Rating of mineral wool manufacturers

The technology for the production of thermal insulating mineral wool has been mastered by dozens of factories in different countries of the world. In our country, on construction sites you can find products from domestic companies and European holdings, which occupy leading positions in the world market. Our experts tested basalt and mineral wool insulation from different brands and studied the reputation of the companies based on reviews from professional builders, designers and consumers.

When compiling the review, we took into account:

- Assortment - the portfolio of leading companies includes rolled and plate materials of different densities, thicknesses, degrees of rigidity;

- Environmental friendliness - the raw materials used and the finished product should not emit harmful substances or cause allergic reactions;

- Characteristics - vapor permeability, thermal conductivity, non-flammability must comply with the requirements of GOST and SNiP;

- Packaging – the quality of the protective film, the degree of shrinkage affect the complexity of transportation and storage;

- Installation - working with insulation should not cause problems for the builder; the structure of the thermal insulation necessarily takes into account the specifics of insulation of loaded and unloaded structures;

- Price – when constructing buildings, a large volume of insulation is used, the cost should not negatively affect the estimate.

Not all manufacturers were able to offer high quality products. Low quality packaging, high phenol content, unstable characteristics of different batches of insulation - such brands were excluded from our rating.

Rating of the best mineral wool manufacturers

| Nomination | Place | Manufacturer | Rating |

| Rating of the best mineral wool manufacturers | 1 | ROCKWOOL | 5.0 |

| 2 | Paroc | 4.9 | |

| 3 | Knauf | 4.8 | |

| 4 | Isover | 4.7 | |

| 5 | URSA | 4.6 | |

| 6 | IZOVOL | 4.5 | |

| 7 | TechnoNIKOL Rocklight | 4.4 | |

| 8 | Thermolife | 4.3 | |

| 9 | Beltep | 4.2 | |

| 10 | Isoroc | 4.1 |

ROCKWOOL

Rating: 5.0

The Danish company ROCKWOOL has extensive experience in the development and production of thermal insulation materials. The first insulation products were created back in 1909. Today, the concern has opened many branches in different countries of the world; there are production sites of the brand in Russia. Experts attribute the popularity of ROCKWOOL mineral wool to a good ratio of cost and quality. Thermal insulator is used both in the construction of private houses and in the construction of high-rise buildings and industrial buildings. The assets of Danish mineral wool include convenient packaging, soundproofing abilities, and durability. The brand is the winner of our review.

Domestic consumers speak flatteringly about the affordable price, environmental friendliness and durability. Transporting the material is not difficult.

Advantages

- reasonable price;

- high-quality manufacturing;

- fire safety;

- convenient packaging.

Flaws

- not detected.

Paroc

Rating: 4.9

The Finnish brand Paroc boasts an 80-year history. The mineral wool of this manufacturer is distinguished by high thermal insulation qualities. It is not surprising that the company's largest partners are located in the northern countries of Europe. In 2013, a production site was opened in our country. Insulation has repeatedly won honorary awards at international exhibitions dedicated to building materials. Experts include environmental friendliness and fire resistance as the strengths of Paroc mineral wool.

Russian builders praise the material for its ease of use and harmlessness to the human body. However, you should not neglect personal protective equipment, and you should choose high-density mineral wool.

Advantages

- high thermal insulation qualities;

- resistance to weather conditions;

- fire safety;

- harmlessness.

Flaws

- low efficiency of mineral wool with minimal density.

Knauf

Rating: 4.8

Since 1932, the Knauf company has been producing building materials. In the catalog of the German manufacturer, mineral wool takes pride of place. This thermal insulation product is in steady demand in our country. The raw material for the production of insulation is basalt. The finest fibers are made from it, which are later turned into rolls and mats. There is a special series of mineral wool based on fiberglass; such material is required for thermal insulation of chimneys or stoves. The experts liked the classification of insulation materials; you can choose mineral wool for ceilings or walls, roofs or ceilings.

Consumers are satisfied with the affordable price, excellent thermal insulation properties, and a wide range of varieties. The disadvantage of the product is that it is attractive to rodents.

Advantages

- versatility;

- affordable price;

- variety of varieties;

- excellent thermal insulation properties.

Flaws

- there are rodents.

Isover

Rating: 4.7

The Isover brand is a key business of the large Saint-Gobain corporation. Experts note a large number of developments and patents; it is not for nothing that the company is in the TOP 100 in terms of innovation. The production of mineral wool is established at 40 production sites around the planet. Izover in Russia has become a household name, which is used to describe a high-quality heat insulator. Mineral wool meets all international standards; it is made from natural materials such as basalt and quartz. The main advantages of insulation are strength and elasticity.

Consumers believe that Isover mineral wool perfectly combines affordable price, economical consumption, ease of transportation and installation. But the material is afraid of moisture, and during work you still need to use personal protective equipment.

Advantages

- good thermal insulation properties;

- non-flammability;

- affordable price;

- economical consumption.

Flaws

- hygroscopicity.

URSA

Rating: 4.6

The leading player in the European market is URSA. The company specializes in the production of fiberglass and extruded polystyrene foam insulation. Production sites were built in eight countries, three branches are located in Russia. Since 2021, the brand belongs to the German holding Xella Group. Thermal insulation materials are produced using German high-tech equipment. Experts paid special attention to environmentally friendly, freon-free foaming technology (carbon dioxide plays the role of a foaming agent).

Russian builders praise URSA mineral wool for its decent heat and sound insulation qualities, resistance to weather influences, and resistance to deformation. The weak point of the insulation is considered to be zero vapor permeability.

Advantages

- high-tech production;

- high efficiency;

- environmental friendliness;

- weather resistance.

Flaws

- not breathing.

IZOVOL

Rating: 4.5

A young player on the Russian market is the domestic company IZOVOL. The first products (basalt mineral wool) were released in 2006. The main operating principles are advanced technologies, environmental friendliness, and an individual approach. The manufacturer offers a wide range of insulation materials; the catalog contains both universal and highly specialized products. Thanks to the high quality of mineral wool, IZOVOL is in demand not only in our country, but also among our neighbors. Experts highlight such advantages of heat insulation as light weight, reasonable price and fire safety. The brand closes the TOP 6 of our review.

In reviews, users praise IZOVOL mineral wool for its low price, environmental friendliness, and wide range. Of the minuses, they note a large amount of dust during operation.

Advantages

- low price;

- innovative technologies;

- wide range of products;

- ease.

Flaws

- dusty during operation.

TechnoNIKOL Rocklight

Rating: 4.4

The Russian company TechnoNIKOL was founded in 1992. The first products were rolled roofing materials, and in 2006 the Ryazan plant launched the production of basalt-based stone wool. The uniqueness of Rocklight insulation, according to experts, is the innovative technology for producing cotton wool. Thanks to it, it is possible to obtain insulation that is 98% air. The advantages of the material include non-flammability, environmental friendliness and high vapor permeability. The scope of application of mineral wool is wide, from floor insulation to wall insulation.

Domestic consumers are satisfied with the low price, good thermal insulation properties, and ease of installation. The disadvantages include the loose structure and the formation of dust during the installation process.

Advantages

- non-flammability;

- high vapor permeability;

- wide scope of application;

- efficiency.

Flaws

- afraid of moisture;

- a lot of dust.

Thermolife

Rating: 4.3

Thermolife company has been producing insulation materials for more than 30 years. Basalt rocks are used as raw materials. They undergo rigorous quality control before entering the production site. Experts liked the manufacturing technology, which does not use a slag charge. The high quality of mineral wool is ensured by advanced Italian equipment. The heat insulator has such important qualities as non-flammability, good water-repellent properties, chemical resistance and environmental friendliness.

Builders praise the insulation for its precise geometric dimensions and competent selection of the thickness and width of the slabs. But the density of different mats is not the same; some experts do not recommend using mineral wool for insulating facades.

Advantages

- modern manufacturing technology;

- non-flammability;

- exact geometric dimensions;

- chemical resistance.

Flaws

- non-uniform density.

Beltep

Rating: 4.2

Since 2005, Beltep Belorussian has been producing thermal insulation boards. This is the only manufacturer of mineral wool in the Republic of Belarus. Experts appreciated the wide range of stone wool, consisting of 7 groups. The consumer is offered both rolled products and mats of different thicknesses. The company received a EUCEB (European Union) certificate, which confirms the environmental friendliness of the heat insulator. The insulation should include excellent vapor permeability, fire safety, resistance to deformation, and easy installation.

Users liked the combination of affordable price, durability and efficiency. The most frequently mentioned disadvantage is the unpleasant odor of phenolic resin.

Advantages

- rich model range;

- reasonable price;

- simple installation;

- resistance to moisture.

Flaws

- smell of phenolic resin.

Isoroc

Rating: 4.1

The Russian company registered the Isoroc trademark in 2000. The manufacturer uses non-flammable natural components as raw materials for the production of mineral wool. The insulation successfully combines lightness and compressive strength. These qualities make the material durable. Thanks to its fibrous structure, the thermal insulation material demonstrates a unique ability to absorb noise and vibration. Good vapor permeability helps remove excess moisture from the building, providing additional ventilation of the interior space. Since 2021, the brand belongs to the largest concern Saint-Gobain.

On thematic websites, Isoroc mineral wool is praised for its good quality, affordable price, fire safety and durability. But when wet, the effectiveness of the heat insulator greatly decreases.

Advantages

- non-flammability;

- low price;

- durability;

- ease of installation.

How to choose mineral wool

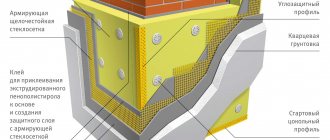

A special feature of thermal insulation work is the formation of a “pie” of insulation, hydro and vapor barrier films, and finishing materials. Mineral wool is located in the thickness of the structure and if its efficiency is low, the entire “pie” will need to be dismantled to replace the insulator or increase its thickness. In order to avoid this situation, which will require additional investments, it is necessary to choose products from the best manufacturers. In the catalogs of leading brands there are all brands of mineral wool, the buyer must take into account the purpose, choose a convenient format, select the density and thermal conductivity. Thermal characteristics depend on the thickness of the insulation, so you need to pay attention to its dimensions.

Purpose

The relatively soft insulation in the structure is subject to different static loads. Under high pressure, mineral wool can be compressed, which causes the formation of voids and a decrease in thermal performance. Manufacturers take this into account and, so that the buyer does not bother studying the parameters of building materials, they offer specialized series of thermal insulation.

Mineral wool for walls has a higher density and rigidity than insulation for unloaded floors. Thermal insulation for a pitched roof is installed from the inside, between the rafters - manufacturers produce products for this work that are more resilient and elastic. Plates for used roofs are able to withstand not only the weight of a person, but also a high snow load, without losing their parameters.

Types of mineral wool

For construction work, you can buy two types of insulation: fiberglass and basalt. Fiberglass insulation has a lower fire resistance limit, but is attractive at a low price. Basalt wool can withstand heating up to 1000 degrees and does not lose its characteristics in direct contact with fire. Other advantages include increased biological and chemical stability and good vapor permeability.

Insulation is available in rolls and slabs. Mineral wool in rolls has a low price and allows you to quickly complete insulation work over a large area. The disadvantage of this format is the low density of the material and increased water absorption. This material is used for thermal insulation of unloaded structures. The slabs have a high density, they hold their shape well under load, and are easily mounted in vertical and inclined frames. Among the disadvantages is the high price.

Density

The denser the material, the higher its thermal conductivity. For private housing construction, it is recommended to use mineral wool with a density of 15 to 35 kg/cub.m. These products have a low price and have good thermal conductivity and vapor permeability.

Insulation with a density of more than 35 kg/cub.m. Designed for loaded structures. The material is able to withstand high static pressure throughout its service life. This helps maintain the thermal performance of the structure.

Thermal conductivity

This characteristic is basic for all thermal insulation materials. The lower the thermal conductivity coefficient, the less insulation is required for high-quality thermal insulation. The use of materials with high thermal conductivity will lead to the need to use slabs with large thickness. This will increase the cost of construction and the load on supporting structures.

The average thermal conductivity of basalt slabs is 0.047 W/m*C - this is 10-12 times less than that of hollow bricks. Accordingly, 5 cm of insulation can replace 50-60 cm of brickwork. Fiberglass mats have an average thermal conductivity of 0.056 W/m*C. The exact parameters are indicated by manufacturers in the material data sheet.

Size

The size 60x120 cm has become a popular format for mineral fiber products. These characteristics were chosen taking into account the recommendations for dry construction systems and pitched roofs. The distance between the plasterboard guides, rafters and components of the suspended facade is 60 cm. This allows you to install the slabs closely and ensure high quality work on insulating the building.

The mats are available in lengths from 3 to 18 meters and widths of 1.2 m. This simplifies installation in two layers between the beams of the floor slabs. The traditional thickness is 50 mm, for industrial use it is 100 mm, but leading manufacturers offer products with increased parameters (up to 200 mm).

Which manufacturer's mineral wool is better?

The companies from our rating produce high-quality products worthy of the attention of a demanding buyer. Each company has its own advantages, so it is difficult to answer the question of which mineral wool is better. These are large concerns that offer insulation for various areas of construction. The VyborExperta.ru team recommends choosing a supplier taking into account the area of activity:

- Rockwool is the best insulation for pitched roofs;

- Isover – products for thermal insulation of facades and interfloor ceilings;

- TechnoNIKOL is a universal budget solution;

- Paroc – mineral wool for used roofs and facades.

All presented brands deserve the title of the best manufacturers. These companies produce products that will last at least 50 years, keeping your home warm and cozy.

List of mineral wool manufacturers in Russia

The group of leaders in the production of mineral wool thermal insulation materials in our country includes several leading enterprises.

- The Rockwool concern has an extensive network of enterprises united in CJSC Mineral Wool. They produce various mineral wool products for all structural elements, household and industrial purposes. They specialize in the use of basalt rock raw materials.

- The TechnoNIKOL company is a Russian manufacturer that has located its enterprises not only throughout the country, but also in neighboring countries (former partners in the USSR) and European countries. The trading network has representative offices in more than 30 countries. The products are designed for private and industrial use.

- Isorok company is a domestic production with foreign shareholders (100% foreign capital). It produces products from stone mineral wool at a plant in Tambov, built in the 80s of the last century and undergone modernization.

- The Ecover company is a newcomer in the production of basalt mineral wool insulation, whose products, manufactured in the Urals, are gaining increasing popularity in all regions. The materials of this company are worthy competition to the products of the leaders.

The production of thermal insulation materials based on mineral wool by the largest Russian enterprises is an opportunity to meet the constantly growing demand in the country and make expensive insulation materials based on stone raw materials more affordable.