Current and future owners of their own homes are well aware that only by creating high-quality thermal insulation for the building can they ensure a constant, comfortable temperature in the premises, and at the same time achieve a reduction in heating costs. For this trivial reason, various insulation materials are used. Since the choice of these materials is quite large, many owners are faced with a painful choice of one of the contenders. Someone follows the advice of friends who praise the heat insulator they have chosen. Others try to independently study all possible options, and then choose the best one - effective, without serious drawbacks. Those who have not yet made a final decision may be interested in one of the possible methods - insulating the walls from the outside with polystyrene foam. The strengths and weaknesses of this material need to be known so as not to encounter unpleasant surprises in the future.

Polystyrene foam and polystyrene foam: differences

Before moving on to studying the topic “Insulating walls from the outside with polystyrene foam,” we need to consider one question that interests many: what is the difference between polystyrene foam and expanded polystyrene. Both materials remain one of the most popular insulation materials; they are often called the same, without understanding or going into details.

The answer is obvious: in this case the name helps. Foam plastic is any foamed plastic; this is a collective name. It can be different “foam” material - polyvinyl chloride foam (PPVC or Vinipor), polyurethane foam (PPU) or polystyrene foam. Since now it is the latter that is used most often, and in various fields, polystyrene foam is usually called polystyrene foam.

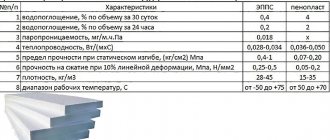

However, experts - professional builders - classify these materials as completely different insulation materials. The first of them is directly polystyrene foam - non-pressed polystyrene foam, the second is an extruded type, which is made using a completely different method.

Pressless expanded polystyrene (BSP)

BSP is “real” foam that is made up of many white balloons stuck together. It is produced from the same raw materials - polystyrene, but the manufacturing technology makes it possible to obtain a completely different product.

To produce BSP, granules with a low-boiling liquid, for example, pentane, are added to styrene. The mixture is then heated: during this stage the granules expand and the foam completely fills the mold. Then the “semi-finished product” is sintered in autoclaves until styrene polymerization occurs.

The output is unpressed polystyrene foam - a snow-white product consisting of small balls that are glued together. The proportion of air in this material is 98%. The strength of the material is low: it crumbles and breaks quite easily. But it has an extremely low thermal conductivity coefficient.

Extruded (extruded) polystyrene foam

This is also polystyrene foam, but only a specific type of it - EPS, XPS. Builders call this material extruded or extruded. The difference between “old” and “new” insulation lies in the production technology.

The method for producing this type is called extrusion. Polystyrene granules are mixed with a foaming component at high temperature and the same pressure, and then extruded by an extruder, which gives the mass its shape. This material differs from non-pressed polystyrene foam because it has closed cells, which make it as durable and dense as possible.

As you can see, the raw materials used are identical, but the result is quite different. The extrusion method allows you to obtain higher quality insulation, but this does not mean that this material is completely free of disadvantages. Now we have to get acquainted with the advantages and weaknesses of both candidates.

Main disadvantages

Now let's look at the problems that we encounter when using this insulation. It is easily exposed to direct sunlight , under their pressure its density weakens and becomes unstable to weather conditions.

- Many people believe that the thicker the insulation layer, the warmer the house. Cold air penetrating between the plates will cause disturbances: waves and cracks. European standard - 3.5 cm thick. With such calculations, heat is well retained, and in the event of a fire, the risk of poisoning from harmful chemicals released will be reduced .

- Another disadvantage is the complete lack of sound insulation. Insulation is completely unable to insulate a room. You can increase the number of layers, but you still won’t achieve a sufficient result. For sound insulation it is better to use another material.

- During the construction phase (more precisely, after the installation of polystyrene foam), it releases the harmful chemical styrene.

- If you heat it to 75 degrees, vapors are released: ethylbenzene, toluene, carbon monoxide and benzene, which will harm the human body. Manufacturers often try to refute this fact.

- Even the best quality insulation can catch fire sooner or later. This is confirmed by the assignment of G3 and G4 markings by GOST 30244−94 of the Russian Federation. Therefore, do not believe it when, when advertising polystyrene foam, they call it fireproof. Moreover, when melting, the smoke produced is so thick that you can’t see your hands. To summarize, calling polystyrene foam “fireproof” means its resistance to fire itself, but not combustion. However, the insulation is never used as a finishing coating for the walls; it is additionally covered with facing structures, which prevents the foam from wearing out.

Insulating walls outside with foam plastic: pros and cons

An additional thermal insulation layer for walls in apartment buildings and private houses is a logical solution, which is dictated by the “whims” of nature - temperature instability in the autumn-winter period. There are a large number of materials on the market, but choosing the most reliable and most worthy one often arises. Polystyrene foam is not the last candidate on the list; it has been used for a long time, and, as a rule, owners do not have any serious complaints. Anyone who is just deciding on choosing insulation would do well to learn about its advantages and disadvantages.

Pros of foam insulation

It is customary to immediately praise any material, so first you need to give a list of advantages.

- Excellent thermal insulation qualities. Polystyrene foam is a solid foam mass, inside of which there are many air cells. It is thanks to them that the material has good heat-insulating properties, because air is not the best conductor of heat.

- Easy to work with foam. It is guaranteed by the lightness of the thermal insulation material. The reason for this “weightlessness” is also air. Cutting the material is quite simple, so the parts are adjusted directly at the installation site. This kind of work is often done independently.

- Versatility of use. Polystyrene foam is used to insulate basements, walls, roofs, floors, and ceilings. They protect both residential and industrial buildings. There are two types of heat insulation: slabs are traditionally used for walls, and crumbs (balls) are used for the roof (attic).

- Resistant to temperature changes. Foam plastic retains its qualities even in extreme conditions: at extremely low and high rates. Its operating range is wide - from -50° to +50°. This property is most important when insulating the facade of a building.

- Possibility of saving on transportation. Foam boards are light in weight and the same size, so delivery can be arranged independently and free of charge.

- Non-toxic. According to construction standards, polystyrene foam is a safe material, since under normal conditions it does not emit any harmful substances.

- Relatively good sound insulation characteristics. Therefore, in addition to warmth, the owners guarantee the absence of extraneous sounds in the house.

- Sufficient moisture resistance. This insulation is practically not afraid of water and does not absorb it.

- Lack of “interest” on the part of insects, mold and microorganisms.

The main advantage of this insulation option is the low price of the heat insulator. This plus often outweighs even some of the disadvantages that are present in any material.

Disadvantages of polystyrene foam as insulation

The material has many positive qualities, but when considering insulating walls outside with foam plastic, you need to become familiar with the weaknesses of this solution. The first drawback is the large amount of debris when sawing slabs. But there are others.

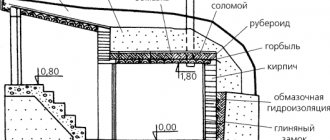

- Destruction at sub-zero temperatures and simultaneous exposure to moisture. For this reason, insulating the base or semi-basement may require a larger operation - arranging formwork and pouring mortar or brickwork.

- Instability to ultraviolet radiation: its effect on foam plastic is, without exaggeration, destructive. For this reason, insulation cannot be stored where it will be exposed to sunlight. After installation, it is recommended to protect the foam from ultraviolet radiation as quickly as possible.

- Fragility is one of the main complaints about polystyrene foam. The material will not be able to withstand heavy loads, so it is additionally reinforced from the outside. The slabs are covered with reinforcing mesh, then the walls are plastered.

- The insulation practically cannot “breathe”; it allows air to pass through very poorly. For these reasons, polystyrene foam is not recommended for use indoors, where the most important condition is to ensure an ideal microclimate.

- Flammability is the main disadvantage that is actively discussed. When ignited, this polymer begins to release toxic substances. Only products from well-known manufacturers have the ability to self-extinguish.

- Destruction due to exposure to paints and varnishes: for example, nitro paints. For this reason, the list of finishing materials is somewhat narrowed: those types that contain solvent cannot be used with polystyrene foam.

- Emission of an unpleasant odor. This process begins over time due to the natural aging of the material. On the other hand, this drawback does not play a big role in the insulation of facades.

- Undesirable use for ventilated facade systems due to very low vapor permeability (0.012 mg/m*h*Pa).

Another claim made by skeptic opponents is the short service life of foam plastic without loss of properties. They say that laboratory tests have confirmed that it is approximately 5-7 years. The owners of insulated houses deny this fact.

Are some disadvantages serious?

As for the service life of polystyrene foam, the durability and reliability of products depends on the manufacturer. As a rule, on the market you can “meet” low-grade materials, the production of which does not comply with standards. By purchasing high-quality insulation, you can hope for a long service life: foam manufacturers claim that it is at least 20 years.

The release of harmful substances at low temperatures is also characteristic of low-quality insulation materials. Over time, such materials begin to release styrene (phenylethylene, vinylbenzene), which is a slightly toxic but still dangerous hydrocarbon. Therefore, the use of foam products in warm rooms (baths or kitchens) is not recommended.

The most discussed disadvantage of polystyrene foam (as well as mineral wool) is the increased interest of rodents in it. It is easy to chew through, and inside you can build burrow-rooms and start a family. Therefore, in areas where there are mice or rats, it is more expensive to experiment with the material, since the thermal insulation will become ineffective very quickly. However, in this case, serious (metal) reinforcement can be a salvation. There are other ways.

Many disadvantages can be ignored, since the material will be reliably protected from many factors that threaten it. These include fire, ultraviolet radiation and ever-hungry “living creatures” that settle where “there is something to eat.”

Selection rules

Polystyrene insulation is a popular and modern building material. Therefore, manufacturers do not miss the opportunity to make money on it. Dozens of types of insulation are sold on the market . How to choose the best polystyrene foam insulation?

- Pay attention to the brand of material. A good indicator is 40, you can buy less, but not 25, since this is considered the lowest quality.

- An important stage of selection is testing the technology. When choosing any products, you should adhere to GOST. There is no need to take risks and take insulation made using the manufacturer’s own technology, because the indicators may be much lower than the standard ones. For example, the PBS-S-40 brand may have a density of 28 instead of the stated 40 kg per cubic meter. As a last resort, ask for certificates that indicate the exact characteristics.

- Before buying a large batch, first buy one sheet and break off a small piece. The fault should form smoothly with regular polyhedra. The presence of large balls and irregularities indicates low quality of the material.

- Popular and already proven companies include: BASF, Polimeri Europa, Nova Styrochem, Chemicals and domestic ones - Technonikol and Penoplex.

Despite all the shortcomings and the difficult choice of insulation, expanded polystyrene is used in the construction of four out of five houses. Most construction companies trust him . If you take all precautions and follow technology, your home will be provided with heat for 30 years or more.

Advantages and disadvantages of the extruded type

Since, when talking about insulating walls from the outside with polystyrene foam, they sometimes mean extruded polystyrene foam, it is impossible to consider its pros and cons. Since this is a more advanced type of material, it has advantages over its old “colleague”, but it is not without EPS and weaknesses.

Advantages of extruded polystyrene foam

It is considered a more advanced material for good reason. The list of its advantages:

- almost perfect geometry, simplifying installation;

- long service life: it is 50 years;

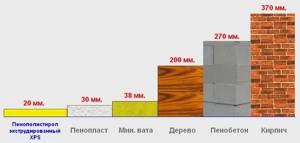

- lower thermal conductivity due to closed cells;

- the presence of locks at the ends: this connection system guarantees the absence of cold bridges;

- installation is just as easy due to the light weight, but there is less chance of accidental damage to the material;

- maximum strength, therefore this material is traditionally used to create permanent formwork;

- flexibility of the insulation: the extruded type of polystyrene foam makes the work easier, it is simpler and cuts more smoothly;

- the possibility of use for insulation of semi-basements, foundations, plinths, because EPS is more resistant under unfavorable conditions (moisture plus negative temperature).

An impressive set of arguments in favor allows us to talk about the great advantage of extruded polystyrene foam over “rustic” polystyrene foam. But in order to consider the relatively new insulation objectively and impartially, we now need to learn about its weaknesses.

Disadvantages of EPS

Everything has its downsides, but in the case of building materials, the main thing is to understand how significant they are. If we compare this heat insulator with conventional polystyrene foam, the disadvantages of extruded polystyrene foam include:

- lower vapor permeability (for example, 0.007-0.012 mg/m*h*Pa for penoplex);

- insufficient sound insulation;

- higher price of insulation;

- greater weight of material;

- high density.

The first minus will definitely affect the microclimate of the room, so in this case the owners will have to ensure the creation of the most efficient ventilation system. High density is a wonderful quality for expanded polystyrene formwork, but for insulation it is not always an advantage.

How to insulate a roof with foam plastic?

The roof is perhaps the only place in the house where foam insulation will be the best compared to other types. The advantages of this roof solution are:

- polystyrene foam will keep warm in cold weather and cool in hot weather indoors;

- unpleasant odors will rise upward;

- when wet, the slabs will not lose their properties;

- no load on the rafter system due to the light weight of foam boards;

- ease of attachment to rafters;

- the insulation needs to be laid in the cavity between the rafters, this will save space;

- high fire safety indicator, since the slabs are covered with a roof on top;

- affordable price of material.

Also, if you choose this type of insulation, remember that non-residential premises should be insulated on both sides. In addition, foam plastic will be indispensable for roof insulation, especially based on materials such as:

- profiled sheet;

- ondulin;

- metal tiles.

Insulation of external walls with foam plastic

Before considering insulating walls from the outside with polystyrene foam, you need to choose the “right” material.

Characteristics

Foam density is the first material characteristic that must be taken into account. More often they use slabs with values of 15, 25 or 35. If we talk about insulating walls from the outside with polystyrene foam, then in this case the “golden mean” is a density of 25.

A lower value will result in reduced thermal insulation efficiency. More is not the best option for two reasons:

- due to the more “ruining” price of such insulation;

- due to the fact that high density means some loss of thermal insulation properties, since the amount of the main heat insulator, air, in the material is reduced.

Therefore, the latter option is not advisable to consider at all, especially for regions with severe winters.

To insulate a house, you can use slabs of any thickness - from 50 to 150 mm. The choice of this parameter depends entirely on the area where the building is located. For southern latitudes, the minimum value will be optimal.

In regions where winter temperatures are relatively low (up to -25°), a thickness of 100 mm is chosen for residential buildings, and 50 mm is limited to 50 mm for outbuildings. Areas with severe frosts require maximum foam protection - 150 mm.

Features of foam

The structure of the foam is a foamed mass, where the bulk of the mass of the slab is air. Due to this, the density of this material is much lower than the density of the raw materials from which it is produced. The huge amount of air in the structure of the material is its undoubted advantage, in addition:

- foam-based panels are lightweight;

- the material has excellent sound insulation properties;

- good thermal insulation properties.

The material has different densities depending on the raw material, and this also affects the level of mechanical strength. The greater the density of the structure, the less air inside the material; accordingly, the thermal insulation properties will be worse , but at the same time the material will withstand more mechanical loads.

When insulating, foam plastic boards, depending on the strength level, are used in the following way:

- slabs with a minimum strength indicator must be combined with insulation with a maximum level of protection from mechanical damage;

- slabs with low strength are best installed for insulation with the frame method of installing load-bearing structures;

- if the slabs have greater strength, protection from mechanical damage will be provided without a frame, but it must still be installed in addition to the insulation.

Hygroscopicity and poor ventilation properties

Expanded polystyrene absorbs moisture. Therefore, when insulating damp surfaces you need to be careful. In this case, it is recommended to use extruded polystyrene foam, which does not absorb moisture.

Another significant drawback is its moisture-repellent properties. Thus, if the house is built from polystyrene foam blocks, it will be impossible to maintain an optimal microclimate in the room.

When breathing indoors, water vapor enters. And if this steam does not escape naturally, the room will become very humid. Under ideal conditions, moisture leaves the room through the walls and ceiling.

If you insulate the walls with polystyrene foam, natural ventilation will be disrupted. Therefore, in this case it is necessary to consider high-quality forced ventilation.

Features of insulating the facade of a building using polystyrene foam with your own hands

Residents of large cities prefer to call a team of specialists for this purpose, especially those who live on the upper floors and the work is supported by height.

However, if you live on the ground floor or outside the city, you can insulate the facade with your own hands. Remember not to allow significant delays in work , otherwise the foam may get wet or bad weather will negatively affect the quality of the material.

The list of tools for work will be as follows:

- hammer;

- smooth and serrated spatulas;

- knife for cutting slabs;

- disc dowels;

- foam boards (expanded polystyrene);

- reinforced mesh;

- primer;

- base profile;

- façade putty;

- polyurethane foam;

- for polystyrene foam - special glue.

The sequence of actions will look like this:

- we prepare the surface of the walls, remove protrusions and seal cracks;

- create a base profile;

- laying the slabs;

- seal the seams;

- plastering the facade.

Now let's look at all the stages of work in more detail.

Preparatory work and laying of the base profile

Make sure the wall is perfectly level. Minor differences are allowed no more than 2 cm. When the wall area is cleared, it must be primed or treated using concrete contact.

If you use polystyrene boards instead of foam plastic, they need to be processed. On the one hand, they need to be made slightly rough using a special roller. In order for the installation of slabs along the entire facade to be level, you need to beat the zero level in a circle so that the first row of slabs lies in a horizontal position. In addition, the base profile serves as protection and prevents all kinds of rodents from reaching the slabs. Do not neglect the installation of the base profile.

It should be installed using a level. Mark the zero point on the facade along the entire perimeter of the profile fastening. Then all the points are connected into one using a tapping cord.

Laying slabs on the walls

Now you can start gluing the slabs to the facade and strengthening them with disc-shaped dowels.

Use special glue on polystyrene foam boards. It should be applied in even layers using a notched trowel on the slab or on the wall itself. Laying should begin with door or window slopes, then install the first row, the position of which is guaranteed by the plinth profile. Then the slabs are laid in a checkerboard pattern , paying attention to the tightness of their fixation. After finishing the work, the polystyrene foam boards are secured with dowels.

The foam is also attached with dowels, this is done like this:

- wait at least a day until the glue dries;

- hammer the dowels into the corners, at the joints of several plates; one dowel will be enough to fix three sheets;

- The first dowel must be driven into the center of the slab, and the rest at their corners.

We are for it"!

This is what people say who have recently insulated their home with polystyrene foam. Indeed, the material has a lot of positive qualities:

- Low weight.

- Low thermal conductivity.

- Excellent noise absorption performance.

- Self-extinguishing property.

- Ease of use.

- Low cost.

Yes, indeed, foam plastic is second only to polyurethane foam in thermal conductivity, the volumetric weight of the slabs is from 10 to 50 kg per 1 m3, while for the best mineral wool materials it starts from 30–35 kg/m3, it perfectly dampens noise and is attenuated in 1 second, and any homeowner can work with it.

Manufacturers and prices

Construction foam is produced in all regions of Russia, since it is very expensive to deliver outside the region or region. Therefore, there is no point in talking about specific supplier companies. Prices for 1 m3 vary within 1790 rubles. for PSB-S-15 insulation up to 3900 rubles. for PSB-S-50.

A number of foreign enterprises also supply their products to Russian markets. Some from their factories outside the Russian Federation, some from production facilities located in Russia. Among them:

- BASF is a German company with branches in Russia;

- Polimeri Europa (Dunastyr) (Italy);

- "Styrochem" (Finland), etc.

Prices for products from foreign companies are 10-85% higher with the same performance characteristics, with the exception of flammability. Imported polystyrene foam does not burn and goes out, but Russian foam does not burn.

Scope of application of expanded polystyrene

Contents of the article

Hide

1. Scope of application of expanded polystyrene

2. Advantages of expanded polystyrene in facade insulation

3. Disadvantages of polystyrene foam as a material for home insulation

4. A mistake when insulating a house, which will later be very expensive

Expanded polystyrene is a gas-filled material made from polystyrene and styrene copolymers. Expanded polystyrene is a type of polystyrene foam.

The main area of application of expanded polystyrene is the insulation of houses in low-rise construction (insulation of walls and roofs), it is used as a heat insulator in household and industrial equipment, and in the food industry it is used for the manufacture of packaging. In interior decoration, it is used as a material for the manufacture of skirting boards, platbands, and various

polystyrene foam on the facade

Styrofoam harbors mice

And one more fact that needs to be pointed out when assessing the pros and cons of foam insulation is that mice breed in the material.

Expanded polystyrene is an ideal habitat for them, because it is warm and soft. Therefore, when insulating with polystyrene foam, block the access of mice. To do this, you can finish the places where rodents can enter with mineral wool, which mice do not like.

Therefore, although polystyrene foam has a number of positive qualities, we should not forget about its disadvantages. Therefore, it should be used thoughtfully and in accordance with all the technological features of the material.

Flammability and release of hazardous substances

The main disadvantage of expanded polystyrene is its flammability. Therefore, it cannot be used to insulate rooms in which there is a high probability of a fire.

That is why it is not recommended to insulate a ventilated façade with polystyrene foam. The voids between the material and the surface of the facade create optimal conditions for combustion. In addition, the voids additionally act as air draft.

Over time, polystyrene foam begins to emit an unpleasant odor. This is due to the natural aging process of the material. The toxic substance that causes the unpleasant odor is styrene monomer. That is why polystyrene foam can only be used for external insulation.

Detailed information in the video:

In addition, when insulating a bathhouse, it is also necessary to ensure that toxic fumes do not enter the room. When polystyrene foam is heated above 90 degrees, the amount of hazardous compounds released from the material increases tenfold.

Where can I use it?

A universal material that can be used to insulate any surface:

- Roofs and walls.

- Floor and plinth.

- Industrial buildings and residential buildings.

This is one of the simplest methods of insulation , which is why many people use foam plastic. The house will become comfortable and warm, and the insulation itself is very reliable. The installation work itself and the material are inexpensive, so if you wish, you can hire a team of workers for these purposes.

To insulate walls, foam sheets are more often used, and crumbs or balls are used for the roof. The floor and base are often insulated with extruded polystyrene foam.

Briefly about the main advantages:

1. Wide range of applications (the ability to insulate walls, ceilings, basements and basements). 2. Durability (more than 30 years with proper use). 3. Low thermal conductivity, providing good thermal insulation. 4. Light weight (starting from 10 kg/m3). 5. Artificial origin, which allows you not to worry about the spread of harmful microorganisms. 6.Attractive, low cost, with good quality.

Common types of expanded polystyrene:

- Polystyrene foams (can be pressless or pressed). Many people imagine pressless foam because it is what they use to pack TVs, refrigerators and other equipment. Due to the large distance between the granules, moisture can penetrate into this type of material.

Pressed polystyrene foam differs little in thermal insulation and external properties. But due to the fact that the granules are more tightly coupled, it is more difficult to break or crumble.

- Extruded polystyrene foam. They have a soft and uniform cellular structure. It consists of closed cells, therefore it is considered the best type of polystyrene plastic.