One of the most interesting topics regarding the arrangement of a fireplace is the question of installing it yourself. It is not possible to answer this question unequivocally due to the fact that the volume and complexity of the work depend on the type of fireplace chosen. A classic structure, entirely made of brick, requires lengthy preparation, and the installation itself must be carried out by a master who has sufficient experience.

To assemble a fireplace with your own hands, you need to choose more modern options in the form of separate ready-made fireboxes, which you only need to install in a prepared niche. However, such work is carried out in several separate stages. This approach will more effectively ensure quality control.

Ready home

Types of fireboxes

Depending on the design of the firebox, there are:

- open;

Open

- closed.

The first fireplace is romantic and beautiful. However, it is not safe. The device must not be left unattended. It is impossible to regulate the burning power of wood. An open type of unit cannot be called an efficient heating system.

Closed firebox models are complemented by a long-burning system. The room is heated for 10-15 hours after one fuel fill.

Which heating system to choose

A stove in a wooden house can perform not only the function of the main heating system. Another, no less important purpose is cooking. Accordingly, according to the type of use, furnaces have the following division:

- heating system;

- combined system (heating and cooking).

Often in homes the second option is used. However, most owners of country wooden houses are content with installing a fireplace, which looks much more aesthetically pleasing than a stove, but is inferior to it in practicality. The main advantage of a fireplace is its cost-effectiveness, which is why many owners of wooden houses prefer to combine a stove with a fireplace.

Do not forget about the safe operation of the heating system. This indicator largely depends on the design of the stove or fireplace.

The following types of heating systems are well suited for arranging a wooden house:

- Classic Russian stove with a stove bench

. Despite the complexity of installation, it is an ideal option. - A decorative fireplace stove

will decorate the interior of the room well. It is a universal and safe source of heat, thanks to the presence of special heat-resistant glass that separates the fire from the living area.

The fireplace stove is equipped with glass doors - and the fire is pleasant to look at and sparks do not fly in all directions Source bauenhaus.com.ua

A massive cast iron stove will ideally fit into the interior of any room. It is distinguished by a variety of models, ease of installation and high fire safety.

Advantages and disadvantages of a cast iron firebox

Positive sides:

- fireproof characteristics;

- resistance to deformation;

- ease of installation;

Installation

- low cost;

- high performance;

- good thermal conductivity parameters;

- tightness of the firebox;

Tightness

- efficient heating of a room of 300 square meters. m.;

Heating of large areas

- heat storage capacity.

Negative qualities:

- a small overview of the viewing window;

- glass quickly becomes dirty with soot;

- only black color.

Color

Carrying out maintenance

In order for the fireplace to serve for a long time, you should adhere to the basic rules of operation:

- it is impossible to forcibly increase the combustion force by replacing firewood with another fuel or coal,

- Under no circumstances should the flame be doused with water.

- The system should be serviced at least once every two months.

After each kindling, a 1 cm thick layer of ash should be left on the bottom of the fireplace insert; the body itself should be cleaned with a rag and warm soapy water. It is obtained by adding liquid soap to water, since liquid soap has a lower degree of acidity. It is recommended to clean the inner walls several times a year with a stiff metal brush in order to remove carbon deposits.

It is necessary to provide a technical hatch in the design of the firebox in advance for the convenience of servicing the fireplace. It is also advisable to take care in advance about the possibility of cleaning the chimney pipes from creosote. It is formed during free combustion, when, during the process of gas release, smoke and steam are mixed, and the resulting sediment accumulates on the inner walls of the chimney. It is important to remember that creosote produces a very strong flame when ignited, so periodic cleaning of the chimney should be carried out to remove sediment. Intensive operation of the fireplace can significantly reduce the level of creosote formation.

The use of wood, especially wet wood, leaves soot marks on heat-resistant glass in a closed firebox. They can be removed quite easily using simple alcohol-based glass cleaners, which allows cleaning work to be reduced to a minimum. In general, it is worth saying that if you carry out maintenance work on the fireplace and firebox in a timely manner, the structure will last quite a long time.

Recommendations for selection

It is recommended to pay attention to:

- Power. You should not buy powerful units to heat a small room.

- Price. It is impossible to buy a high-quality device for pennies. We need to find a “golden mean”. There is no point in buying cheap stuff from China. It will not last long and may be unsafe.

- Design.

Semicircular

Angular

- Door material.

Glass door

Types and features of stove foundations in frame-panel and wooden houses

When arranging furnaces, several types of foundations are used, each of which differs in its design features. Before deciding on the type of foundation for furnace equipment, you need to consider the following factors:

- The final price of installing

the foundation, which consists of the cost of purchasing materials, preparatory and construction work. - Structural features

of the foundation and type of soil. - Calculation of the dimensions of the foundation

for the furnace, based on its characteristics.

In addition, the construction of stoves in a wooden house may involve the construction of a foundation for them simultaneously with the general foundation of the building. Common types of foundation for a stove or fireplace are concrete, piles and pillars. Note that most stoves can be mounted directly on the floor. To do this, it is necessary to take into account all fire safety requirements and recommendations of the stove manufacturer.

Most often, a concrete foundation is used to install a fireplace or stove Source vbanepar.ru

Features of glass doors for cast iron models

Regular glass will not work. A material with a high heat-resistant index is used.

Glass door

Glass installation is carried out by specialists. Requires knowledge and skills.

The operational parameters of glass depend on the type of fuel. The maximum combustion temperature changes.

Door for cast iron unit

Finishing the fireplace - the last stage of work

Different options for finishing a fireplace can radically change its style. The vast majority of bricklayers would like to use natural texture as a decoration. But to achieve an aesthetic appearance, you have to practice bricklaying, and the stove does not tolerate mistakes. Then finishing will come to the rescue. Various options will allow you to put your artistic taste into practice. Decorative stone in the form of tiles will add originality to the composition, as it will return the observer to the primitive era.

Ceramic and decorative stone tiles are glued onto the prepared fireplace surface using tile adhesive. If you have absolutely no experience, experts recommend using stone. Its texture hides all the imperfections of the masonry. It is very easy to process with a grinder. The cladding options depend on each individual’s design abilities.

Additional finishing options include installing items on the mantelpiece that clearly indicate a specific time or style. These can be utensils, toys, clay crafts. Tools for an open hearth, standing in the corner, will also contribute to the design of the room. The fireplace can be used only after the solution has completely hardened.

Features of installing a cast iron model

It is recommended that installation work be carried out by specialists. But you can do it on your own.

The door can be purchased at the store. Installation features depend on whether the firebox is built into a finished structure or installed from the very beginning.

Door

Designer door

Fireplace design

Fireplaces are either wall-mounted or corner-mounted. The most important part of a fireplace is its firebox. It is laid out from fire-resistant bricks. In an open fireplace, it is important to calculate the required chimney cross-section, otherwise the fireplace will smoke directly into the house. To protect the draft from tipping over in open fireplaces, a chimney tooth is installed - the back wall of the firebox is laid out with an inclination at a certain angle, creating an obstacle to swirling smoke. When installing cast iron fireboxes, it is important to insulate all wooden connections to avoid fire. The outside of the fireplace is faced with brick, stone or tiles.

Installation of a cast iron firebox: step-by-step guide

Installation work is carried out strictly according to the instructions. Safety regulations and building codes must not be neglected.

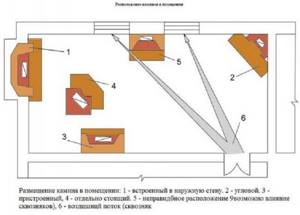

Step 1. Prepare the place

The location of the fireplace is determined. Depends on the placement of doors, the area of the room, and the features of the roof. It is necessary to take into account the type of structure and the possibility of placing a chimney system. It is planned to install a chimney through the wall and roof.

Accommodation

The base must be strong and level. Even a slight slope will reduce the efficiency of the unit. Normal traction will be disrupted. Irregularities need to be eliminated. A building level is used to control the evenness of the pedestal base.

Markers and chalk are used to mark the future fireplace. Accurate slope measurement is carried out using a building level.

If the surface of the wall to which the fireplace unit will be adjacent is wooden, a brick wall is laid out. The brick wall is made on the same base as the fireplace.

If you do not have bricklaying skills, it is recommended to do it dry immediately. Once you are sure it is correct, use the solution. Defects will be immediately visible.

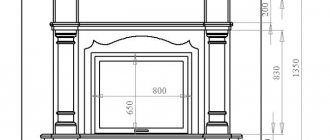

Building codes require the construction of a concrete foundation. It should be 15 cm larger than the fireplace on each side.

Foundation

When marking, draw contours under the foundation.

You can start creating wooden formwork. The deepening of the foundation for the firebox of a cast iron appliance is no less than 0.5 m. It is prohibited to install the structure on a wooden floor covering. A recess is made according to the size of the fireplace stove. The tree ball is removed.

Installation

The concrete solution is made, the first ball of the foundation is poured. Reliability is achieved using reinforcing mesh. After the first ball has dried, pour in the second one. The foundation can be made of brick. Concrete screed is required.

Brick pedestal

The finished pedestal is checked for evenness using a building level. We are waiting for it to dry completely.

Step 2. Install the pedestal under the firebox

When the base is ready, we proceed to arranging the pedestal - the letter “P” made of brick. Four rows are laid.

U-shape

The number of rows depends on the height of the fireplace structure. 4 is the minimum number of orders. Possible increase. The bricks are connected using a cement-clay mixture. The required shrinkage is achieved with a rubber hammer. The evenness of each brick layer is checked using a building level. There should be no slope.

Design

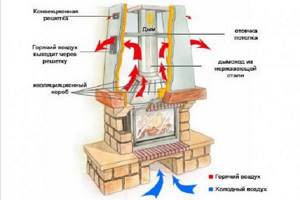

The movement of air currents works in such a way that warm air will rush out, mixing with cold air.

The sides are reinforced with metal corners. A brick is placed on them - the base for the firebox.

Grooves are made in the bricks with a file.

The basis

Shrinkage of the brick material is carried out on metal corners, strengthening with a cement mixture. Horizontal evenness is checked by a level, vertical evenness by a plumb line. The structure is left to dry well.

Ash pan

The ash pan is an important part of the fireplace, capable of accumulating ash and ashes. Cleaning is done through the door.

Step 3. Installation of the combustion chamber

You can begin installing a cast iron firebox:

- the surface of the base is treated with fire-resistant mastic. A cast iron combustion chamber is installed. The work is performed by two people. The weight of the device is large;

Installation of a cast iron combustion chamber

- The device is carefully lowered and fixed. It should not reach the back of the fireplace by 40-50 mm.

Step 4. Installation of the chimney circuit

Once the installation of the brick base is complete, you can begin installing the chimney line. Features and location of the chimney are determined when creating a fireplace. It is better to use the original sketch;

Chimney circuit design

Double-circuit sandwich pipes are characterized by practicality and ease of installation. Ready-made elements are purchased at a construction supermarket. They come together on the spot. The fewer bends the chimney contour has, the better the performance of the fireplace;

Sandich

In the process of organizing a system for removing combustion products, it is necessary to take into account fire safety requirements. Building codes require a chimney height of no more than 5 m, with an inclination angle of up to 45 degrees. Otherwise, traction will decrease. Smoke will enter the room.

Basic moments:

- Before installing the overall chimney structure, the individual pieces are connected to each other. The joints are sealed with sealant, otherwise smoke will come out. Heat leakage will occur;

- the first element of the pipeline is put on the element coming out of the combustion chamber using the slip-on method. The joints are treated with sealant;

- the smoke flow is directed by a splitter;

- fixation in a vertical position is carried out with brackets on the external wall of the house;

- the tee is used to collect condensate;

Fastening with brackets

- fix the chimney circuit with clamps. They are pulled together and secured to the wall surface with brackets. Leaning on the firebox must not be allowed;

- for decoration in the old style, a box made of a metal profile is erected on top of the sandwich structure;

- the frame is covered with heat-insulating building material with a foil surface facing the firebox;

Metal profile frame

- external cladding - plasterboard sheets;

Ready box

- the coating is treated with decorative plaster.

It is necessary to make a hole in the frame to allow hot air to escape.

Step 5. Finishing facing.

After arranging the chimney system and combustion chamber, you can begin finishing the structure. Decorating with brick will give the device an attractive design and improve heat transfer performance. Thermal energy will remain in the heating circuit longer, warming the room.

Brick cladding

When it is impossible to equip a massive furnace unit, they make a chamber with a glass door. You can decorate the device with a pedestal.

The classic cladding model involves the use of brick and stone of natural origin.

Classic

Decorating with fireclay bricks is practical. Withstands temperatures up to 1000 degrees above zero. Shows good heat-resistant characteristics. Upon completion of the wood burning process, the material releases heat to the room for 2-3 hours.

Cladding with fireclay bricks

Country style

Aerated concrete blocks are used as external finishing material. The internal cavity is first insulated with basalt wool. The heat resistance of the blocks increases.

If this is not done, cracks will appear in the aerated concrete building material. The technical parameters of the unit will deteriorate, appearance. The blocks are decorated with decorative plaster and artificial stone.

Fireplace stove made of aerated concrete blocks

You can update the look by making a metal frame and covering it with gypsum board sheets. The internal cavity is treated with basalt fiber. Fire resistance increases. Installation is simple and does not require large investments.

Sheathing with plasterboard

You can decorate the heating device with a forged structure. A custom-made grille will increase fire safety in your home.

Forged screen

Designs are often stylized with accessories: poker, tongs, firewood.

Stylization

The fireplace has many positive aspects. Used as a heating unit, room decor. Can completely change the look of your home. You can create a design according to your own design, adhering to the basic rules of installation. The main thing is to do it in good faith. Do not neglect safety rules. Use high-quality building materials.

Average score of ratings is more than 0

Share link

Comments There are no comments yet, but you could be the first...

Hull masonry technology

It is not difficult to guess that each master begins work according to his own personal scheme, which provides step-by-step instructions. We will describe the most popular of them.

- The pedestal is laid out in several layers of bricks with regular shapes. It has a cavity that will serve as an ash pan, but the main portion of air enters through the gap between the walls of the fireplace and the combustion chamber.

- Do not rush into work, as a special degree of accuracy is required at this stage. After installing the next row, you should check the horizon. You can turn the bricks with a mallet. Excess fragments of the solution are immediately removed.

- The ash pit is completely covered by the fourth row, but how to provide support for the bricks above the void? The answer is to use corners that are laid parallel, these corners will support the masonry. Having filed each brick with a grinder, we build a base on which we will install the product. Don't forget about the level, check it.

- Before installing the fireplace insert with your own hands, let the masonry dry a little; you may have to make some changes. Any cast iron fireplace should have a mantel; this is a horizontal surface that is decorative. The shelf can be cut out of a piece of porcelain stoneware. The edges of its contact with the wall are deepened, providing additional support. Now everything is ready to continue working.

Installation of a finished hearth

- The installation of a cast iron firebox itself is not difficult. The contact area between the firebox body and the stove is treated with heat-resistant sealant or glue. The firebox must not be moved close to the wall. Measure the distance from the back wall of the chamber to the wall of the house on one side and the other several times. Equality of indicators indicates that the design is straight and symmetrical.

- All joints formed by the installed firebox and mantelpiece are sealed with gypsum mortar. The cladding of a cast iron firebox consists of laying a brick frame around it. As before, it is necessary to observe the level when laying. Another similar slab is attached on top of the masonry. It is recommended to apply more glue under it, since with its help you may have to adjust the desired level. Remaining glue is immediately removed.

- When laying out the cladding, you can use creativity. If the outer bricks are pushed forward more with each row, you will get a cornice along the perimeter of the portal, and some facing bricks are already specially prepared for this; they just need to be laid in the last row.

Good to know: How to make a fireplace from a stove, a couple of simple ways