A ventilated facade made of porcelain stoneware allows you to successfully solve a whole range of problems that arise when cladding the walls of buildings:

- Protects against dampness - the ventilation gap makes it possible to create air circulation under the cladding, remove accumulated moisture, and prevent the occurrence of fungus;

- gives the building a respectable appearance;

- allows you to effectively insulate a building - timely removal of moisture does not allow the insulation to become damp and freeze.

In this article I want to look at the features and nuances of constructing a porcelain stoneware façade.

Design features of the ventilation façade

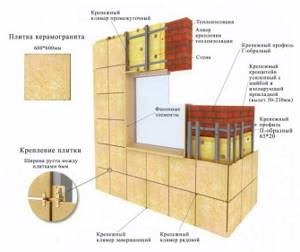

Ventilated facades made of porcelain stoneware consist of four components:

- Frame, which is installed directly on the facade wall of the building;

- Insulation and waterproofing;

- Porcelain stoneware cladding;

- Additional nodes and elements.

Frame

The frame is intended for fastening porcelain stoneware slabs to the walls of a building. It consists of a system of guide profiles and fasteners; installation is carried out on a load-bearing wall using dowel-nails or anchor bolts.

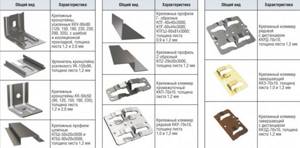

The profile for porcelain tiles is made of stainless steel or aluminum alloys, and comes in two types - horizontal and vertical.

Wall-mounted fasteners are a system of brackets, the installation of which is carried out by fastening to the wall and supporting frame. The special design of the brackets makes it possible to adjust the size of the gap between the wall and the porcelain stoneware. Thanks to this, on the one hand, it is possible to more effectively ventilate the interior space, and on the other, to level out unevenness of wall surfaces.

Insulation and waterproofing

The technology for installing a ventilated facade made of porcelain stoneware involves the creation of thermal insulation and waterproofing layers. The following materials are most often used for external insulation of a building:

- Expanded polystyrene sheets;

- Mineral wool slabs;

- Polyurethane foam.

The table below provides comparative characteristics of the thermal conductivity of various thermal insulation and structural building materials.

Installation of the ventilated facade cake is carried out according to the following scheme:

- Internal vapor-waterproofing layer located between the concrete or brick surface and thermal insulation;

- Insulation layer;

- The outer layer of waterproofing laid on top of the insulation;

- An air gap used to ventilate the space under the facade;

- Porcelain stoneware cladding.

Decorative porcelain tiles

Porcelain tile is a composite material made from a mixture of clay, quartz, feldspar and, if necessary, various pigments. All components are thoroughly mixed, pressed and fired in high-temperature ovens.

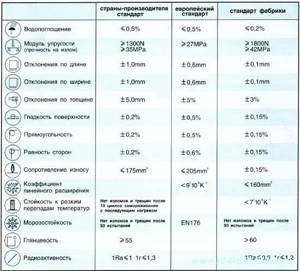

Table 1. Comparative characteristics of porcelain stoneware and ceramic tiles.

There are several types of porcelain tiles on sale:

- Technical – the most budget option. In appearance it practically does not differ from natural stone; it has an untreated surface. Used as flooring and for finishing internal and external walls of industrial, commercial and warehouse premises;

- Glazed. It has a smooth glossy surface and can be tinted during the production process with pigmenting compounds;

- Satin. Its front part is treated by applying a solution of mineral salts, as a result of which it becomes matte. Also during production it can be painted in different colors.

Facades are most often installed using glazed tiles, due to their high aesthetic qualities; matte satin porcelain tiles are less commonly used.

The main difference between tiles for ventilated facades and tiles for interior work is the requirements for them. She must:

- be resistant to external loads;

- do not lose color saturation and brightness under the influence of ultraviolet radiation;

- be resistant to changes in temperature and humidity;

- It is good to tolerate exposure to acidic, alkaline and other aggressive environments.

The linear dimensions and shape of the slabs can vary significantly. Facade porcelain tiles 600x600 mm are the most common option. It has an acceptable weight, and the equal length of the sides simplifies the marking and installation of frame guides.

Table 2. Requirements for the quality of porcelain stoneware for ventilated facades.

Additional nodes and elements

Additional components include various sealing materials and additional elements: gaskets made of paronite or rubber for installation under fasteners, decorative inserts for sealing joints between tiles. Inserts can be made of aluminum or polymers - polyurethane, polyvinyl chloride, etc.

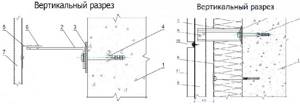

Nodes

In order to obtain units of ventilated facades, it is necessary to obtain an Album of Technical Solutions from the manufacturer.

In this article we will present some nodes from different albums of our choice. But you should understand that the node published here is not necessarily suitable for the system you choose. Standard nodes, common to almost all systems, look like this:

Installation techniques

There are two technologies for installing ventilated porcelain stoneware facades:

- Hidden fastening method;

- Installation using clamps.

Hidden fastening of porcelain tiles

Hidden fastening of the facade to the frame subsystem is carried out using anchor elements. The hidden fastening option allows you to get the visual effect of a solid wall, without visible joints or seams.

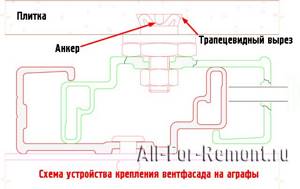

Several installation technologies can be used depending on the frame subsystem used. One option is to use agraph:

- A trapezoidal recess is drilled on the inner surface of the tile;

- An anchor bolt of a special design is inserted and secured into the recess;

- Hinged fasteners are screwed to the anchor bolt - the so-called “agraphs”;

- The tiles, using agrafs, are attached to the supporting base - transversely fixed guides.

Another option is to cut slots on the end part of the tile (either pointwise or along the entire end surface), and then use them to fasten the porcelain stoneware to the profile (see photo below):

This facade fastening scheme makes it possible to obtain a surface with high decorative qualities and ventilate the interior space. At the same time, hidden fastening of porcelain tiles is very labor-intensive - installation time and the total cost of work increase.

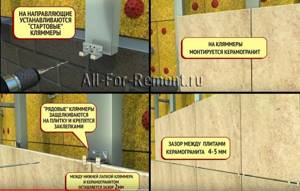

Fastening using clasps

Clasps are plates made of stainless steel or duralumin, equipped with curved “legs” into which facing tiles are inserted. The clamps are secured to the frame using self-tapping screws or bolts.

Because This technology is the most common (due to its relative simplicity compared to the “hidden” method). Let’s consider this particular method of finishing buildings with porcelain tiles.

Main functions

By installing ventilated facades, you can solve several problems at once: ensure reliable protection of the building from the destructive effects of moisture, wind and temperature changes, reduce energy costs due to thermal interlayers, improve sound insulation of the interior space, extend the service life of the structure, create interesting decor with a wide range of colors and designer finishing.

In terms of their functionality, ventilated facades are universal systems that provide great opportunities for standard and unusual solutions.

Installation of a ventilated facade

Installation of porcelain stoneware on the facade using the open method is regulated by the provisions of SNiP No. 3-01-85 and is carried out in several stages:

- Preparing the wall surface;

- Installation of frame fasteners;

- Installation of thermal insulation layer and waterproofing;

- Assembly of the supporting frame;

- Installation of facing tiles.

Preparing the wall

First of all, you should assess the condition of the wall surface - it should be relatively flat, without obvious bumps and depressions. Minor differences from the vertical can be leveled out using the free movement of fasteners provided for by the design. Large defects will need to be corrected with plastering work.

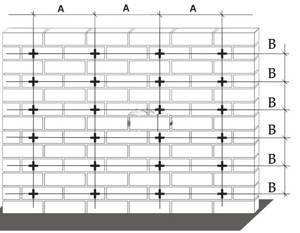

The next step is to mark the surface, which is applied depending on the façade design. The wall is marked for fasteners on which guide profiles will later be installed.

The first marking method can be seen in the following video:

The second marking method involves the use of laser levels that have both vertical and horizontal adjustments. Work begins from the very bottom of the wall: using a level, a starting line is drawn along the ground. In the same way, with a step equal to the height of the selected porcelain tile, the entire wall is marked with horizontal lines.

Next, at intervals corresponding to the width of the selected facing slabs, marks are made - at the intersection of horizontal and vertical lines the frame fasteners will be located.

The brackets must be positioned so that the joints of adjacent slabs fall in the middle of the profile.

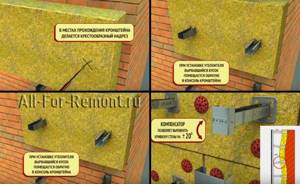

Installation of brackets

The brackets should be mounted using a hammer drill and anchor bolts. Particular attention should be paid to the projection of the bracket - it depends on the thickness of the insulation layer (see below). It is necessary that after installing the frame profiles and facing slabs, there should be a ventilation gap of 3-5 cm between the wall and the thermal insulation.

To compensate for heat shrinkage (cycles of compression and expansion under the influence of temperature changes), gaskets made of paronite or dense rubber are installed between the brackets and the wall.

Various options for mounting brackets manufactured by Crospan

Air gap system design

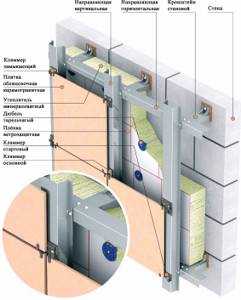

The ventilated facade consists of:

- load-bearing base;

- substructures;

- layer of sound and heat insulation;

- parapermeable membrane;

- a gap providing ventilation;

- decorative finishing.

Each element of the substructure consists of load-bearing profiles and brackets, which are secured to each other with rivets and to the wall with an anchor. Various cladding elements are also used, which are attached to a slide with glue, a clamp and other elements.

Each element of the substructure creates a single frame system. Materials for cladding the building are installed on it.

Using the substructure, the facing elements are securely fastened, creating a ventilation gap.

Installation of insulation and waterproofing

After installing the fasteners, you can begin installing the vapor barrier and insulation. Isopan or other similar materials are used as a vapor barrier membrane - they allow excess moisture to be removed from the walls, while at the same time preventing it from passing through from the outside.

A layer of insulation is laid on top of the vapor barrier. The thickness of the thermal insulation depends on the thermal conductivity of the material and on the minimum winter temperatures for a given region. The required thickness of the heat-protective layer is calculated using the following formula:

R=δ/k , where

- R – required resistance for a given region;

- δ – thickness of the insulation layer;

- k is the thermal conductivity coefficient of the insulation.

Thermal resistance indicators for various regions of the country are given in the provisions of SNiP No. 230199 on construction climatology, and are given below.

The most often used for façade insulation are:

- Minvata;

- Expanded polystyrene;

- Polyurethane foam.

Mineral wool is supplied to the market in the form of rolls or slabs, which differ in density and thermal conductivity. It is attached to the wall using special plastic mushroom dowels with a wide head.

When using mineral insulation (glass wool, slag wool, basalt slab), you should remember that they are very susceptible to dampness.

When mineral wool gets wet, it compacts and loses its thermal insulation qualities, which are not restored even after it dries, so the external waterproofing of the insulation should be carefully carried out.

Expanded polystyrene (foam) sheets also have high thermal protection and can be mounted both on dowels and on adhesive solutions. They are laid on a supporting base in 2-3 layers so that the joints of the upper and lower layers do not coincide. To protect against the penetration of drafts, the seams are sealed with sealants.

Polyurethane foam is applied to the wall using special foaming machines in which chemical components are mixed. The advantage of this method is the possibility of obtaining a monolithic seamless layer of thermal insulation. However, compared to mineral wool and polystyrene foam, polyurethane foam is quite expensive: the price is 1 sq.m. insulation can reach 500 - 800 rubles.

According to SNiP standards, the minimum thickness of the thermal insulation layer for various materials should be (without taking into account the thickness of load-bearing walls):

- Mineral wool with a density of 50 kg/m3 - for the Moscow region - 20 cm, Krasnodar - 15 cm, for Yakutsk - 35 cm;

- Expanded polystyrene with a density of 100 kg/m - for the Moscow region - at least 15 cm, for the Urals, Far East and Southern Siberia - about 20 cm, for Northern Siberia - up to 25 cm;

- Polyurethane with a density of 50 kg/m3. – for the Moscow region – about 8 cm, for the Urals and Southern Siberia – 10-12 cm, for the northern regions – 15-18 cm.

Installation of frame profiles

The installation of the frame should begin after the building is completely finished with thermal insulation. Initially, vertical posts are strengthened on the wall plane. They can be T-shaped, U-shaped or angular. Each type of rack is used for specific purposes - internal and external joints, facing corners, window and door openings.

The main type of vertical profiles are T-shaped, used to create a single, flat plane on the surface of the building being coated. Vertical posts perform the main, load-bearing function. Fastening clamps are installed on them, which are used for fastening porcelain stoneware.

As additional strength elements, in some cases, vertical posts are connected to each other by horizontal jumpers, giving additional rigidity to the entire structure.

Application area

Suspended ventilated systems are used for exterior finishing of buildings and structures using a wide range of finishing materials.

Due to its versatility and variety of installation options, the technology is in demand both in the construction of new facilities and in repair work and reconstruction of old buildings.

Ventilated facades are suitable for private and multi-apartment residential buildings, and are actively used in industrial and public facilities, commercial buildings, technical rooms of bus stations, gas stations, etc.

The functionality of materials can be adapted to any needs, which determines the relevance of ventilation facades.

Cladding with porcelain stoneware slabs

After installing the supporting frame, you can begin installing the facing slabs. Depending on the shape of the tile, the clamps are fastened to the frame profile in such a way that each slab fits exactly into the fastener tabs. The legs of the clamps are made elastic for better fixation of the tiles.

Porcelain tiles should be attached to the wall in horizontal rows, starting from the very bottom of the wall. At corner joints and connections with door and window slopes, the slabs are cut to the required size using a grinder with a diamond wheel.

Preparation of surfaces for thermal insulation

The construction of a ventilated facade does not impose any special requirements on the preparation of surfaces in terms of their ideal alignment. Before starting insulation, the following work must be done:

- remove flaking old façade finishing, such as plaster;

- repair cracks on the surface of the walls;

- on wooden walls, caulk the gaps between the crowns and other joints;

- remove all protruding parts - window and door frames, canopies, gutters, etc.;

- Wooden walls must be treated with an antiseptic; this equally applies to wooden frame elements.

Insulation of a wooden house should begin after the final shrinkage of the structure. It usually ends 12–18 months after the construction of the building. Otherwise, there is a high risk of ruptures and other damage to the thermal insulation.

Possible mistakes

I would like to note a number of typical errors that arise during the work process:

- Installation of load-bearing frames in cold weather. As the temperature rises, there is a high probability that the fasteners will weaken and the fastening subsystem will lose its rigidity and strength;

- Installation of brackets on the wall without compensation spacer. This leads to a gradual weakening of the fasteners due to seasonal cycles of compression-tension of the material under the influence of temperature fluctuations;

- Coincidence of seams when installing several layers of insulation. As a result, cold bridges are formed, which significantly reduce the effectiveness of thermal insulation;

- Installation of the clamps too close, as a result of which the plate fits too tightly into the fasteners. When a slab is heated in the sun, it may burst due to expansion and the resulting internal stress.

I'll wrap it up here. I am always ready to listen to your wishes and recommendations in the comments.