Methods for insulating facades

Insulating an apartment or country house from the inside will not provide the required effect, so there will be a risk that the premises will still be cold in winter or that more resources will have to be spent on heating.

Insulating the house from the outside allows you to avoid:

- – formation of condensation resulting from temperature changes;

- – accumulation of humid air indoors, promoting the growth of mold on the walls;

- – the appearance of cracks and destruction of materials filling the joints between the slabs.

Wet facade

There are two common methods of insulation - “wet” and ventilated facades. Both technologies can be used for both brick and panel houses.

The structure of the wet facade includes:

- * thermal insulation layer – mineral wool, polystyrene foam, expanded polystyrene;

- * reinforcement – plaster stack fixed to an adhesive solution;

- * decorative surface finishing - decorative plaster and profile are used.

The advantages of using the “wet facade” technology include quick installation, high level of insulation, and minimal likelihood of efflorescence formation. This type of insulation is suitable for panel, prefabricated, monolithic and brick buildings.

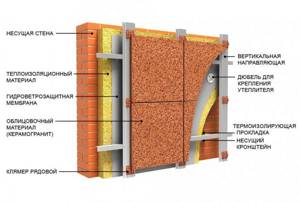

Ventilated facade

A ventilated façade has additional heat capacity characteristics due to the presence of free air space between the wall and the facing material. To insulate walls using this method, non-hygroscopic materials are selected.

Among the advantages of installing a ventilated facade:

- – large palette of colors;

- – free removal of steam, which prevents the accumulation of moist air in the room;

- – maintainability of the system, you can replace a separate part without dismantling the entire lining;

- – long service life.

Choice of thermal insulation

Insulation of the facades of apartment buildings is usually carried out using one of the following materials:

- Styrofoam;

- mineral wool;

- expanded polystyrene;

- foam glass.

Each type of thermal insulation has its own pros and cons, which determines the relevance of using a certain material in a specific situation. If you want to save money, you should use polystyrene foam. It has a low price, which is why it is most common. It can be used anywhere, the thermal insulation efficiency will be sufficient. However, the pursuit of cheapness is not always justified. If the walls initially have a normal thermal insulation class, then foam insulation will allow you to achieve the desired result. When choosing this material, you should consider its density. The higher it is, the lower its heat-conducting properties.

Insulation of the facades of apartment buildings is often carried out using expanded polystyrene. It is quite inexpensive, and its thermal insulation properties are better compared to polystyrene foam. Among the advantages are low weight, ease of installation, hydrophobicity and long service life. Expanded polystyrene is excellent for cladding corner apartments. The material almost does not absorb moisture.

If you plan to insulate the facades of apartment buildings using polystyrene foam, then you should also take into account its disadvantages. They are expressed in low resistance to fire and lack of soundproofing abilities. The first quality requires the installation of fire protection jumpers. However, expanded polystyrene is excellent for insulating walls inside and outside the house.

How and when is it better to insulate a facade?

For external insulation of the facade, 2-3-layer thermal insulation structures are used. However, the top layer of plaster is not considered one of them. When choosing methods and materials, you must adhere to the following rules:

- – brick, reinforced concrete and block houses can be lined with any type of insulation;

- – frame walls require three-layer insulation, the insulation is located inside, it is surrounded by a ventilated or non-ventilated layer;

- – wooden houses are insulated in 2-3 layers using an air gap, which provides additional ventilation and reduces the risk of condensation;

- – buildings made of cellular concrete require a ventilated and non-ventilated layer; they can be decorated with brick cladding on top.

The building can be insulated when all construction and repair work has been completed, including installation of the roof, installation of window and door openings. The foundation must first be waterproofed and all utilities secured.

It is best to install insulation during the period of the year when the temperature remains positive for a long time (+5 ... + 25 C) and the air remains dry. It is unacceptable to carry out work if the weather forecast includes rain or snow. The optimal time for installing insulation is the beginning of autumn or the end of spring.

It is important to know!

Before starting insulation work, the shrinkage of the house must be completed. Otherwise, cracks may appear on the façade in the future.

Possible difficulties and errors of the process

It is only important to carry out insulation in the summer, in dry weather.

Home craftsmen make the most mistakes during internal insulation, sometimes after completing the work - they do not get the expected effect from implementing the measures. Therefore, before starting work, you need to listen to the advice of experts :

- If vertical cracks appeared, the reinforced mesh was laid incorrectly without overlap.

- The appearance of a “cobweb” on the outer finishing layer is an incorrectly laid mesh on the insulation, not glue.

- The heat insulator slabs are not located in the same plane - the finishing has peeled off and a vapor barrier has not been installed.

- Freezing of the wall - the material is not tightly joined.

Legal nuances

According to federal laws, unauthorized changes in the appearance of the facade of multi-story buildings are strictly prohibited. To carry out such work, it is necessary to obtain permission from the housing and communal services authorities.

The most difficult thing is to obtain permission to insulate the facades of buildings located in the central part of the city. Here it is better to enlist the support of neighbors to submit a collective application for such work. They approve of her more readily.

It is convenient if the company that will insulate the facade takes care of the issues of obtaining permits.

Important!

By the way, we are engaged in the preparation of construction documentation: obtaining an OATI warrant, a color passport.

The effectiveness of insulation depends not only on the technology used, but also on the correct choice of materials. Let's look at the characteristics of each of them separately.

Who pays?

The issue of payment is the second most important after obtaining permission. The best option is to carry out insulation at the expense of the management company. The most difficult option in terms of implementation is insulating all the walls of the house at the expense of the residents. If there is no fundamental ban on insulation in your region, then we recommend holding a meeting, collecting signatures from residents and trying to resolve the issue of payment by involving the council or management company. If there are indications for insulation, then this scheme may turn out to be quite realistic.

golicin/Fotolia

How to choose material?! Comparison of insulation materials

Basalt wool has the highest performance characteristics. But it is hygroscopic, so without proper waterproofing it will lose its properties over time. This insulation option is suitable for ventilated facades.

Polystyrene foam and extruded polystyrene foam are suitable for insulating the facades of panel houses. These materials are resistant to moisture, so they last 50-100 years. To restore the aesthetics of an insulated facade, it is enough to simply paint it once every 5-10 years.

You cannot use polystyrene foam or extruded polystyrene foam to insulate wooden houses. It is often damaged by rodents and, due to low vapor permeability, causes condensation. If there is excess humidity and lack of ventilation, the wood will quickly rot.

It is important to know!

Wall insulation can be carried out at any time of the year. But the weather is important. If it is raining or snowing outside, work should be postponed. Excess humidity is especially dangerous for mineral wool.

Insulating walls in apartment buildings - secrets and recommendations

Absolutely all high-rise buildings that are built today must comply with special state standards, which in turn provide for special technical requirements related to heat. The houses of an old residential building suffer more in this regard - their walls were not initially insulated with anything and therefore the level of heat loss in Stalinist buildings, Khrushchev buildings and other houses of the old housing stock is much higher than in new buildings. Just a few years ago, the cost of heating was miserable - most residents didn’t even think about saving money and simply heated the street. Insulation of the walls of an apartment building from the outside

Today heat is very expensive. When more than 60 percent of heat losses occur within the walls, organizing insulation of an apartment building becomes simply necessary. This situation is especially true for new panel-type buildings - in such houses the temperature in the coldest time of the year can drop down to minus twenty degrees Celsius and below. Properly organized wall insulation will save money and make the apartment warm. This statement is true for both an autonomous heating system and a centralized one.

In this article we will look at what schemes are used to organize the insulation of any apartment buildings in modern construction and which of them are justified in a particular case.

Preparation for insulation can take a long time - from several hours to a whole day

Foam extruded polystyrene foam

Polystyrene foam is the most budget-friendly option. It is produced in slabs with a thickness of 25 mm. The material is resistant to moisture, but at the same time has a low level of vapor permeability.

An improved version of polystyrene foam is extruded polystyrene foam. The material has a flammability grade G1-G2, that is, it does not support combustion. Inside it consists of many small empty cells. This significantly reduces the heat transfer of polystyrene foam and allows it to also be used as sound insulation. The service life of the insulation is from 70 years.

The thermal conductivity coefficient of the material is 0.0228 (W/m/K), with a density of 30 to 45 kg per 1 m3.

Advantages:

- + waterproof, does not get wet and does not lose its performance characteristics when exposed to moisture;

- + ease of installation on the facade;

- + low level of thermal conductivity with minimal thickness;

- + resistance to a wide temperature range, from -100C to +120C;

- + minimal weight, practically no additional load on supporting structures;

- + resistance to inorganic solvents.

Flaws:

- — low level of vapor permeability;

- - quite high cost.

It is important to know!

Extruded polystyrene foam is used not only for insulating facades. It is also suitable for attics or basements where there is a high level of humidity.

Glass wool and basalt wool

Previously, glass wool was used to insulate facades and many other building structures. It is cheap, vapor permeable, and easy to install. But at the same time, such material is very harmful to human health. When the material deforms, small particles become released into the air and, if inhaled, can cause lung damage. That is why when laying glass wool it is necessary to use a protective respirator and gloves to protect the skin from irritation.

Basalt mineral insulation is absolutely safe, the thermal insulation characteristics of which are 0.041 (W/m/K).

Stone wool has the following advantages:

- + environmental friendliness, the material is made from environmentally friendly raw materials, when heated it does not emit harmful substances;

- + durability, the service life of mineral wool is up to 100 years;

- + resistance to fire, the material does not burn even with prolonged exposure to fire;

- + vapor permeability, the structure of basalt wool allows steam to penetrate through it.

Disadvantages of mineral wool:

- - high hygroscopicity (moisture absorption) - if the material is moistened by at least 2%, then its thermal insulation characteristics will immediately decrease by 10%.

When insulating a facade with basalt wool, additional vapor and waterproofing is required. It protects the material from getting wet and extends its service life. This is an excellent choice for curtain wall facades where ventilation gaps are provided.

It is important to know!

Basalt wool is often the best option for insulating residential premises, because moist air will not accumulate inside the building, which reduces the risk of mold or mildew forming on the walls.

Disadvantages of patchwork and spot insulation of an apartment building

In many cities of the Russian Federation there is the same picture - dozens of Khrushchev buildings with multi-colored spots. What do you think it is? That's right - the residents of these houses just want to make their apartment warmer. attracts many, but of course, we can’t say that the appearance in this case suffers quite a lot. Much more important is that such independent insulation most often suffers from poor quality, and as a result, the facade walls of the home quickly collapse.

The boundaries along which external facade insulation occurs are exactly where the boundaries of the slabs are located. It is in them that the dew point, as mentioned a little earlier, can elude the insulation, directly inside the facade wall. That is why, often after improvised insulation, fungus and increased levels of moisture appear in any apartment of a multi-storey building, and as a result, mold and other similar problems. Moreover, the fungus forms not only in the insulated dwelling itself, but also in the neighboring rooms - which are located next to the insulated one. As a result, after unscrupulous external insulation of the facade, the main walls are destroyed and the house gradually falls into complete disrepair.

Are there other disadvantages to patchwork insulation? Unfortunately yes. Thus, the insulation of the external walls of an apartment building from the outside requires constant moistening and wetting of the upper part of the insulation. Yes, they try to protect it from the influence of the external environment and precipitation, but permanent exposure to moisture will eventually destroy the glue and water will rush inside. It is impossible to seal the upper section of the insulation - it is simply impossible to create a continuous insulation contour due to the laws of physics. That is why effective and non-damaging external insulation of the building can only be complete - from the foundation to the roof. Moreover, complete external insulation of the facade of an apartment building is much more profitable from a financial point of view, even without the use of government programs. So, once again: the best insulation is the one that is done completely. At the same time, it does not harm the building and allows it to be warm in all zones.

A warm wall becomes renewed and beautiful

Polyurethane foam

Polyurethane foam (PPU) is an insulation material applied by spraying. It has a thermal conductivity of 0.024 (W/m/K). The material does not require additional vapor or waterproofing. But this is far from the only advantage of polyurethane foam.

Pros:

- + lightness, can be used for any type of facade, since it places minimal load on the load-bearing structures;

- + integrity, when the insulation is sprayed, it turns out to be solid on the entire facade, there are no joints or seams through which cold or moisture could penetrate;

- + resistance to temperature changes and moisture;

- + environmentally friendly, does not emit harmful substances into the environment;

- + high adhesive characteristics, there is no need to use fasteners that violate the integrity of the wall.

Flaws:

- — rapid wear of the material under the influence of ultraviolet rays;

- — the need to use special equipment for spraying insulation;

- - not suitable for insulating roofs made of corrugated sheets or metal tiles, since in the absence of a ventilation gap there is a risk of condensation causing damage to roofing materials.

It is important to know!

In addition to the facade, polyurethane foam can be used to insulate complex surfaces. It is suitable for spraying on pipelines, freezing and isometric structures. PPU often insulates joints between panels in apartment buildings.

Using thermal panels

Facade cladding with thermal panels has been popular in European countries for more than 50 years. The material is produced in a factory. It consists of a layer of insulation (polyurethane foam) and a final exterior finish (like clinker bricks or painting). The thermal insulation indicator directly depends on the materials used for manufacturing and the thickness of the panel. Additional advantages of thermal panels include:

- + attractive appearance, large selection of colors and shades;

- + long service life – from 50 years;

- + ease of installation on any surface (concrete, brick, wood), but if the wall is uneven, then you should think about installing lathing.

Disadvantages of thermal panels:

- – can only be mounted on hard surfaces with a smooth surface;

- – high cost of material.

How to calculate the required thickness of insulation?

The choice of insulation thickness depends on the wall material and its width. For example, let's look at a brick wall, 250 mm thick (one brick). To insulate it you will need polystyrene foam 40 mm thick.

To insulate a wall one and a half bricks thick (380 mm), use insulation 38 mm wide. For a wall of two bricks, 32 mm of insulation is enough. Approximate calculations taking into account the thermal conductivity of other materials can be seen in the table.

| Name of wall material | Coefficient of thermal conductivity | Required insulation thickness (mm) |

| Wooden beams, solid wood | 0,18 | 53 |

| Ceramic blocks | 0,17 | 57 |

| Aerated concrete blocks | 0,18 | 61 |

| Polystyrene concrete blocks | 0,19 | 64 |

| Expanded clay concrete blocks | 0,31 | 104 |

| Clay brick | 0,76 | 223 |

| Sand-lime brick | 0,87 | 256 |

It is important to know!

The calculation of insulation thickness should be carried out by an experienced engineer. This will allow you to get the maximum effect from insulation with minimal material costs.

Stages of work execution

Insulation of facades can be carried out using the method of industrial mountaineering, it is possible to use scaffolding or high-altitude special equipment. The promalp method is considered the most practical and cost-effective. But you should choose the best option depending on the total area of the insulated facade and the complexity of the work. If polystyrene foam is chosen as insulation, then the insulation technology does not change.

The work is divided into several stages:

- Surface preparation. Dust, efflorescence and contaminants that can reduce adhesion are removed. Defects (cracks, chips, unevenness) are sealed with plaster.

- The facade is primed. An adhesive composition is applied to the foam sheet. A comb spatula is used. The insulation boards are glued horizontally, from bottom to top. It is necessary to bandage the vertical seams; they are laid in a checkerboard pattern. It is important that the adhesive composition does not get into the joints between the polystyrene foam boards.

- The insulation is secured with disc-shaped dowels. A hole is drilled in the façade. The dowel is driven flush with the surface of the polystyrene foam board. The number of fasteners depends on the height of the building and expected wind loads. Usually 6-8 pieces are enough. for each slab.

- Reinforcing elements are used for window openings and corners of the building. They are fixed with glue.

- The reinforcing mesh is fixed. It is attached with glue. Minimum overlap – 10 cm.

- A decorative coating is applied. Facade plaster is used, which is subsequently painted in the desired color.

The technology for insulating a ventilated facade is slightly different. Usually mineral wool is used for it, so a waterproofing membrane is laid on top of the insulation. It protects it from the harmful effects of moisture.

The performance of façade insulation work is regulated by the following regulatory documents:

- – GOST 33160-2014 “Thermal insulation. Physical quantities and definitions"

- – GOST92 “Thermal insulation materials and products for construction. Classification and general technical requirements"

- – SP 23-101-2004 “Design of thermal protection of buildings”

- – SNiP 3-04-01-87 “Insulating and finishing coatings”

It is important to know!

In Moscow, obtaining permission to carry out work on insulating the facade of one apartment is almost impossible. Work can only be carried out if the entire façade is completely insulated.

Preliminary preparation of walls

In order for the insulation to fit tightly to the wall, the surface must be leveled and the cracks sealed.

Important! All stages are carried out only by specialists. You need to thoroughly know the sequence of work and its features.

The foundation preparation process goes through several stages:

- the wall is cleaned of old layers of any coating (paint, plaster, whitewash, etc.);

- dust and dirt are removed, the surface is sprayed with water;

- interpanel seams and cracks are cleaned of dust and insulated with installation foam, and hardened excess is removed;

- cleaning is carried out again.

Along with preparing the walls, the window slopes are put in order. To avoid the formation of fungus, the surface is primed. For this, a sprayer is used, or less often a special roller.

Interesting! This type of work is carried out mainly at heights. This is a dangerous activity, and most often, 2-3 people are involved in installation. But there are also loners who have gotten used to performing all the stages on their own.

Mistakes when insulating a house outside

Façade insulation should be carried out by experienced specialists. Otherwise, critical errors are possible, which will significantly reduce the service life of the materials and everything will soon have to be redone. Improperly performed insulation will only slightly reduce the heat loss of the room, but it may disrupt the microclimate in the rooms. This will lead to the formation of fungus or mold on the walls.

Typical mistakes:

- Incorrect calculation of insulation thickness. It is necessary to take into account the wall material and climatic conditions in the region.

- Ignoring foundation preparation. Poor adhesion is possible; air “pockets” form under the insulation.

- The choice is to insulate the premises from the inside. If the walls are insulated internally, the entire renovation will have to be redone. In addition, the thickness of the insulation will reduce the area of the rooms.

- Incorrect installation of insulation. The “thermos” effect may be disrupted. “Cold bridges” are formed at the joints of the slabs, through which heat will escape from the premises.

- Poor quality fasteners or non-compliance with their installation technology. You should not skimp on glue; the reliability of insulation depends on its durability. When laying basalt wool mats, the fasteners are equipped with special gaskets that prevent moisture penetration.

It is important to know!

At the same time as the facade, the foundation is usually insulated. This helps to further reduce the heat loss of the building and extend the life of the load-bearing structures.

Types of materials

The quality and durability of the insulation depends on the chosen material. Mineral wool and polystyrene foam are popular.

- Extruded polystyrene foam or polystyrene foam is the most affordable material. Foam boards differ only in thickness. It is lightweight, absorbs excess sound well, and does not release heat from the room. It may seem like an unreliable and fragile material. This is true. But this problem can be easily solved with plastering. The weight is minimal and the excess is cut off with a knife, making it easier to work with at height. Polystyrene foam practically does not absorb water - this extends the service life of the material.

Price list

| Name | 50 mm | 100 mm | 150 mm |

| Ventilated facade with thermal insulation layer thickness, rub/m2 | 3330 | 3440 | 3550 |

| Wet facade with thermal insulation layer thickness, rub/m2 | 2340 | 2560 | 2780 |

| 60mm | 80mm | 100mm | |

| Installation of thermal panels lined with artificial stone, thickness, rub/m2 | 3300 | 3450 | 3550 |

| Processing the seams of a panel house using warm seam technology – 300 rubles/m. |

Ventilated facade

| Name | Price per m2 |

| Thermal calculation | For free |

| Pull-out testing of anchors | For free |

| Geodetic survey of the facade | 20 |

| Design work | 70 |

| Installation/dismantling of frame scaffolding | 120 |

| Marking walls for brackets | 50 |

| Installation of brackets | 150 |

| Attaching extension cords | 100 |

| Installation of the first layer | 200 |

| Installation of the second layer | 100 |

| Installation of guides | 200 |

| Fastening the facing layer | 600 |

| Construction of a subsystem for a parapet cover | 500 |

| Installation of parapet ebb, m. | 400 |

| Installation of ebbs, slopes, drips, linear m. | 350 |

Facing of thermal panels

| Name | Price per m2 |

| Thermal calculation | For free |

| Installation/dismantling of frame scaffolding | 120 |

| Leveling plaster (with a difference of more than 30 mm) | 520 |

| Frame structure (with a difference of more than 30 mm) | 300 |

| Fastening thermal panels | 800 |

| Grouting joints | 300 |

| Construction of slopes, running meters: | |

| Plastering | 650 |

| Steel | 350 |

| From clinker tiles | 800 |

| Installation of ebb tides | 350 |

| Installation of spotlights | 600 |

| Attaching the end strip | 350 |

| Installation of a drainage system | 350 |

Inter-wall insulation

| Name | Price per m2 |

| Thermal calculation | For free |

| Installation/dismantling of frame scaffolding | 120 |

| Rough masonry of partitions (thickness up to 200 mm for blocks and 120 mm for bricks) from: | |

| Foam blocks | 400 |

| Gas silicate blocks | 400 |

| Expanded clay blocks | 400 |

| Brick | 450 |

| Rough masonry walls (thickness more than 200 mm for blocks and 120 mm for bricks) from, m3: | |

| Foam blocks | 2600 |

| Gas silicate blocks | 2600 |

| Expanded clay blocks | 2600 |

| Brick | 2800 |

| Fastening thermal insulation with disc dowels | 200 |

| Facing brick walls half a brick thick | 800 |