There are many types of insulation materials and several methods of insulation. They differ in properties and level of microclimate preservation. It is important to choose coatings that are cheap, have good characteristics, and are easy to install.

Stone wool for facade insulation is an excellent choice. Fiber products occupy up to 70% of the insulation market. The material and methods of its use will be discussed in the article.

Insulation process

Description and features of manufacturing fibrous material for external wall insulation

The main components for creating stone wool are:

- Fibrous parts.

- Fragments of basalt, quartz, and other minerals formed during mining.

The minerals are melted and passed through industrial sieves to form thin threads, which are then placed between mineral wool fibers and left to cool. Depending on the thickness, the characteristics change significantly. The main types include:

- With a thickness of up to 15 micrometers, it is characterized by low weight. It has low thermal conductivity and retains thermal energy well. Used for installation of ventilated facades.

- 30 microns – medium hardness. Universal, can be used to work with different designs.

- 30 microns and more are the hardest slabs. Manufactured specifically for increased loads.

Stone wool is highly resistant to ignition and combustion. It is often attached in areas with constant high temperatures: chimneys, boiler rooms.

The process of laying around the window

Due to the increased rigidity, some types can be used to insulate the ceiling.

Roofing pie composition

External roof insulation of an attic has few differences from the internal method of thermal insulation. The only difference is that before installing the mineral insulation, the inside of the roof remains bare.

Option with a residential attic

If the space under the roof allows you to equip an additional living room in this place, then the owners of private houses almost always take advantage of this advantage. A popular option is the vertical arrangement of the attic walls.

Vertical arrangement of the partition

Firstly, this allows you to increase the usable area, and secondly, it is possible to create a better thermal insulation cake. But more often there are sloping walls repeating the slope of the roof. With this method, external laying of insulation is used.

When insulating an attic internally, the following pie is used:

- A vapor barrier is laid on the sheathing.

- The second layer is laid mineral sheets, the thickness of which corresponds to the climatic conditions of the region.

- Next, the slats are filled horizontally, and the last 50 mm layer of thermal insulation is laid on top.

- At the final stage, a vapor barrier layer is filled.

Important! To reduce pressure from air flows, it is recommended to stuff slats over the vapor barrier.

What to pay attention to

When positioned vertically, there is free space between the roof and walls that needs to be insulated. In this case, the vapor barrier is installed from the roof side and on vertical structures. You should not ignore the installation of insulation on this section of the roof. If neglected, the indoor temperature may decrease or heating costs may increase.

Space behind the wall

Since cotton wool is afraid of high humidity, it needs enhanced protection. To do this, a vapor barrier is laid on both sides of the thermal insulation cake. Builders recommend using an auxiliary layer of polystyrene foam insulation. It will create a repulsive obstacle to a humid environment, preserving the quality of the mineral wool.

Advantages and disadvantages

Mineral wool has its own advantages and disadvantages that are worth considering. Therefore, you need to familiarize yourself with them. Let's start with the advantages:

- No harmful impurities. In production, practically no harmful substances are used: resins, phenols, so they are not released during operation.

- Low thermal conductivity, good heat retention.

- High sound absorption.

- It does not ignite or burn. At temperatures up to 600 degrees, the structure remains virtually unchanged.

- Service life up to 50 years.

- Resistance to biological, physical, chemical factors.

- Easy to install.

Disadvantages include:

- Ability to absorb moisture. This characteristic is common to all fibrous materials. You can get rid of it by installing vapor barrier membranes.

- High mass. This will require additional calculations about the ability of the supporting structure to withstand the insulation.

- The price is slightly higher than other, less traditional insulation materials. However, the quality of insulation is better.

Based on the listed features, you can choose cotton wool or another heat insulator.

How to choose stone wool

When selecting stone wool, you should definitely pay attention to the properties of work using it, as well as the advantages and disadvantages of such an insulation material.

Features of application. The criteria for choosing stone wool are price, environmental friendliness and compliance with the technical characteristics of the destination and application.

Advantages and disadvantages

The advantages of using basalt wool are determined by its properties, or more precisely:

- Ease of installation work.

- Complete environmental safety.

- Long service life.

- Low level of water absorption.

- Resistant to microscopic organisms, rodents and chemicals.

- Versatility of use.

- Fire safety.

- Excellent sound insulation properties.

- Excellent thermal insulation properties.

There are also disadvantages, but they are much fewer than the advantages:

- Relatively high price.

- There is dust during installation, which will adversely affect human health.

- When carrying out installation work, it is necessary to seal the joints between individual strips (sheets) of insulating material.

And now about the installation.

Properties, types and characteristics

Mineral wool has long been used to insulate houses. There may be several options on the building materials market. Moreover, each differs in the degree of filling and properties.

Glass wool

It is made from glass production waste, typical components for the same production. This is sand, limestone. After collecting the components, they are mixed, melted, and blown into glass wool strands. They are combined with organic thickeners, resulting in the formation of layers with certain dimensions. The thickness of the thread reaches 15 microns, the insulation practically does not conduct heat.

Glass wool

Due to the production technology and raw materials, glass wool has the following characteristics:

- Low heat conductivity.

- It conducts sound poorly.

- Practically does not burn.

- Resistant to chemical, biological and physical influences.

- Low level of moisture absorption.

- The fibers break off easily and can get into the eyes and respiratory tract, leading to allergic reactions or irritation.

- At high temperatures, a change in structure and properties begins.

Glass wool in slabs

Slag wool

From metallurgical waste and other slag rocks. The production method is similar to other types, with the exception of raw materials. However, the characteristics are significantly lower.

Peculiarities:

- Service life does not exceed 15 years.

- Maximum heating temperature up to 300 degrees. Then the structure changes and the properties deteriorate.

- Absorbs moisture well and then conducts heat much better.

- It melts quickly when exposed to fire.

- Compared to analogues, the thermal conductivity is slightly higher.

- May break during operation.

The main advantage is low cost.

Slag wool

Facade wool

Made from rocks. High temperatures are used during production. Therefore, it turns out durable and plastic. Features include:

- Used at temperatures from -180 to 700 degrees.

- Practically does not shrink.

- The fibers hardly break.

- Hygroscopicity is lower than that of analogues.

From all the options, you can choose the one that is suitable in terms of means and properties for the planned operating conditions.

Basalt material

In what cases is it better to use mineral wool?

It is difficult to answer the question of what is better to insulate a house, mineral wool or polystyrene foam. After all, various factors are taken into account. For example, polystyrene foam is not suitable for wooden houses, since it is not vapor permeable. But, protection from moisture is better. On the other hand, it burns, is not environmentally friendly and is spoiled by rodents. Although, mineral wool weighs more and is more expensive. Such nuances are taken into account and the best option is selected.

Insulation of the walls of a wooden house from the inside is done with cotton wool, since polystyrene foam releases harmful substances when heated. In conditions of elevated temperatures, cotton wool is also better suited (sauna, bathhouse, wall near the fireplace or near the stove). The same applies to insulation in a house where an allergy sufferer lives. It is also better to insulate the roof and ceilings with cotton wool.

Insulation methods

Insulation can be applied externally or internally. However, external insulation is more preferable. There are several methods.

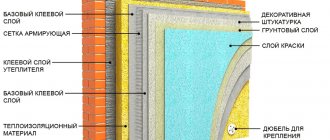

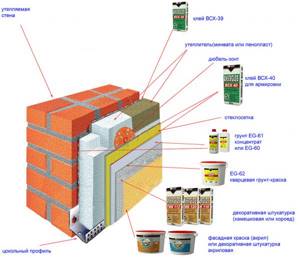

Wet facade

The wet facade technique is carried out by applying insulation to the wall using an adhesive composition. Decoration is carried out on top of the insulating layer. After the surfaces have completely dried, moisture remains in minimal concentrations.

There should be a minimum gap between the different layers of components. Only if this rule is followed will the ventilation gap perform its functions normally.

Wet facade technology

For thermal insulation using wet façade technology, stone wool is usually used due to its rigidity and strength characteristics. It gives minimal shrinkage. Therefore, it is an ideal base for plaster. It is plastic enough that small gaps on the surface are filled due to the bends of the material.

For greater reliability of attachment, the slabs are additionally secured mechanically. Often these are butterfly dowels.

Ventilated facade

For this method, basalt material is used. The peculiarity is the additional gap, which is required for air circulation. This type of cotton wool allows steam to pass through well.

Ventilated facade

The insulation is fixed in sections formed by the frame. The fibers are strong enough and no protective equipment is needed when working.

Insulation under siding

Siding and lining transmit noise well. It is necessary to choose insulation with a high sound absorption coefficient. This is mineral wool.

It absorbs noise and completely removes it during atmospheric conditions. Basalt wool is combined with breathable finishing materials and plastic finishing.

To insulate or not to insulate?

A wooden house is always much warmer than a concrete or brick one. Wood not only looks beautiful, but is also environmentally friendly, so a wooden house breathes - it’s comfortable to be inside. Of course, when deciding on the need for insulation, owners are concerned not only with saving money, but also with preserving the properties of a wooden house that distinguish it from buildings made of other materials, and first of all, preserving the ability of wood to “breathe.”

Among some owners of wooden houses, there is a widespread belief that wood itself is warm, it does not need insulation, and the imposition of the need for insulation is associated solely with benefits for construction companies. There is some truth in this, but not much. There are experts who believe that it is enough to strengthen only the foundation, but the majority believe that it is still necessary to insulate.

The region in which the house is located decides a lot. If the climate is warm and mild, and people do not live in the house in winter, using it, for example, as a summer house, then it may be sufficient to insulate only the seams and treat the wood with special protective agents. However, in regions with harsh winters, where the family lives all year round, insulation will be required, without which, due to increased heating (which in turn is associated with costs) and under the influence of the external environment, the tree will quickly fail - it will begin to crack, rot, dry out, cold bridges will appear and the microclimate inside will worsen.

If you want to save on heating, get an optimal microclimate in a wooden house and increase the service life of the building, properly insulate your wooden house.

Experts recommend insulation two years after the construction of the house, when the walls have finally settled.

There are a certain number of ways to insulate the outside and inside, but most home owners considered the best option to insulate the house externally with stone wool. Let's figure out why this is the best option, and how to carry out such insulation correctly.

Thermal insulation technique

Insulation work is carried out according to a plan that must be followed. Attaching fiber insulation is one such process.

Preparatory work

Preparation includes the following points:

- Remove old finish.

- Remove hanging structures.

- Remove the fastening elements: nails, dowels, screws.

- Seal the cracks with cement or sealant.

- Clear the walls of construction debris.

- Treat mold or fungal stains with an antiseptic composition and apply a deep penetration primer with antifungal properties.

- Coat the outer parts of the walls with a primer.

- Attach a vapor barrier membrane to the wall surface.

Attachment instructions

Next stage of installation:

- Installation of the starting profile at a distance equal to the width of the material.

- Preparation of adhesive composition. Use ready-made or dry mixtures. The finished ones are simply mixed. Powdered ones are mixed with water according to the instructions.

- A strip of reinforcing mesh is attached to the starting profile so that when plastered, a monolithic structure is obtained.

- The adhesive composition is evenly applied to the basalt wool. The corners are carefully lubricated.

- The first of the slabs is glued to the initial profile and pressed firmly against the wall.

- All those following in the first row are pressed against the surface and the previous slab.

- The second row is laid out in a checkerboard pattern for dressing.

After the adhesive composition has completely hardened, fix the insulation with dowels with a wide head. Use a drill to drill a hole, insert a dowel, and tighten the self-tapping screw. This reduces shrinkage of the dowel.

Protection of the thermal insulation layer

After the installation of thermal insulation is completed, wind protection is installed. The film protects against environmental factors and delays the circulation of cold air.

The surface is covered with the final layer. The application method depends on the material. Therefore, it is necessary to adhere to the manufacturer’s recommendations indicated on the label.

The wet facade is plastered. First you need to prepare the solution, then apply it to the slabs. Attach the reinforcing mesh, press it into the solution, and apply a decorative layer.

Is there any harm during installation?

Mineral wool, like any other, consists of many fibers. However, unlike glass wool, they are not as sharp. However, during the installation process it is still advisable to use protective equipment: thick clothing, a respirator, glasses that will protect the skin and mucous membranes.

Basalt wool is one of the universal types of insulating materials. It can be used for both external and internal insulation. The installation method in this case is not important. During the work, it is necessary to use protective equipment to protect the limbs.

Facade finishing

The last step is the decorative design of the facade. The best solution is standard plaster, and its decorative varieties will only decorate the appearance of the building. If we compare the price for insulating the façade from the outside with mineral wool, it is low compared to other works.

It is very important to “get your teeth into”, that is, to have experience, since its absence can lead to unforeseen expenses not only for the purchase of materials, but also for inconsistencies in the correct installation work. Additional construction work, and further payment of heating bills due to incorrect installation.