What is a fistula in the pipe? In plumbing, a fistula is a hole of small diameter through which fluid under pressure enters. If the pressure is high enough, the liquid sprays, forming a mist and producing a whistling sound.

Fortunately, high pressures are not used in water supply and heating systems of residential buildings. So anyone can cope with a fistula in a heating or water pipe - provided they have a strong desire, suitable materials and tools, as well as minimal plumbing skills.

Causes of fistula

The main cause of pipe breakage is pitting corrosion. Externally, the appearance of a problem can be noticed even before a fistula appears. Corrosion growths on the walls of the pipe, when lumps of rust appear under the swollen paint, are a signal that the pipe may burst at any moment.

The corrosion process develops most quickly in the off-season, when the air temperature is within +150 C. Metal pipelines are corroded by rust and a through hole appears in the pipe wall through which water flows out.

The main reason for the appearance of a fistula in plastic pipes is a poor-quality connection; in addition, plastic weakly resists mechanical stress.

What to do

If the water is in full swing, it is recommended to change the system or part of it immediately ; all attempts to solve the problem by other methods can only be temporary.

If the trickle is small, the leak can be eliminated by sealing the hole after turning off the water supply. After draining the system, it is easier to determine the size of the hole. To do this, clean the leak area with sandpaper, removing a layer of paint and rust.

Before you begin to fix the problem, you need to degrease the surface with acetone or gasoline.

Note! Cleaning and degreasing is an important stage of repair; if you neglect this and try to seal the hole on an untreated, uneven surface, it will be difficult to achieve maximum tightness, and after a while the problem will make itself felt again.

By cleaning and degreasing the surface, you can assess the nature of the hole and its size, and choose the most correct repair method.

Options for eliminating a fistula in a metal pipe

| Way | Description | Peculiarities |

| Rubber pads | A strip of rubber with a length greater than the diameter of the pipe by 50 mm and less than the circumference of the clamp by approximately 100 mm is wrapped around the pipe at the site of damage. The bandage is tightly fixed with a clamp. | A universal method that is suitable for repairing various types of leaks in pipelines for various purposes. |

If the hole is small, you don’t even have to interrupt the water supply.

Options for eliminating leaks in plastic pipes

Fistulas on plastic pipes can be eliminated by welding or threading:

Hello, dear readers!

You can easily detect a fistula in a heating or water supply pipe by looking at the fountain of water gushing from the riser. Know that after this the problem must be eliminated as quickly as possible. Otherwise, because of a small hole, your home will soon float. And the apartments located below will set sail with it.

Leaks in various systems

A fistula in a hot water pipe or any other system that consists of metal pipes can be quickly repaired in the following ways:

Option 1.

Medical bandage and cement solution. It is cut into pieces and soaked in pre-prepared cement mortar. These bandages are wrapped around the leakage area, forming a cocoon-like structure.

Finally, the resulting structure is also covered with cement mortar. It dries in about one day.

Option 2.

Pieces of rubber. Rubber is cut into strips. Each of them should be slightly longer than the circumference of the pipe.

Option 3.

Table salt and bandage. As a rule, this method is used to seal pressure leaks in couplings, elbows, etc. The leaking area is wrapped in a bandage mixed with salt.

When dissolved, salt fixes micro-leakage. If we compare this method of sealing under pressure, it is immediately worth noting that it is not as reliable as the first two.

Option 4.

Bandage. This method can be used for pressure pipes. The bandage is considered one of the oldest and most proven options. A small car clamp can be used for a fistula with a volume of up to 0.005 cm.

For the clamp, a strip of rubber is cut out, a couple of millimeters wider than the clamp itself. The length of the strip should be one centimeter shorter than the circumference of the pipeline. .

This entire structure must completely cover the fistula. Next, the clamp is tightened. During these activities, the surface at the site of corrosion must be cleaned.

Video: ways to repair a fistula

It should not contain any irregularities. If this is not done, the liquid will pass through the bandage in the area of uneven areas.

What is a fistula?

A fistula is damage to the pipeline wall in the form of a crack or through hole. Leaks of this nature indicate that it is time to replace a section of pipe. However, it is not always possible to do this immediately after detecting a leak on your own. By the time the called technician arrives, a significant part of the apartment will be flooded with water, not only yours, but also your neighbor’s. But installing a temporary patch is not that difficult.

Leak location in the pipe

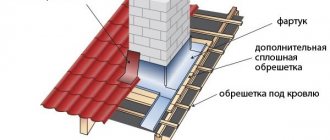

In the heating system (not to be confused with the hot water pipeline for the tap), coolant leaks are possible in the following three areas:

1. On the straight part of the pipe in case of an undetected defect when purchasing the product. 2. In the area where pipes connect to each other and to the heating device. The reason for a possible leak when connecting polypropylene pipes to batteries is the use of a connecting element such as an American one, one end of which is made in the form of a thread; without sealing it, a breakthrough is possible. 3. In the area where battery sections are connected to each other.

Thus, a leak can form not only in steel heating systems as a result of iron oxidation, but also in stainless polypropylene parts. In pipes of various materials, there may be leakage in areas of high resistance to the coolant, turns, joints, etc., which increases pressure and reduces the flow rate of hot water for heating or steam, which causes mechanical stress on the pipe and reduces its wear resistance in such areas.

Ways to repair a fistula with your own hands

What to do if a fistula takes you by surprise? Do not panic. Take a look around - you will probably find improvised means for sealing a fistula in your home:

- bolt;

- temporary or adhesive bandage;

- cold welding.

If you found any of the above, then consider that the problem is solved. Do not forget that the coolant and hot water are under pressure in the system. Therefore, if possible, turn off the water or coolant supply at the shut-off valves before proceeding with the repair using a method suitable for you.

Sealing with a bolt

This option will not suit you if the pipeline is too old. This involves cutting threads, but it is impossible to do this on a dilapidated pipe. In addition, the leak may become even larger due to the breakage of the pipe walls. In other cases, follow the simple instructions:

- Using a drill and a drill bit, drill out the fistula to the size of the bolt.

- Cut the thread using a tap.

- Tighten the bolt.

Sealing with a temporary bandage

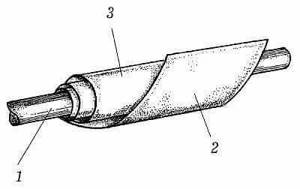

The method is justified if the leak is caused by an elongated crack. The bandage can be a bicycle tire, a boot top, a medical tourniquet, a glove, or just a piece of thick rubber. The size of the patch should significantly exceed the area of the fistula. Place the bandage on the pipe and secure it with wire or a clamp.

Sealing with adhesive bandage

One of the most difficult methods of sealing a fistula on a water pipe, but at the same time very reliable. The procedure is as follows:

- Clean the leak area from dirt, then degrease it with gasoline or acetone.

- Prepare a piece of fiberglass fabric 3 times wider than the fistula and of such length that you can wrap it around the pipe at least 6 times.

- Apply epoxy glue to the edges of the fiberglass tape and wrap the tape tightly around the pipe.

- Secure the resulting bandage with metal tape.

Sealing with an adhesive bandage: 1 – pipe with a fistula, 2 and 3 – tape

Cold welding repair

Cold welding is a special two-component composition, completely ready for use. Usually sold in transparent plastic tubes. The product is intended for sealing holes and other defects in containers for various liquids. Cold welding has also proven itself to be effective in the temporary repair of fistulas.

Before use, the composition must be kneaded in your hands, then covered with it over the hole in the damaged pipeline and thoroughly smoothed with moistened fingers or a spatula. Cold welding dries and hardens in 10–20 minutes. After this time, hot water can be used again.

Which way is better?

The choice of a method of dealing with fistulas does not have clear criteria. It all depends on the scale of the disaster and the availability of certain materials and tools at hand. For example, a temporary bandage is the simplest thing you can do to stop a leak for a while. A permanent bandage is more durable, but you must have fiberglass and minimal skills with epoxy glue.

The situation is similar with a bolt plug - you will need both an electric and a special plumbing tool, which not every home has. In my opinion, the most affordable way to remove a fistula is to use cold welding. It is sold in many construction stores, in handling it is somewhat reminiscent of ordinary plasticine or clay, dries quickly and is inexpensive.

Why does the system start to leak?

There are many reasons for leaking heating pipes, but if we highlight the main ones, the list will be as follows:

- The tightness of the connection was broken. The cause may be a connection defect or incorrect installation.

- Poor quality pipes were used for installation.

- Violation of operating conditions. Usually associated with excess operating pressure, water hammer, excess temperature

- Normal wear and tear. The main reason is that the lifespan of the system is very long. The impact of wear is most pronounced on steel heating pipes.

The above list of reasons may lead you to think about whether it is even worth installing communications in the house in a hidden way? In order to minimize this risk, several nuances must be observed:

- It is best to lay pipes without joints. If this is not possible, then it is best to make a frame onto which you can then attach the trim.

- You should not “tightly” seal the joints. You may need to access them at any time, so try to leave this option - this will help you avoid hammering the walls in the future and maintain their aesthetic appearance.

- If possible, use continuous long sections of pipe. This is especially important if pipes are laid in the floor.

An emergency has occurred: first steps

First of all, remember that you should always have several clamps equipped with rubber seals at home, since such a “strategic reserve” will help to avoid a large number of unpleasant problems.

If an accident does occur, then first of all shut off the fluid supply to the area where the accident occurred. Turn off the boiler and circulation pump, and also be sure to block any possible access of liquid to this area. Using a clamp will help temporarily solve the problem, but repairs will not be possible.

If we are talking about an apartment building, then you will need to shut off the heating riser, which is the prerogative of the plumber, the manager of the remote control unit or another person. It is advisable to know this in advance in order to take timely measures.

Before starting repair work, prepare in advance everything that may be required for it, turn off the taps leading to the damaged area, turn off the heating and make sure that there is no liquid in the system. It's best to drain it. Depending on what the heating system pipes are made of, repair work can be carried out in different ways.

How can you fix a leak on a steel pipe? If this problem lies in the threaded connections, then they need to be disassembled and the winding needs to be replaced, of which there are many types.

When disconnecting pipes, act as carefully as possible so as not to accidentally damage the connection itself or the seal. To make the pipes easier to disassemble, try preheating the connection - the metal will expand, and it will be much easier to unscrew them. If the cause of the leak is on the body of the pipe or its joint, then you will have to use welding - electric or gas, whichever is more convenient for you.

What to do if a fistula appears on the heating pipe? There are several options:

- Install flange connection.

- You can put a fiberglass bandage on the pipe, which is impregnated with sealant. To achieve the best effect, the number of layers of such a bandage should be at least six.

- You can repair the pipe using an ordinary bolt. The place where the fistula appears is drilled out, after which a thread is cut into it, into which the bolt is tightly screwed.

We repair copper pipes

If a copper heating pipe is leaking, the steps are almost identical to repairing pipes made of steel, and you will similarly need a welding machine. Repairing copper pipes has many unique features, which makes welding this non-ferrous metal quite difficult. There are nuances here that only qualified specialists know about, so it is best to entrust such work to them.

Copper is one of the metals that perfectly resists the destructive effects of corrosion, so heating systems made from this metal last much longer than all others. If the installation of a heating system made of copper was carried out with high quality, and all relevant standards were observed, then the operation of such a system can take place for 30 years or more without the slightest problem.

Metal-plastic pipes - they can also be repaired

If your home's heating system uses pipes made of a material such as metal-plastic, then there is a high probability that you will have to completely replace the entire leaking section of the system. The leaking piece of pipe is cut out, and a new one is installed in its place using fittings of various types. Fistulas on metal-plastic pipes most often appear at the junction of the pipes.

Polypropylene pipes - restoration method

Even polypropylene heating systems can experience leaks. In addition, sometimes the location of a leak in such a system is extremely difficult to determine, especially if the leak is small:

- The process of soldering pipes from this substance is carried out according to clearly defined technological processes. The heating duration and temperature must be strictly observed. An error during soldering can cause the system to collapse in the near future.

- If the leak manifests itself in a straight section, or in a place where the pipes are welded, then the repair will consist of completely replacing the damaged sections of the pipe.

After completing all the necessary work, do not rush and immediately turn on the heating boiler. First make sure that the pump is also turned off, then fill the system with coolant and make sure that there are no airy areas. Only after this can the heating equipment be turned on. For some time after switching on, monitor the restored section of the pipe. Ideally, during the first 24 hours you should check the repair site once every one to two hours.

There is extraneous noise in the heating system

Sometimes various extraneous noises may be observed in the heating system - humming, clicking, knocking, etc. Why do radiators click? There are not many reasons for this:

- During the repair, you installed pipes of too small a diameter.

- There is a leak.

- During operation of the heating system, the diameter of the pipes decreases.

Remember that when you hear extraneous noise in the system, do not think for long about why the radiators are humming, but first check for leaks.

This phenomenon is typical mainly for heating systems in apartment buildings, and this is due to the abundance of air in the system. As air bubbles circulate with water and become more numerous over time, they begin to accumulate at the top of the radiators, thereby creating air locks. This is typical for the non-heating season, when the water stands still and the air gradually rises. That is why, in order for heating to flow throughout the entire riser, air is vented at the beginning of the heating season. In other words, if you hear noise in the batteries, open the Mayevsky tap; most likely the reason is the accumulation of air, which just needs to be released.

VIDEO: Repairing a heating battery without releasing water from the system, do it yourself. Personal experience

One of the most common problems that arise in a metal water supply and heating riser is the formation of a fistula.

Most often, a fistula appears on hot water pipes. It is quite simple to determine this problem: in the place where the fistula forms, a red growth or pitting corrosion appears.

The cause of a fistula on a metal pipe is wear. However, when this problem appears, it is necessary to think not about the reasons, but about rational ways to avoid a pipe break.

Before you begin to solve the problem that has arisen, you need to drain the water from the system by closing the stop valve and opening all the taps. After this, you can choose one of the acceptable methods.

This method is not suitable for old pipes, since it involves cutting threads, and old pipes are not suitable for this operation, which can simply increase the diameter of the resulting leak. If you are planning to repair new pipes, then you will have to do the following:

- take a drill and expand the fistula;

- make a thread with a tap;

- screw the bolt into the threaded hole.

Causes of malfunctions of metal-plastic pipes

The metal-plastic pipe is a relatively new product that has proven itself to be the best when creating indoor plumbing. The material is based on an aluminum base, covered on both sides with a durable polyethylene coating. This structure makes the material flexible and lightweight, significantly expanding its scope of application. Thanks to these qualities, the pipe can be shaped into any shape without any effort or special tools.

A metal-plastic pipe can withstand enormous pressure without deforming or losing its load-bearing qualities. In practice, a violation of the integrity of the highway is possible, but it depends on reasons of a completely different nature and is completely unrelated to the quality of the products. The main factors that can lead to failure of a metal-plastic water supply system are:

- errors in connecting system elements;

- exceeding the permissible pipe bending angle;

- maximum mechanical loads;

- deformation of metal adapters due to thermal overloads.

The above list of reasons has a direct impact on the functioning of the water supply system and its integrity. Therefore, when designing and constructing a system, it is necessary to follow installation rules based on the technical characteristics of the material. Ignoring the norms and neglecting existing standards will inevitably lead to the formation of leaks with all the ensuing consequences.

Pipe connection

A pipe has burst and fittings are leaking: types of damage

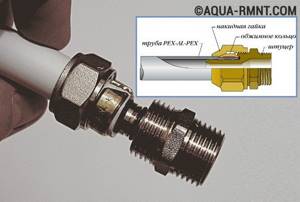

The longitudinal strength of a metal-plastic pipe has fairly high values. Therefore, in a stationary (installed) state, there are very few factors that can lead to a violation of the integrity of the material. Most often, problems arise at joints that have much less longitudinal stability compared to the base of the pipe. As a rule, the main types of malfunctions of a metal-plastic water supply system are:

- leaking fittings;

- cracks in the metal casing;

- cracks in fittings.

The most common problem in the functioning of metal-plastic pipes is leaking fittings. Systematic operation and the resulting vibrations lead to a gradual deterioration in the waterproofing qualities of the transition sections of the system. The pipes wear out, the nuts and fasteners become loose, and the rubber gaskets lose their elasticity. Such changes remain unnoticeable for a long time until the fitting begins to leak.

Cracks in a metal-plastic pipe can also cause leaks. As a result of exceeding the permissible bending angles of the material, deformation of the aluminum body of the product occurs. At first it may remain completely unnoticed, since the polyethylene sheet does not lose its integrity. However, after some time, in places of cracks, due to the pressure in the system, plastic delamination occurs and a leak forms.

Another problem that has become widespread is the formation of holes in fittings. There can also be several reasons for their formation, starting with poor-quality material at the base of metal parts and ending with thermal overloads.

Excessive pipe bending

Flowing in the middle of the pipe

You need to inspect everything and identify the location of the damage. What to do if the hole is small and water is flowing, but there is no way to call a plumber? You can use Titanium White automotive putty and fill the hole with it.

This repair method will extend the life of the pipe by several years, but only if it does not supply water under high pressure.

If the leak is significant, then a layer of rubber, the so-called bandage, is placed in place of the gap, which should be larger in size than the hole.

The patch is fixed using soft wire. All of the above items can be purchased at a hardware store.

Do not forget that this method can be repaired only for a temporary effect (until the arrival of a master who can properly fix everything).

Unreliable connecting seam

What to do if water flows at the junction of the pipe to the battery, tap or in the area of the threaded joint? In this case, eliminating the problem will be somewhat more complicated, since sometimes elements of different diameters are connected.

What to do in this case? You can seal the hole using a piece of thin rubber, which must be clamped with a special metal clamp.

This solution cannot be a 100% solution to the problem. The joint will have to be disassembled and thoroughly welded or glued.

Final repairs can only be made if the heating and water drainage systems are completely turned off. If in a private house this process can be done independently, then in an apartment it is recommended to entrust such work to a specialist.

If the house has autonomous heating, the owner must always have new couplings and spare connecting elements on hand so that in the event of an accident, the hole can be quickly repaired.

Leaking between battery sections - what to do?

A small hole from which water flows can be sealed using a regular self-tapping screw, which can be found in every home.

Naturally, such a solution will not be enough for a long time, but it will still help eliminate the damage that even a slight leak can cause.

When the fabric is dry, you can connect the battery to the system, but in order to seal it properly, you should still seek help from a plumber.

What to do if the cause of the accident was a surge in water pressure? First of all, you should take care of eliminating the internal problem.

The use of pipes of different cross-sectional sizes may result in water hammer, especially in the process of eliminating air pockets.

In what cases is heating system repair necessary?

In any case, major repairs of heating systems are carried out on warm spring or summer days before the start of the winter season.

If there have been iron pipes in the apartment for more than five years, you need to think about replacing them with reinforced polypropylene samples, without waiting for it to burst.

The latter do not undergo oxidation when interacting with water and withstand water hammer, which makes them more durable compared to iron ones.

All of the above methods for repairing heating pipes are not bad, but they can only save for a while, so in order not to ask yourself the following question: “The heating pipe is leaking, what should I do?” – call a plumber who can correctly and reliably fix all problems associated with the operation of the heating system, so that later, when winter comes, you do not have to carry out expensive repairs and do not turn off the entire house from heating.

Features of hot water supply

A fistula in a hot water pipe appears more often than in other places. The place that is most susceptible to this phenomenon is the riser. The first signs of danger in such a system are rusty growths.

Video: how to fix a leak on the drain

It was already written above that if a decision is made to seal a leak, then this build-up cannot be torn off. In the case of hot water, such actions can cause serious burns.

Such a fistula in the pipeline can be repaired using a bolt or temporary bandage. In both the first and second cases, it is impossible to act under pressure. The water supply must be shut off before work can be done.

A small leak can be sealed under pressure using an adhesive bandage. The edges of fiberglass with BF-2 glue applied are applied to the damaged area (the tape is applied very tightly). At the end, the tape must be tightened with a metal plate. Such a section will be able to function under pressure only after 24 hours.

Also in this situation, you can seal the leak with “cold welding”. It is better not to do such work under pressure. The resulting hole is slightly enlarged using a drill, and the area is degreased.

When everything is dry, apply the compound to the leaking crack. It should freeze completely. This takes approximately ten minutes.

Fistulas in wells

If we consider the sources of water supply in private areas, wells can be called the most promising. Compared to wells, they contain water of higher quality. It practically does not require cleaning or additional filtration.

During operation, the well, pump and water-lifting pipelines vibrate. This leads to weakening of the joints on the water-lifting mains, and accordingly, leaks (fistulas) appear. This often ends in serious accidents.

The well operates with vibration of the water-lifting pipe due to the pumping equipment, and this provokes weakening of the joints. As a result of the appearance of a fistula, the functioning of the well may be completely disrupted.

Such repairs cost a lot of money, but they are completely worth it. Repair work on wells involves a number of complex operations that require special equipment.

Non-professional craftsmen may not be able to do this work. You can clean the well yourself and replace the pump. And carrying out these events will also require some skill in this matter.

How to fix a leak yourself

What to do if leaks occur? Neutralization of damage to metal-plastic pipes can be done with your own hands, without the involvement of specialists. Carrying out independent repairs not only makes it possible to save money, but also allows you to restore the functionality of the plumbing system in the shortest possible time. Depending on the type of damage, there are several options for solving the problem:

- Leaking fittings. To eliminate the leak, you need to take a wrench and slightly tighten the loose connections. As a rule, half a turn is enough to completely neutralize the leak. In general, the nut should be tightened until it is completely secured. However, you should not overdo it, since excessive tension can lead to cracking of the fitting body.

- Cracks in the metal-plastic body are repaired using a simple bandage. The principle of such a device is to place a small rubber gasket on the pipe and then secure it. The role of a bandage can be a piece of thick rubber, part of a bicycle or car tire. The retaining gasket is fixed in 4-5 places with special clamps or by twisting ordinary wire.

- Cracks in fittings. Elimination of such malfunctions is possible only by completely disassembling the system and replacing the damaged element. Other methods of solving the problem are absolutely ineffective and cannot completely neutralize the leak.

Symptoms of a fistula: how dangerous is it?

Fistula manifests itself with a number of symptoms:

- unpleasant odor from the mouth;

- tooth mobility;

- feeling of foreign taste;

- mucous membrane is bluish or, conversely, pale in color;

- discharge of purulent mucus, often with blood;

- painful sensations during mechanical contact (chewing food, drinking hot drinks, brushing teeth).

The disease may also be accompanied by symptoms not directly related to the oral cavity. It is manifested by such signs as apathy, general weakness, and fever.

Despite the small area affected, the fistula poses a certain health hazard. Thus, purulent discharge can penetrate the lymph or blood, which will lead to diseases of the internal organs, pathological processes in facial tissues and even loss of teeth. Therefore, even at the first relatively mild symptoms, it is important to consult a doctor.

It is worth keeping in mind that the disease is asymptomatic for a very long time. Moreover, if treatment is delayed, this can lead to partial death of the periosteum. And then the patient will have to remove not one, but several teeth at once.

Features of pipeline repair using press fittings and compression fittings

In the design of metal-plastic water supply systems, 2 types of connecting elements can be used:

- compression fittings;

- press fittings.

The principle of operation of a compression fitting is to screw a special nut onto the threaded connection, ensuring complete fixation of the clamping ring. This type of connection is considered the simplest, since it does not require any special tools. At the same time, it is not the most reliable and requires constant human monitoring.

Working with compression fittings is as easy as installing them. To troubleshoot you need to:

- determine the specific location of the violation of the integrity of the system;

- turn off the water;

- unscrew the clamping nut;

- press out the fixing ring;

- disconnect the pipe from the adapter;

- if necessary, trim part of the pipe a little, clean it or tighten the ring;

- put the ring on the pipe, insert it back into the groove and screw on the nut.

The sequence of actions for disassembling and assembling a compression fitting is quite simple and does not require any effort. Troubleshooting press fittings is a much more labor-intensive process.

Compression fitting

A press fitting is a much more reliable connecting element for metal-plastic, providing high-quality fastening and not requiring systematic monitoring. However, to assemble similar systems, it is necessary to have special crimping pliers, without which it is unlikely that it will be possible to organize a full-fledged pipeline.

Leakage of a compression fitting in itself is considered a fairly rare problem, associated more with violations of the installation technology than with connection defects. To eliminate leakage in press fittings, the following actions are carried out:

- determine the specific location of the violation of the integrity of the system;

- turn off the water;

- unscrew the cap nut;

- disconnect the pipe from the fitting;

- cut off the part of the pipe with the old sealing ring;

- Reassemble the connection and crimp the fitting.

In any case, repairing a broken press fitting will not be as reliable a solution as replacing it completely. As a result of a violation of the tightness of the connecting parts, the risk of repeated leakage increases several times. Therefore, it is better not to repair this type of adapters, but to completely replace them.

Press fitting

How to weld a fistula in a plastic pipe with water

Unlike the previous option, which could be used not only for plastic products, this method is suitable for working with polypropylene pipe products.

The actions are carried out using a special tool for soldering plastic - an iron. This tool melts the prepared components and fastens them after cooling.

To repair minor damage to an area, all repair measures can be carried out under pressure.

But, for a formation of significant size, the water supply system will have to be shut off, since it will be impossible to weld the defect under pressure.

Anyone can operate an iron. No special experience is required for this. Such devices come with instructions that describe the entire operating process step by step.

After reading it carefully, you can safely begin repairing the PP pipeline. It is not difficult to seal a leak this way.

Recommendations from specialists and a list of necessary tools

If a leak occurs, only the connecting parts of the pipeline are replaced. However, it is better to carry out a complete repair of the burst section, including updating or completely replacing the pipe. During a long stay at the joint, the metal-plastic end undergoes partial deformation and loses some of its insulating qualities. Therefore, to organize a full connection at the place of fixation to the fitting, the pipe is cut by 2-3 cm.

Tire pad

A rubber coupling is an excellent means of local repair of a water supply system. However, its use is justified only in cases where it is impossible to fully replace a damaged pipe. The formation of cracking in one place is a signal to action and complete repair of metal-plastic pipes of the damaged area.

To carry out work to eliminate leaks in metal-plastic pipes, you will need the following tools:

- wrench (one or more);

- specialized pipe cutter or hacksaw for metal;

- roulette;

- pencil;

- pliers;

- crimping pliers (for press fittings).

The presence of such a tool makes it possible to completely replace leaking parts of the pipeline at home. At the same time, repairs will not take much time, as a result of which the system will be ready for operation within half an hour.