The facade is the face of the building. In addition to decoration, it performs a number of technical functions to protect the foundation of the house. The façade system improves the energy efficiency of the building. Due to cladding, heating and air conditioning costs are significantly reduced. Read our article on how to install an air conditioner on a ventilated façade.

Facade systems are divided into two groups:

- “Wet” façade – the building is finished with plaster and putty mixtures. Finishing is carried out on a finished stone or brick base, as well as on insulation made of extruded polystyrene foam or basalt mineral wool.

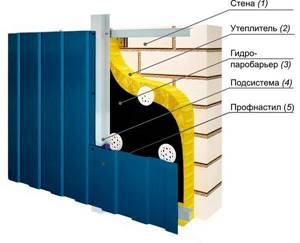

- “Dry” façade – the building is clad with sheet finishing material over a metal sheathing. Finishing is carried out on a finished stone or concrete base, as well as on insulation made of basalt mineral wool.

Among framed facades, the metal ventilated facade is especially popular. With its help, facades of residential buildings, public buildings, production workshops and a number of other objects are equipped. Let's take a closer look at this technology, its pros and cons, types of facing materials, installation options, and methods of caring for the suspended facade system.

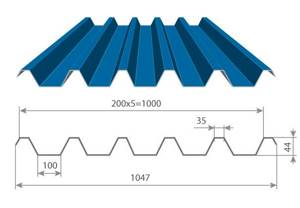

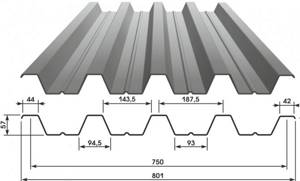

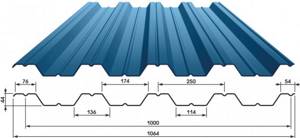

Basic properties of corrugated sheets

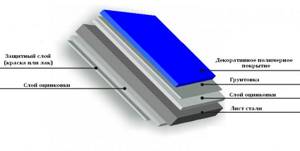

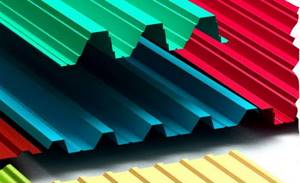

Profiled sheet is a thin metal panel made of galvanized steel. To increase the rigidity of the material, each fragment has “ribs” of a wave or trapezoid, which are repeated with a certain step. During the production process, each sheet is coated on both sides with polymer paint, so it has an aesthetic appearance.

The main properties of the profiled sheet are: high mechanical strength; long service life: 30-45 years; resistance to wind, ultraviolet rays; different sheet thickness: from 0.6 to 1 mm. Corrugated sheets are used not only for installing ventilated facades, but also for laying roofs and installing fences.

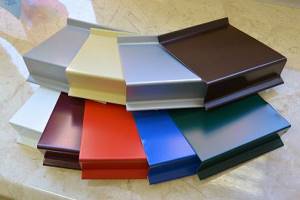

The profiled sheet can be colored. Different types of paint are applied to the galvanized surface: polyester, polyvinyl chloride, acrylic. As for the decorative layer, it can also be different: glossy or matte, with a brick, stone or wood texture.

Due to its good strength, this material can be dismantled if necessary and then used again.

Advantages of metal profiles for ventilation façade construction

The facade subsystem of a ventilated facade made of galvanized profiles in combination with corrugated sheets and mineral insulation has a number of advantages that distinguish it from other technologies:

- High strength characteristics. The suspended facade made of galvanized steel combines rigidity and plasticity. Rigidity protects against destruction. Plasticity eliminates temperature deformations of the metal. Design temperature differences from -60 °C to +120 °C.

- The wall is reliably protected from the aggressive action of water, wind and snow. The insulation is always dry and does not lose its properties.

- The service life of a suspended ventilated facade is 30 years or more. It all depends on the operating conditions, the quality of installation and materials, as well as timely maintenance.

- Fire safety. All parts of the facade, including insulation, burn poorly. Under normal conditions it is impossible to set them on fire.

- The polymer-coated surface practically does not fade in the sun. It will retain its presentable appearance for many seasons.

- The galvanized facade system includes a full set of basic and additional elements. This allows it to be installed in difficult conditions on the most inhospitable grounds.

- Using brackets with variable shelf lengths, you can align walls with differences of up to 150 mm to the height of the object. This does not affect the strength characteristics of the system.

- Installation of steel structures is carried out almost all year round. The exception is hurricane winds, severe frost and rain.

Types of material and modifications

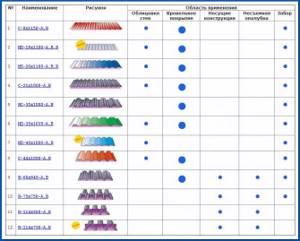

The following types of corrugated sheets are used to equip the façade:

- Wall. It is used directly for cladding the outer side of the wall and making ventilated facades.

- Carrier. It has a large height of stiffening ribs, therefore it is considered durable and resistant to large mechanical loads. It can be used for cladding technical buildings or industrial buildings.

- Universal. This material is used not only for facade cladding, but also for the construction of fences and roofs.

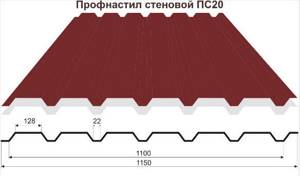

The optimal wave height of the material is 0.8 mm. The wall profiled sheet has the corresponding marking - “C”. It is designed for fixing to vertical surfaces. In order to increase the rigidity of the structure, you can first install a layer of material with a vertical direction of the waves, and then a second layer with a horizontal direction of the corrugation.

The material used for the facade has several modifications: with perforation, with insulation. The first option is used to reduce the noise level in the room, as well as to improve the ventilation of the facade. Perforation is located both over the entire surface of the sheet and in its individual parts. In addition to changing the acoustic properties of the facade, these sheets perform a decorative function.

Sandwich panel is a combination of several fragments of corrugated sheets, between which insulation (expanded polystyrene, mineral wool) is laid. This material allows not only to clad a building, but also to improve its thermal insulation characteristics.

General information

The production process of profiled sheets is very simple, and the raw material is galvanized sheet in a roll with a thickness of 0.035 to 0.12 cm. The technology for creating the profile is cold rolling. It turns out that there is a roll of steel sheet, it is untwisted by inserting the end into a rolling machine. The equipment system contains rollers of different sizes, and they are supplied in series. And the further you go, the larger their diameter will be. It turns out that the sheet is rolled between the rollers, and profiles are obtained on it.

Rolling will continue using this method until the required wave sizes are formed. After this, the sheet will be cut on a special machine. The maximum leaf length is 13 meters, and the minimum is 0.5 meters. In this case, trimming can be adjusted to different sizes in increments of 0.5 meters.

Nowadays, profiled decking is not just galvanized panels, although these are commercially available. These are sheets painted or treated with polymer compounds with a long service life. Manufacturers are gradually stopping using paints and varnishes, since the material with a polymer layer has higher operating parameters. For example, a painted sheet will last no more than 15 years, with a polymer layer up to 50 years. It should be noted that the finished sheet is not painted or polymerized. These raw materials (finished) in the form of rolled sheets leave the factory in this form.

It turns out that the material is painted or polymer is applied under factory-type conditions using special equipment. This is a certified material, and standard No. 24045-2010 was created for it. But it should be noted that not all manufacturers will adhere to such a document and produce products according to specialized technical conditions, but this will not contradict current legislation.

So, according to GOST, profiled sheets can be divided into 3 groups:

- Roofing.

- Carrier.

- Wall.

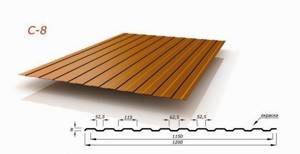

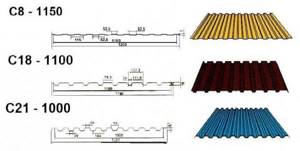

Since we are talking about covering a house with corrugated sheets, we will mainly talk about the wall option. But here it should be noted that the other 2 can be used to decorate house walls. They cost a little more, and therefore there is no point in resorting to using them. So, the wall material is marked “C” with the addition of sheet parameters in the form of numbers, where the main characteristic is the wave height. For a wall, this size varies between 8-44 cm. It is the profile height that determines the strength characteristics of the material, and the larger it is, the higher the strength. Most often, the C8 brand is used for home decoration. This is the cheapest option, and it also has excellent strength characteristics. But when choosing a brand, you need to take into account the loads acting on the building. For example, if the current wind loads on the building are enormous, then it is better to sheath it with sheets C15, C20 or C21. They have higher strength and are not prone to bending.

Advantages and disadvantages of the material

A curtain wall façade made of corrugated sheets has the following advantages:

- high speed of finishing the facade: the sizes of the canvases are different, so the wall can be closed in a few hours;

- ease of installation, which allows you to do it yourself;

- complete protection of walls from the influence of moisture, ultraviolet radiation, wind, precipitation;

- a large selection of shades (there are also sheets with designs);

- light weight of the material (since the strength of the product is ensured by stiffening ribs, there is no need to increase the thickness of the metal);

- absence of toxic components in the composition of the material;

- fire safety of metal cladding;

- ease of processing: the fabric can be cut using metal scissors;

- resistance to rust and corrosion.

The material also has some disadvantages. Its texture is the same, regardless of the color of the product. The metal has a high level of thermal conductivity, so in summer the cladding can become very hot. When cutting the fabric, the anti-corrosion protection is violated, so corrosion processes can begin in this place. This material is not always able to provide good sound insulation.

Advantages of corrugated sheets for cladding a wooden house

Wood, especially old wood, is a problematic material. It absorbs moisture well, is easily flammable and is not very dense, sometimes even loose - in especially advanced cases, even to the point of crumbling into dust even under light load. Therefore, covering the outside of a wooden house with corrugated sheeting is the best choice. For at least seven reasons.

The first reason is fire safety. Corrugated sheet is a sheet of steel coated with galvanization or a polymer protective layer. Its ignition temperature is more than 1000 °C, which is practically unattainable in a normal household fire. Therefore, if you cover a wooden house with corrugated sheets, its walls will be reliably protected from an accidental spark, and a tight-fitting cladding will reduce the rate of flame spread if a fire starts inside the building.

The second reason is hygiene. Corrugated sheeting is not affected by fungus, mold and lichens; it is not eaten by insects and rodents. This means that the number of “inhabitants” of wooden walls, at least, will be greatly reduced, since in order to get to the tree, they will have to go through the cladding pie with a top layer of metal.

The third reason is durability. Of course, finishing a wooden house with a metal profile will not last as long as facing it with stone or brick. However, these cladding options are not for wood. But 20–50 years, depending on the type of polymer coating, is more than a realistic period for a profiled sheet. Corrugated sheeting with a PVDF coating lasts the longest - 40–50 years and even more, least of all - with a polyester protective layer, the service life of which is about 25 years when installing the sheet on a wall.

Polymer coatings for corrugated sheets

A detailed description of five types of polymer coatings for corrugated sheets: features, application, pros and cons.

A comparison table of properties that will greatly help you in your choice. Click and read! The fourth reason is moisture resistance. Moisture is the main enemy of wooden walls of a house. It causes wood to rot and is necessary for mold to appear. Corrugated sheeting does not absorb moisture, so covering a wooden house with corrugated sheets reliably protects the walls of the house from getting wet. Thanks to this, the impregnation against insects and fungi applied to the walls remains active for years.

The fifth reason is ease. Wall corrugated sheet C8 weighs only 4–5 kg per 1 m2. Even very old wooden walls can withstand this weight, unless, of course, they crumble in your hands.

The sixth reason is ease of maintenance. The profile sheet does not absorb dirt, so the lining of a log house with corrugated sheets can be cleaned of dirt with an ordinary damp rag. Moreover, with vertical installation, dust from the sheets is washed off with every rain, which is why the walls need to be cleaned no more than once a year.

Is it possible to sheathe a wooden house with corrugated sheets if it is old?

Yes, you can.

But in this case, it is necessary to treat the tree with compounds against mold, mildew and insects, as well as clean and replace rotten areas, if any. Finally, the seventh reason is aesthetics. In addition to the standard one-color profiled sheet, there is a decorative metal profile with a pattern like wood, stone or brick. This material is more expensive than regular material, but it looks better. For example, it is difficult to distinguish a wood-look profiled sheet from a distance of 4–5 meters from real wood cladding.

So, the advantages of corrugated board:

- fire safety,

- hygiene,

- durability,

- moisture resistance,

- ease,

- ease of care,

- aesthetics.

Step-by-step instructions for installing corrugated sheets on the facade of a house with your own hands

The design of a ventilated facade is simple, but installation is carried out in compliance with technical nuances. The essence of the cladding is that there should be an air gap between the profiled sheet and the base. Its thickness usually does not exceed 3 cm, but this arrangement of the facade allows air to circulate. At the same time, excess moisture does not accumulate on the base.

The installation technology consists of the following stages:

- Marking. On the surface of the facade you need to draw the placement points of the brackets. The step between them should not exceed 80 cm. Near window and door openings, this figure is reduced to 60 cm. It is better to retreat 20 cm from the corners of the building. After marking, you can calculate how much material and fasteners will be required for cladding the building. Now, using a drill, holes are drilled for the anchors and brackets. Their depth is 8-10 cm.

- Installation of fasteners. When installing the brackets, it is important to use a polyurethane gasket, which will prevent the appearance of cold bridges and destruction of the wall. To install one bracket you will need 2 anchors.

- Installation of heat insulator. Dowels are used for this. As insulation, you can use rigid materials (foam plastic) or mineral wool boards with a density of 80 kg/cub.m. They should be attached in each corner and in the center. You should not use rolled materials, as under the influence of their own weight they will slide down over time.

- Attaching the windproof membrane. It must have fire retardant properties. Installation is carried out from the bottom up with an overlap of 10-20 cm. This way, moisture will not get on the heat-insulating material. Dowels are used for fastening. Vertical panels should also be laid with an overlap of 10 cm.

- Fixing the sheathing. For its manufacture, a metal profile is suitable, which is attached to brackets. During installation, it is important to constantly use a building level. To prevent the profile from moving, it must be secured with a clamp, which is removed after all fasteners have been secured. After installing the vertical strips, the horizontal ones are attached. Their installation is not difficult.

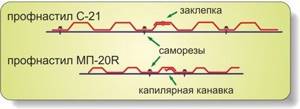

- Fixing the profiled sheet. The canvases are screwed together with an overlap of 0.5 waves using self-tapping screws. If you need to ensure a high level of structural rigidity, then fasteners must be installed frequently. The optimal step is through the wave. The vertical distance between the screws is 60 cm.

Lastly, the installation of additional elements and ebb linings is carried out.

The working process

To better understand the topic, it should be divided into stages:

- Selection and acquisition of materials;

- Collection of tools and accessories;

- Facade preparation;

- Frame construction and surface insulation;

- Fastening the corrugated sheet.

If desired, you can also find corrugated sheets that imitate stone

Stage 1 – purchasing materials

Let's figure out how to choose a quality option:

- Buy products with a polymer coating, as it is more reliable than a paint layer. Polymers adhere to the surface much better and do not break off when hitting a sheet;

This is what the structure of a high-quality corrugated sheet should look like; in addition to the polymer coating, there should be layers of zinc and primer

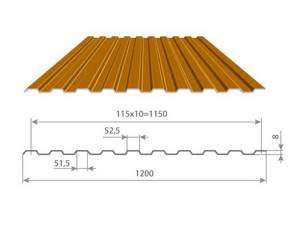

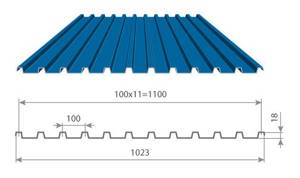

- Corrugated sheeting for walls is marked with the letter “C”, followed by the wave height indicator. I recommend using options C8 or C10, that is, their wave height is 8 and 10 mm, respectively.

More prominent options look worse and resemble a hangar or warehouse rather than the facade of a house;

Standard width 1200 mm, useful 1150 mm

- The thickness of the material should be 0.5 mm or more. Cheap options are most often made of 0.4 mm material, which is not durable or reliable;

- The price depends on the thickness of the sheet. The approximate figures are as follows: a 0.5 mm profiled sheet costs 240 rubles per square, 0.6 mm – 285, and 0.7 mm – 325 rubles. If you decide to use not a plain version, but one decorated to look like wood or stone, you will have to pay from 450 rubles per square meter;

Options with decor are much more attractive, but also cost twice as much

- If there is such a possibility, then it is better to order corrugated sheets cut into pieces of the required size. This will simplify the work process and speed it up, because cutting takes a lot of time.

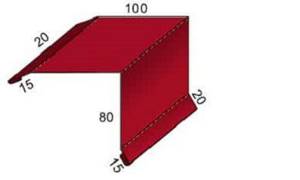

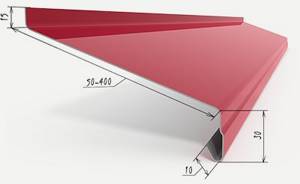

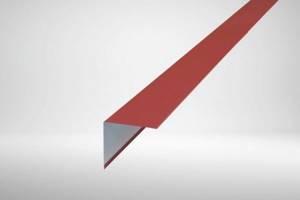

The design of the exterior decoration of a house with corrugated sheets involves the use of components at the corners, as well as the openings of windows and doors. For this, corners made of tin of the same color as the corrugated sheet are most often used. But you can also use contrasting color options to make corners and frames more noticeable. These products can be ordered in the size you require.

Corners can be made in any size

Sometimes the corners and slopes of windows are made of boards, this gives the house a special charm

In addition to the finishing material itself, we also need a solid base. The frame can be built from different materials; I will tell you about the three most popular options.

| Material | Advantages and disadvantages |

| Wood block | Options with a cross-section of at least 40x40 mm should be used, since the loads on the facade are significant. The advantages of the material are availability, low cost (13-15 rubles per linear meter), ease of processing and fastening. Disadvantages - low resistance to moisture, tendency to deformation due to temperature changes, short service life, especially if water penetrates inside |

| Profile for drywall | A guide profile (27x28 mm) and a main profile (60x27 mm) are used. The products are made of galvanized steel with a thickness of 0.4 mm (it is better to use 0.5 mm or more), standard length is 3 meters, the price is 100 rubles for the guide and 150 for the main one. This solution is better than the first, but there are still questions about reliability under high wind loads |

| L-shaped façade profile | In my opinion, this is the best option, which is highly reliable (made of 1.2 mm metal). Products of 40x40 mm are used, this is quite enough to create a durable frame. The cost per linear meter is 60-70 rubles |

L-shaped elements are durable and easy to use

Let's look at the fasteners:

- To position the frame perfectly evenly at the required distance from the surface, the easiest way is to use special facade brackets. They are L-shaped, the short side is attached to the wall, and the lathing is fixed on the long side . The length may vary, depending on it, the cost per unit ranges from 10 to 40 rubles;

This type of fastener is simple and reliable.

- The brackets are fastened with self-tapping screws (if the wall is wooden) or dowel-nails (if the base is made of brick or concrete). The length should be at least 40 mm, and if the material is unreliable, then even more;

Such fasteners allow you to carry out work quickly and efficiently

- It is best to fasten the frame elements together with self-tapping screws and a press washer. Choose one with a drill bit so you don't have to drill holes. The length may be short - 16 mm is quite enough;

- The corrugated sheeting is secured to the surface using roofing screws. They can have any desired color, which is convenient. The washer with a rubber lining allows you to reliably protect the attachment point, and the drill tip penetrates the metal well. For work, options with lengths from 19 to 30 mm are used.

Roofing screws allow you to securely attach the corrugated sheet to the frame

The last group of materials that we need is insulation and wind protection:

- For insulation, you can use mineral wool, polystyrene foam or extruded polystyrene foam. The main thing is to choose the optimal thickness so that during the coldest period of the year the house will be warm. For the middle band, the standard thickness is 50 mm;

The thickness of the insulation depends on the region

- Fastening of materials can be done either with special dowels (mineral wool) or with glue (foam plastic and extruded sheets);

- To protect the thermal insulation layer from atmospheric influences, it is necessary to cover it with a windproof membrane . It differs in that it does not let moisture in, but releases evaporation outside. This prevents rotting of structural elements due to moisture accumulating in them.

The membrane protects the insulation from moisture

The calculation is made based on the quadrature of the walls (do not forget to subtract the dimensions of the openings). Additional elements are measured in linear meters. The frame should be located in increments of 40 to 60 cm.

Stage 2 - collecting the necessary tools

Now let’s figure out what we need to do the work ourselves:

- To cut corrugated sheets (even if they are of the required size, it is worth trimming individual sections and making holes for pipes and other communications) special scissors or a jigsaw are used. The second option is often at hand; you just need to buy metal blades. Electric scissors can be rented and are much easier to work with.

It is imperative to use a special metal blade

Never use a grinder for cutting. When using this tool, the edges overheat, which subsequently causes corrosion.

- If you need to drill holes for dowels, you need a hammer drill with a drill of the appropriate diameter;

- It is best to tighten the fasteners with a screwdriver. For standard fasteners, the PH2 nozzle is used, and for roofing screws, the M8 nozzle is needed. All equipment can be purchased at any hardware or hardware store;

The bit for roofing screws can have different lengths

- All measurements are made using a tape measure. For marking, it is most convenient to use a felt-tip pen; it writes better on metal. The plane is controlled by a level of 1 meter in length. You will also need a construction cord to create guidelines during installation;

The level allows you to perfectly align all frame elements

- The insulation is cut with a hacksaw or a special knife. The film can be cut with scissors.

Stage 3 – surface preparation

Many people believe that if the facade is sheathed, then there is no need to prepare it in any way. This is a big mistake; heat will still escape through the damage, and pockets of dampness can develop into mold over time. .

To prevent this from happening, you should follow a few simple recommendations:

- First of all, the surface should be cleaned of dirt. If there are areas with poorly adhering plaster, then they need to be removed and re-sealed with cement mortar;

- If you have a wooden facade, then all cracks and dry joints must be repaired. If the width of the damage is large, then you can push insulation there or fill the voids with foam. If the cracks are small, they are simply covered with weather-resistant acrylic-based sealant;

It is advisable to repair cracks

- If the corrugated sheet will be attached to a wooden facade that has not been treated with paint or other composition, then an antiseptic must be applied. This is a mandatory condition for the safety of the material under the insulation layer. The composition can be distributed with a brush, roller or spray gun;

Antiseptic treatment is a mandatory preparation step

- If there are metal structures on the surface or the exterior of the balcony is finished with corrugated sheets, then the steel elements need to be protected. For work, it is best to use 3 in 1 compositions, which act as a rust, primer and paint converter;

Finishing the outside of a balcony with corrugated sheets requires high-quality processing of metal structures

- All pockets of mold, if present, must be treated with special compounds. If you have concrete or brick surfaces, you can additionally burn them with a blowtorch, this will definitely kill the fungus.

Stage 4 - frame construction

At this stage we need to carry out the following work:

- First, it’s worth determining what type of structure the structure will be. The racks can be positioned both vertically and horizontally. It all depends on the location of the corrugated sheet, because the fasteners must run perpendicularly. That is, if the sheets stand vertically, then the frame should be horizontal, and vice versa;

- Decide on the pitch of the profile or bar. After this, you can make marks on the wall so that you can navigate during installation;

- If the wall is made of brick, concrete or blocks, then you need to mark the position of the holes. Next, drilling is carried out to the required depth. At this stage, the most important thing is to control the position of the hammer drill so that you do not drill incorrectly. When the dowels are positioned evenly, they hold much better;

Drilling holes is a simple process, the main thing is to mark the surface correctly

- Next, the brackets are attached. If you have dowel-nails, then you can hammer them in; if you have ordinary dowels with self-tapping screws, then it is better to tighten them. It is important that each element is firmly fixed and does not wobble;

Elements are located strictly along the lines

- After attaching the brackets, you can begin laying the insulation. It is very important to remember a simple rule: there is no need to cut holes in the material where the brackets exit. Simply make a cross-shaped cut in the desired location . This will result in a better connection of the mineral wool to the surface without large holes through which cold can penetrate;

This is how you need to cut the material for the brackets, or even better, make thin cuts as in the photo on the right

- Additionally, mineral wool is fixed with mushroom dowels. It is important not to compress the insulation when fastening; you need to secure it and not deform it;

If you are finishing the facade with corrugated sheets from bottom to top, then I recommend insulating the base with extruded polystyrene. This material resists dampness much better, which means it will last longer even with constant humidity. Simply attach one row of polystyrene at the bottom, and place mineral wool slabs above.

This option is the most optimal

- The surface is completely covered with mineral wool; neat cuts are made at the locations of beams and other elements. The slopes can be additionally insulated so that there are no gaps around the perimeter;

High-quality insulation is an essential part of the work, since corrugated sheeting does not retain heat

- A windproof membrane is laid on top of the insulation. Neat slots are made at the locations of the brackets . Fastening to mineral wool is done using additional disc-shaped dowels or special clamps with a wide head;

When covering the facade with wind protection, the extruded polystyrene foam on the base does not need to be covered

To prevent moisture from penetrating at the joints of the windproof material, make an overlap of 100 mm.

- Lastly, the frame is secured. Elements, if necessary, are cut into pieces of the required length, after which they are leveled and screwed with self-tapping screws. In order not to be constantly distracted by controlling the plane, you can first secure the two outermost elements and pull a cord between them from above and below;

It’s easy to attach the frame over the insulation

- After installation is complete, check the plane between the posts with a level; the difference should not be more than a couple of millimeters . If there are problems, individual posts can be reattached, this is not difficult to do at this stage.

Stage 5 – fastening the corrugated sheet

This is what the correct design looks like in cross-section, we do everything using technology

The work instructions consist of the following steps:

The scheme of work is not complicated

- You should start work from a corner or junction. If you need to cut a hole or make a bevel, then the work is done after preliminary marking. You can also cut with hand scissors, but in this case it is better to use a tool for figure cutting so that you do not have to lift the cut part of the sheet when working;

Corrugated sheeting with a low wave can also be cut with hand scissors

- The sheet is applied to the wall so that you can make sure that it is the right size and fits accurately on the frame. Here you need to work with two assistants, since you will not be able to hold the profiled sheet and fasten it at the same time. But before starting work, study the figure below, which shows the correct position of the screws;

The screw must be positioned correctly

- The fastening is made through the lower part of the wave adjacent to the frame. The screws are simply screwed in with a screwdriver to the desired position. Fasteners are located in every second wave;

Self-tapping screws are screwed through the wave

To keep the fastening line straight, you can stretch the cord as a guide.

- Next, the next sheet is placed, the main thing is to correctly combine it with the already fixed element. After this, fastening is carried out in the same way as above. If elements are joined vertically, the top sheet should always be above the bottom to prevent water from getting into the joint. That is, installation is always done from the bottom up;

- If your wave height is large, then it is better to fasten the sheets together using fasteners. An option of the required color is selected, holes are drilled and the elements are tightened using a special gun;

High waves are pulled together by rivets at the joints

- Lastly, the corners and slope elements are attached. The main thing here is to cut the elements correctly so that they fit together perfectly. You can fasten the components either with self-tapping screws or with rivets, decide for yourself which is more convenient.

Window frames must be done carefully

The finished finish is easy to clean; dirt can be removed using a garden hose or mini-wash.

Material calculation

Before installing a facade made of corrugated sheets, it is necessary to calculate the amount of material. Since the canvas will be installed overlapping, and in some cases it will have to be cut, it is better to purchase it with a reserve. First, the area of the facade is calculated. To do this, the length of the wall must be multiplied by its height. The area of the adjacent wall is determined in the same way. These values must be added and multiplied by 2. Thus, you can find out the entire area of the building’s facade.

From the total value you need to subtract the area of all windows and doors. If the master does not have experience in installing ventilated facades, then it is better to purchase 15% more material. The area of the sheet itself is also taken into account.

Preparation for sheathing

First of all, it is necessary to measure the area that will need to be sheathed. Finishing of facades with metal profiles occurs using corrugated sheets of the PS-8, PS-10 and PS-20 brands. These types do not have condensate grooves, so they can be used without waste.

When calculating the amount of material, it is necessary to take into account the installation direction: vertical, horizontal or diagonal. You also need to buy additional elements: corners for doors, window openings, corners of the house, drains for the roof, strips for the plinth, and self-tapping screws .

How much will a ventilated façade made of corrugated sheets cost?

The cost of the material is affected by its type, modification, place of sale, as well as the reputation of the manufacturer. The price also depends on the thickness of the metal, coating, additional decorative finishing, and the presence of modifications. For high-quality sheets you can pay from 300 to 1000 rubles. for 1 sq.m. It is also worth considering the cost of additional elements and fasteners, insulation, windproof membrane, and metal profiles. Cladding the facade with corrugated sheets is considered a practical and profitable solution. It increases the service life of the building and improves its thermal insulation properties. The climate in the house will always be favorable. The walls will not be susceptible to the negative influence of atmospheric and biological factors. In addition, this material is cheaper than many other cladding options, and you can install it yourself.

Types of profiled sheets

First, let's get acquainted with the markings of corrugated sheets and analyze what certain alphanumeric designations mean. As an example, let's take the product C8-0.5-1160-11000.

Marking and application of corrugated sheets

The letter at the beginning of the marking demonstrates the purpose of the corrugated sheet. According to this criterion, sheets are classified into the following types.

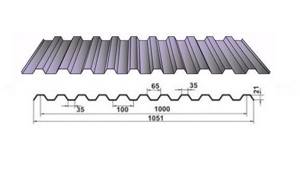

- C – wall corrugated sheeting . It is used for external decoration of walls and roofs of buildings, as well as for the construction of various fences and fences. It is characterized by low metal thickness, low value and relatively low load-bearing capacity.

- N – load-bearing or structural corrugated sheeting. It is used for the construction of industrial premises, workshops, garages and sheds. As a rule, material of this brand has a significant corrugation height and is made of thick sheets of metal.

- NS – universal corrugated sheeting , also known as roofing sheeting. A transitional option between wall and load-bearing corrugated sheets. NS corrugated sheeting is used mainly for finishing the roofs of industrial and private buildings, as well as for the construction of fences, canopies and canopies.

Variety of marking material

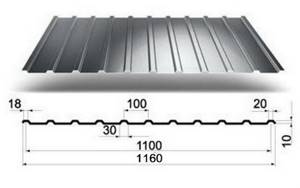

The number next to the letter indicates the profile wave height, expressed in millimeters. In this example, C8 means that we have a corrugated sheet intended for wall cladding, whose corrugation height is 8 mm.

Next you may notice three more numbers:

- 0.5 – sheet thickness, mm;

- 1160 – sheet width, mm;

- 11000 – maximum sheet length, mm;

Important! It should be remembered that in some cases the order of the numbers indicating the thickness, width and maximum length of corrugated sheeting may vary.

Table. Profiled steel sheets for house cladding are the most popular brands.

| Designation | Description |

C8 | The most common brand of profiled sheet for house cladding. Can also be used for the construction of lightweight fences. There are a large number of color options. The recommended spacing of the sheathing posts on which the C8 profiled sheet will be mounted is 60 cm. |

C10 | Profiled sheet with narrow waves, load-bearing capacity higher than C8. Also very popular as a decorative material. Analogues of sheet C10 can be designated as T10 or RAN-10. The recommended spacing of the sheathing posts is from 60 to 80 cm. |

C18 | Another example of a profiled sheet with a narrow corrugation, but at the same time significantly greater height. It is used not only for wall decoration, but also as a roofing material. When arranging the sheathing, it is necessary to place small stiffening ribs that will prevent the C18 profiled sheet from making popping noises in strong winds. |

S21 | Durable and rigid profile with wide corrugations. A universal material that is equally suitable for finishing walls/roofs and for erecting fences, partitions and canopies. Two sheets of C21 fit well together with a high degree of tightness. |

C44 | Strong wall corrugated sheeting with fairly high corrugations for this type of material. Very often it is used not so much for finishing houses, but for laying roofs. |

H57 | A universal material whose high strength is due to the use of thick metal and the presence of additional stiffeners. |

NS44 | Another example of a universal profiled sheet, but with a large number of stiffeners that increase the rigidity and strength of the material. |

Types of corrugated sheets

Description of corrugated sheets and selection rules

Profiled metal sheets are made by cold rolling steel. As a result, a wave-like profile is formed, which is a stiffening rib. The material is treated with anti-corrosion protection and can have one or two-sided polymer coating. Corrugated sheets are used in the construction of roofs, fences and other enclosing structures, and finishing of facades.

Metal profiles can be used to cover old buildings made of logs or timber, improving their appearance and increasing fire safety. The advantages of finishing include:

- durability;

- environmental friendliness;

- non-flammability;

- protecting walls from weather influences;

- originality of the facade;

- possibility of DIY installation;

- affordable price.

The disadvantage of metal sheets is that they are noisy; precipitation and wind cause them to make loud sounds. Proper installation using soundproofing materials and reliable fasteners will eliminate the problem.

The following is used as the outer covering of corrugated sheets:

- galvanizing – hot application of zinc prevents rust, the cheapest option, service life 15 years;

- plastisol - a layer up to 200 microns thick can have an embossed structure, is resistant to mechanical stress, the disadvantage is rapid fading, sensitivity to temperature changes;

- polyester - a polymer that is resistant to ultraviolet radiation, can withstand a wide range of temperatures, and due to its low price is the most common coating option;

- pural - the coating is not afraid of corrosion and sunlight, a wide range of colors, glossy or matte surface are offered;

- PVDF coating – the composition is resistant to any weather influences and mechanical damage, does not change color intensity.

The type of coating determines the lifespan of the finish. With proper installation, corrugated sheeting with a polymer layer will last at least 50 years. Decorative and protective coating is applied on one or both sides. You can sheathe the house with products with external paint, the other side will be hidden. Such sheets will cost less. Also, when choosing a facing material, take into account the dimensions of the sheets: thickness, length, width.

Advantages of purchasing corrugated sheets

The main use of corrugated sheets is the installation of fences. They are also used for cladding walls and roofs of outbuildings - garages, sheds, etc.

The cold-rolled steel base is given a rectangular, wavy or trapezoidal shape. To increase strength, the steel is coated with a zinc or aluzinc layer. An additional protective coating in the form of a polymer film can be applied on top.

Corrugated sheeting is not only cheap, but also practical. Has the following advantages:

- high resistance to external factors;

- fire safety;

- requires minimal care;

- durability;

- 3D effect.

A wide variety of corrugated sheet colors allows you to buy a roofing material that, in the opinion of home owners, creates the most aesthetically attractive exterior.

Using our online catalog, you can profitably purchase corrugated sheets by choosing the appropriate color, wave height, sheet thickness, and dimensions. You can pick up your order made online yourself from the nearest hypermarket chain in Moscow or use the delivery service from our company.

Sheathing the plinth and foundation

The basement part of the house is one of the most important.

The covering of such a surface must be done with high quality. When working, you need to remember that the result should be an acceptable appearance and protection from wet damage to the surface. It is not enough to purchase only profiled sheets for such finishing. You need to stock up on waterproofing and heat-insulating materials in advance.

Finishing the base begins with measuring the sheets

It is important to decide in advance what height and size the corrugated sheeting layer will have on the base part

To cut metal, you will need a grinder or special scissors designed for separating metal structures.

If the master's choice is a grinder, you need to take discs with the least thinness, but it is better to use scissors that can make a cut of the correct shape without defects.

Of course, working with scissors will slow down the whole process a little, but the edges of the product will be smoother than with other methods.

Ideally, it is better to select sheets in the store that do not need to be adjusted to your base, since they will already be suitable for use.

After cutting the sheets, they need to be impregnated with a composition of paints and varnishes. This will avoid burrs and cracks on the surface.

Sheathing process

Work on covering the basement of the building begins with the installation of a waterproofing layer. There are several ways of high-quality waterproofing of this building object:

- waterproofing using coating material.

Experts recommend using bitumen mastic as a reliable solution. The surface of the base is coated with this product several times so that it is thoroughly saturated.

It is also possible to use other compositions available on the building materials market.

In recent years, builders have begun to use membrane waterproofing.

This waterproofing material is distinguished by its high-quality composition, ease of installation and durability. To install this type of insulation, you need to cover the surface of the base with membrane material and secure it with special locks;

If the task is to use dense waterproofing materials, it is best to use adhesive protectors.

Any materials from the roll series are suitable for this process. The product is heated before gluing.

After carrying out waterproofing work, you need to make a frame on which the corrugated sheets will be held.

To create the sheathing, it is recommended to use wood or metal profiles. The sheathing is installed using dowels on special hangers.

If the master has chosen a metal profile as the base of the product, it must be fastened so that the lower ends serve as guides and are installed in a horizontal position.

Then the surface is insulated and finished:

- Insulation material is laid between the frame posts. It is recommended to use polystyrene foam or polystyrene foam.

- If the frame is made of a metal profile, then the corrugated sheet can be fastened using self-tapping screws.

It is important to take into account that the screws must be equipped with water-resistant gaskets. The joints will form cracks when strengthened

Such gaps must be covered with additional materials.

The process of cladding the basement segment of the building is carried out from the corner part.

The joints will form cracks during reinforcement. Such gaps must be covered with additional materials.

In the basement there should be places designated for ventilation openings of the building.

It is through such openings that the subfloor and basement floor in the house will be ventilated. Such places are treated with finishing strips.

If, after installing the corrugated sheeting, the corners do not turn out smooth, or defects appear on them, you can cover the inaccuracies with special corners, which are sold in hardware stores.

If the color of the installed sheets does not satisfy the interests of the master, it can be painted in a different shade. If the material wears out, after a few years it can be easily replaced with new sheets.

There are some types of corrugated sheets designed for repeated use. Sometimes craftsmen use used sheets to build fences or buildings intended for household needs.

How to cover the base of a frame house with a profile sheet with your own hands, see the video:

How to fasten corrugated sheets

Installation of a profiled sheet involves fixing it to the frame.

A galvanized self-tapping screw with a rubber gasket is used to secure the corrugation in increments of 35 cm. Self-tapping screws for corrugated sheets have a thread and a special tip in the form of a drill. They are usually made from high-strength alloy carbon steel grade C1022 with a finishing zinc coating. The design of the self-tapping screw with such a tip allows them to be attached to the frame without pre-drilling holes.

So, self-tapping screws for corrugated sheets with a diameter of 4.8 mm can drill through metal 2.5 mm thick.

Rubberized gaskets protect the cavities of the building material from moisture.

The sheets are always laid with an overlap of 5 cm. When cutting metal, the burr is removed so as not to cut yourself.

Additional elements are fixed along the entire perimeter of the house (corners, doors, windows). Then the building receives a complete and neat appearance.

Attention! Do not use a punch or nails. Fastening corrugated sheets with self-tapping screws

Fastening corrugated sheets with self-tapping screws

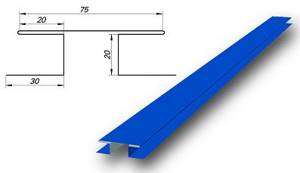

Additional elements for corrugated sheets

In addition to the sheets themselves, additional elements will be needed for finishing. Each of them performs specific functions and is an integral part of the house’s cladding.

| Item name | Purpose |

| Outside corner External corner | Used for framing external corners. Gives the skin a finished look and at the same time protects the joints from precipitation, dust, and small debris. Mounted on top of the corrugated sheet, as a result of which the screw heads remain visible |

| Internal corner Internal corner | It is attached to the inner corners of the building and performs protective and decorative functions. Mounted on top of profiled sheets, fasteners remain visible |

| External corner difficult | Performs the same functions as a regular corner, but it is attached to the sheathing before installing the sheets. This installation allows you to make hidden fasteners |

| Inner corner difficult | Installed in the internal corners of the facade before installing corrugated sheets, it performs protective and decorative functions |

| Intended for protecting and finishing sheathing joints on the wall plane. Attached to the sheathing before installing the corrugated board |

| It is used to frame the ends of the sheathing, protects them from the effects of precipitation, and gives a neat appearance. Attached to the sheathing before installing the sheets |

| Used for framing door and window openings. Protects against precipitation and debris, attaches to the sheathing before installing the sheathing |

| Performs the same functions as a complex docking strip, but is attached after installation of the sheathing, as a result of which the fastener heads remain visible |

| Molding | It is used to finish the joint between the facade of the house and the lining of the eaves overhang. Attached to the sheathing before installing corrugated sheets |

| Used to protect window sills from rain flows. Installed at the bottom of the window slopes before installing the casing |

| Platband | Used to decorate door and window openings, giving them a finished look |

| It is used to protect the upper part of the base from rain and snow, thereby extending its service life. Attached to the bottom of the sheathing before installing corrugated sheets |

As a rule, these products are produced in lengths of 3.2 and 1.25 m, although each manufacturer may have its own parameters. It is much easier to calculate their number than sheathing sheets, since here everything is measured in linear meters, and not in square meters.