As practice shows, finishing the façade with polystyrene foam makes it possible to ensure effective insulation of the house with minor investments, although there are some doubts about the safety and durability of the material. At the same time, correct installation of foam plastic cladding with the obligatory application of protective plaster guarantees high performance qualities of the cladding. Despite the fact that this polymer insulation is a budget option, the energy-saving effect of the material does not differ from the more expensive technoplex or penoplex.

Features of installing facade decor with your own hands

We have already touched a little on the description of the installation of facade slabs and the application of decorative plaster.

All that remains is to learn how to attach façade elements from the most popular materials. The easiest way to install foam products and parts made of polystyrene foam. Polyurethane parts of the facade are installed in the same way. This DIY facade decoration is so simple that even a person far from construction can handle it.

First of all, you need to remember that attaching foam parts is possible only in the warm season. The outside temperature should be between +15 and +25.

- Surface preparation is one of the most important steps. If the wall is not prepared appropriately, the elements will fall off over time. First you need to clean the surface of everything unnecessary - old paint, plaster, protruding parts. To do this, use sandpaper, a spatula, and in some cases a sander. Tap the wall with a rubber or wooden hammer. Where the wall is damaged, repair the surface and allow to dry. Another important point in preparation for installation is checking the surface with a level. When gluing slabs, unevenness of 10 mm per 1 square meter is allowed. When gluing small parts, it is good if the wall is perfectly flat.

- The next stage will be disassembling and fitting the parts. Lay out all the parts on the floor, check the labels on them. Remember that both the sandals and the moldings have extra length. Cut them to size using a special knife or small hacksaw.

Trying on parts

Attach multi-spikes to the wall along the entire plane of the part. They are necessary to keep the element from moving while the glue dries. Try the pieces on the wall.

Now you need to apply glue and attach the decor to the facade. Press harder, try not to let the glue protrude from the edges. Now coat the joints with acrylic sealant. After installation, it is advisable to paint everything.

Installation of decorative foam bricks on the corner of a building

Large facade structures are mounted on anchors or other fastening systems. You can learn how to install large polystyrene foam curtain rods using video instructions.

Video: Fastening large decorative elements

Decorating the appearance of a building is a creative matter, and you need to approach it with soul. At the same time, this is serious work, since the facade decor will be the first thing your family and friends see. If you want to make a uniquely beautiful home, then apply the information from this article, a little financial investment, artistic taste and time. Anyone can do this with their own hands.

Step-by-step installation

Facade decor made of polystyrene foam

Like any finishing work, installation of facade foam must begin with the preparation of materials and tools. For work we will need:

- Primer for facade or impregnation.

- Adhesive for polystyrene.

- Set of spatulas.

- Jigsaw.

- Pencil.

- Roulette.

- Building level.

- Roller.

- Plastic container.

- hammer

If everything from the list is at hand, you can proceed to the installation of façade foam blocks.

The first step is to thoroughly clean the façade surface. Remove everything unnecessary from it: sills, ventilation grilles, gutters, lighting fixtures.

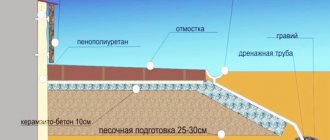

Insulation using foam plastic

If the façade surface was previously plastered, then it needs to be tapped all over with a hammer. Poor quality or old coating should fall off. All protruding irregularities and defects are also removed.

Ideally, degrease the entire facade using gasoline or solvent. This will remove possible oil and grease stains from the surface, as well as remove contaminants in the form of dirt and dust.

Important: if you install facade slabs on a non-greased surface, the glue will not obtain proper adhesion to the wall and will quickly lose its qualities.

When the facade surface is completely cleaned, it must be treated with deep penetration primer and impregnations that protect against fungus and mold. After this, the wall must dry completely, otherwise the glue will not set.

When the facade surface is completely cleaned, it must be treated with deep penetration primer and impregnations that protect against fungus and mold. After this, the wall must dry completely, otherwise the glue will not set.

Now you need to dilute the glue. To do this, pour water into a plastic container and, stirring constantly, add the mixture until it reaches a thick consistency.

Tip: you need to prepare the glue in small portions so that you have time to use it before it hardens. Drying time is approximately 30-40 minutes, based on this, you need to calculate the amount of the finished solution.

After a portion of the solution is thoroughly mixed, it should be allowed to brew for 5-10 minutes, after which it should be mixed thoroughly again. As you work, the mixture will thicken and will need to be stirred again, and perhaps add a small amount of water.

Using a notched trowel, apply glue to the surface of the foam facade block. The solution should cover the entire surface in as even a layer as possible.

Tip: when applying the solution to the block, you should leave about 5 cm on each edge, then when you press it against the wall, you won’t have to remove the excess.

Next, the facade foam block is pressed tightly against the wall, in this position it needs to be fixed for 10-15 seconds, this time is enough for the glue to set. If excess has come out from under the foam, it must be removed so that it does not interfere with subsequent joining. Now you can move on to the next slab.

Insulation of a private house using polystyrene foam

The next foam segment must fit tightly to the previous one with as little gap as possible, otherwise the joints will have to be removed with joint grout, which is extra work and additional costs.

When the façade finishing is completed, holes are drilled in all the necessary places and items removed before finishing are installed. Now all that remains is to secure the decorative elements in the form of stucco molding and cornices. They are made from exactly the same reinforced facade foam, which means their installation is no different from the installation of slabs.

Advice: decorative facade elements and the foam blocks themselves must be from the same manufacturer, then their colors and textures will not differ.

At this point, the finishing and insulation of the facade are completed, and you can forget about them for the next 30 years, and this is exactly the warranty period that manufacturers give for foam plastic facade slabs.

Window and door decoration

TechnoNIKOL adhesive foam for quick and high-quality installation of polystyrene foam and XPS

Decorated window and door openings immediately attract attention. Previously, all home decor was aimed specifically at decorating them.

When drawing up a design project for windows and doors, you need to be moderate, because their design should not deviate from the overall style of the house. For example, a building lined with metal siding will look funny with stucco on the windows and plaster angels above the door. To select details for finishing these parts of the building, you need to imagine their types. We list the main decorative elements with a short description of each.

Sandriki

Sandrik is a decorative component above the door and window opening. Previously, this part served as protection from rain. It protruded more strongly and was made of wood, concrete, brick or plaster. Today, sandriks can be purchased separately or as a set with other window decor.

Sandrik

Moldings

Molding is used everywhere for finishing buildings. They decorate the perimeter of windows and doors. Molding can be used to decorate the base or base of the roof. On windows, facade molding can serve as a platband. Moldings are among the accessories for facade slabs, or you can purchase them separately from polyurethane or foam.

Decoration with moldings

Arched frames

The name itself says that they are used for round and semicircular windows, and sometimes doors, if the style of the house implies just such doorways. Today you can purchase or order a solid arched opening or one consisting of segments.

House with arches

False shutters

These decorative parts of the facade are hung on windows for beauty. These include false panels for window decoration. The panel is usually mounted under the window opening. It can be made from any decorative material or wood.

These are just some of the details that can be used to decorate your home. There are still many of them; it is quite difficult to cover everything in one article.

Window decorated with false shutters and false panels

Features of the material

Advantages of polystyrene foam:

Foam boards come in different thicknesses

- light weight, reducing the load on the load-bearing elements of the roof structure;

- ease of installation and processing with working tools;

- resistance to temperature changes and certain mechanical loads;

- low thermal conductivity due to 98% air content in the material;

- long service life;

- retains its properties and shape in a humid environment, is not afraid of mold and mildew;

- affordable price;

- environmental friendliness;

- fire safety (the material melts without ignition);

- hypoallergenic.

Flaws:

- release of harmful substances when exposed to open fire;

- the ability to accumulate a small amount of moisture, which can cause the formation of mold and mildew on rafters, sheathing, finishing materials and corrosion of metal fasteners;

- the impossibility of completely filling the niche between the rafters due to rigidity; this leads to the appearance of condensation and cold bridges;

- the material is almost impervious to air;

- rodents can live in polystyrene foam (this does not apply to extruded polystyrene foam);

- afraid of contact with solvents, alcohols and petroleum products;

- ultraviolet radiation destroys the foam.

Standard foam sheets have dimensions:

- 500 mm x 1000 mm;

- 1000 mm x 1000 mm;

- 2000 mm x 1000 mm.

The thickness of the insulation falls within the range of 10-100mm. In the marking of foam plastic, the number indicates the density in kg/m³. When insulating a roof from the inside or outside, the PSB-S-15 and PSB-S-25 brands are more often used.

After studying the characteristics and comparing them with other types of heat insulators, each owner independently decides whether it is possible to insulate the roof with foam plastic, or whether another material is suitable in his case.

What is this

Advantages of silicone plaster for facades and application technology

What exactly is stucco? These are products made from various materials that complement the appearance of your home, decorate it with original architectural solutions, introduce notes of different eras, and emphasize the strengths of your chosen style.

The original facade stucco molding can be presented in the form of:

- Columns;

- Half-columns;

- Bases;

- Moldings;

- Baluster;

- Slopes;

- Arch;

- Pilaster;

- Eaves;

- Bassages, etc.

This is not the entire list of elements that manufacturers offer today. Among them there are domestic companies, such as Europlast. The Europlast company produces an impressive range of stucco moldings of various types. Unlike foreign analogues, they are cheaper, but at the same time they are not inferior in quality to well-known Italian, French or British manufacturers.

Features of choice

You should choose stucco for the facade carefully so that the planned decor has the best possible effect on the appearance of your home, and also does not harm its structure.

Pay attention to a few basic questions during the selection process

Elements. You should not use all kinds of stucco products at the same time, as this will negatively affect the opinion of your taste. Excessive overload of elements will only do harm. Choose décor options that will highlight your home's strengths or that will turn bland architectural design elements into the center of attention. Material. Stucco molding is made from various raw materials. The Europlast company offers façade stucco moldings of excellent quality. But each material, including Europlast products for the facade of a house, has its own strengths and weaknesses

We will talk about this in more detail today. Weight It is important to take into account that the decor will load the walls of your home. Therefore, estimate the weight of the future decorative structure. In some cases, installation of stucco molding made of gypsum, concrete or polymer concrete may require additional strengthening of the facade to avoid deformations and collapses in the future. Price

The cost of products directly depends on the quality of the raw materials used for its production, as well as on the complexity of decorative elements for facades. Natural products are cheaper than artificial ones, since their production costs are higher.

And as I said above, from a protective coating.

There is a huge selection of protective coatings on the market now. Our company has tried almost all of them, from Russian manufacturers to Turkish mixtures. They have proven themselves to be market leaders very well, their mixtures are of high quality and over the 5 years of our cooperation we have not had any defective batches of the mixture. Our company uses a sand-acrylic mixture on a quartz base; it allows you to create clear corners and beautiful transitions with curves. To put it simply, you will end up with a façade element that will have straight corners that are 90 degrees and not a floated corner that won’t look nice.

Foam facade molding

Metal profiles for roofing: advantages, installation stages

Previously, molded curls, curves, ornaments and bas-reliefs, which gave the building a complete look, were made from plaster and concrete by casting. At the same time, the customer could choose a pattern only from the available casting molds. Making stucco from these materials is a labor-intensive process that requires high qualifications.

Figured foam products for facades, imitating such decorations, are now cut from the densest and finest grade of material - PSB-S-35. Lightness, elasticity, ease of gluing decorative parts - the advantages of modern stucco do not end there. Thanks to the protective coating, it is not affected by ultraviolet radiation, does not crumble or turn yellow. The finishing coating allows you to disguise stucco as marble, plaster, wood and natural stone.

Basic installation rules

To secure finished parts, you do not need special skills - you can easily do it yourself, achieving additional savings.

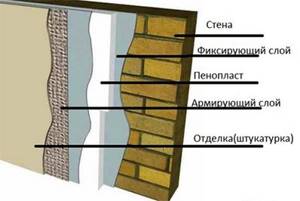

1. Preparing the base. It must be clean, dry and level. If insulation is carried out, then the gluing of the facade foam is carried out after plastering and priming.

2. Marking. Using a plumb line and a building level, vertical and horizontal lines are drawn.

3. Fixation of the material. Apply a uniform layer of Merolith S95 adhesive to the reverse side of the decorative products using a notched trowel. If there are protrusions and dents of 3-15 mm on the walls, the adhesive mixture is applied in sections of 8-10 cm at intervals of 5-7 cm. The foam element is attached to the base and pressed down firmly so that the gaps between the edges of adjacent elements do not exceed 3 mm. The parts are secured with facade dowels, recessing their caps by 3-4 mm, and remove excess uncured glue with a spatula.

4. Processing of joints. This important process makes the elements elastic and avoids cracking. When the structure is dry, the joints between the decor and the base, and the gaps between the foam parts are sealed with Merolith S1 joint compound. If the temperature is above +20 °C, the seams are sanded after 24-48 hours.

5. Final finishing. Completely dry parts are primed and painted. The durability of the coating will help preserve castings made from materials such as metal or plastic.

https://youtube.com/watch?v=4xByJXvgxsk

Practical application of foam plastic on the facade

Above we mentioned all the options for using polystyrene foam on the facade. The only thing they didn’t mention was the decorative insulating material – thermal panels, the installation of which allows you to simultaneously improve thermal efficiency and decorate the walls. This approach is much more profitable than using expanded polystyrene in a ventilated facade, when you first need to install the frame, then the insulation, and then hang the panels.

Everyone knows how to count money, so foam plastic is generally installed on the facade according to two schemes: as a base for plaster, and as an independent cladding. All that remains is to consider these methods in more detail and understand their nuances.

Plaster base

Installation of the insulating foam layer, on top of which the plaster will be applied, consists of 11 main stages.

Table 1. How to prepare the base

| Steps, photo | A comment |

Step 1 – priming

Thermal panels

To insulate external walls while simultaneously decorating them, panels made of rigid facade foam are used. On top it is lined with a decorative layer, which is also designed to protect the insulating part from external influences. This could be artificial stone tiles, clinker, marble chips, or a layer of textured fiber-reinforced concrete.

In terms of configuration, the panel itself may also look different:

- in the form of a rectangle with rustication or other texture;

- modules with jagged ends imitating brickwork;

- long length, joined in a similar way to lock siding (it is called thermal siding).

Why is polystyrene foam attractive?

Decorative products made from natural materials, of course, look presentable and give the building individuality and uniqueness. But they are so heavy that installation of such decor requires additional strengthening of the walls and even the foundation. And polystyrene foam elements are so light that they are suitable for installation in houses that have been in use for a very long time.

In addition, there are other distinctive features that allow this material to become so popular:

- Poor thermal conductivity. Installing such decorative elements will help retain heat inside the house.

- Chemical and biological inertness. Facade elements made of expanded polystyrene remain in good condition after exposure to alkalis and acids. But fungi and mold cannot develop on such a substrate.

- Temperature stability. The material does not deform when heated or strongly cooled.

- Has moisture-repellent properties. Therefore, it is able to protect the main structure from the influence of water.

- Long service life.

- Affordable price.

- Simple and quick installation of polystyrene foam elements.

But you need to be prepared for the fact that such excellent material also has disadvantages. There are few of them, and they are not so significant, but they can cause some difficulties both during transportation and installation, and during operation.

- The material has electrostatic properties, so a lot of dirt and dust collects on the surface.

- Expanded polystyrene is easily damaged during installation and transportation. Therefore, it is better to take parts with a reserve.

- Although the substance does not burn, it melts when exposed to fire and can release caustic substances.

- Such decorative façade elements require additional protective coating to extend their service life.

Features of using polystyrene foam as insulation

Polystyrene foam, as a thermal insulation material, has become widespread. It is relevant for the construction of residential and industrial facilities, and has a lot of positive qualities. Most people choose it because of the low cost and ease of installation of foam sheets on walls .

Easy to install and accessible

The technical characteristics of the material are almost identical to modern analogues, but, at the same time, polystyrene foam remains accessible to the majority. The cladding technology is not complicated, which reduces the final cost of finishing work. On average, the price of a cubic meter of polystyrene foam is 2,000 rubles, while the same amount of mineral wool will cost from 4 to 6 thousand. But, even if the materials cost the same, for work on insulating a specific surface, a smaller amount of polystyrene foam is required than mineral wool.

An important advantage of the material described is ease of installation. Installing the sheet does not require the creation of an additional supporting structure, since a special adhesive composition .

The material is suitable for insulating any surfaces: walls , ceilings, floors, facades, roofs and even interfloor ceilings. Less commonly, polystyrene foam is used to insulate walls inside the house.

The main advantages of polystyrene foam

This material, as insulation, has many positive qualities.

Advantages of façade cladding with foam plastic:

- the material is resistant to moisture and practically does not absorb it;

- good thermal insulation;

- mold or mildew does not form on the surface of the foam;

- easy to process and install;

- small weight;

- availability;

- lasts a long time;

- resistance to temperature changes;

- serves as an additional sound insulator;

- no waterproofing required.

The only disadvantage of this finishing material is that when burned it releases harmful substances into the air. But this drawback is evened out - before installing the sheets, the wall surface is treated with special protective compounds.

EPS or EPS: polystyrene foam or extruded polystyrene foam

Both materials are made from polystyrene, but differ in production technology. According to finishing specialists, EPPS is better suited for insulating facades, as it is more durable and has excellent thermal insulation and strength characteristics.

Figure 2. PPS slabs for facade insulation.

If we consider the difference in numbers, we get:

- the water absorption parameter of EPS is 10 times less compared to polystyrene foam;

- EPPS is characterized by better heat transfer resistance – 1.3 times;

- compared to EPS, extruded polystyrene foam is 2.5 times stronger and 1.2 times heavier;

- EPPS is finding wider application.

Based on these data, we note that the use of extruded polystyrene foam is beneficial not only from the point of view of insulation, but also saving money. Less heat is lost, and accordingly, the amount for heating will also decrease. EPS is more demanding in terms of installation, therefore, when finishing the facade with expanded polystyrene , the surfaces must be plastered .

Possibility of using polystyrene foam as insulation for wooden walls

Often the walls of houses are insulated from the inside with slabs of ordinary foam plastic In this case, one rule applies - additional hydro and vapor protection is installed. When making interior finishing, a gap is left between it and the insulation, which will eliminate settled steam.

For wooden walls, foam is considered not the best material due to low air permeability. This leads to a greenhouse effect being created in the room, that is, the walls do not have the opportunity to “breathe”. The issue is being resolved by installing additional forced ventilation, and this is good for the wallet.

Insulation of facades with foam plastic

It is quite possible to insulate a private low-rise house yourself, using polystyrene foam decor for the facade. The main points of the technology are outlined below:

1. Preparing the walls. They are cleaned of dirt and mortar, milled, cracks are plastered, and a primer is applied.

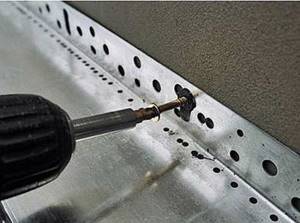

2. Fixing the starting profile. The dowels are placed at intervals of 30 cm, the distance between the profiles around the perimeter is 2-3 mm.

3. Preparing the foam decor for gluing. If the base of the facade is flat, special glue (for example, ceresite SM11) is applied to the entire surface of the sheets using a ridge spatula. If there are obvious deviations of the walls from the vertical, 3-6 beacons are placed on each insulation slab. After this, the adhesive composition is applied with a roller to at least 40% of the sheet area.

4. Gluing the material. Foam panels for facades are glued horizontally, from bottom to top, in a checkerboard pattern. They are pressed well against the wall, tapping them with the palm of your hand or a special grater. Excess adhesive mixture is removed, after which the cracks are sealed to avoid the formation of cold bridges: small gaps are insulated with polyurethane foam, medium ones with sealant, wide ones with pieces of polystyrene foam. To ensure that there are no joints in the corners of window and door openings, they are framed with solid sheets of insulation with holes cut in them.

5. Fixation. Drill holes, insert dowels with disc-shaped plastic caps (4 in the corners and 1 in the center), screw in the spacer cores. The corners of the facade, door and window openings are reinforced with corner elements.

6. Material reinforcement. Using a notched trowel, a plaster solution (2-3 mm) is applied to the foam plastic slabs for facades, a polymer fiberglass mesh is installed with an overlap of 10 cm, and evenly covered with a second layer of the mixture.

7. Application of decorative coating. After the obligatory primer, facade plaster is applied in two layers so that the thickness of the layer covers the caliber of the filler grain. Finally, the walls are coated with paint based on lime and cement or liquid glass.

Decor of facades made of foam plastic. Advantages, manufacturing method

You can refine a building using various architectural details: keystones, cornices, columns and pilasters, platbands, window frames, moldings. Decorative elements for facades are made from foam plastic and have many advantages over their counterparts made from other materials:

- moisture resistance - unlike gypsum and wooden structures;

- light weight and ease of installation - compared to stone products;

- wide range of colors;

- variety of forms;

- durability;

- affordable price.

First, the parts are cut out of ordinary foam plastic using the contour thermal cutting method (with a hot wire). In industrial conditions, this is done on a computer machine, having previously programmed the shape of the product.

The finish acquires additional protective properties by applying a reinforcing layer to it - in this case there is no contact with the external environment at all. After cutting out the part for façade decoration, it is covered with alkali-resistant fiberglass mesh. The next few layers are a cement-adhesive mixture of deep penetration, creating a film on the surface with a thickness of at least 1.5 mm. The parts become stronger, more resistant to ultraviolet radiation, and they no longer attract dust. In addition, the film is the basis for painting.

Special types of decor

Facade foam plastic successfully imitates various natural materials and accurately reproduces a complex molded surface.

Foam plastic under the stone

To decorate the corner areas of the building, foam facing stones are used. In appearance they cannot be distinguished from marble or granite. The relief is formed due to protrusions relative to the walls; a particularly interesting look is obtained with different textures.

Optical effects appear with different installation techniques of foam decor for the facade (in the horizontal or vertical direction, diagonal, offset). If you place the material vertically along the corners, the building takes on a solid and durable appearance. Elements laid across the column make it more elegant. Dimensions vary from 200x200 to 350x700 mm, thickness - 30-50 mm.

Criteria for choosing polystyrene foam for facade finishing

The first question related to the purchase of insulation material concerns the choice between polystyrene foam (EPS) and extruded polystyrene foam (EPS). Both options are made on the basis of polystyrene, but differ significantly in characteristics:

- polystyrene foam has a density of 17 kg/m³, while the same indicator for expanded polystyrene is 35 kg/m³;

- EPS is susceptible to environmental humidity, EPS practically does not absorb moisture;

- Rodents and insects love polystyrene foam, while pests are indifferent to polystyrene foam.

With good characteristics, foam cladding costs half as much as its “brother.” The main disadvantage of expanded polystyrene is its high cost; prices for a sheet with dimensions of 1200x600 mm vary in the range of 4,400-5,200 RUR/m³ depending on the thickness. In this case, preliminary treatment of its surface is required for the next stages of cladding, and this is an additional waste of time. A big plus for EPS is the extremely low risk of cold bridges due to the small number of direct joints when installing insulation.

Facade decor made of polystyrene foam

Architectural elements used in the design of buildings made of polystyrene foam are exceptionally light in weight, as well as resistant to natural influences. In addition, reinforced polystyrene foam has high strength, which makes it possible to produce facade decor of almost any complexity and in any buildings.

Watch this video on YouTube

Decorative elements are quickly made from polystyrene foam. Their use significantly reduces financial costs.

The dimensions of the decorative finishing elements of the facade remain unchanged and no cracks appear on them. This decor is safe for health and non-toxic.

Facade elements can withstand temperature changes, and, accordingly, facades can be made from this material in any climatic zones and latitudes.

Today this type of facade decoration has become very popular; it is also used in the restoration and construction of buildings. It also has a special place in the design of facades of country houses. Facade decor made of expanded polystyrene has been used for decorating facades for more than 50 years.

Modern decor facade made of exclusively natural materials - stone and wood.

Modern and unusual decor facade made of white polyurethane.

The decor of the facade of the building is made of natural wood, which has retained its original texture and color.

Modern façade decor made of polyurethane and natural wood using tinted window glass that does not let in hot sunlight.

White facade decor with a combination of black details and natural wood elements.

Modern facade decor made of polyurethane and natural wood, which also combines contrasting dark elements.

Modern facade decor made of natural dark wood, with large panoramic window openings.

Modern facade decor made of natural gray stone using small metal parts.

Classic façade decor made of natural stone using a gable roof.

Classic facade decor with plaster and cement trim on the windows and doorway.

Terracotta panels for facades

Terracotta facade tiles are created from ceramics obtained by firing special types of clay. Modern terracotta slabs are a practical and reliable facade material. It is produced in the form of large-format slabs, which are characterized by ideal geometry. Facade terracotta visually looks expensive and impressive. Terracotta facade panels have natural and soft colors. On sale you can find soft beige, red-brown and grayish versions of products. Facade panels are attached using a hidden method. Therefore, the terracotta facade looks elegant and graceful. You can purchase such facade slabs directly from the manufacturer. Terracotta panels have many advantages:

- The tile coating is smooth and even.

- The products are characterized by a smooth geometric shape.

- Light weight of the slab.

- The panels have sufficient strength and density.

- Installation of the products is not difficult.

- The material is not flammable.

- Low degree of water absorption.

- Frost resistance.

- The surface has the ability to self-clean.

Manufacturers produce facade panels with various types of surface. Products can be absolutely smooth, rough or embossed. Each option deserves special attention and is perfect for facade decoration. Glazing is used when it is necessary to create a shiny surface or achieve brightness of color.

Manufacturers also offer consumers panels with wood or stone textures. Despite their simplicity, terracotta slabs for facades attract many property owners who want to decorate the exterior walls of their home in an original way. This material is of natural origin. There are no visible fasteners on the facade, since the panels are installed in a hidden way. Such panels are often used to design ventilated facades. But it is necessary to take into account that such material may cost more than other finishing options.

Installation of facade decor made of polystyrene foam

At the beginning of the installation of decorative elements, you need to clean the finishing surface, level it and prime it with a binding solvent. It is necessary to ensure maximum tightness of contact between the polystyrene foam and the wall, without cracks or gaps.

The components to be decorated are attached to the base as follows:

Drilling holes in the decoration for dowels in advance. There must be at least 5 pieces per linear meter. This will make the fastening procedure easier. Applying glue to the part to be decorated. Fitting and pressing façade polystyrene foam to the base. This must be done with little force so as not to crush the material.

The second step is to join the components to be decorated and seal the gap. It is done using specialized foam adhesive and a mixture for sealing seams. These are means that provide good gluing and sealing of joints and cracks. The thickness of the adhesive mixture must be less than five millimeters. This also applies to the gaps between the joints; they must be finished before sealing with a specialized primer mixture. The primer, for its part, must get deep into the gap.

Stage three consists of final cladding.

After the above stages, the time comes for work related to the primer and the actual painting of the components. The primer should have quartz sand in its composition, and the paint should have a flexible structure, the color - according to your desire. At points of sale there is a great opportunity to find a wide variety of paints just for facade work. Farb must be applied in 2 layers.

To increase the operating time of the façade decor, it must be protected as much as possible from the influence of humidity. When installing decorative strips, try to attach them with a downward slope so that water flows. You can also install a roof drain, which will have silicone sealant sealed at the joints.

Certain installation points

There are several tips that affect the magnitude of the method and the very element of its fastening to the base:

Components up to 10 cm can be attached using a single foam adhesive. Components from 10 to 35 cm are attached not only with dowels and adhesive. It is recommended to install a drain over such products. Decorative elements larger than 35 cm must be secured with glue and dowels, and then (this is already a necessary procedure) a drain must be made over them, which will have an individual supporting system.

We conclude that with the help of facade decoration made of polystyrene foam, we can not only visually change the building, but also positively hide various imperfections on the surface of the walls. With a subtle approach to façade components, execution of proportions and a thoughtful image will certainly create a building of amazing beauty and give it grace.

Do not forget, no matter what material is selected to decorate the building, it must certainly fit into the architectural ensemble of the street or block. And when decorating the facade, it is necessary to take into account the system and architecture of the building.

Architecture and its adjacent decorative elements depend on the prevailing fashion of the current time, as well as on the imagination, professionalism and experimentation of the architect. Having found specialists in their field, you will certainly be satisfied with decorating from such a unique material as polystyrene foam.

Preparatory work

Insulating the facade with foam plastic begins with preparing the walls. Let's immediately say when it is better to start work - in the warm period of time. But the most important indicator is the humidity of the walls. They must be dry. After the rain, it is advisable to wait a week for dry, preferably windy, weather. After that you can start.

Preparation of external walls

Preparation for insulating the facade with polystyrene foam begins with cleaning everything that flakes and falls off. If the walls were covered with paint, it is removed, the lime is cleaned off. If there are swollen areas of plaster or tiles, they will be resurfaced. Only what holds tightly should remain.

You need to clean everything that can fall

Then it’s time to level the walls. It is very good if the insulation boards lie on the wall with their entire surface, without voids. But such walls are the exception rather than the rule, therefore unevenness of about 1 cm per square meter is acceptable. Protrusions and holes that are large in depth/height must be leveled - filled with plaster mortar (pre-primed) or cut off. The smoother the surface, the easier the work will be.

To prime or not

There is no need to prime only those walls; running your hand over them will leave your palm clean. If there are white marks, pieces of plaster, sand, etc., it is better to prime it. This will ensure better contact of the glue with the wall. The operation takes little time, is simple, requires little money, and has great benefits. So if you are doing the insulation of the facade with foam plastic or EPS “for yourself”, it is better to prime it.

Priming is a simple process, but very useful.

Any primer is suitable for facade work. Normal companies are Ceresit, Master, Stolit, Kreisel, Tokan, Ekomix. The primer is diluted or not, depending on the release form and instructions, applied with a brush or spray. Spraying is faster and easier, but using a brush is better.

Preparation of EPPS

If you decide to insulate the walls outside with expanded polystyrene (EPS), its surface must be made not so smooth. Polystyrene foam has a looser structure and does not require preliminary preparation. You need to make scratches on the surface of the EPS, otherwise it will fall off from the glue.

Tools for preparing EPS

Take a spiked roller, which is used to process drywall, and roll it well in all directions. The second way is to take a brush with metal bristles and make grooves with it. Softer methods don't work. The work is not hard, but it takes a lot of time. This must be done before you begin installing polystyrene foam on the walls. If the insulation is laid in two layers, it is necessary to process the sheets for both layers.

Finishing window sills, slopes, ebb

It is better to install all elements - window sills, slopes and ebb (drip) before installing the insulation on the walls. When installing, you need to remember that you will still have a significant thickness of insulation + finishing. If window sills and slopes have already been installed, they will have to be replaced - they will be too short. In order for everything to look organic and fit easily into the insulating pie, the elements must have the following dimensions:

- The window sill should protrude beyond the plane of the wall by 3-4 cm (more or less is not necessary). If the insulation thickness is 60mm, you will need a window sill 100-110mm deep (60mm insulation, 10mm finish, 30-40mm overhang). When installing a window sill, all voids must be filled. You can lay thermal insulation plates, fill the gaps with polyurethane foam and lay a window sill on top of it all, load it with something heavy and leave it for 3-4 hours.

Insulation of the facade with polystyrene foam begins with the slopes - When separating the slopes, they should protrude beyond the plane of the existing wall (without insulation) by 1 cm. This will make it easier to connect it with the insulation. They sit it on glue (the same one that will be used when insulating the facade with foam plastic). There is another subtlety here: finishing the slopes requires insulation of a smaller thickness - 20-30 mm maximum. The thicker one will simply “climb” onto the glass (don’t forget about the presence of finishing layers, leave about 10 mm on them).

- Between the base and the insulation, a drip line is installed (also called a “drip cap”). This is a strip of galvanized steel with powder paint. It is mounted on the base with self-tapping screws or dowels (depending on the material of the base) in increments of 20 cm. Sold in pieces of two meters, during installation one piece overlaps the other by 10-15 cm. The ebb is necessary so that water flowing down the wall does not flow into the house, and merged into the street.

Installation of ebb (drip)

As you can see, the preparatory work before insulating the facade with foam plastic (polystyrene) also takes time. They are not complicated, but have a significant impact on the overall result.

Decorating the facade of the house with decorative elements

What are the decorative components of the facade and why use them in architecture and decoration. This question does not arise when you see ancient buildings in Moscow, Venice or St. Petersburg. The beauty and uniqueness of the decoration attracts, you want to touch it. Such buildings are remembered for a long time. All this happens thanks to decorative elements.

Various arches, rustications, capitals, columns, platbands, balusters, rosettes and much more make the image of the building complete. The house takes on its own personality. Looking at ancient buildings, we often don’t think about what it’s all made of, and we are absolutely sure that it is impossible to do this on the walls of our own home, but this is not so.

Facade decor

Stucco molding

The word stucco causes a grimace of rejection among many. For most of us, it means something ancient, necessarily white and definitely not suitable for a modern home. What is it really? Only façade stucco can create elegant details and subtle reliefs on the façade. Previously, it was made of plaster. This is an environmentally friendly material that allows you to make facade decor directly on site or cast it in ready-made molds. But it also has disadvantages. First of all, it's weight. Plaster parts are very heavy and put a noticeable load on the building. Installation of such decorations is difficult, which is why in the old days many large decorative elements were made directly on the facade. In addition, gypsum is destroyed over time under the influence of atmospheric changes.

Restoration of gypsum stucco

Yes, gypsum stucco can give the building a chic look, but today gypsum has been replaced with stronger and lighter materials that are not inferior in beauty to plaster. Polymer concrete combines the strength of concrete, but is ten times lighter. Installation of these products is simple even with your own hands, and in terms of aesthetics they are not inferior to plaster. The peculiarity of the composition is that it can imitate various structures, for example, granite and marble. The photo shows how polymer concrete imitates old stucco.

Window decoration with polymer concrete

An interesting and very popular building composition for home decoration is glass fiber reinforced concrete or fiber reinforced concrete. It is made from dry construction mixtures with fiberglass additives. Its strength and lightness allows it to be used to make columns and other supporting architectural elements. Many multi-storey buildings in Moscow are finished with glass fiber reinforced concrete.

Stucco molding made of glass fiber reinforced concrete

Decor with polyurethane

A new structural element that has found its niche in decorating private homes is polyurethane. Lightweight, durable, wear-resistant material that is easy to install with your own hands; all you need is special glue. Polyurethane belongs to the facade decor of the middle price category, but its qualities are worth the expense. After all, polyurethane is not only durable, but also elastic, so façade elements made from it do not deform or delaminate.

Polyurethane stucco molding

Decor with polystyrene foam and polystyrene foam

One of the most popular textures for making decorative facades is polystyrene foam and expanded polystyrene. Lightweight, unaffected by precipitation, frost-resistant and indifferent to all types of fungus, it has several more qualities, due to which the façade parts are much cheaper than the previous ones.

Facade decor made of polystyrene foam and expanded polystyrene is made using non-molding technology, and therefore does not require expensive molds for its production. For production, a string cutting mechanism with digital computer control is used. The dimensions of the finishing components are unlimited, since it weighs almost nothing. The surface of the foam elements is reinforced with an acrylic fiberglass mesh, onto which a coating of cement-adhesive composition is applied. After all the manipulations, the product resembles a plastered surface.

Sectional view of façade decor made of expanded polystyrene

Fiberglass decor

Fiberglass or fiberglass composite is becoming a durable and effective replacement for concrete, polyurethane and polystyrene. Not only decorative elements are made from it, but also facade panels. Fiberglass composite does not deform, does not corrode, is resistant to any temperatures, but at the same time is very light.

Fiberglass facade

Advantages and disadvantages of use

Finishing the facade with polystyrene foam and plastering are considered one of the most profitable ways to insulate a house:

- foam plastic cladding has high thermal insulation properties;

- the cellular structure of the finishing material determines excellent sound absorption characteristics;

- The panels are not difficult to transport due to the low weight of the product. Also, due to the lightness of the material, there are no difficulties in installation work;

- polystyrene foam is resistant to pathogenic microorganisms;

- the material is offered in a wide variety of models;

- foam finishing is sold in the budget segment;

- If the installation technology is followed, the cladding can last at least half a century.

An important advantage of using this cladding is the ease of installation. Any beginner who has the minimum necessary knowledge and skills can handle the work of decorating the facade of a house with polystyrene foam and plaster.

Disadvantages of foam cladding:

- Due to their high toxicity, some types of foam finishing cannot be used when arranging the facades of residential buildings;

- the material is highly flammable and releases harmful substances when burned;

- foam sheathing is an attractive object for rodents and insects;

- significant waste during installation work due to the high fragility of the material.

Foam cladding is an attractive object for rodents and insects

Due to the high fire hazard, foam plastic finishing is not used when arranging the facades of public buildings, buildings of children's institutions and hospitals.

FACADE DECOR OF A PRIVATE HOUSE EXAMPLES OF WORK

Take a look at our selection of beautiful facades of private houses with facade decoration. You will certainly get a lot of ideas for decorating your facade.

PROJECT No. 1501

Project for finishing the facade in a Mediterranean style house on the coast of Spain.

An interesting option for using the dark color of facade stucco - contrasting color combinations always make a bright impression.

Decoration of facades of private houses

Characteristic finishing elements in the Mediterranean style were used: brackets under the roof overhang, arched details and columns.

PROJECT No. 1502

Classic design of the facade of a one-story house in clinker tiles.

House facade decor made of polystyrene foam

The corners are decorated with a bright and figured upper profile - a capital. The plaque under the window opening is a classic example of the design of first floor windows.

House facade decor: photo

PROJECT No. 1380

The technique of finishing an arched opening may be interesting. The stucco molding is large in size and covers only the top of the arch.

The castle completes the picture. At the corners of the house, classic pilasters with flutes are proposed.

Decor of house facade windows

PROJECT No. 1506

One example of decorating the facade of a private house with a bay window. The finishing option for a large staircase window is made of two stucco elements located at a distance from each other.

Decor for the facade of a house made of polystyrene foam

Painting the space between them a darker color relative to the main wall color adds visual interest to the front of the house.

Exterior decor of house facade

The combination of clinker tiles and bark beetle plaster always produces a richer impression due to the complexity of the façade design.

Decor of the corners of the house facade

PROJECT No. 1051

An example of the maximum budget design of the facade of a private house for two owners - a duplex.

Simple techniques with zoning always give excellent results

House facade wall decor

The seemingly complex façade of a private house is actually achieved using very inexpensive finishing techniques: two colors, clinker and just a little bit of architectural stucco to indicate the boundaries of the materials.

Final finishing: applying protective plaster

Before you start plastering, profiled corner strips with mesh sides are installed at the corners of the facade. To reinforce the plaster layer, an external painting mesh is used. The working solution is applied to the surface of the foam sheathing from the corners and carefully leveled.

An hour after completion of the work, the coating is rubbed down for finishing in the form of acrylic paint or decorative plaster, or cladding with facade panels.

Artistic decoration plays almost a decisive role in creating the architectural appearance of buildings. Thanks to the opportunity to buy facade decorative elements made of foam plastic in Moscow, the walls of city buildings no longer look gray and dull. They acquire original protruding forms, attracting the attention of others and creating a positive emotional mood.

Modern facing materials for house facades from the collection of our online store can turn any cottage into a work of architectural art.

Properties of expanded polystyrene

Low heat conductivity and thermal increase. Has thermal conductivity from 0.037 to 0.041 W/(m*K). This value determines the ability of expanded polystyrene to transfer internal energy from more heated parts of the material to less heated ones.

The compressive strength with small deformations will be at least 0.1 MPa. With high bending, the strength of polystyrene foam will be at least 0.18 MPa. With a wide range of temperature conditions (-180...+80 °C), the design of the material remains the same over a long period of time. Also, the material can maintain a temperature of +110 °C, but only for a short period of time. For example, this may be contact with hot bitumen.

Resistance to various chemical-based substances, as well as biological influences. Polystyrene foam is not susceptible to chemical substances such as lime, alkali, gypsum, salt water, soap, weak acid solution, bitumen, anhydrides and much more.

Resistance to water and moisture. When exposed to wet weather or rain, it does not change shape or swell. It is not considered a breeding ground for various fungi and microorganisms; naturally, it is not subject to decay. Despite the low density of the material, it has great strength. considered an unusual sound insulator. If there is any noise on the street, then foam with good soundproofing will ensure silence in the building. Light weight. Ease of installation. Excellent adhesion to each other and to other repair or cladding components. The warranty period is up to seventy years, provided that all parts are treated with a protective substance or a specialized solvent.

Environmentally friendly. The composition contains environmentally friendly substances, namely carbohydrates and hydrogen, which fill polystyrene foam granules. Does not have electrical conductivity parameters. Does not support the flammability process.

The pricing policy is quite loyal to consumers. When polystyrene foam is damaged, no substances harmful to the environment are released.

Selection of materials

Before work begins, many questions arise regarding the choice of materials. The most pressing one: which polystyrene foam is best for insulating the outside of a house? For these purposes, the PSB-S-25 brand product is optimally suited. Among the convincing arguments in favor of this choice is the optimal combination of thermal insulation properties and strength. Of course, polystyrene foam for walls with a density of 15 retains heat better due to more air bubbles. But the opinion about its high efficiency is erroneous due to the presence of a number of negative aspects:

- the material crumbles heavily during installation;

- cutting sheets exactly is quite difficult;

- it is extremely difficult to rub the sheet with a grater;

- plaster is applied poorly;

- The wall surface is not sufficiently resistant to mechanical stress and is very easy to push through.

Therefore, the preference for the PSB-S-25 brand is quite justified.

The choice of foam thickness for insulating outside walls depends on a number of factors:

- The desired effect. It’s one thing when you plan to insulate a frame house with polystyrene foam, and a completely different approach when calculating the thickness if you plan to insulate a garage with polystyrene foam.

- The climate of the region, average temperatures during cold periods, and wind strength also matter.

- Wall surface material and subsequent finishing. Usually, at the final stage, the external thermal insulation layer is plastered and painted. Sometimes they are finished with foam plastic under the siding.

The calculation of the thickness of the thermal insulation material for a brick wall deserves special attention. A layer that is too thin will not cause the dew point to shift. In this case, moisture accumulating in the brick will provoke its premature destruction. The worst case scenario if the insulation layer is too thin is that the water will turn to ice and the foam sheet will come off.

Advice! If you need insulation with a product 100 mm thick, it is better to purchase a double set of 50 mm. Overlapping installation will eliminate the appearance of cold bridges at the joints of the sheets.

The question of whether polystyrene foam is harmful when insulating walls from the outside is, in principle, not relevant. But even when used internally as thermal insulation, the material does not pose a danger due to the absence of substances harmful to health.

The choice of fiberglass mesh deserves attention. Its fixation in an alkaline environment provokes the destruction of the reinforcing fibers after some time.

Therefore, it is important to find a mesh impregnated with a special composition that prevents the development of destructive processes

The composition of the plaster, which will be used as the final finishing of the walls after insulation, also matters. The most common options:

- Acrylic. Due to the dense structure it lasts a long time, but the vapor permeability is not high enough.

- A vapor-permeable cement mixture (mineral plaster) is suitable for treating the surface of walls after insulation with polystyrene foam or expanded polystyrene. It reacts well to changes in humidity and temperature, but over time it begins to crumble.

- Silicate breathes well, even suitable for mineral wool. The protective layer is durable and does not crumble.

For garage insulation, you can choose inexpensive plaster; restoring individual crumbling areas will be quite simple.

Research papers writing help

So, the research paper involves the disclosure of a specific topic, as well as a statement of own views on the problem. In structure, this is similar to a large abstract and includes several parts. The main distinguishing feature of research paper is that writing occurs preferably in an academic style. The difficulty of preparing high-quality paper lies in the fact that it is necessary to successfully cope with three tasks at once: to conduct research, to skillfully provide results, to fully answer the questions posed, if any. How to prepare a competent and interesting paper? Alternatively, you can order the paper in advance or at the end of the time. However, it is worth remembering that not every author will be able to write such paper in general. A research project prepared by a qualified performer will definitely be worthy of competing with the work of other speakers.

Everyone knows that our life is unpredictable. No one knows what awaits him around the bend. So in student life, you never know what will happen tomorrow. The reason for the unwritten research paper can be anything: a disease, injury, family, work or travel to another city. All these reasons are real and can happen to anyone. In order to avoid problems at the university, you can ask for help in special online services. The authors work by writing student papers. Such companies that can provide help write a research paper are in great demand in the market of goods and services of intellectual property. Specialists are engaged in writing papers of various types. Their task is to create an ideal product that will be clear to you, and will also be interesting to the listener. You can be sure that with these services you will receive only the highest marks for your paper.

In order to write a good research paper, you need to attend all year's lectures and seminars, as well as practice and take all laboratory papers, if your course provides for this. Only after all this knowledge is already in your possession will you be able to write good paper, which will be understandable and interesting to the commission and to listeners as well. It is very easy to buy research paper. You can contact the special support services for students. There you will talk to the authors and discuss all the details of your future paper. Also, you can chat with the master himself, who will work on your text. With him you can already discuss all the nuances of this paper. Together you can come up with interesting details about your paper.

This is a very hard work that requires full commitment and patience. You should understand that working with such texts should completely absorb you. If such a return does not work, then it is better to use professional services as the experts already have a lot of experience in such a business. In addition, for the entire existence of such an industry, many customers have already been satisfied with the result that was presented to them. As a rule, the thoughts of a person are always interesting to read, and the thoughts of an intelligent person fascinate with their beauty and diversity. Specialists do not care about the complexity of the paper. The authors will be able to cope with projects of any size and level.

Finishing facades with foam plastic for a unique design of your home

If the construction of your own house has already been completed, then it’s time to think about finishing its facade. If you have not yet chosen a suitable material for yourself, then finishing your facades with foam plastic can be an excellent choice; this material can become a real highlight of your home. Using this material, you can easily emphasize the beauty of your entire home or any specific part of it.

Before you buy polystyrene foam to decorate the facade of your house, you will need to measure the walls to understand exactly how many slabs you will need for this. To do this, simply multiply the width of the walls by the height, but do not forget to add more for the seams, and also do not forget to subtract door, window openings and building slopes.

The installation of the foam itself is not at all complicated; moreover, such work takes very little time. First, using a tile spatula, apply glue to a sheet of foam plastic, and then level the sheet with the flat side of the tool, and only then with a comb. You will also need to apply another layer of glue directly to the wall. Next, the foam is pressed against the wall and tapped with the palm of your hand. At the same time, it is very important not to overdo it with glue, since when heated, this material can expand, and then, due to poor elasticity, cracks will appear in it.

The process of creating decorative elements

To cut a specific part from polystyrene foam, a special machine is used that operates according to the selected program. Everything is done precisely according to size, so there is no reason to worry that the parts will not match in thickness or other parameters.

After the element has received its shape, it must be processed in a certain way to create the required strength.

- Volumetric elements, without a large number of small patterns, are first covered with fiberglass. It performs the function of reinforcement. If there is no such coating, then the strength decreases.

- The next layer is a cement-adhesive composition with mineral and synthetic additives. The thickness of the layer will also depend on the decorative elements made of polystyrene foam (where exactly it is installed, what pattern).

- If an element has a large number of small parts or a complex geometric shape, then it is not possible to cover it with reinforcing fiber. That’s why a special protective compound is used here.

Conclusion

If you decide to create a house facade, all work needs to be divided into three main stages:

- Design or architectural design of the facade (you will need the help of an architect), although the price of the work is steep, it will allow you to bypass all the pitfalls and with this architectural project it is easier to explain to the manager what you want.

- Once you have a project in hand, then you contact the manager for the production of decor. For example, you contacted us. You can come to us, including for production. We will give you catalogs, samples, or we will come and take measurements ourselves. This project that the architect created for you will be exactly what you need from you. Or if you know what you want, then in the process of measuring or conversation we find out what you need, in what quantities.

- Also, the main stage after production is the installation of products. There's nothing complicated about it. You can install it yourself or hire a team of installers.

If after reading the article you have any questions, call us, our managers will help you.

Insulation options

First of all, I note that there are two ways to insulate a house with polystyrene foam:

| Insulation methods | Peculiarities |

| Wet facade technology | In this case, the walls are covered with foam plastic, after which they are plastered using a special technology. This method of insulation is the most economical; in addition, it has other advantages:

However, the technology also has some disadvantages:

|

| Curtain facade | The essence of this technology is the installation of a frame, which is sheathed with special facade materials (siding, lining, facade panels, etc.) In this case, the insulation is located in the space between the sheathing and the insulation. This technology has the following advantages:

The disadvantages include the following:

|

Thus, before deciding on the type of insulation technology, it is necessary to estimate all the pros and cons.

An example of finishing using wet facade technology

Sequence of installation of external insulation

Important. The primer for finishing with polystyrene foam must be designed specifically for the material from which the building is constructed. Acrylic-based primer mixtures for concrete plastered surfaces, for example, not only increase the adhesion of materials and ensure the strength of the finish, but also protect the walls from the occurrence of fungal and mold processes under the cladding.

- Fastening sheets of foam plastic to the prepared surface using special adhesive mixtures for polystyrene foam boards.

When finishing the facade of a private house with polystyrene foam is carried out independently, many make the following common mistake - they purchase a more expensive adhesive composition, deciding that the higher price is due to the quality and composition of the adhesive mixture. This is not entirely true.

Different adhesive compositions are designed for use in different climatic conditions. For example, in areas where winter temperatures do not exceed twenty degrees below zero, it is not at all necessary to use an adhesive composition that has high frost resistance. And increased frost resistance naturally increases the cost of polystyrene foam glue.

Advice: Carefully study the composition of the adhesive mixture, as well as its technical characteristics. More expensive is not a synonym for better.

- Additionally, the insulation sheets are fixed to the wall using self-tapping screws;

Important. Attaching foam sheets must be done from the bottom up. In order for the material to be installed level, it is first necessary to secure a guide bar parallel to the wall.

- After the lined surface has dried (on average three days), the joints between the plates are grouted; large gaps can be filled with polyurethane foam;

Advice. In some cases, during work on the exterior decoration of houses, it is necessary to achieve a more dense shrinkage of the adhesive mixture. Craftsmen advise adding a soap solution or ordinary detergent to the adhesive mixture, which gives the composition elasticity and ensures good shrinkage.

Reinforcing mesh

- Finishing facades with foam plastic also involves installing a reinforcing layer on top of the insulation. The mesh should be pressed tightly against the insulated wall and fixed at the edges. Reinforcement protects the insulation from impacts and gives strength to the finish;

- After the reinforcing layer has dried, the walls are finished with plaster.

The finishing of insulated walls can be very varied.

Advice. The formation of “cold bridges” should not be allowed when externally insulating the façade. Such problem areas most often arise in places where cornices are attached, insulation is connected to window and door frames, as well as in places where utilities are installed. It is important to carefully treat with polyurethane foam and insulate the junctions of metal structures with insulation.

Finishing facades with foam plastic - stucco decoration for the exterior of your home

After you have completed all of the above steps, the foam will need to be secured using dowels, which will need to be nailed in all four corners. And places near doorways and near slopes require cutting of this material.

After absolutely all the foam sheets have been fixed to your facade, it’s time to putty. First, painting corners are attached to all corners and slopes. And then a layer of putty is applied, and it is very important to note that if you plan to apply another finishing material to the foam, then you will also need to apply a reinforcing mesh on top of it. Then you can move on to grouting the joints, then after that your unique facade will be completely ready.

To increase the thermal insulation of a home, in some cases, polystyrene foam is used as insulation. In this case, you don’t have to putty it, or you can attach only two dowels to each sheet of foam plastic.

When using foam panels to decorate the facades of private houses, home owners can subsequently significantly reduce heating costs by approximately 30%. At the same time, this finishing of house facades with polystyrene foam makes the building even more beautiful and attractive, and that is why it is so in demand. As for the costs of such repair work, they are minimal, because polystyrene foam is a completely inexpensive material, and if you do not want to spend money on cladding your own home, then you should choose it.

Types of expanded polystyrene - pros and cons

In northern latitudes, thicker insulation slabs are used

How to choose the right option for the required insulation, and what technical characteristics of the material should you focus on?

- All types of foam plastics have low thermal conductivity. For example, one layer of medium-density foam is comparable in thermal insulation properties to a 40-centimeter-thick finish of pine or sixty centimeters of aerated concrete. Therefore, the affordable price of polystyrene foam makes this material a leader among modern insulating materials.

- It is worth noting that the ability to absorb noise depends on the structure of the foam itself - porosity. Closed porosity (all types of expanded polystyrene, extruded polyethylene and polyvinyl chloride foams) provides sound absorption with a frequency of 1600-2000 Hz. This means that footsteps will be heard, but the fan or air conditioner will not. It is worth paying attention to this fact when choosing polystyrene foam for finishing the facade.

Note! The open structure of the granules, characteristic of polyurethane foam, ensures that the cladding will protect the room from any noise.

Let's take a closer look at the different types of polystyrene foam insulation.

Extruded polystyrene foam

An example of thermal insulation of a one-story building

They can be produced by pressing or non-pressing method. On the shelves of construction supermarkets you can often find insulation materials produced using the non-press method, since pressing significantly increases the cost of finishing.

Plates produced by the pressless method are marked with the abbreviation “PSB”; an additional letter on the marking indicates a modification of the material. For example, “PSB-S” is self-extinguishing polystyrene foam.

For reference: Expanded polystyrene boards produced by pressing, which ensures greater strength of the material, are marked “PS”.

It is important to note that the instructions for insulating the walls of residential buildings in areas of high humidity, as well as in places with high groundwater levels, do not recommend the use of extruded polystyrene foam as insulation. Despite the fact that the technical characteristics of the finish indicate water absorption from 0.2 to 0.4 percent, the material tends to accumulate moisture.

Since air cavities are formed between the granules, this allows water vapor to penetrate the material. When the temperature drops, condensation increases the humidity of the finish and reduces the thermal insulation properties by up to ten percent.

An increase in the humidity of the finish at low temperatures leads to the destruction of the thermal insulation layer. Water, freezing in the body of the foam, expands and destroys the slabs. Therefore, in regions with high average annual humidity, as well as in places with high groundwater levels, moisture-resistant insulation materials should be chosen.

Extrusion foam

Thermal insulation of a brick building with extruded polystyrene slabs

This type of insulation has zero water absorption, is durable and resistant to mechanical stress. The price of such material is an order of magnitude higher than that of conventional polystyrene foam, but this is justified by its unique properties:

- Durability – service life up to 80 years;

- Strength and resistance to deformation;

- Excellent water-repellent characteristics;

- High noise absorption;

- High-quality thermal insulation.

The only disadvantage of this insulation is its high flammability. Therefore, when choosing materials for exterior finishing, you should pay attention to the marking - self-extinguishing polystyrene foam “PSB-S”.

Important. Regardless of the choice of foam type for the external cladding of the building, it is necessary to protect the finish from fire using plaster. Finishing the facade with foam plastic and plaster is necessary not only for decorative purposes, but also to comply with fire safety measures.

Polyethylene foams

The photo shows the main types of extruded polyethylene foam

Extruded polyethylene foam is produced in the form of sheet panels of various thicknesses. This finish has a translucent color, the material is elastic and can be easily mounted on any surface. Often used as insulation for floors and roofs.

The photo shows all the stages of finishing the insulation layer

Insulation of private residential buildings using polystyrene foam is an affordable and easy-to-install option for external cladding, which can be done independently. We hope that the video in this article will help you understand all the nuances of the correct choice of materials for the exterior decoration of houses and the step-by-step implementation of the corresponding cladding work.