Need repairs or has a cast iron pipe burst? This article details how to repair a crack in a cast iron sewer pipe!

The use of cast iron sewer pipes is now almost complete, but in many apartments or houses they are still reaching their service life. Durability, reliability and lack of noise still attract users; cast iron risers are installed almost everywhere in old apartment buildings. Replacing them is difficult, since this requires completely replacing the entire riser. It is easier to solve local problems that may arise during operation. Let's look at how to repair a crack in a cast iron sewer pipe and how it is usually done.

Causes of cracks

There are two main causes of cracks or fistulas in cast iron pipes:

- negligence of installers;

- fragility of cast iron as a material.

Poor quality sealing of sewer joints often causes leaks. They occur both on old connections and on transitions from cast iron to plastic pipes, if standard adapters were not used. Cement mortar was used to seal the flares, and errors in mixing proportions could cause leaks in weak areas over time. In such situations, cast iron sewer pipes are the easiest to repair.

If a crack or hole has formed in the drain, the cause can only be mechanical impact - impact, damage received during unqualified installation or repair work. Many users do some of the work themselves.

Lack of professional training and poor understanding of the properties of cast iron do not allow them to repair cast iron sewer pipes properly. Careless actions, using ordinary hammers instead of rubber mallets, falling pipes - from all these influences, cast iron pipes burst and fail. Often cracks go unnoticed, or careless plumbers simply install a product that is obviously defective in the hope that everything will work out somehow. The sewerage system is a non-pressure system, so cracked elements are not detected immediately, sometimes after several years of operation.

There is another possible reason for the formation of holes - corrosion. A low-quality casting with cavities or shells can rust through, especially if the drainage system has been in operation for a very long time.

A cast iron sewer pipe burst, what to do?

During operation, elements of the sewer system may fail. This causes trouble for owners and the need to look for effective ways to fix the sewer. We often encounter problems such as pipe leaks. A related problem is an unpleasant odor in the house.

Considering that most multi-storey buildings still have old cast iron sewer pipes installed, leaks can occur quite often, because their service life has long expired.

Sometimes leaks can occur even after sewer pipes have been replaced. In this case, you should look for technological factors causing problems. If you do not pay attention to the problem in time, you may face unpleasant consequences. It is necessary to discover the cause of the leak, and only then decide on a quality seal or replacement.

Leak in the pipe

Causes of leakage

The main sign that a sewer pipe is leaking in an apartment is a persistent foul odor. To solve this problem, you need to find the source of why your house smells bad. There may be several reasons, but first of all these are:

- expiration of the operational life of the sewer system;

- errors that were not noticed during installation work;

- lack of sealing of joints;

- defective materials;

- violations during sewerage operation.

If the pipes are old and damaged by corrosion, very small cracks may form on their surface, which are the main cause of leaks.

Also, elements of the sewer system may fail due to mechanical stress on them. In this case, it is impossible to do without dismantling part of the system or the entire sewer system and carrying out a series of repair work.

In other cases, the breakdown can be corrected using simpler methods.

A simple blockage of the pipe as a result of the formation of a fat plug in it or the entry of a large mechanical object can also cause a leak. If the pipes are cast iron and leaking at the joints, the sealant may have run out, especially in cases where organic fiber was used.

Note! For stamping cast iron pipes, it is recommended to use a graphite gland. It will ensure maximum reliability and strength of the joints, and protect the pipes from leaks at the joints.

This is what the lack of sealing of pipe joints looks like

How to repair pipe damage

There are a number of methods to fix a leak. The most global is the replacement of the sewer system or its section. But this is not required in all cases. Or it may be that the owner does not have the financial means or time to complete such a voluminous and costly work.

If the cause of the leak is mechanical damage (crack), measures to correct the problem will depend on what material the system elements are made of. A set of measures aimed at eliminating leaks in pipes is carried out depending on the location where the damage was discovered. Most often you need to do:

- processing of pipe joints;

- removing blockages;

- fistula repair;

- sealing cracks.

Before repairing a sewer pipe, you should prepare the necessary materials and tools, as well as pre-treat the surface of the pipe.

Algorithm for sealing joints of cast iron sewer pipes

Fistula repair

If a sewer pipe is leaking, there may be several repair options depending on the complexity of the situation and which pipe is damaged. If fistulas occur in the body of the sewer riser in a multi-storey building, the problems should be repaired together with the neighbors, otherwise after some time the problem will return again.

Before taking any repair measures, you should carefully inspect the pipes, evaluate defects, prepare the surface, clean it and dry it, and you can begin to carry out the main set of work.

- To eliminate a small fistula, you can use a regular bandage that should be wrapped around a sewer pipe. The bandage or gauze is pre-treated with epoxy resin. To increase the strength of the connection, you can wrap the pipe with wire.

- To repair a pipe in which a small hole has formed, special wooden blades are used.

- The most reliable way to eliminate the defect in the event of a fistula formation is to use a clamp.

A clamp is a special device for repairing sewer pipes. You can buy it on the market in the construction or plumbing goods department. This small part costs about 5-8 dollars. If you don’t want to spend money, you can try making a clamp yourself.

First, apply epoxy resin to the problem area. After it dries a little, rewind it with reinforced tape.

Sealing cracks

Owners often find that a hole in a sewer pipe grows into a large crack. This happens as a result of mechanical damage or sudden temperature changes. If the crack is not detected and repaired in time, you may encounter a more unpleasant situation - the pipe bursts.

Note! Cracks and damage to the exhaust part of the sewer riser most often occur due to freezing and the formation of an ice plug inside the pipe.

If there is no unpleasant odor from the sewer pipe in the house, but a crack is clearly visible, it is most likely superficial. The moisture on the surface of the pipe is condensation. When the damage is complete, it is necessary to urgently take measures to repair the sewer system.

Surface cracks are eliminated using a conventional sealing compound designed for sealing joints. Repairs are carried out as follows:

- the crack site should be thoroughly cleaned, all residues, dust and dirt should be removed, cracked open so that the sealing compound can penetrate deeper;

- the surface of the damaged area should be treated with a degreasing compound and dried thoroughly;

- Apply the sealant and leave it to dry for a while.

Ways to solve the problem

The most correct answer to the question - how to repair a crack in a cast iron sewer pipe - is to replace the section that has failed. However, this option is not always available, especially for residents of the lower floors. In most cases, you will have to go through the entire riser, or perform a partial replacement by cutting and removing the problem area. For the entire duration of the work, it is impossible to use sewerage and water supply, which is extremely inconvenient for all neighbors and very difficult to organize. Therefore, they usually prefer to temporarily plug the hole with something until a better repair becomes possible. If the work is done carefully and efficiently, the drainage system can last for many years without increasing the problem.

We repair

Let's look at how to repair a cast iron sewer pipe without replacing the problem area:

- The simplest, but quite effective way is to install a rubber pad pressed to the crack with a clamp. A patch is cut out of a piece of soft rubber, which is applied to the crack and pressed with a standard or homemade clamp. It is recommended to use materials that are not susceptible to corrosion - nylon or copper.

- Installing a homemade bandage from a bandage soaked in cement mortar. This method is more complicated and requires stopping the sewer system for about a day, so it is used much less frequently. Most often it is used when it is impossible to get by with simpler methods. When creating a solution, you can replace water with glue (liquid glass), and use old tights instead of a bandage.

- Using a repair coupling. This is essentially a modified way to repair a pipe using a clamp and rubber. The coupling consists of two halves, completely encircling a certain section of the element and tightened with bolts. All that remains is to install a rubber gasket on the resulting gap and press it with a coupling to completely seal the hole.

Cold welding

You can also mention one of the temporary (although often permanent) options - cold welding for cast iron sewer pipes. This is a two-component (most often) composition, mixed immediately before application. Before you begin to cover a crack with cold welding, the surface must be cleaned of rust and other deposits, degreased and dried. There are two types of such glue - liquid and thick mass, similar to plasticine. The first type is mixed with a hardener, and the second, before starting to seal the gap, is intensively kneaded to achieve softness and elasticity of the material.

There can be quite a few ways to repair a crack in a cast iron sewer pipe. The basic principle of such repairs is to apply a quickly hardening compound to the problem area, fill the crack, and apply a fixing bandage or clamp over it. New products are constantly appearing on sale that allow you to solve the problem without calling plumbers and performing labor-intensive and expensive repair work.

You may also like: Sewerage in an apartment - diagram and installation

Sealing with sealant

To eliminate fistulas and small cracks in cast iron pipes, you can use new materials. These include sealants. When using this product, it is necessary to take into account the recommendations indicated on the label, the hydraulic pressure in the system and comply with technical regulations.

The sealant is selected taking into account the diameter and length of the sewer system and drainage pipes. Issues related to leakage at joints must be taken seriously. Several types of insulating material are classified:

- Self-adhesive tapes. They are used to seal joints between pipes, insulate couplings, units, and drainage systems of wastewater structures. Anti-corrosion tape is made from a bitumen-rubber mixture, with a protective film applied on top. The advantages of this material include high strength and resistance to chemical reagents of any composition. It is able to reliably contain leakage, allowing the pipe to remain in working condition for a long time.

Repair using self-adhesive tape

- Silicone based sealant. There are two types: neutral and acidic. Fixing problem areas with a neutral product will cost more than sealing cracks with an acid sealant. The material is made on the basis of silicone, which has excellent adhesion properties.

Self-adhesive tape is a modern insulating agent that can easily be used in emergency situations involving pipe leaks. To use it correctly and carry out quality repairs, you need to do the following:

- Prepare the metal surface near the leak by first cleaning it from rust and dirt.

- Tear off the end of a whole roll of tape and attach it to the side of the crack being repaired.

- Then, using a winding motion, the electrical tape is placed on the problem area. When working, make sure that the material is tightly stretched and overlapped in a spiral.

- Ultimately, the crack location should be under a double layer of sealant.

Silicone sealant is a universal tool for sealing holes not only in cast iron, but also in plastic. To work with this material, you will need to perform a number of simple steps:

- Before you begin, inspect the surface of the pipe and make sure it is dry and clean.

- Bring the nozzle of the tube with the gel and carefully distribute it over the entire surface of the crack, including the areas adjacent to it.

- It should be applied in 2-3 layers, without smearing on the sides of the joint, but only slightly going beyond the boundaries of the problem area.

Silicone sealant Moment

Experts advise squeezing out the sealant using a special pistol device. If this is not the case, you can use a regular hammer.

What materials can be used

To solve the problem of how to plug a sewer pipe, the following materials can be used:

- rubber patch with clamp;

- cement mortar;

- cold welding.

ways

These materials and methods of performing the work have already been discussed above. There are other technologies for which appropriate materials are suitable:

- self-adhesive tape . There are plastic or metallized types with a sticky layer, which are very easy to use and the results are very effective. The only limitation is the difficulty (or impossibility) of winding some pipes with tape due to the tight connection to the wall surface;

- silicone sealants . These are materials that are in a semi-liquid state, but harden in air and become rubber-like. They do not react at all to moisture, fill the entire crack cavity, and have a long service life;

- To seal the sockets, use ordinary linen sanitary winding impregnated with PVA glue and cement. Before sealing a hole in a sewer pipe, it is necessary to clean it of old filler or deposits;

- a mixture of copper oxide and phosphoric acid in a ratio of 3:2 . This compound is used to fill large holes or potholes. The solution hardens quickly, so you first need to prepare the area for application and only then start mixing the components.

Most users try to use the simplest and most accessible materials that are at hand or on sale.

Types of common types of sealants, their properties, rules of use, pros and cons

In order to make quality repairs and not return to them for as long as possible, you need to choose the optimal method for sealing the seam in the sewer. Each type of sealing material has its own scope of use. In addition, the operating conditions of the system and the economic feasibility of using a particular option should be taken into account.

Types of common sealants

Metal polymers

Metal polymers are an innovative technology for pipe repair. It is also suitable for high pressure pipelines. Sewage systems operate by gravity, without pressure. Therefore, the use of metal polymers is generally not economically feasible. However, in critical areas, in systems operating at the limit of design capacity, the use of this method is justified. In this way you can seal the joint of any sewer pipe.

Useful tips

So, a cast iron sewer pipe has burst - what to do? First of all, you need to carefully examine the entire visible surface of the riser. Perhaps the number of cracks is greater than it seems at first glance. Then you need to decide on ways to solve the problem - change the section of the riser to a plastic pipe with a diameter of 110 mm, or seal it yourself using improvised means. If the fastest ways to resolve the issue are not suitable, you will have to go and negotiate with your neighbors not to use the sewer and water supply for some time. This is very inconvenient, but sometimes there are no other options.

It must be remembered that a full replacement is always better than the highest quality repair, so you should first consider this option. Qualified plumbers will be able to complete the job quickly and solve the problem in the most effective way.

Eventually

If problems arise in your cast iron sewer system, do not despair. There are many remedies that will help eliminate the crack and avoid big troubles. By following all the rules for working with the material, you can carry out a high-quality seal of the leak with your own hands.

In some cases, urgent repairs of cast iron pipes can be done independently. Let's assume that the riser located in the bathroom or toilet begins to leak. If the crack or fistula is minor, and the leak from the riser does not threaten to flood either you or your neighbors, you can try to solve the problem without resorting to such drastic measures as completely replacing the riser. We want to talk to you about the technology for performing such repairs in this article.

How to change?

To replace a riser that has failed or needs replacing, you should contact the management company with an application addressed to its head.

Before writing an application to the Criminal Code, you can call a plumber to your home, who will draw up an inspection report of the sewer riser, document the damage and the need to replace the riser.

Next, you need to draw up an application for replacing the riser in free form addressed to the head of the management company, justifying the reason why the replacement work should be carried out.

At the end of the application, you should write a specific request for replacement or repair of the sewer riser. Next is the date and signature of the owner. The application is drawn up in two copies, one of which remains with the owner, the other is given to the management company.

Read more: What kind of house can you build with maternity capital?

Sample application for replacement of a sewer riser.

The homeowner submitting the application must be a bona fide utility payer in order for his application to be accepted and considered.

After reviewing the application, a convenient time for the work is agreed upon with the owner. The riser is replaced by employees of the management company or contractors hired by the management company.

The owner must provide free passage to the bathroom in order for the pipes to be replaced. How much does it cost to replace a sewer riser in an apartment?

The owner is not required to pay additional funds when replacing the riser or branches from it before the first connecting connection.

The approximate cost of replacing a sewer riser in one apartment is from 4 to 7 thousand rubles.

Quite often, homeowners are faced with the fact that management companies demand payment for the replacement of the riser, citing the fact that the riser pipes are located on the owner’s premises and the homeowner is responsible for them.

In such cases, management company employees should be reminded that sewer, water risers and battery risers serving more than one apartment are common property, and the management company is responsible for their replacement and repair.

Moreover, the replacement of risers will in any case be paid for by homeowners from the funds they pay in utility bills.

You can learn what to do if one of the residents of the house is against replacing the common sewer riser from the video:

Didn't find the answer to your question? Find out how to solve exactly your problem - call right now:

It's fast and free!

Over time, various communications in residential buildings become unusable. And a situation may well arise due to a leaking sewer riser. Despite the fact that this problem can arise at any time with any person who lives in an apartment building, very few know the answer to the question: “The sewer riser is leaking: who should repair it?”

If you want to find out, Or call us at 8(800)-350-30-02 (free call for all regions of Russia)!

Imagine the following situation. The sewer pipes in your apartment have rotted and started leaking. As a result, your bathroom is flooded and the neighbors below begin to flood. Their apartment turned out to be insured, but they are still going to sue you for compensation for the damage caused.

Naturally, unpleasant questions arise: “Are you the culprit? Do you have to pay full damages? If not, then who should change the sewer riser?” And the most important question: “Who should have changed the riser in time and at whose expense, so that this trouble would not happen.”

Replacing an old section of the system

If you decide to undergo a major renovation, stock up not only with patience, but also with the necessary materials and tools. When everything is at hand, replacing the sewer riser in the apartment will go much faster.

What you will need

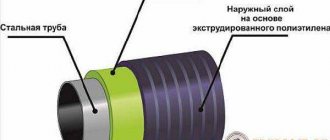

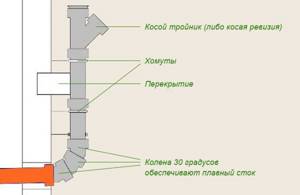

Scheme of the riser with the necessary elements.

- Plastic pipe of the required length, diameter 110 mm.

- Plastic cross 110×110×110×50 mm or tee 110×110×110 mm.

- Compensator for connecting pipes.

- Rubber cuff for tight joining of a plastic pipe with a common cast iron pipe.

- Adapter with rubber cuffs for connecting to a top tube without a bell.

- Clamps for attaching the riser to the wall.

- Plastic bends 110 mm, for shifting or leveling the riser.

Tools

- Grinder with a set of discs.

- Gas burner or blowtorch.

- Silicone sealant.

- Hammer, chisel, screwdriver.

- Durable stepladder.

- Respirator and safety glasses.

Replacement process

Before replacing the sewer riser in your apartment, warn your neighbors. It is advisable that they stock up on drinking water so that there are no unnecessary complaints against you. To prevent any complaints from you about them, it is better to turn off the water supply in the basement. Thus, you will deprive individual “well-wishers” of deliberately actively flushing the toilet, watering you with waste through the cut-off drain.

Pipe dismantling

Replacing a sewer riser in an apartment: dismantling the old pipe.

Using a grinder, make an incision at a height of about a meter from the distribution tee. The second cut is made at the top of the pipe, at a distance of 7/8 cm from the ceiling. A chisel is driven into the resulting cut, tapping it with a hammer. The chisel will “open” the pipe, which will burst around the circumference. Do the same with the lower part, then carefully pull out the cut out fragment.

Chasing

Burning out sulfur coinage.

Tap the pipe carefully with a hammer. Ideally, the bell should wobble

This suggests that during the initial installation they were caulked using rope winding with carbolic acid. Pry up the winding rope with a screwdriver and carefully pull it out with pliers. Slowly loosen the bell until it comes out. Sulfur embossing is often found, this will add problems. It is almost impossible to swing the element with bare hands. Use a blowtorch or gas torch to burn the sulfur around the circumference. This method almost always helps.

- When the sulfur melts, the bell can be pulled out. It is convenient to clamp it with an adjustable wrench and, wobbly, pull it towards you.

- The bell seat should be cleaned of residues with a chisel or chisel. Then the sealing cuff will sit without distortion.

Installation of a new riser

Before changing the sewer riser in your apartment, remove the one that has already been dismantled and get rid of everything unnecessary around it.

Provide access to the work site and prepare tools.

Installed cuff.

- A rubber cuff - an adapter - is installed on the cast iron pipe coming out of the upper apartment. The joint should be coated with sealant.

- A plastic adapter is installed on top of the cuff.

- The second rubber adapter is installed in the same way below, near the floor.

- A pipe with a compensator is measured. One end of it is inserted into the adapter from above.

- The lower end of the pipe is cut off just above the socket with the compensator.

- Now you can connect all the parts, carefully coating the joints with sealant.

The photo shows the pipe being secured with a clamp.

- The almost finished riser is secured to the wall with plastic clamps. This must be done, otherwise over time the pipe may move down and rupture.

- If the tee is also replaced during work, a compensator is installed in it. In the case of installing two riser pipes, a compensator is used at the points of their connection.

- Upon completion, all joints are inspected for cracks and the tightness is checked.

Conclusion

Replacing the riser yourself, provided you have permission and comply with all standards, is not such a difficult task. The price of materials is minimal, and the house owner will not need hired labor. After proper repairs, both you and your neighbors will become more comfortable.

A description of the process is provided by the video in this article.