Is it necessary to insulate a metal garage?

A structure made of a metal profile and thin-sheet galvanized steel has the property of quickly heating up and releasing heat to the environment. Therefore, in hot weather it is stuffy to be in the garage, and in winter the car freezes. As a result, transport servicing is accompanied by significant discomfort.

When temperatures change inside the structure and on the surface of the car, condensation forms. Moisture has a destructive effect on the anti-corrosion coating. This fact leads to the appearance of rust on the metal.

Metal walls without anti-corrosion protection in damp rooms quickly rust

The extremely low temperature according to SNiP 02/21/99 is considered to be +5 degrees Celsius. This condition can only be ensured by thermal insulation of the walls and ceiling of the garage. The event will also help prevent overheating indoors in the summer.

Methods for insulating a metal garage

You can insulate a metal garage inside or outside. If the structure is an autonomous building, then the priority option would be to carry out work on the facade side. Often the premises are located inside the complex. In this case, the insulating materials will have to be placed indoors, on the inside.

Insulation of a metal garage from the outside

For external insulation, materials are selected in accordance with the selected finish. If plastering is involved, then it is better to stick to hard slabs. These include expanded polystyrene. Mineral wool and polyurethane foam can also be used under cladding or brickwork made from frost-resistant materials.

As an alternative, manufacturers offer ready-made decorative sheets with insulation. These include rigid slabs to which corrugated sheeting, clinker tiles or plastic panels are glued. They can be installed using a special solution, polyurethane foam or lathing.

Insulation from the outside is completed by painting

Less commonly, brick is used to insulate a metal garage. On its own, this finishing material copes with maintaining heat inside in conditions down to -15 degrees Celsius without wind. In other cases, additional thermal insulation is fixed between the masonry and the metal base and an air gap is created.

Insulation of a metal garage from the inside

The interior space of the garage is often used as a workshop, a place to store tools and things. That is, shelving, a workplace, and tanks can be located around the perimeter. This helps to reduce the area for placing a car.

Insulation of metal walls, protection of thermal insulation sheets, and decorative finishing lead to a reduction in the garage area. Therefore, when choosing materials, their thickness is taken into account. Thin-layer options are polyurethane foam and extruded polystyrene foam.

Polyurethane foam dries relatively quickly, the layer can be 5-6 cm

Additional events

The inside of the garage walls requires special preparation, which includes plastering with a “warm” type of plaster or applying heat-insulating paint to the surface.

The ability to shift the dew point to the outside of the garage walls allows you to protect them from the negative effects of freezing and excessive moisture. Experts recommend installing a forced ventilation system designed for high air exchange rates.

Application of liquid thermal insulation

The use of liquid thermal insulation, presented in the form of paint or polyurethane foam, is among the most popular options. The variety of paints used provides a choice: thermos paint, isolat, etc.

Liquid foam, which is a foam-like mass, is produced directly at the construction site using the so-called. foam generator.

The hardened foam has the appearance of a hard crust with excellent adhesion.

Fastening foam boards with glue

Attaching foam plastic with glue is one of the simplest and most affordable ways to insulate garage walls from the inside.

When using it, it is necessary to pay increased attention to the issue of cleaning and degreasing metal surfaces.

This measure ensures reliable and durable fastening of the heat-insulating material.

It is best to fill the gaps formed between the sheets with polyurethane foam. After this, paint can be applied to the surface of the insulation.

When using polystyrene foam boards, it is necessary to remember about its increased flammability and the fact that during combustion a large amount of toxic substances are released.

What features should insulation have and why?

All materials that can be used for thermal protection must meet the following requirements:

- Have a low thermal conductivity coefficient;

- Possess good fire safety performance;

- Have low water absorption;

- Have no shrinkage or shrink as low as possible;

- Have good environmental friendliness.

- Let's look at why these properties are needed in more detail.

Thermal conductivity

This indicator is responsible for the ability of insulation to transfer heat. The lower this coefficient, the less heat the material transmits. This means that in winter the insulation prevents the building from quickly cooling down and, accordingly, from warming up in summer.

Advice! Based on this indicator when choosing, the user must take into account the thermal conductivity coefficient when used in specific climatic conditions.

Fire safety

This indicator is responsible for the ability of insulation to withstand high temperatures without losing its functions, without deforming, without changing its structure. Insulation of frame houses with mineral wool is considered reasonable and correct because this indicator is regulated by GOST standards. Mineral wool has them and fully meets them.

Water absorption

The next important parameter after the previous one is responsible for the ability of the material to absorb moisture and retain it. If the material absorbs water strongly, it releases heat faster and stronger. This happens because the pores in the insulation are clogged with water, and, according to the laws of physics, it has greater thermal conductivity than air.

And then, if the moisture absorption is too high, the material, at too low a temperature, can simply freeze, and when it turns into ice, it can completely lose its properties.

Therefore, the smaller its parameters, the better the material.

Shrinkage

When choosing to insulate a frame house with high-quality mineral wool, you should also pay attention to this parameter. This coefficient should be as small as possible. Otherwise, over time, after shrinkage, subsidence will begin to appear in the places where the heat insulation is laid. This means that cold bridges will definitely appear there, and this is very bad. A cold bridge is an ideal area for removing heat from inside a room.

Environmental friendliness

The basis of thermal protection is insulation, which is located along the entire perimeter of the building. It is very important that it does not emit harmful radiation and fumes in the form of compounds and substances hazardous to health.

Types of insulation

The process of insulating a garage depends on the selected thermal insulation material. In some cases, installation involves additional costs for lathing and finishing; in some cases, insulation is simply applied to the walls. Since the garage is made of iron, it heats up in the sun and collects condensation well. Therefore, materials should be chosen that are most moisture resistant.

For example, mineral wool is not suitable in this case. It will begin to rot, and the insulation will have to be replaced pretty soon.

The following materials are ideal as insulation for an iron garage:

- extruded polystyrene foam boards, polystyrene foam or penoizol;

- polyurethane foam;

- heat-insulating paint (for example, “Astratek”).

Other materials

Among such materials are the following:

Penoizol

It is a liquid form of polystyrene foam. It is characterized by durability (retains properties for more than 40 years), water resistance, and a high fire resistance limit.

Astratek

Belongs to the category of liquid insulation. The method of applying astratek is similar to applying paint, and the effectiveness of a layer of insulation with a thickness of only 1 mm is comparable to the thermal insulation properties of a layer of mineral wool 50 mm thick.

To apply thermal insulation per square meter of area you will need only 0.5 liters of astratek.

Polyurethane foam (PPU)

When applying polyurethane foam, special equipment is used. The service life of this insulation is more than 70 years.

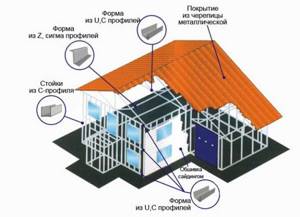

How to make a metal frame yourself?

If you need to assemble factory parts into one design, this can be easily done with help. The difficulty lies in finding the required element and installing it according to the drawings.

If it is necessary to weld frames from a profile pipe, then this is a rather complicated matter. Although for the construction of a small country house, the frame is installed similarly to a wooden one. For a one-story building, pipes of 80*80 mm are suitable; for intermediate elements, a smaller diameter is suitable. But it also needs to be insulated.

ATTENTION! For reliability, it is best to purchase a disassembled house structure from the manufacturer.

Description of the insulation process

When insulating different types of enclosing surfaces of a frame house with mineral wool, their own insulation scheme is used. But just like for frame walls, one general rule applies - the vapor barrier of the insulation is carried out from the side of the heated room.

The vapor barrier is laid in a continuous layer without “gaps” between the insulated surfaces

Floor slab above basement

In the case when the frame house project includes a basement, a strip foundation is used as the foundation.

Exterior decoration

For the interior and exterior decoration of a metal frame building, you can use almost all finishing materials available on the construction market. You must make the choice yourself based on your personal preferences. The most economical option would be to use heat blocks or sandwich panels to enclose metal structures. If you want to give your home some extravagance, decorate the walls with a material that imitates natural stone.

Using modular blocks, you can make additions to an existing building at any time. A house made of a metal frame does not shrink and can withstand even a magnitude 9 earthquake. This is one of the best modern designs for residential buildings, bringing excellent cost savings even after construction.

We recommend reading:

- roof of a frame bathhouse with your own hands;

- do-it-yourself one-story aerated concrete house;

- how to properly pour the foundation for a house.

Garage Doors

Insulating a metal garage also means insulating the garage door.

Curtain device

It is recommended to make a small door in one of the garage doors, and attach a curtain made of thick fabric or polyethylene film with a thickness of at least 0.8 mm to the upper edge of the door, designed to retain some of the heat in the room. But it is better to use transparent plastic for this purpose, which provides sufficient visibility when leaving the garage.

The selected material should be cut into strips of such length that, when fixed above the gate, they are at a distance of 1 cm from the floor level.

The width of the strips can vary from 20 to 30 cm. The strips should be stapled to a wooden batten so that an overlap of 1.5-2 cm is formed between them.

Under the influence of gravity, the strips will hang evenly, and after a forced deviation, they will return to their original place.

Gate panels

It is recommended to use foam plastic for thermal insulation of gate panels. From the inside you should make a sheathing, which must be filled with foam plastic.

The gaps resulting from the junction of the gates must be eliminated using adhesive tape - this will prevent the entry of cold air. Rubber seals are also suitable for this purpose.

Anti-corrosion protection at the points of contact between insulation and metal will prevent the appearance of condensation.

After applying the waterproofing layer, the frame is installed, which is the basis for future cladding. The frame elements must be coated with a primer to avoid warping and the spread of fungus, and it is recommended to clean the foam layer. The sheathing can be made from OSB (oriented strand board) or thin boards, and it is better to use heated drying oil as a primer.

Technologies for insulating walls of frame houses from the inside

Diagram of the construction of frame walls and their thermal insulation

Firstly, for this you need to stock up on the following materials:

- glassine (to create a waterproofing layer);

- beams or metal profiles (for assembling the frame);

- vapor barrier (for example, penofol);

- insulation (let's take mineral wool as an example);

- edged board with a section of 2.5x15 cm and a humidity of no more than 15%.

Floor insulation

Insulation of floors in a frame house, as well as insulation of walls, is a mandatory procedure. Otherwise, all the heat will go into the basement of the house. Insulation allows you to avoid heat loss and cold air entering the room from the ground.

The sequence of work is approximately the same as when insulating walls. You will have to act depending on how the floor in the house is arranged. Usually these are logs that rest directly on the foundation or special support pillars.

And here you can see perfectly installed logs of the future floor

Note! Even at the stage of building a frame house, it is necessary to ensure that the logs are made with an interval of no more than 58 cm. Then it will be possible to simply lay mineral insulation of the required length. Too large a distance between the joists is inconvenient not only for subsequent thermal insulation, but also due to the fact that the finishing floor covering may begin to deform over time.

Floor insulation in a frame house begins with the construction of a subfloor, which is necessary for laying a heat insulator between the joists. It is made from a 10x2.5 cm edged board. The boards can be laid in various ways.

Here's one of the simplest:

- Screw 5x5 cm beams from below and across all the joists so that you create a division of the floor.

- Lay the edged board of the required length parallel to the joists, between them. Thus, the edges of the boards will rest on the foundation, and in the middle they will have support from the beams.

Subfloor

- Cover the subfloor with a waterproofing membrane to protect the insulation from moisture. The membrane is attached between the logs with an overlap on them using a construction stapler (step 20-25 cm).

Moisture-proof membrane

- Next comes the installation of the heat insulator. For floors, it is better to buy rolled insulation, as it is convenient to roll it out to the desired length. It is laid in at least three layers (that is, the result should be about a 15-centimeter layer).

Laying mineral wool along joists

- The top of the insulation is covered with a vapor barrier membrane with an overlap of 10 cm. This way you will protect your work from water and steam that can penetrate from the room.

Vapor barrier membrane for floor

- The final stage will be laying the floors themselves. It all depends on your needs and capabilities.

Important! Do not forget that all wooden materials used in the thermal insulation process must be treated with antiseptics to protect them from rot and wood beetles.

Comparing to a tree

A frame house built from metal is unlikely to ever replace a house with a wood frame. At best, they will develop in parallel. And this is quite reasonable - both a metal frame and a wooden one have their pros and cons. In this regard, it is worth studying buildings with a metal frame - what advantages and disadvantages they have compared to houses with a wooden frame.

Metal has high thermal conductivity and wood is much better in this regard. The wood material itself acts as thermal insulation and contributes to the overall insulation of the building. For a metal frame house, thermal insulation is performed using insulation and sheathing.

Life is more comfortable in a house made of wood. Wood creates an optimal microclimate in the building. However, the material can be damaged by parasites or rodents, moisture or fungus. Of course, methods have been invented to protect against such misfortunes, but this will entail a waste of money. Metal is not afraid of such influences, with the possible exception of moisture.

But houses with a metal “interior” still have some unobvious disadvantages. A modern person in his home has a lot of electrical appliances, which undoubtedly have an impact on the frame of the house by magnetizing it, which can affect sensitive people.

The low weight of the metal frame makes it possible to build a house on light foundations. Even if you have a plot with heaving soil and it is not possible to build a deep foundation, you can build a fairly large house. A metal and frame house does not dry out and there is no need to wait for it to shrink during construction.

Advice from professionals

You can reduce the thickness of polystyrene foam when insulating a garage internally using isolon. Polyethylene foam with foil coating is glued on top of thin sheet foam indoors. The disadvantage of such insulation is its relatively soft design. It is impossible to attach heavy shelves with objects to metal walls and ceilings. Therefore, this approach is relevant for a horizontal base.

The effectiveness of foam board insulation can be increased in two ways. Arrange thin sheets in a checkerboard pattern, foaming the joints. The second option is not limited to isolon. You can also carry out a combination with mineral wool. In this case, polystyrene foam acts as a water barrier.

If the building is autonomous, then it is better to insulate the facade. This way less condensation forms. In addition, the design of the ventilation gap promotes natural weathering of moisture. Inside a metal garage, forced ventilation will be required and the working area will be reduced; outside everything happens naturally.

Ceiling

It is recommended to insulate the ceiling of an iron garage both from the inside and the outside.

For external insulation, painting agents can be used.

For internal insulation, the following options exist:

- applying several layers of thermal paint;

- gluing slabs of mineral wool or expanded polystyrene;

- spraying one of the liquid materials.

It is best to glue the slabs using bitumen mastics. The seams formed when using polystyrene foam should be treated with sealant.

The insulation does not require special treatment, unlike, for example, mineral wool, which should be covered with a waterproofing layer to protect it from moisture.

For external insulation of a ceiling made from a reinforced concrete slab, you can use extruded polystyrene foam, which should be glued to bitumen mastic.

To improve the waterproofing characteristics, roofing material or any under-roofing film is placed on top of the insulation.

Next, reinforcement, plastering or pouring of bitumen composition is carried out.

Thermal insulation of the outside of the roof ensures that there is no humidity inside the garage and ensures that the dew point is transferred.