, sheets of material are laid evenly across the entire work area. Compared to using a frame structure, covered areas are more difficult to process and must be treated with caution in further finishing. The easiest way is to resort to plastering the surface, but this method is not very suitable for wooden houses. It would be better to build additional sheathing for the facade so that the choice of design becomes wider.

Adhesives for foam plastic in tubes Source samodelino.ru

Finishing

Using polystyrene foam allows you to create a kind of “thermos” that effectively retains heat inside the home and prevents cold from entering the building. This way you can significantly reduce heating costs and save significant money in winter.

Universal polymer glue Source samodelino.ru

After preparing the base and sheathing, a layer of insulation is laid, and then the finishing of the building begins. If you approach this process responsibly, you will eventually be able to bring almost any idea to life. The most commonly used materials are wood - lining, imitation timber or block house. Sidings are also popular. Each type of finish differs in the method and type of fastening. Usually, to equip the facade, an additional frame is used, which is installed on top of the main sheathing.

What you should know about this insulation option

| Low vapor permeability | As you know, for the best preservation of wood, it is necessary that moisture from the material can evaporate freely. But if the surface is covered with foam, then the moisture has nowhere to go, and condensation can form inside the wood, so it is necessary to install high-quality exhaust ventilation for a wooden house |

| Material hardness | If you use mineral wool, it can be inserted into a wooden sheathing and it will hold without additional fastening. Polystyrene foam can also be arranged in a similar way, but the sheets may crumble during operation |

| The need to seal joints | After completing the fastening, the cracks must be sealed to prevent the penetration of cold; this complicates the process and makes it more labor-intensive. This stage should not be neglected, since the result of the work largely depends on the insulation of the joints |

Gluing foam to a wooden surface

Before fixing the material, the surface is thoroughly cleaned and dried. To remove dust and small debris, use a sprayer and a regular brush.

Sheet of foam plastic on a wooden surface Source blog-potolok.ru

The base must be coated with a primer, and then a mesh must be glued for subsequent reinforcement. Using a stapler or adhesive, the material is securely attached to the surface.

Since the mesh is supplied in the form of rolls, before starting to work with it, it is necessary to cut identical strips approximately 40 cm wide. It must be secured in such a way that at least 10 cm is under the foam layer. After installing the insulation, the remaining sections of the product are wrapped and glued to the sheets.

Video description

What is the best way to glue polystyrene?

Before directly applying the glue, the surface must be treated with antifungal and antiseptic drugs. It is important to choose the right composition, since subsequently access to the junction of materials will be very difficult.

The cheapest option is dry polystyrene foam adhesive, which is made from cement. For use, this product is diluted with liquid. The result is a reliable and durable compound for attaching foam to virtually any type of material.

Also recently, solutions based on polymer cement have become increasingly widespread. They are universal in use and are well suited for gluing insulation to any type of base. To work with facades, you can use products that contain various mineral fillers. Many companies produce products to increase the protective properties of polystyrene foam. After applying glue to the front surface, the material becomes resistant to various environmental factors. In addition to the advantages, such substances also have disadvantages - a long polymerization time, which is about 3 days.

There are also aerosol mixtures containing polyurethane. They can be used as glue or to fill gaps and seams between sheets. These are universal substances that behave equally well both indoors and outdoors. They can be applied to facades, roofs and walls of houses, flooring and other wooden surfaces. In all these cases, the products set quickly and hold the material securely for a long time. And although the prices for such mixtures are relatively high, they are justified by the convenience of applying the glue.

Expanded polystyrene sheets usually begin to fix within 2 hours after gluing the surface. For better stability, the material is secured with anchor bolts for facades.

The main advantages of polyurethane products are: fire resistance, good tolerance to changes in humidity and temperature, environmental friendliness and safety for health. Modern production technologies make it possible to obtain high-quality and easy-to-use compositions. When choosing an adhesive, it is important to consider its chemical reactions with the material. To prevent the destruction of polystyrene foam, you need to purchase products that do not contain acetone or gasoline.

Sometimes sheets of expanded polystyrene need to be glued together. For these purposes, use any wet or dry glue that does not contain solvents. When choosing products, a specific task is taken into account, and then the most suitable product is selected to solve it.

Stages and nuances

Gluing foam plastic is carried out in several stages:

- Disconnect power from the electrical wiring.

- Clean the base from paint, whitewash, residual finishing materials and dirt.

- Remove irregularities deeper than 1 cm, that is, level the surface. If this is not done, the foam boards will break during installation.

- Treat the surface with a primer that contains antiseptics. This will improve adhesion and prevent the appearance of mold.

- Wait for the primer to dry.

- Foam boards are usually glued from a corner or lamp. During operation, the desired configuration is given using a mounting knife.

- If aerosol glue is used, insert the can into the gun and cut off the tip. Apply the composition to the underside of the foam board in strips along the edges (step back 2-4 cm from the very edge) and diagonally. It is also permissible to squeeze out the glue in dots - in the center and in the corners.

- Dilute the dry mixture with water until you obtain a homogeneous consistency and spread it on the stove with a small notched spatula, you should get a homogeneous thin layer. Another option is to apply glue pointwise around the perimeter and in the middle, spreading it evenly over the surface.

- Press the foam onto the base and hold for a few seconds. Remove excess glue with a damp cloth or even spatula.

- In the same way, glue the next plate end-to-end to the previous one. If a gap more than 2 mm wide has formed between them, fill it with foam or putty.

It is necessary to press the foam to the surface as a rule, and level it using a building level.

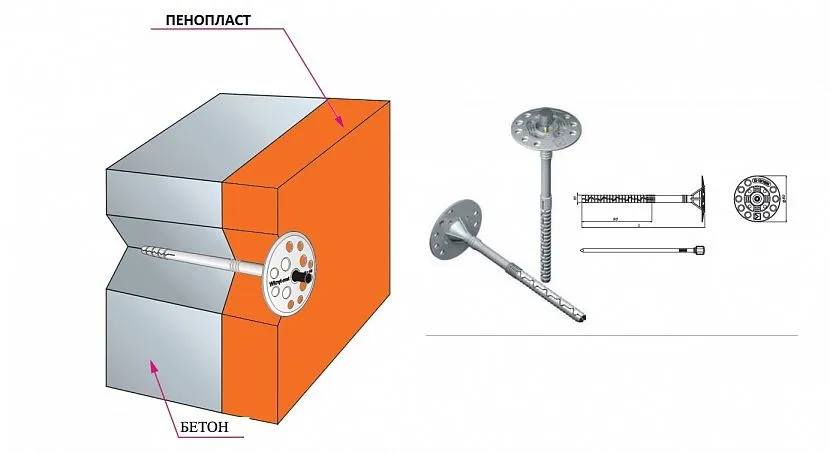

Fastening foam with dowels

For external finishing of facades, sheets of expanded polystyrene are used, which are attached to the frame using disc dowels. These elements are considered mandatory for reliable fixation of the material. The parts act as insurance in case the slabs sag, so that they cannot slide and peel off from the wall. Dowels are placed according to certain patterns, which are selected for each specific building.

Most of the elements will be needed to fix the material on the plaster. For solid foundations, 2 to 5 dowels per square meter of area will be sufficient. To calculate the appropriate length of fasteners, it is necessary to measure the thickness of the plaster layer. The size of the element must extend through the entire layer and be fixed at the base of the wall.

The foam is secured using dowels as follows:

- Fixation is carried out 4 hours after applying the glue, so that it has time to set well and is not damaged during installation of fasteners.

- Surface drilling is performed with high precision, having previously installed a special limiter in the hammer drill, which does not allow penetration beyond the size of the fastener.

- A disc-shaped dowel is placed in the completed opening. Inside the element there is a plastic core, which is designed to open it in the hole.

- Drive the fasteners very carefully so as not to deform the surface of the insulation. Otherwise, its characteristics will suffer, the foam will be less effective at retaining heat inside the building. If you have difficulty placing the core, you will need to replace the drill with a new one.

Conclusion

In fact, attaching polystyrene foam to a wooden base is not difficult; it is important to carry out this work in such a way as to ensure the best thermal insulation performance and prevent damage to the material due to the formation of condensation. The video in this article will talk about the workflow in more detail and clearly show some of the points described above.

Wood is a material that “breathes”, and this is the main advantage of wooden houses. Therefore, doubts arise about insulating a wooden house with polystyrene foam. Some people argue that this can and should be done, others are sure that the wood will begin to rot under the foam. However, experts say that this can be done, but only with “breathable” insulation. Otherwise you will deprive the building of its benefits.

There is a rule that says: the vapor permeability of materials towards the street should increase so that there is no obstacle to the escape of moisture to the outside. If this rule is neglected, then moisture will condense at the border of the dense material, which leaves the room, which will lead to the formation of condensation and rotting of the wood. Therefore, vapor permeability is a very important factor when choosing insulation.

Polystyrene foam has a lower vapor permeability than wood, so it is not the best option for insulation. But if you organize a high-quality ventilation system, the amount of steam escaping will be minimal, and therefore there will be no harm from it. Therefore, if you have properly designed ventilation, then polystyrene foam can be used to insulate a wooden house.

Important! Under no circumstances should you use this material to insulate rooms and buildings with high humidity (baths, saunas, kitchens, etc.).

Fixing polystyrene foam to a wooden ceiling

Before starting the main work, the ceiling must be carefully prepared, whitewash, dust and debris must be removed from it. You should also immediately place the electrical wiring, which will then be covered with plates.

The sheathing for insulation is made from wooden blocks. They are laid at such a distance from each other that the sheets of material are tightly located between them. Then the foam itself is mounted, and adhesives or fasteners are used to secure it. The cracks and recesses are filled with sealant. You can also use polyurethane foam for this purpose.

Next, a vapor barrier is placed on the frame. This is a film that will prevent moisture from entering the ceiling from inside the room. Lastly, the foam boards themselves are laid.

During preparatory work, the ceiling should not only be thoroughly cleaned, but also its surface should be disinfected using antiseptics. Then the entire area is covered with primer. If it is impossible to remove all the whitewash, it is recommended to completely treat the ceiling with special glue. The product is applied to the material with a dotted line. The sheets begin to be placed from the middle, moving them slightly. For greater reliability, it is advisable to add fasteners. Expanded polystyrene is also strengthened using a reinforcing mesh, which is subsequently puttied and processed.

Methods of gluing and types of adhesive compositions

You can attach foam boards to the surface using glue, dowels, or both. Foam plastic is usually attached with adhesive compounds indoors, and with dowels and glue - when working on the facade. Fixation only with dowels is used in extremely rare cases, this is explained by the fact that the required level of reliability cannot be achieved in this way. If the roof is insulated, then expanded polystyrene is simply inserted into the sheathing.

Foam gluing is carried out using dry compounds and ready-made adhesive mixtures.

Advantages of powdered products:

- excellent adhesion (adhesion) to brick, plaster, concrete, cement;

- immunity to temperature changes and precipitation;

- elimination of small irregularities on surfaces;

- relatively low cost.

Disadvantages of dry mixes:

- the adhesive composition must be prepared, this will take time, in addition, you need to know how to properly combine the powder with water in order to achieve a uniform consistency;

- You will need a mixing container and a construction mixer;

- Dust is released during the cooking process.

Ready-made adhesives will allow you to quickly and efficiently glue polystyrene foam to polystyrene foam, concrete, brick and wood surfaces, OSB panels or cellular blocks. Aerosols are most often used in cans based on polyurethane foam. Such materials are very convenient, and one cylinder is enough to glue approximately 10 m2 of foam plastic boards inside or outside the building. The glue is resistant to temperature changes and high humidity, hardens in about half an hour and securely attaches the foam to the base.

Penosil polyurethane foam

All photos from the article