A heated towel rail is not just a useful, but also a convenient device that allows you to heat your bathroom. In addition to the useful functions it performs, the heated towel rail must have a beautiful appearance so as not to spoil the interior and maintain it in perfect condition. To do this, the heated towel rail in the bathroom is painted.

Before starting work, you need to prepare the necessary materials and tools. Let's consider the sequence of painting work.

How and with what to paint a heated towel rail and water pipes in the bathroom

Modern materials and equipment used for laying water supply, heating and sewerage systems do not require painting. Pipelines are made of polymers, non-ferrous metals, stainless alloys. In addition, today communications are carried out hidden, in building structures. However, owners of apartments and houses of old construction are faced with the fact that pipelines made of ferrous metal and cast iron, which are practically not used today, corrode and need protection. Painting may also be necessary for aesthetic reasons. We will tell you how and with what to paint a heated towel rail in the bathroom, heating pipes and water supply pipes made of different materials.

Content

Painting metal pipes ↑

The general rule for ferrous metal pipes is to clean the steel from rust, first coat it with a primer, then paint.

To paint metal pipes you will need:

- Tools for cleaning the pipe surface from rust and old paint: grinder, grinder, turbine, sandpaper, spatula.

- Household chemicals to prevent rust and remove its residues.

- Flute brush or roller.

- Primer for metal pipes

- Rags

- Covering material to prevent paint from getting on surrounding objects.

- Gloves.

You should not paint rusty pipes; they need to be prepared. Traces of corrosion are completely removed with a stiff wire brush or sandpaper. Phosphoric acid-based rust converters can only serve as an aid by modifying small, hard-to-reach areas of corrosion left after machining.

To paint a metal pipe, you should choose primers and paints based on organic solvents. Water-soluble ones cannot be used. Among primers, the domestic GF-021 has an excellent price/quality ratio.

We can recommend domestic oil paints, pentaphthalic paints, ours and imported alkyd paints. If a primer is available, a water-based finishing enamel can also be used. Today, manufacturers also offer universal paint compositions that simultaneously function as a primer and paint. It is more convenient to work with them, because you can paint a steel water supply or cast iron pipe in one step. However, the traditional option still gives better results: the primer provides the best adhesion of the coating to the surface, and the paint provides a smooth and easy-to-clean finish layer. In addition, the variety of shades of paints is much wider than that of primers.

As for heated towel rails, modern models are made of stainless steel or have a galvanic coating; only very old ones, made of ordinary metal, need to be painted.

Galvanized water pipes do not need painting, except in places where threads are cut by hand, where the coating is damaged. You cannot weld galvanized steel, but if you have already done this, the seam should also be protected.

Painting plastic pipes ↑

There is no need to paint plastic pipes; they are not afraid of external influences, except perhaps ultraviolet radiation. The application of a coating can be justified by aesthetic considerations, because standard colors (white, gray, less often beige and green) will not always satisfy everyone in open areas. Manufacturers offer, as for metal, special primers for plastic. However, in all honesty, there is little sense in them and you can completely do without it. Polymer products should be painted with non-aggressive compounds, exclude brands NTs, ML and those whose solvents are acetone, 646 and the like.

Hot and cold pipes ↑

Many people are interested in whether there is a difference and how to paint a hot pipe, heating, for example. There are no fundamental differences, but at elevated temperatures, compositions based on organic solvents change color slightly, especially white ones. The main problem when painting hot water pipes, heated towel rails that cannot be turned off and central heating radiators is that the paint dries very quickly. No matter how hard you try, the paint will still lie unevenly. Smudges or streaks will be visible from the brushes. Some people recommend sanding off any major imperfections and then reapplying paint. But, you see, you can paint like this ad infinitum.

Many “buy” into the marketing ploy of some sellers who sell enamels “for painting hot radiators.” We will have to disappoint those who have already bought this paint - it is not much different from ordinary enamel, except that the color changes less when drying.

Water pipes need to be insulated. Hot to avoid unnecessary heat loss. Cold to prevent condensation from forming on them. This is especially important for steel pipes; uninsulated cold ones are constantly moistened and because of this they serve several times less than hot ones, which always remain dry. Both hidden and open areas should be insulated, not forgetting the distribution cabinet.

Video tips for painting a radiator in a bathroom ↑

Painting water pipes in a bathroom or heating in a room is not difficult; you can do it yourself. Or, if an apartment or house is being renovated, entrust it to specialists; it would be better if plumbers immediately protect the metal with a primer.

Preparatory work

The effectiveness of the entire work will depend on the quality of preparation: if the product is not given ideal smoothness, the paint will not be able to adhere to its surface.

Cleaning the base

The old coating must be completely removed so that no paint or varnish remains. This can be done with sandpaper or a metal brush, but if you have an angle grinder or a grinder, the work will go much faster. Professionals often use sandblasting machines to remove paint from metal. A chemical remover or a hot air gun are also suitable for this purpose.

Before carrying out preparatory work, put on gloves, goggles, and a respirator. Organize good ventilation of the room or clean the heated towel rail in the open air.

They act this way:

- Clean off the loosest pieces of paint, removing them in layers.

- Use sandpaper to work out cracks, corners, and bends.

- Corrosion elements, if any, are removed especially carefully.

- Wash the heated towel rail with water and detergent, removing all the smallest particles of paint and dirt and assessing the result.

- The metal is cleaned again if untreated areas are identified.

- Dry the base, then wipe it with a degreaser.

- If there is rust on the metal, apply an anti-corrosion compound to all surfaces.

Heated towel rail primer

Priming is the final stage of preparing a heated towel rail for painting. You need to choose the soil carefully, because it must also be resistant to elevated temperatures and well suited for metal surfaces. It is best to buy an alkyd primer and apply it in a thin, even layer. After drying, you need to repeat the process again.

Coloring

There are usually no difficulties with painting; all work is done using a brush:

- Mix the paint thoroughly until it has a uniform consistency.

- Gently dip the tip of a narrow brush into the paint and apply it to the upper areas of the heated towel rail - this will help avoid drips and drips.

- Completely paint the product and allow the material to dry (usually 2–3 hours).

- Repeat painting 1-2 more times.

- After 4–5 days the coil is put into operation.

Instead of a brush, you can use a small spray bottle. It will allow you to apply the product without streaks, in a strictly uniform layer, and there is no risk of hairs appearing on the surface of the product.

Spray paint should be thinner than when using a brush, so you need to add a little thinner to it.

Painting of metal, galvanized and polymer pipes - features

The main thing when painting a metal heated towel rail and pipes is to thoroughly clean the surface not only of old paint, but also of rust. Anti-corrosion treatment cannot be ignored: a new source of rust will quickly begin to form under the paint, and the paintwork will begin to snap off.

Galvanized pipes usually do not require painting because they have a durable protective layer on the surface. But if it is necessary to stylize the heated towel rail, it can also be treated with an alkyd or silicone composition of the desired color. Before applying it, be sure to prime the base: without this, the quality of adhesion will be greatly reduced. Before painting, you need to check that there is no condensation on the item.

Polymer products are also painted only for the purpose of making changes to the interior of the room, while the work does not require anti-corrosion measures, but priming is mandatory. For plastic, paints without acetone or other aggressive solvents are used.

An overview of how to paint a heated towel rail with your own hands

Having a heated towel rail in your bathroom is very useful. This device heats the room, dries clothes, and warms your towel while you shower. Plus, modern models can become a very important attribute of interior design, adding some zest. However, over time, the device may lose its original appearance. Therefore, painting a heated towel rail is often the solution that can save you from the problem of an unsightly coil.

Of course, if the dryer not only lost its original appearance, but also began to work frankly poorly, there can only be one solution - replace it. However, as a rule, everything is fine with their reliability, but the aesthetic component fades over time. Therefore, it is enough to simply update the coil and give it some minor cosmetic repairs by simply painting it.

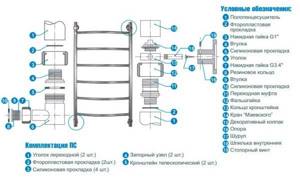

- 1 Materials and tools

- 2 Preparatory work

- 3 Painting 3.1 Useful tips

Materials and tools

Of course, you can’t just take a brush, the first paint that comes to hand, and start painting your heated towel rail. This type of work requires careful approach and preparation. Plus, first you need to arm yourself with everything you need. Namely, tools and materials:

- Sandpaper;

- Brushes (only with natural bristles);

- Primer;

- Protective gloves;

- Detergent;

- Screwdriver Set;

- Putty knife;

- A clean rag (cotton) or paper towels.

Of course, the most important component of the renovation will be the paint. But not ordinary, but special. Whatever one may say, a heated towel rail tends to heat up to a high temperature, and therefore the coating must withstand it.

Silky-glossy alkyd enamel has proven itself most well, which is precisely used for painting heating radiators, that is, radiators. Its properties are such that the coating can withstand heating up to 180 degrees Celsius. This will be more than enough.

It would be a mistake to use plain enamel, as this will cause the material to crack very quickly, after which you will have to paint the dryer again.

If you are thinking about color, then you should focus on your own preferences, the theme of the interior, and the style features of your bathroom. You can easily find paints that will imitate gold or bronze, or a chrome surface. Or you can opt for ordinary colors like blue, black, red and so on. Don't forget about the ability to combine colors. Due to this, you can paint the coil, for example, in the color of your favorite flag, the color of your favorite team, and so on.

But what color it is not recommended to choose exactly is white. And even if we are talking about specialized high-quality paints. Their problem is that they quickly lose their original whiteness. Over time, the surface will become yellowish, and this will obviously not be much fun for you.

Preparatory work

A device such as a heated towel rail requires preliminary preparation for subsequent painting. You cannot start painting immediately without any surface treatment. Follow these steps and you will get the job done well.

- Take sandpaper and sand the entire surface of the dryer. Especially carefully clean areas where rust has appeared, the old coating has come off, the paint has cracked, or cracks have formed. Try to do the work conscientiously, since preparing the device is the most important step in terms of the final result.

- If possible, remove the entire protective layer. This will allow the new layer to lay perfectly flat and last on the device for many years. This is especially important when it comes to chrome surfaces. The enamel does not adhere well to it, so clean it thoroughly.

- After finishing cleaning, wash off any remaining particles of the coating with a wet cloth and detergent. This will not only remove any remaining dirt, but will also degrease the surface.

- The final stage of preparation is primer. Also be careful when choosing a primer. This must certainly be a primer that is intended for use at high temperatures. Nowadays, German-made alkyd primers are in particular demand. Do not apply the composition in rough layers. On the contrary, the layer should be thin and very uniform.

Now you can go about your business for a while, since the primer should dry. Once this happens, you can proceed to the next stage.

Painting

If you have ever held a brush in your hands, you should not have any difficulties with painting a heated towel rail. Follow the instructions and everything will be fine.

- Arm yourself with a brush, but only with natural bristles. This will allow you to apply layers more evenly and not leave pieces of lint on the surface.

- Take the above paint, some old screwdriver, for example, and mix the composition with it. The mixture should be homogeneous, so stir well. It is best to do this in several approaches in order to achieve the ideal consistency.

- Now take a brush, carefully dip it into the paint so that the composition is literally on the tip. Start painting from the top to avoid smudges. Even if the drops fall down, they can be smeared, thereby avoiding unevenness.

- The paint is applied in at least two layers, but three is best. Each new layer is applied only after the previous one has dried. Not necessarily completely, of course. Moreover, alkyd paints have the excellent property of drying quickly, so a gap of 2-3 hours between layers is quite enough.

- After finishing painting, leave the heated towel rail undisturbed for about 5 days so that the composition is completely absorbed into the surface of the device and dries completely.

Useful tips

Agree that useful advice is never superfluous. Despite the fact that we have already talked about the main nuances of painting a heated towel rail, there are a few more points that you should know about.

- It is not necessary to use brushes exclusively to apply layers of paint to the surface of the dryer. There is a great device called a spray gun. This is an effective device that can provide maximum results with minimal paint consumption. The layers are applied evenly, there are no streaks, and there is a risk of leaving brush hairs on the heated towel rails, since they are not always of good quality.

- If you purchased alkyd enamel, but it turned out to be quite thick, you should not use it in this form. Use a special solvent, which is not at all a problem to find in any hardware store. Bring the paint to the desired consistency, after which you can begin painting.

- Do not start painting while the dryer has not yet cooled down. Also, do not turn on the device if the layers have not dried properly. We have already noted that after painting is completed, you should wait about 5 days. Therefore, the optimal time to perform such work is the end of the central heating season if you use a water heated towel rail. Then you will not depend on any deadlines, which means you will complete the task efficiently and reliably.

Preparatory work

The effectiveness of the entire work will depend on the quality of preparation: if the product is not given ideal smoothness, the paint will not be able to adhere to its surface.

Cleaning the base

The old coating must be completely removed so that no paint or varnish remains. This can be done with sandpaper or a metal brush, but if you have an angle grinder or a grinder, the work will go much faster. Professionals often use sandblasting machines to remove paint from metal. A chemical remover or a hot air gun are also suitable for this purpose.

Before carrying out preparatory work, put on gloves, goggles, and a respirator. Organize good ventilation of the room or clean the heated towel rail in the open air.

They act this way:

- Clean off the loosest pieces of paint, removing them in layers.

- Use sandpaper to work out cracks, corners, and bends.

- Corrosion elements, if any, are removed especially carefully.

- Wash the heated towel rail with water and detergent, removing all the smallest particles of paint and dirt and assessing the result.

- The metal is cleaned again if untreated areas are identified.

- Dry the base, then wipe it with a degreaser.

- If there is rust on the metal, apply an anti-corrosion compound to all surfaces.

Heated towel rail primer

Priming is the final stage of preparing a heated towel rail for painting. You need to choose the soil carefully, because it must also be resistant to elevated temperatures and well suited for metal surfaces. It is best to buy an alkyd primer and apply it in a thin, even layer. After drying, you need to repeat the process again.

Coloring

There are usually no difficulties with painting; all work is done using a brush:

- Mix the paint thoroughly until it has a uniform consistency.

- Gently dip the tip of a narrow brush into the paint and apply it to the upper areas of the heated towel rail - this will help avoid drips and drips.

- Completely paint the product and allow the material to dry (usually 2–3 hours).

- Repeat painting 1-2 more times.

- After 4–5 days the coil is put into operation.

Instead of a brush, you can use a small spray bottle. It will allow you to apply the product without streaks, in a strictly uniform layer, and there is no risk of hairs appearing on the surface of the product.

Spray paint should be thinner than when using a brush, so you need to add a little thinner to it.

Painting of metal, galvanized and polymer pipes - features

The main thing when painting a metal heated towel rail and pipes is to thoroughly clean the surface not only of old paint, but also of rust. Anti-corrosion treatment cannot be ignored: a new source of rust will quickly begin to form under the paint, and the paintwork will begin to snap off.

Galvanized pipes usually do not require painting because they have a durable protective layer on the surface. But if it is necessary to stylize the heated towel rail, it can also be treated with an alkyd or silicone composition of the desired color. Before applying it, be sure to prime the base: without this, the quality of adhesion will be greatly reduced. Before painting, you need to check that there is no condensation on the item.

Polymer products are also painted only for the purpose of making changes to the interior of the room, while the work does not require anti-corrosion measures, but priming is mandatory. For plastic, paints without acetone or other aggressive solvents are used.

Sunerzha - STAINLESS steel dryers: how to choose the best

Like many other pieces of bathroom equipment, heated towel rails have been the subject of significant engineering and design efforts at the beginning of the 21st century. Their goal was to bring this essentially simple heating device to the level of a work of art.

All that glitters is not stainless steel

For many users of heated towel rails, it doesn’t matter what they are made of, as long as they dry. But even those who prefer such equipment made specifically from stainless steel do not always have a clear idea of what “stainless steel” is. But, firstly, stainless steel can be different, and in order not to go into technical details and not to use specialized terms, in this article we will only indicate the parameters of the steel used.

Photo: Valery Stobbe

Food grade stainless steel AISI 304 is a modern, reliable material used for the production of heated towel rails and radiators. Special technologies are required both to create stainless steel itself and to weld parts made from it. In order to provide welded seams with strength identical to that of steel, technologists and designers decided to use the so-called TIG (Tungset Inert Gas) method. This is welding with a tungsten electrode in an inert gas, without the use of filler metal. Test results show that heated towel rails intended for installation in a hot water supply or heating system, given the above parameters, are capable of withstanding water pressure of up to 25 atmospheres. By the way, in Russian heating networks under standard operating conditions the pressure is practically not raised above 12 atmospheres.

There are heated towel rails to suit your taste and color

Modern consumers, thanks to the worldwide computer network, can learn about the latest technologies almost as quickly as manufacturers. The same applies to fashion for certain colors and textures. The developers of the Sunerzha heated towel rail collections take all this into account. They constantly introduce models of new shapes, colors and finishing methods into production.

Photo: Valery Stobbe

21st century buyers have quickly become accustomed to the ability to choose the color and type of finish of home equipment. This is what Sunerge designers are trying to provide them with, offering various colors and finishes. Vacuum spraying improves the durability of the metal, and powder coating helps increase the heat transfer of pipes.

At the MosBuild 2014 construction exhibition, the Sunerzha exposition attracted visitors not only with its smooth and shiny surfaces, but also with its velvety flocked surfaces.

Photo: Valery Stobbe

In addition to the shapes and colors, the originality of the heated towel rail model can be emphasized by specially designed components in the same style: shelves, hangers, hooks, as well as valves, corners and holders.

Large towels - large heated towel rails, if the bathroom allows

The dimensions of a heated towel rail intended for connection to a hot water supply or heating system are best determined in accordance with the volume of the bathroom and the size of the wall chosen for its installation. With a relatively small wall surface for a heated towel rail in a large bathroom, you can use models with improved convection properties.

Photo: Valery Stobbe

Autonomous or systems dependent

All models of Sunerzha heated towel rails can be divided into two categories according to the heat source: water and electric. Water radiators are connected to a hot water supply system or central heating. The water temperature in these systems usually does not exceed 70°C.

In electric radiators, the main coolant is household antifreeze, which is poured into the pipes during the production of heated towel rails. A small device, usually called a heating element (tubular electric heater), converts electricity from a 220-volt network into heat. With it, users typically heat antifreeze to a temperature in the range of 55 to 70°C.

Photo: Valery Stobbe

Heated towel rails, among other things, are also divided by specialists according to the type of connection. Sunerzha usually produces these devices with side connections (vertical) and diagonal/bottom connections. It is better to clarify what this means in your specific case during the purchasing process, but, more often than not, this does not significantly narrow the choice.

More details about the features of electric and water heated towel rails using the example of Sunerzha products are described in more detail in the article “Water or electric: when and which heated towel rail is better to choose?”

Photo: Valery Stobbe

Bathroom climate control during local warming

The fact that the Sunerzha electric heated towel rail has an automatic temperature control unit built into the heating element is probably considered common and ordinary by most modern buyers. Of much more interest is a water radiator, equipped at the customer’s request with an automatic thermostat. There is a certain attractive contradiction in this: the device is connected to a common source of hot water, and at the same time, it is possible to set the desired temperature.

We wish you the right choice of the best heated towel rail for your circumstances.

The history of chrome plating

A mirror emulsion, which is applied in compliance with a whole set of rules and conditions, creates a specific coating that completely imitates perfectly polished metal. This effect is created due to the fact that the special paints contain the smallest particles of the metal itself, as well as a unique varnish. It is thanks to this composition that when applied, a thin layer is formed, which forms a very smooth and shiny surface on almost any object. The range of applications of this new product is increasing every year, and the popularity of this invention is only increasing.

Chrome products have always attracted attention with their shine. Chrome plating technology developed rapidly in the mid-twentieth century. This type of coating has become very widespread in plumbing. With proper care, this type of item always pleases the eye with its brilliance and irresistibility.

At one time, chrome plating was used extremely widely in the automotive industry. North American automakers especially distinguished themselves by this in the 50s and 60s of the last century. If you look at the cars of those years, you will notice that they literally shone with an abundance of chrome. Bumpers, moldings, side view mirrors, many overhead parts - everything is covered in chrome. Aesthetically it looked great, while providing a fairly good anti-corrosion coating.

However, achieving such an effect was possible only when manufactured in a factory and with strict adherence to technology. Deviation from the technological process threatened that the chromium would peel off from the metal. There was another drawback at that time - chrome plating could only be applied to metal surfaces.

Progress does not stand still. Today, chrome plating of various surfaces is possible. However, real chrome plating still remains the lot of manufacturing enterprises. This is due to the fact that the application of chromium metal is an electrical process.

An alternative to the technology of applying metallic chrome is chrome effect paint. Two options are possible here. This is the use of compositions using a traditional spray gun and liquid in cans. The first option can be divided into simple painting and using heat treatment.

How and with what to paint a heated towel rail in the bathroom: subtleties on which the result depends

When the irritation from the untidiness of the heated towel rail has reached its limit, it’s time to deal with this issue thoroughly . If the heated towel rail is made of ferrous metal, the problem can be solved simply.

Useful tips: is it possible to paint a hot heated towel rail?

- If there is mold in the bathroom, it is not the heating device that is to blame , but poor ventilation;

- if the heated towel rail is made of stainless steel or chrome , only the brackets on which it is supported are painted;

- dryers made from plastic pipes are usually not painted;

- work is carried out in the summer , when the heating is turned off and the pipes are cold.

Important! Do not use white enamel: over time, the coating fades and deteriorates .

Materials and tools: choosing paint

First, buy brushes with natural bristles so that the bristles do not remain on the surface, or a foam roller with a short paint surface, in this case there is no danger of smudges. Then choose an organic-based primer and enamel : they are heat-resistant and abrasion-resistant. The paint chosen is a glossy alkyd paint from a German manufacturer for metal work .

Photo 1. To paint an old heated towel rail, you should choose a similar special glossy paint for metal.

Preparatory work

The most important thing at this stage is to clean the heated towel rail from old paint and rust . For this, sandpaper with a grain size of 60-80 is used , and a converter based on orthophosphoric acid is also used . A reliable way to remove old dye is to use an industrial hair dryer or blowtorch .

Important! To degrease and treat rust, the surface is wiped with a solvent .

Painting

The cleaned and degreased surface is painted once with a primer and left until completely dry. Then they paint it twice with enamel , keeping a break of several hours between layers so that the first layer dries.

If the work is done from a spray can, it is recommended to protect the wall behind the device from getting dye on it .

Sealing at joints

Leaks of the device are often observed if, during the installation process, the connecting elements were not tightened securely enough or there is not enough winding in such areas. Fixing problems in threaded connections will require unscrewing the fittings, as well as using flax and plumbing paste.

The Unipack composition, designed to operate under temperature conditions within 140°C, has proven itself very well. This paste, in combination with flax fibers, provides excellent tightness and also allows for convenient adjustment during the assembly of any joints. Before winding, the threads are thoroughly cleaned of dirt and dust. A layer of paste is evenly applied over the flax, after which the elements are assembled and the fittings are tightly tightened. At the final stage of repair, the heated towel rail is connected and tested for leaks.

The method for eliminating heated towel rail leaks should be chosen depending on the location of the leak and its level of complexity. However, in some cases, the best option would be to completely replace such an emergency device that has become unusable with a new and high-quality device for drying towels.

How to paint a stainless steel heated towel rail in the bathroom?

Heated towel rails are designed for heating the bathroom, drying small wet clothes, and many people wonder how to choose a heated towel rail. Traditionally shaped heated towel rails can be purchased not only in specialized stores, but also in the building materials market. It is quite difficult to choose a heated towel rail, despite their variety, which will perform its functions and at the same time be combined with the interior of the bathroom. In all apartments, without exception, the heated towel rail is a metal pipe attached directly to the wall, which has a U shape. When starting a renovation in the bathroom, the first thing you need to do is replace the standard heated towel rail with something more modern and beautiful. There is a huge selection of heated towel rails on the market in various shapes and sizes. The most common models are snake-shaped heated towel rails, which are curved pipes, and ladder-shaped heated towel rails. For longer service life, experts recommend purchasing heated towel rails made of stainless steel or sanitary brass. The new heated towel rail can be installed in place of the old one without much difficulty. If the diameters of the pipes of the new and old air dryers do not match, then it is necessary to purchase additional special adapters. If you want to place the new heated towel rail in a different place, this will cause some difficulties and will require you to work a considerable amount of time. Heated towel rails can also be purchased in the online store, after receiving specialist advice over the phone.

Currently, there are heated towel rails of various exclusive models: in the form of a waterfall, a guitar, leaves and other various shapes. By purchasing one of these heated towel rails and installing it in your bathroom, you will give the room an unusual and attractive look. Modern heated towel rails can be made in various colors. Painting a potency dryer allows you to hide some defects and give it an even more unusual and interesting look. However, it is worth considering the fact that painting heated towel rails is practically impossible without smudges and the service life of such a coating is quite short. During operation, mechanical damage to the paint is possible, and rust will subsequently appear in places where the paint is damaged. When buying a heated towel rail, you cannot buy the first model you like. It is necessary to study the materials from which heated towel rails are made. It is necessary to choose a heated towel rail that will serve you for a very long time, while we will have a conventional external one and further emphasize the exclusivity of the interior of your bathroom.

Low device temperature

The most common problem with heated towel rails is that the device does not heat well over time.

If you have any suspicions that the mechanism is not heating well, this point needs to be checked. Compare the temperature in the heating radiator and in the heated towel rail. Since the temperature in the heating system is constant, it must be the same in all pipes.

The reason that the device does not heat well, that is, the temperature of the drying device is low: a blockage may have formed in the pipes or the amount of scale on the internal walls has exceeded the norm.

Solution to the problem: you have to clean the internal walls of the device or supply line.

First, you need to determine where the blockage is occurring by touching the pipe connected to the heated towel rail with your hand. In the place where you felt a temperature difference (where the device does not heat well), there is a blockage.

If the problem is in the device itself (scale), you need to dismantle the heated towel rail, for which turn off the water in advance. And if the mechanism is connected to the heating system, dismantling and other repair work are carried out only in the summer, when the heating is turned off.

Cleaning the heated towel rail pipes:

- Tap along the entire length of the appliance pipe.

- Clean the device. To clean the pipes, use a plumbing cable or stiff wire.

- After the work has been completed, the heated towel rail must be treated with hot water (inside) under strong pressure.

- At the points where the device connects to the pipes, you need to install high-quality plugs, then open the fittings again.

If you see water in this place, you need to immediately turn off the water

You can do this kind of work yourself by consulting with a specialist or studying the material online. If you are inexperienced and do not want to risk a heated towel rail, contact the appropriate company for help, however, prepare funds to pay for the services.

Modern plumbers note that cleaning pipes on your own is quite dangerous and ineffective. Our compatriots often use aggressive cleaning agents to remove sediment (salt scale), which is wrong.

The fact is that for the production of heated towel rails, various materials and compositions are used for the internal coating of pipes, which can be easily damaged. Yes, you may not damage the device, but the quality of its operation and service life will decrease.

Powder coating of heated towel rails

- Painting sectional radiators

- Painting steel panel radiators

- Painting steel tubular radiators

- Painting cast iron radiators

- Painting heated towel rails

Cost of painting: 55,000

Cost of painting: 55,000

Cost of painting: 55,000

Cost of painting: 55,000

Cost of painting: 55,000

Free painting of 2 samples

Painting 2 samples in any color according to the RAL catalog*

| Name | Cost of painting |

| Powder coating of heated towel rails | from 1500 rub. |

| Additionally | |

| There is a surcharge for colored candy polishes | from 2800 rub. |

| Painting in two colors | +100% |

| Chemical and organic contamination, as well as traces of metal corrosion more than 10 microns | from 10% of the order value |

| Prefabricated and oversized products | individually |

| Urgency of order execution | individually |

| Painting more than 2 layers (primer, varnish, paint, etc.) | 100% layer |

| The cost of painting is indicated for a heated towel rail in the shape of a ladder, “M” or “S” shaped, without protrusions. If the heated towel rail is voluminous or has protrusions | from 250 rub. |

| Valve/Tap | from 500 rub. |

| Connection angle | from 120 rub. |

| Taps/valves and connection angles are not included in the cost of painting and are painted provided they are dismountable. | |

| Minimum order value | 1500 rub. |

The cost of painting includes:

- Primary color painting

- Application of powder varnish (glossy, matte)

- Removal of fittings/installation

- The cost of painting includes mounting hardware.

- Painting of plastic elements is not included in the price

- The final cost of the service is determined only upon inspection

offers painting services for heated towel rails. It’s hard to imagine a comfortable modern bathroom without this device. It ensures dry and fresh towels and a comfortable indoor microclimate. Especially valued are steel and aluminum heated towel rails, which are famous for their strength and durability, but, alas, do not always fit into the interior of the bathroom. Painting services can solve this problem. Thanks to them, you can achieve the aesthetic appeal of the heated towel rail and its compliance with the interior.

The advantages of painting batteries with powder paint are undeniable. The appearance of the heating battery is the most important characteristic of this product. The technological process allows us to create a unique appearance that fully satisfies the tastes of the most demanding customers. Various paint textures, gloss and matte powder coating - all these possibilities of powder painting are actively used today in the protection of heating radiators. Moreover: with the right approach, this element will become its “highlight”.

And all thanks to the variety of color solutions and the ability to choose the characteristics of surfaces, because painting allows you to get both smooth and textured coatings.

Painting heated towel rails in TermoColor

We offer professional level services and European quality service. Our clients can count on an individual approach and responsibility from our specialists, who strictly follow all technological processes and check the quality of the final painting for compliance with state standards. We have a powerful production base, so we offer a wide range of powder coating services. From us you can order a heated towel rail painted in bronze, wood, natural leather, or in one or more colors from more than two hundred on the RAL scale. After the work is completed, we will carry out quality control and hand over to you a heated towel rail ready for use.

Functionality and aesthetics of a painted heated towel rail

Powder painting technology has found wide application in a variety of sectors of the economy - and all because it can extend the service life of metal products significantly! Heated towel rails are no exception... They are used in conditions of high humidity, and they often come into direct contact with wet towels or clothes that need to be dried. Is it worth saying that no matter how durable the metal is, the effect of moisture on it will be destructive? A layer of properly applied powder coating will extend the service life of a standard product by 10 or even 30 years! Agree: such figures are impressive... Thus, by purchasing a heated towel rail for painting and paying a low price for it, you will receive an even more functional element. Powder coating is not called vandal-proof for a reason; it is not afraid of influences:

- water;

- humid air;

- ultraviolet rays;

- mechanical nature;

- chemical reagents.

While maintaining its original appearance, it provides a high level of protection for the metal, which remains invulnerable throughout the entire period of operation. As for the appearance, as already mentioned, we offer a wide variety of design options. Thanks to this approach, the heated towel rail will ideally fit into the interior of any, even the most sophisticated bathroom and will look organic in it. Especially popular in this regard are finishes like “gold”, “chrome”, “copper” and “bronze”, however, painting in one or more of the 213 colors of the “RAL” scale is also possible. Even the bathroom in your home should be elegant. Contact TermoColor - and we will help you realize any design ideas!

Mirror effect paint

Chrome paint is used to create an original decorative layer, which in appearance resembles metal polished to a mirror shine. This effect is achieved due to the components included in the composition. Chrome plating is a fairly expensive service, so doing the work yourself is a great opportunity to save money.

Types of mirror paints

Chrome effect paint is available in several options that differ in structure. Each variety involves its own technology for preparing the mixture and applying it to create a mirror effect.

Powder version

This composition is a crushed mixture, the components of which include hardeners, film-forming resins, pigments, special additives and modifiers. The advantages of this material:

- Durability. The coating is one of the most durable.

- Strength. The surface can withstand various mechanical impacts.

- Decorative. Painting allows you to get an excellent mirror effect.

On a note! To do all the work yourself, you will need special equipment for powder coating, in particular a heat treatment oven. Although all the necessary devices can be purchased or made with your own hands, this will require considerable effort and money.

The application of such paint has a certain scheme:

- The product being processed is thoroughly cleaned.

- Anti-corrosion treatment and degreasing are carried out.

- The primer is laid.

- The part dries well.

- The composition is sprayed.

- The product is sent to the oven.

Due to the fact that modern powder materials do not require high processing temperatures, this method is becoming increasingly accessible for home use.

One-component solutions

The one-component composition is a fairly common chrome paint in cans. Product manufacturers claim that chrome plating using this option is not particularly difficult.

Indeed, the aerosol variety allows you to avoid the use of complex equipment, and besides, the cost of this paint makes it accessible to literally everyone. Although the price may vary depending on the manufacturer.

The solution has significant disadvantages:

- The chrome effect that many people expect does not always live up to expectations. In most cases, the surface acquires a light silvery tint.

- Complex application technology. The process requires compliance with many nuances and rules; any flaw will lead to damage to the decorative layer.

- This option is only suitable for painting small items.

There are several recommendations for using such compositions:

- It is better to abandon cheap materials and give preference to foreign manufacturers.

- Applying an aerosol is a very difficult process, so before use it is necessary to practice to understand the principle of spraying.

- The big problem is drips. They indicate that the installation technique was chosen incorrectly, as well as the required distance was incorrectly defined.

- This spray paint can be silver or gold in color, depending on the dye used. Glass, plastic and even wood lend themselves well to processing.

- If subsequent varnishing is intended, the composition is selected especially carefully, and compatibility tests are required. The fact is that some types of varnish destroy the chrome layer.

On a note! An alternative to this option could be simpler paint. It is also sold in cans, but has a matte silver finish. Working with this composition is much easier, because there is no need to achieve a mirror reflection.

Two-component composition

It is essentially a chrome liquid paint. This option includes a base and hardener, which are thoroughly mixed before use. The excellent technical characteristics of this product make it very popular.

Positive qualities of the material:

- Similar to polished and mirror surface.

- Wear resistance. The coating is additionally protected with varnish.

- Heat resistance.

But the workflow will require much more effort than in the previous version.

Two-component paint and protective varnish Chrome Effect

Types of chrome paints

When choosing paint with a mirror effect, you need to take into account the features and properties of the solutions presented on the shelves of construction markets. There are two main groups, which include all materials used for chrome painting.

One-component compositions

Most often, these coloring agents are sold in cans and are not suitable for all types of work; they have their own advantages and disadvantages. The first include the absence of the need for special tools for applying liquid chrome (the packaging is already adapted for spraying), as well as compactness and ease of storage (the paint in cans is hermetically sealed and will not dry out). Inexpensive one-component chrome-effect paints are sometimes packaged in cans.

The disadvantages of these materials are the following:

- the resemblance of a surface painted with one-component chrome paint in a can or can to real polished metal in most cases turns out to be distant;

- the process of painting by spraying is quite complicated, a good result is possible only if all the subtleties of the technology are fully observed;

- due to lightning-fast drying, the material sometimes simply does not have time to adhere to the base, as a result, the coating peels off even with weak mechanical stress;

- Purchasing chrome-effect aerosol paint to cover large surfaces is an impractical step, since canned formulations are more expensive per gram.

Two-component paints

Such solutions are usually sold in cans and are made on an epoxy or acrylic base. The process of working with them takes more time, since before use the base composition must be mixed with a hardener, and after painting, a protective layer of varnish must be applied to the dry surface.

The advantages of two-component chrome paints are very significant:

- the resemblance of the painted surface to real metal is very reliable;

- the coating has high wear resistance;

- painting for chrome with a two-component composition is relatively inexpensive;

- The coating is heat-resistant.

These are the materials that are used in professional activities.

Recommendations for using paints

Each type of emulsion provides a certain range of areas where they are recommended to be used. So it is with chrome types of dyes . There are a number of recommendations for using this type of emulsion:

- The best results are obtained from formulations from well-known global manufacturers. It is better to refuse cheap options from unknown brands;

- Applying the composition requires certain skills. Before painting the product, it is necessary to conduct training;

- Training is also necessary to prevent smudges, this very significantly reduces the visual appeal of the final look;

- It is not recommended to use this type of dye on flexible plastic;

- If you intend to further coat the painted product with varnish, then you must first select the appropriate varnish. Otherwise, the paint coating may be damaged, which will lead to the need to repeat the painting process.

Following these recommendations will reduce work time and also save money.