When it comes to choosing a material for insulating houses, pipelines or other objects, many consumers choose common optionswhich have been used for many years. One of the most popular is basalt insulation, which has excellent technical characteristics. All components create a material that operates in a wide range of temperatures and is suitable in terms of service life and vapor permeability. But, nevertheless, we need to talk about this in more detail in order to know all the advantages and disadvantages of the material.

general information

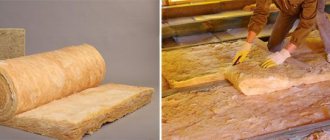

Basalt insulation is a building material made from mineral wool . Basalt rock is used as a filler , which imparts unique properties. It is obtained by high-temperature processing of rocks. The material is stretched into threads and inserted into mineral wool. As a result, the insulation has some excellent characteristics in the form of good density, thermal conductivity, and a high melting point. At the same time, there are now several main types:

- Soft material . It has a high density, but at the same time good thermal insulation.

- Medium , which allows you to insulate any structure.

- Hard . It is used when there are high loads. This variation of insulation is considered the best for insulating chimneys, fireplaces and stoves. It is this material that meets all the parameters for use.

Isover - high quality mineral wool to choose from

Photo: atlaccapital.ru

The manufacturer offers two solutions: glass wool and stone wool. This is a big plus when choosing thermal insulation, since both of these materials are usually in demand in the construction of a particular facility. Izover has an excellent reputation in Russia and offers thermal insulation only with environmental quality certificates. The constant introduction of modern technologies makes it possible to improve the characteristics of manufactured products and reduce costs. The latest “new product” from Isover is the release of mineral wool with high strength and elasticity, without dust and with a minimum of “prickliness”. In terms of quality, products under this brand are unlikely to compare with more expensive competitors, but in terms of price/quality ratio, Isover mineral wool is one of the best.

Rating : 9.9 points out of 10

Reviews from builders : “Isover mineral wool is cheaper and better than many other insulation materials, so I use it for large volumes.”

Advantages of basalt insulation

If we talk about the positive characteristics of such material, then there are several main points to note:

- Excellent durability . It is thanks to this property that the material is perfect for facade insulation using the wet method. It is installed on the surface, and after that reinforcement and plastering are carried out.

- Fire safety . Basalt insulation is manufactured at a temperature of 1000 degrees and therefore does not burn or melt.

- Good sound insulation , which allows you to eliminate all extraneous noise from the outside.

- Resistance to deformation with increasing and decreasing temperatures. At the same time, this increases the scope of its application.

- Slight shrinkage.

- Quite a long period of use . If installed correctly, the insulation will retain all its properties for 50 years.

- Good resistance to chemical and biological factors . The material is in no way suitable for rodents and withstands chemical exposure well.

- Simple installation that does not require any special skills. You can install such material yourself and not pay specialists for the work.

As you can see, there are a huge number of advantages now. Most of them come from technical specifications that have been in development for quite some time. Having examined this series, we can say with confidence that this is a pretty good option for insulating a house. But, nevertheless, it is also necessary to consider the disadvantages that basalt insulation has, like other materials.

Rockwool - stone wool without disadvantages

Photo: zorenko.ucoz.ua

Despite its Danish roots, Rockwool has many factories in Russia, which allows the company to offer a range of European quality, but without unnecessary price markups. The high quality of this mineral wool is confirmed by builders who consistently choose products from the Danish brand when carrying out work.

Rockwool mineral wool has enhanced characteristics:

- fire safety - Rockwool fibers can withstand up to 1000 degrees with standard data of 600 degrees Celsius;

- absorption of sound and vibration, which is why the material is chosen to create noise barriers and to increase the acoustic comfort of rooms;

- environmental friendliness - Rockwool has an EcoMaterial Green certificate, although it has long been known that many people do not like mineral wool, attributing to it properties that are dangerous to the environment, life and human health;

- durability without deformation and destruction;

- thermal insulation.

We are, of course, talking about real Rockwool; purchasing from unreliable suppliers does not guarantee the above-mentioned quality.

Our rating : 10 points out of 10

Reviews : “Rockwool light butts mineral wool is the best - it holds its dimensions perfectly and does not fray.”

“The house was saved in a fire only thanks to the presence of Rockwool slabs in the ceiling - it does not burn, does not shrink, and does not form dangerous voids at high temperatures.”

Disadvantages of basalt insulation

If we talk about the negative features of such insulation, then among them the following should be highlighted:

- When water or any other liquid gets on the insulation, its thermal conductivity increases . Because of this, many suffer from loss of thermal insulation performance. To prevent this, many manufacturers impregnate materials with special water repellents that prevent moisture retention.

- The composition contains special resins that allow you to hold the fibers in place. Thanks to this, the material retains its shape, but in large quantities the environmental friendliness decreases. That is why such substances can get into the air in the house and worsen the atmosphere.

- When such insulation is used, the space of such a room is very often reduced . It all depends on how thick the material is.

- Under no circumstances should you bend the basalt insulation during installation . It may break and you will break the entire structure, after which you will have to purchase the material again.

- Dust formation . If the fibers inside break off, they form fine dust. It is because of this that the lungs of household members can become contaminated, and asthma and other diseases appear. To avoid this, it is necessary to cover the insulation with special membranes.

- High price . Products from good manufacturers will always be expensive. That's why you need to figure out whether you want to save money or buy components that are truly suitable for use.

Knauf produces everything!

Photo: www.dostavkasmesi.ru

Knauf is a manufacturer that has proven more than once that it can provide the construction market with the best offers. Thermal insulation is no exception. Knauf offers good quality mineral wool based on basalt fiber, as well as glass fiber composition. The first option is widely used for technical insulation, in construction and in the production of complex equipment. Fiberglass insulation is produced for specialized purposes (TEPLOKnauf), as evidenced by its names:

- HEATWALL;

- HEAT stove;

- WARM roofing;

- Acoustic partition;

- HEATROLL.

Most of the mineral wool sold by the manufacturer belongs to the Knauf Insulation series. There are no toxic phenol-formaldehyde resins used in the production of this product. The Knauf Insulation and TEPLOKnauf thermal insulation lines are intended for the construction of residential buildings by individuals and construction organizations.

Disadvantage : high price

Rating : 9.9 points out of 10

Reviews : “You rarely hear a bad word about Knauf. This means that the material is truly excellent.”

Varieties

During production, the BU acquires a certain density. Moreover, manufacturers are achieving different indicators in order to expand the scope of application of the material.

It cannot be said that a heat insulator of one density or another is better than its analogues. They all have their own characteristics, which largely determine their scope of application.

There are several types based on density. Density is determined in kg/m3.

- 25-30 is mainly used for floor insulation;

- 35 is ideal for sloping roofs;

- 40-50 should be used for walls and frame structures;

- 50-60 is suitable as layered masonry;

- 70-80 is recommended for use when organizing a ventilated façade;

- 120-140 will be the best solution for creating a wet facade followed by plastering the insulation;

- 150-200 is used mainly for thermal insulation of flat roofs.

In addition to density, stone wool is also classified according to its degree of hardness.

The following options are possible:

- Soft insulation

. Includes the finest fibers. The structure is porous. Allows you to retain air, providing thermal insulation properties. But such slabs or rolls cannot be used where the insulation may be subject to a large load; - Medium hardness

. Or semi-rigid insulation. Used in the construction of ventilated facade systems; - Rigid thermal insulator

. Suitable for situations where subsequent reinforcement is expected, as well as the application of plaster. Also a good option for floor screed.

Therefore, you need to approach your choice responsibly. After all, the above information showed that not every basalt insulation for a facade will be a suitable option. This is especially true for wet facades. This requires an insulator of high density and rigidity.

Ursa - a new generation of mineral wool

Photo: alkiv.kiev.ua

For a long time, the Ursa brand was known for its fiberglass products. But technology does not stand still, and today the company offers the market PureOne - a new generation of mineral wool made from natural and naturally renewable components, interconnected with an acrylic-containing binder.

The effectiveness of PureOne in terms of heat and sound insulation is very high, there are almost no complaints about other characteristics. The material has a bright white color, does not chip, does not crumble, and does not deform.

In addition to PureOne, Ursa also offers a standard range of glass wool, with all their disadvantages and advantages. The cost of products does not differ from analogues of other companies.

Rating : 9.8 points out of 10

Reviews from builders : “PureOne is the best mineral wool; its elasticity and rigidity are 1.5 times higher than traditional fiberglass insulators.”

“A friend who has been working on the construction of dachas for many years said: take Ursa insulation, you won’t regret it - it keeps you warm, it’s easy to work with, and it doesn’t burn. I insulated the attic at the dacha, then I itched for a week, but the house is now warm.”

Basalt wool - characteristics

When choosing this material as insulation, you need to pay attention to its technical characteristics.

Thermal conductivity

The material has high heat-insulating qualities due to its porous fiber structure. Its thermal conductivity can be from 0.032 to 0.045 W/mK . This is on par with regular or extruded polystyrene foam, foam rubber and cork.

Basalt fiber has high mechanical characteristics. This is explained by the short length of its fibers and their arrangement in a chaotic form. Therefore, during operation, the insulation does not shrink and is not subject to deformation.

Vapor permeability

Stone wool has a porous-fibrous structure, due to which it has high vapor permeability. This characteristic is very important when insulating any structures. When using cotton wool, steam passes unhindered through the external walls, which means that moisture does not accumulate in the surrounding structures. This extends the service life of buildings and products insulated with basalt wool.

Density

Insulation is available in different densities, which can be from 40 to 200 kg/m2 . To use stone fiber on pitched roofs or suspended ventilated materials, you must choose insulation with a density of 100 kg/m2. Such material will not slip, and fibers will not be blown out of it.

Due to the different densities of basalt wool, it can be used to insulate both unloaded and loaded structures, that is, roofs and floors.

Compressive strength

Depending on the type of insulation, the compressive strength of basalt wool at 10% can range from 8 to 60 kPa . This characteristic of the material is important when using it to insulate rolled flat roofs. Rigid slabs of material for these structures meet the necessary requirements. The tear strength of the layers is also very important. This figure should be no less than 15 kN/m2. Basalt wool meets these requirements.

Soundproofing

Mineral insulation is able to muffle vertical sound waves along the walls, thereby isolating the room from noise emanating from outside. The material, absorbing sound waves, reduces reverberation time. This means that noise will not be heard in the rooms adjacent to the isolated room.

Moisture absorption

Basalt wool impregnated with special oils has the property of hydrophobicity , that is, water falling on the material does not penetrate inside. Thanks to this, the thermal insulation properties of the insulation do not change. No more than 2% is the water absorption of mineral stone wool by volume. Ordinary mineral wool can absorb a fair amount of water, which significantly reduces its thermal insulation properties. Therefore, if you need to insulate a bathhouse, sauna or other wet room, then it is best to choose basalt wool.

IZOVOL mineral wool is the best choice for walls and roofs

Photo: stroimaterialytorg.ru

Izovol is another type of basalt wool that is in high demand and is used for thermal insulation of walls, roofs and ventilated facades. It has excellent physical, mechanical and operational characteristics. It is non-flammable, has standard density indicators for the material, so it can crumble during operation, causing some discomfort.

It does not have a high price; all thermal insulation is available for sale and is in demand by construction organizations. The most popular line of materials is recommended for insulating pitched roofs and attic spaces.

Rating : 9.5 points out of 10

Reviews about Izovol mineral wool : “The material showed its best side. Very easy to work with, non-allergenic, fireproof. It doesn’t cut well in terms of thickness—perhaps the only drawback.”

Which mineral wool is better?

Often, a comprehensive analysis of any product at the end allows us to say: “This brand is the best. We recommend it for purchase!” It is impossible to draw such a conclusion with mineral wool. Assessments of the quality of manufactured products are too subjective; diametrically opposed reviews can be found about the same product. Therefore, “Expert Price” does not take the liberty of naming the best manufacturer of mineral wool, but makes the following recommendations :

- The 7 brands mentioned are truly the best on the Russian market and the most in demand in the construction of residential buildings and utility rooms, so it is best to purchase something from the announced list.

- To choose the optimal thermal insulation material after reading the article, it is best to carry out your own subjective assessment in a building materials store: look, touch, test for breaks - in a word, understand which thermal insulator is convenient for your work.

The combination of these two simple tips will allow you to choose what is truly best for insulating and insulating your home from external adverse factors. Happy shopping and have a comfortable winter!