Before figuring out how to fix a radiator leak between sections or in another place, you need to understand the causes of the problems that arise:

- Cast iron radiators are heavy and are mounted on durable hooks. With minimal error, radiators sag under their own weight, and a misalignment of several millimeters causes the formation of air pockets. Corrosion begins in these places - the cast iron becomes thinner and over time a fistula forms. A minor leak appears, which it is advisable to quickly fix.

- In houses with a centralized heating system, water hammer often occurs, which sometimes causes radiators to leak at the joints (especially for bimetallic radiators).

- Cast iron radiators are rough inside, so all kinds of debris and foreign inclusions linger on the surface: pieces of metal, rusty sediment, etc. Gradually, the channels begin to clog, and deterioration in coolant circulation leads to the risk of a breakthrough or leak. This is another reason why batteries, both cast iron and steel, leak.

- Gaskets and nipple threads are the weak points of heating radiators, so leaks can form in these places.

Practice shows that leaks in aluminum, steel and other radiators do not appear suddenly. First, characteristic signs appear: the air temperature in the room decreases, plaque forms on the radiator, and corrosion spots form on the surface.

Do not remain idle when you notice these signs, but decide what to do - the battery is already leaking. If you ignore the situation, an accident may occur. You may also soon find a puddle of water under the radiator, and the humidity level in the room will increase noticeably. You can repair the leak in the heating radiator yourself or contact a professional. An experienced plumber from our company will quickly fix leaks in any radiator: aluminum, steel, bimetallic, cast iron.

Many people are concerned about the question: if the battery is leaking, who should they call? If you live in an apartment with central heating, contact the management company or us. In other cases, you can do without a management organization - it will not help you.

Cast iron batteries: do-it-yourself repairs, causes of breakdowns

Repair of cast iron heating radiators can be superficial or major. In the first case, they try to eliminate the leak using the simplest methods in order to “hold out” until the end of the heating period. In the second option, the battery is completely disassembled, the sections are unscrewed, and washed.

- Features of cast iron battery repair

- Why can a cast iron battery break?

- Methods for repairing cast iron heating radiators

- How to repair a cast iron radiator

- Advice from professionals

- Conclusion

Types and causes of leaks

As a rule, a leak occurs in the off-season, when the heating is turned off, as the metal cools down, the metal narrows and water begins to seep into the threaded joints.

If the heating radiator is leaking, then it is necessary to determine the cause and location of the breakdown. Each plumbing point consists of a heating radiator and an adjacent pipeline. The connections of these elements can be disrupted under the influence of the following factors:

- Long service life as a cause of wear;

- Poor installation of the heating system;

- Mechanical impact, brute force;

- Corroded metal.

Depending on which elements the coolant leak occurred between, the following types of failures are distinguished:

- Violations of the seal between the riser pipes and the battery pipes;

- Partial destruction of the main pipes that connect the radiator and the riser;

- Leakage in the area of intersection connections;

- Formation of a fistula or crack in one of the radiator sections.

For each of these cases there is a different way to eliminate the accident. If the battery is dripping, don’t rush to find out what to cover it with. You may not need to smear at all.

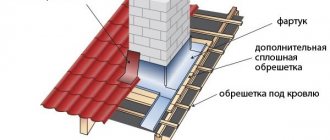

Dripping between the nozzle and the main pipe

A leak at the junction is often the result of improper installation, or a domestic situation where the batteries were used as a support for heavy objects or residents. To complete the repair you will need:

- Car clamp or wire;

- A piece of thin and flexible rubber.

Procedure:

- Cut strips of rubber measuring 5x35 cm or use a rubber bandage from a pharmacy;

- Wrap the strip around the damaged area;

- Secure the rubber with wire or a zip tie.

In this situation, a clamp will be a more suitable option, since it is inexpensive and fixes the damaged joint reliably, evenly, without the risk of overtightening.

Main pipe leaks

There are always two such pipes. One for supplying coolant to the radiator, and the second for discharging cooled water. They are made of steel and tend to corrode and wear out from the inside over time for two reasons:

- Filling with water in the off-season;

- Impurities in water supplied through heating mains.

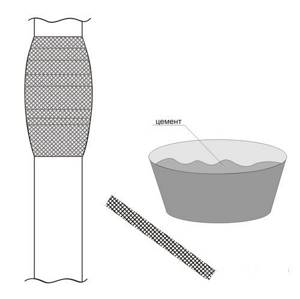

Most often, the question of what to do if the heating radiator is leaking arises at the height of the heating season. In the event of an accident, a cement-plaster bandage is used on a straight section of pipe. To prepare it you will need:

- Non-sterile bandage;

- Cement;

- Alabaster;

- Container for mixing the mixture.

Important! Alabaster is required when there is no way to turn off the water. It is applied as the first layer, as it dries faster than cement and adds reliability to the dressing.

- Mix cement with water to the consistency of liquid sour cream;

- Prepare strips 25-30 cm long;

- Soak the bandage strips in the mixture;

- Wrap them around the damaged area layer by layer;

- Continue until a tight bandage is obtained.

If a stream of water gushes like a fountain

If a fistula has formed and water flows in a stream, then you can hammer in a wooden wedge before the mechanics arrive. The wood gets wet and holds water well.

Threaded connection is leaking

In the case when a leak in the heating battery has formed in the thread area, a bandage is used again, but this time a salt one:

- Wet the bandage;

- Roll strips in salt;

- Wrap the damage;

- Apply a cement dressing.

Important! Salt can coke a place that allows water to pass through.

Leaks between sections of cast iron radiator

If a heating radiator drips between the sections, it’s not difficult to figure out what to do. The joint is represented by a small straight section, which can be easily repaired temporarily. Necessary materials:

- Car clamp with tightening corresponding to the direction of the screw;

- Flexible rubber gaskets;

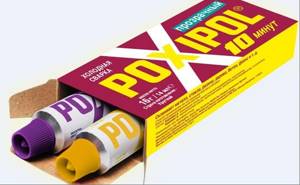

- Epoxy adhesive;

- A piece of fabric.

Procedure:

Leaking from the radiator walls

A reasonable question when a battery leaks is what to cover it with? If the accident occurred in the wall of one of the sections, then it will have to be covered with cold welding. There is no more effective way yet. The “cold welding” ball must be pressed tightly to the leak site and kept in this position for 3-5 minutes. After half an hour, the mixture will completely harden, and after another day the battery will be ready to perform its functions. As a conclusion, it is important to note the following. All of the above measures are “first aid” actions. If the heating system fails once, this means that it is time to prepare for a major overhaul. Calling a specialist will be the best prevention of serious problems

Preventing leaks in the heating system

Sometimes you have to turn to specialists, although you can do a lot on your own. Owners of the private sector have to do a lot with their own hands to reduce the cost of repairs. In most cases, you can handle it yourself with tools and available supplies.

To avoid flooding your neighbors and avoid having to make repeated repairs, it is recommended to have everything you need to quickly fix a leak on hand. Any light repair begins with preparing the tool:

- adjustable wrench No. 2, 3 for plumbing work;

- radiator wrench for nipples 5/4 (old “accordion”) or nipple 1 (modern models);

- a piece of pipe that helps turn the key;

- sealant, silicone glue or other analogue;

- tow with grease;

- clamps of suitable size;

- elastic bands or strips of rubber;

- "cold weld" or other two-component polymer that reacts to form a solid.

After temporarily eliminating the problem, a major restoration of the cast iron appliance will still be required.

Note! The puddle under the battery is not always visible. Sometimes depressurization of sections can only be detected by high humidity in a separate room.

It’s good if you have the skill of applying clamps to a small crack in pipes or at joints. To do this, you will need to shut off the coolant supply in the apartment or separate room and block the depressurization area.

Cold welding - quick help to eliminate a small leak in the battery

After performing the simplest manipulations to process the joint and apply the clamp, you can resume the supply of hot water. It is recommended to check if there is any airing (open the air release valve if necessary). All stages are available for independent execution. But this is a temporary measure; you should not put off replacing worn-out radiators indefinitely.

How to fix a leak

There are several options for solving the problem, using:

- self-tapping bolt;

- rubber pad with wire or clamp;

- cement-plaster bandage;

- fabric impregnated with heat- and water-resistant glue;

- special sealant;

- welding

The easiest way to fix a small leak in a cast iron radiator is to fix a self-tapping bolt in the hole.

It must be remembered that all these methods of eliminating leaks are only a temporary measure - it is advisable to replace old radiators with new products as soon as possible.

Ways to synchronize with banks / Knowledge base / Zen-money

To make it easier to track expenses in Zen Money, there are several types of synchronization with banks:

- Processing SMS from banks

- Processing email notifications from banks

- Connecting to banks from the server

- Connecting to banks from the application (sync plugins)

- Processing push notifications from banking applications

You should not use several synchronization options with the same bank at the same time - in this case, duplicate transactions may occur. It's better to choose and leave one thing. The same applies to family accounts - you only need to create a connection to the same bank account on one of the phones.

SMS processing

SMS from banks are processed in Zen Money mobile applications. At the same time, Android and iOS have their own characteristics. More details about this in a separate article.

Email processing

No longer supported. Works "as is".

Zen Money can process letters from banks if they are sent to a special user address, which can be found in the Accounts section on the web version website. Now letters are processed only from a small list of large Russian banks. We are trying to move away from email recognition and replace it with synchronization with banks directly from the application (method 4, below).

Connecting to banks from the web version of zenmoney.ru

No longer supported. Works "as is".

On the website of the web version, in the Accounts section, you can configure connections to banks directly. This is a limited list of banks that was created many years ago and is no longer being updated.

This synchronization method involves automatic synchronization with banks from the Zen Money server according to a certain schedule: once every 6 hours or when logging into the web version. If necessary, synchronization can be started manually from the Accounts section on the website.

Through the site you can import accounts and transactions from Yandex.Money, Webmoney, Qiwi, PrivatBank (Ukraine). We are gradually disabling server synchronization options and switching them to synchronization from the mobile application. The crossed out options are just one of these (except for Webmoney, no one has written a connection to them yet) - create them from the application.

Connecting to banks from the Zen Money application

Synchronization with banks from the application is a new method that we are now trying to focus on.

It works on the principle of plugins written on the open Zen Money API and uses open data from online banks. If there is no synchronization with your bank yet, then if you have the desire and knowledge, everyone can write and connect their own bank independently.

Examples of plugins and a description of a debugger based on the Chrome browser are publicly available on GitHub: github.com/zenmoney/ZenPlugins.

There are also examples on the new API - https://github.com/zenmoney/ZenPlugins/tree/master/src. A new approach to plugin development allows you to write JavaScript using ES5/ES6 standards, allowing for step-by-step debugging and breakpoints while debugging in the Chrome debugger. This is much more convenient than the old approach. Try it!

If you have questions about development, feel free to write to us by email or ask them in Telegram chat.

About security

All connection data to banks is stored only on the user’s phone in encrypted form and is not transferred anywhere except to the bank. This data is deleted automatically when you delete the Zen Money application, change the encryption key, or log out of the user profile. You can read more about this in a separate article. If you wish, you can delete the connection in your account settings without deleting the application.

Types of cold welding used to repair cast iron batteries

Despite the general disadvantages that are inherent in all types of adhesive compositions, the industry has mastered the production of several compositions that have their own specialization. So there are mixtures for repairing plastic, metal, aluminum and gluing wood, there are universal compositions. For repairing heating appliances, a mixture for gluing ferrous metals and steel or a special composition for repairing radiators and steel heating pipes is best suited. Cold welding for heating radiators, unlike other compositions, has its own characteristics - it must be heat-resistant, quickly fixed on a metal surface, and form a coating that has a linear expansion coefficient similar to metal. Simple or universal compositions can solve the problem of sealing a leak, but at the same time, the service life of the composition will be limited.

Another point that needs to be taken into account when choosing the type of glue is the setting time. If 3-4 hours are enough to splice parts under normal conditions, then if the battery leaks, there is no such time, here the count is in minutes, therefore, the faster the patch hardens, the better.

Particular faults and their symptoms

Despite the fact that cast iron is resistant to the imperfections of the central heating coolant, and the radiators from it form wide channels so that dirt does not accumulate in them, problems can arise even for them. At the same time, the metal does not know what wear is. The cause may be a fistula that has formed in the walls of the battery, or a rupture of the device itself. The following factors contribute to this:

- Everyone knows the large dimensions and weight of cast iron radiators. If, when installing the structure, fragile brackets were used or there were few of them, then over time the installation may sag or tilt. Even small deviations of a couple of millimeters will reduce the productivity of the equipment. And if you don’t do anything about the distortion, then after a few minutes there will be no coolant in the zone, and corrosion will form. At first it will be a small brown spot, which will grow with each heating season until a fistula appears in its place. Both old and new models of cast iron radiators have a long service life, but provided that they are installed in the contour of an apartment building no higher than 6 floors. If the heating network is reliable and there are no strong water hammers, then they can be installed in nine-story buildings. Otherwise, under strong water pressure, the cast iron battery may leak at the joints of the compartment fastenings. If the battery leaks during the heating season, you need to first know how to repair it. Today there are a huge number of sealants that will help equipment survive until warmer days;

- The internal design of domestic batteries is such that the cast iron from which they are made has roughness that is not found in foreign analogues. Therefore, over time, a lot of dirt accumulates on the walls, which fills the water in the heating network. Lime, rust, metal particles - all this settles on the surface and makes the channel so narrow that it does not allow coolant to pass under strong pressure. The structure may rupture, and then the problem will have to be solved urgently;

- Nipple gaskets and threads are the weak point of heating devices. If cast iron does not have a service life, then the battery parts cannot please you with such reliability. In order not to lead the situation to repairing a cast iron heating radiator with your own hands, the joint areas should be checked after each heating season and the gaskets should be changed regularly.

In practice, it has been shown that problems with the heating system arise when repairs need to be made. To know in advance about all the problems, you need to listen to the bells indicating the presence of defects.

DIY repair

Not all cases require the help of an emergency team. Sometimes even a home handyman can cope with the situation. In order to seal the resulting leak, use known methods.

How to fix a leak between two sections

It can sometimes be very difficult to determine where exactly the moisture is oozing from, since the water floods a large area. You have to wipe away the liquid, trying to find a fistula or crack. Once this has been done, the shut-off valves are closed. But residual pressure still remains. To bleed it, open the Mayevsky valve located at the end of the heating device.

After making sure that the water has stopped leaking, proceed with the repair:

- The surface of the damaged area is thoroughly cleaned with a wire brush or coarse sandpaper to remove dirt, rust, and paint.

- After this, epoxy mastic is applied, consisting of two components: a hardener and a thinner, which are mixed immediately before use. You can use “cold welding”. It comes in the form of a “sausage” or in a set of two tubes, the contents of which are thoroughly mixed before application. The “sausage” must be kneaded thoroughly, since it consists of two parts: the hardener is located inside the filler. When kneading, the two components are mixed together, forming a homogeneous mass. To prevent the composition from sticking to your hands, it is pre-wetted under the tap.

- After installing the seal, it should dry well. Only then is it possible to open the shut-off valves to restore the flow of coolant. Do not cover a crack under pressure.

There is another way - the “old-fashioned” one. If the leakage is dripping, pour a couple of pinches of ordinary table salt onto a rag. A rag is wrapped around the damaged area. Salt must come into contact with it. After a few days the rag will be dry.

Cold welding prices

Battery crack

This malfunction is rare, but a hairline crack in one of the sections can cause the heating radiator to leak.

The problem is solved in the same way as when eliminating a leak between adjacent battery cells:

- The highway is blocked.

- The pressure is released.

- The damaged area is cleaned and covered with a repair compound. Epoxy for metal is preferable as it dries in 3-5 minutes. Before application, take the required amount of epoxy resin. A few drops of hardener are added to it. The composition is thoroughly mixed and applied to the crack or fistula. “Cold welding” will take 2-3 hours to set.

Construction of cast iron radiators

This type of heating device consists of sections. Models of the old type, even today, are produced in the form of “accordions”, while the new generation has a flat outer panel, which provides better heating of its entire area.

When operating, these devices use two types of heat transfer:

- Radiation, or as professionals call it, radiation accounts for up to 25-30% of heat. It not only heats the air, but is transferred to nearby objects, providing better heating of the room.

- Convection produced by the heating battery ensures constant movement of air masses around the room and accounts for about 75% of the heat transfer.

The structure of the cast iron battery, despite all the external changes, remained the same. It consists of sections equipped with:

- plugs;

- locking devices;

- traffic jams;

- shank and thermostat;

- locknuts;

- nipples and gaskets.

No matter how strong cast iron is, even it has its limits. As a rule, the service life of cast iron radiators is 25-30 years, and with proper care and optimal operating conditions they can operate without interruption for 50 to 100 years.

The same cannot be said for the parts that hold the sections together, such as spacers. With frequent water hammer, they can “sway” or crack over time. In this case, a leak appears between the sections of the cast iron battery, which, if not eliminated in time, can cause a serious accident and a threat to human health and life.

To avoid this, you need to check the condition of cast iron radiators after the end of the heating season. In this case, you can detect completely different problems in the heating system.

How to fix a leaking heating battery: a general guide to action

If a cast iron battery is leaking, the most likely cause of this phenomenon is wear and tear of the product. It is also necessary to take into account the materials from which the gaskets and main pipes were made, and the specifics of connecting the elements. Experts emphasize that primitively covering cracks with plaster is only a temporary measure; if you rely only on it, there is a high risk of worsening the problem.

Even if the leak is extremely small, you should not limit yourself to localizing it using a can or basin (although this should be the first step); if a significant pressure drop occurs in the network, a hole will form at the site of the crack, which is fraught with a full-fledged flood. Even small drops mean urgent elimination of the defect.

Leaks occur either due to loss of tightness of joints, or due to destruction of the material. Of particular danger are leaks that disappear from time to time - in such conditions, ordinary people hope for the material to stick, which can be a big mistake.

If the radiator is not suitable for repair, you need to drain the coolant from the system and replace the defective element. The main step here is to shut off the flow of water.

Materials for sealing cast iron pipes

Methods for sealing the joints of sewer pipes are described above, especially since they have become known since the advent of cast iron pipes for the sewer system (read: “How to seal a sewer pipe - a review of the advantages and disadvantages of materials and methods”). However, innovative technologies are constantly being introduced into this area and now experts say that the most effective way to eliminate leaks is the use of phosphoric acid and copper oxide.

The heating battery is leaking - what to do?

The first thing to do if the radiator is leaking, as in the photo, is to turn off the water. But if the leak is serious, then it is urgent to call an emergency team - plumbers have all the necessary tools and materials to eliminate the problem if the battery leaks.

If boiling water is pouring out of the radiator in all directions, then you need to throw something thick over it - for example, a blanket. This is not a way to get rid of a leak, but at least you will be able to approach it without fear of injury.

Next, if possible, you need to turn off the water. It’s good if there is a tap or valve in the apartment itself - this will allow you to quickly turn off the water supply and save your property. But what if there is no such valve and the radiator is leaking - what to do? Then you need to turn on the coolant supply valve to the heating system, which is located on the main pipe near its entrance to the basement. If the leak is minor, then you can try to fix it yourself (for more details: “How to fix a leaking heating pipe if it is leaking”).

What to do from the very beginning

If the damage is serious enough, you must immediately call an emergency team. In any case, professional plumbers will at least have all the necessary tools and materials to localize the accident.

If boiling water is pouring out of the battery in all directions, then it is better to throw something like a blanket over it. This will not eliminate the leak, but it will allow you to approach the heating device without the risk of thermal injury.

Throwing a blanket over the radiator

Shutting off the water

Remember, is it possible to shut off the water supply to the heating system in the apartment? If the water can be turned off with a tap or valve, then this makes it possible to at least save property.

Typically, the valve for shutting off the coolant into the heating system is located on the main pipe near the entrance of this pipe to the basement.

Typical view of a tap on a heating system pipe

If the leak is not very strong, you can fix it yourself.

Fixing a leak using a self-tapping bolt

If a leak has formed on a cast iron radiator, it can be eliminated using a self-tapping bolt, which is fixed in a hole on the battery section or on a section of heating pipe.

Repairing a minor leak with a cement-plaster cast

Before fixing a leak in a heating radiator, you need to prepare.

In order to “defeat” a minor leak, you will need the following materials and tools:

- ordinary medical bandage;

- cement;

- plaster (alabaster);

- salt;

- container with water.

The leak is eliminated by applying a special bandage to the damaged area.

If you manage to turn off the water, then the next steps are as follows:

- Cement is diluted in a container with water to the consistency of thin sour cream;

- The bandage is cut into strips about 25-30 cm in length;

- The bandage strips are thoroughly soaked in the cement mixture;

- Impregnated strips are wrapped around the damaged area;

- The process is repeated until a strong bandage is formed.

Repairing a leak with a cement bandage

Important! If you cannot turn off the water, then instead of cement you should use alabaster, which dries quickly. A cement bandage should be applied on top of the plaster cast.

If a leak has formed at the threaded connection, then regular table salt should be used as follows:

- Soak strips of bandage or cloth in water;

- Roll the soaked strips generously in salt;

- Wrap the leak area.

Salt, dissolving in water, cokes the gap. A cement dressing should be applied on top as described in the instructions above.

Leak elimination scheme

Fixing a leak using a clamp or rubber

If the location of the damage is at the connection between the radiator and the main pipe, then it is possible to stop the leak for some time if you use a rubber band and wire (a car clamp). A piece of rubber is wrapped around the damaged area and secured with wire.

Pieces of rubber can be cut from a bicycle inner tube. To do this, you need to prepare strips 4-5 cm wide and 30-35 cm long.

If there is a clamp, the leak can be completely stopped for some time. Therefore, it is useful to have a couple of clamps on hand at home just in case, especially since their price is low.

Photo of the applied clamp

Repairing leaks with moisture-resistant glue

If the battery leaks at the junction between the sections, then the problem can be eliminated using a cloth soaked in moisture-resistant and heat-resistant glue. After the glue dries, the leak will at least be reliably sealed.

A two-component epoxy adhesive is suitable for eliminating leaks.

Repairing leaks with a sealed seal

For minor damage, you can use a special polymer or powder-based sealant. Such compounds are sold in hardware stores, and they are intended specifically for such repairs.

Upon contact with air, the material polymerizes. When cured, it creates a strong filling that will allow time for more significant repairs.

How to repair a leak between radiator sections

It is possible that the radiator plate, made of thin material, may break. Over time, corrosion will corrode the battery from the inside (this is especially true for steel radiators), a fistula with a leak will appear - you will immediately see water oozing out.

In this case, you need to act quickly. If the radiator is bimetallic, replace one of the sections that is leaking. As an emergency measure, cold welding is suitable, which needs to be used to seal the leakage site, having first turned off the water. You are unlikely to be able to disassemble a bimetallic or cast iron radiator on your own to replace individual sections, so it is better to call a specialist.

Do-it-yourself heating radiator repair

Finding the leak is usually not difficult. If you still cannot determine the problem area, you can remove the batteries and place them in a bath of water. In the place where air bubbles appear there will be a leak. Next, you need to use the methods described above.

You can fix a small leak yourself, as this does not require any special knowledge or skills. If you have repaired a heating radiator several times, it is better to replace such a heating device with a new one.

FAQ

Homeowners have the same questions about how to solve such problems.

The following are often of interest:

- where to go if the battery leaks;

- what to do if it is not possible to turn off the water;

- who is to blame if the neighbors are flooded?

Where to go if the heating battery is leaking?

It makes sense for owners of apartments in multi-storey buildings to call a plumber by contacting the housing and communal services service, HOA or management company. Emergency telephone numbers should be posted in entrances. There is an option to call an employee of a private company that provides such services. In a private home you will have to deal with the problem yourself.

How to eliminate a leaking heating battery without shutting off the water?

If the cause of the leak is a crack in the pipe, it can be wrapped in rubber and tightened from above with any clamp or wire. If it is a small sink, then you need to take a metal screw with a rubber washer and screw it in with a screwdriver. These measures are only effective at low pressure in the circuit. After the manipulation, you need to turn on the pump and make sure that the repaired area can withstand the water pressure in the system.

When radiators leak in an inaccessible place and the leak is small, you should add mustard to the expansion tank. Place a container under the dripping unit and increase the temperature of the water in the system. Mustard powder, like a liquid sealant, reaches the leak and closes it. There are ready-made liquid sealants on sale just for such cases. Add them to the system, and all minor leaks will stop bothering you.

Repairing a crack in a pipe:

First, let's look at what can be used to seal a leak if a cast-iron sewer or water pipe cracks.

There are two possible cases:

- leaks at the pipe joint;

- there is a crack or fistula in the riser.

Type 1 failure can be eliminated by using a new caulking of the socket.

To eliminate this type of leak, you need to perform the following set of actions:

- disconnect the sewage or water supply system;

- Dry the joint using a hairdryer or rag;

- remove remnants of old cement mortar and packing;

- using linen plumbing tape, caulk the gap between the pipes;

- Make 200-300 ml of an aqueous solution from polycement and PVA glue, and apply it to the embossing area several times, at intervals of 8-10 minutes;

- Do not use the sewer system for 24 hours.

In the second case, there are several ways to repair the riser:

- Chemical method

To do this you need:

- using a wire brush or coarse sandpaper, thoroughly clean the area of future repair;

- Thoroughly degrease the problem area with acetone or another solvent;

- take copper oxide and phosphoric acid, prepare the mixture necessary for work in a ratio of 3:2;

- Using the resulting composition, carefully cover the joint. The procedure should be carried out with a freshly prepared mixture, since it hardens within a few tens of seconds. Therefore, you will be able to use the sewer in 2-3 hours.

- “Cold welding” To reliably seal the hole, you should buy “Cold welding” - this is the name of the special glue. So, before sealing the hole, you need to clean the desired area from dirt, water, rust, and mark the place for repair with chalk. After this, you should sand the desired area on the surface of the collector well with coarse sandpaper and degrease it. Then apply a small patch of glue to the hole and place a sealing rubber patch on top. A similar method is used to eliminate a hole in a plastic pipe.

- Reliable In order to give a complete answer to the question of how to repair a crack in a cast iron sewer or water pipe, you need to remember one more, most reliable, method. To bring it to life, it is necessary to take sulfur, iron filings, and powdered ammonia in approximately equal proportions.

Mix all ingredients thoroughly, adding the required amount of water to form a homogeneous mass, the consistency of which would resemble thick sour cream. Seal joints and other openings with this solution. As practitioners say, there is no best way to seal cracks and holes.

- Using a clamp Water supply and sewer systems have been repaired for decades using a special clamp. It is very effective at sealing holes. Before starting work, you need to purchase a clamp or, as a last resort, make it yourself, taking into account the diameter of the pipe. First, wrap the pipe very tightly in the place where the hole is located with a rubber winding. Then they put a clamp on this place and securely tighten the bolts on it. This way you can get rid of any leak, even a big one.