Facade plaster protects walls from external factors: precipitation, high and low temperatures, UV radiation, fungus. As a finishing layer, it forms the impression of the building’s exterior. Therefore, her appearance must be impeccable. Dry plaster Ceresit copes with this task perfectly.

The German brand Ceresit has existed on the construction market for more than 100 years. Since 1999, its building mixtures, including facade plaster, have been produced in Russia.

What is Ceresit facade plaster?

Factories where Ceresit plaster is produced are located in various countries. There are several production facilities registered in Russia, which once again confirms the demand for the company’s materials. The manufacturer uses a slightly different technology for the production of decorative coatings, unlike its competitors.

Ceresit façade plaster contains only high-tech components that make it possible to obtain high-quality material. The company offers customers a wide selection of products that have different compositions and texture options depending on what surface will be processed.

Pebble facade plaster Ceresit

Beautiful decorative plaster “bark beetle”, “lamb”, “fur coat” is made using mixtures containing marble or granite chips of different fractions. Pebble marks are intended for finishing facades:

- Acrylic ST 60, ST 63, ST 64.

- Silicone acrylic ST 77.

- Elastomeric ST 79.

- Polymer-cement ST 137.

- Silicone-silicate ST 174, ST 175.

Acrylic plaster is easy to apply and adheres well to the surface. Silicate provides maximum water resistance. Silicone adheres well and resists precipitation well. The polymer in its composition maintains structural integrity during temperature expansion.

Characteristics of pebble plasters:

- Good adhesion to the base.

- Plasticity lasting 1 hour.

- Water and UV resistance achieved 24 hours after application.

- The water absorption coefficient is no more than 90 g per 1 m².

- Strength coefficient 2.5 MPa.

- Application temperature +5°C ~ +30°C.

The best prices for installing a wet facade!

| Service | Cost, rub. per sq. m |

| Installation of a “wet facade” (plaster) without taking into account materials | 700 — 900 |

| Installation of a “wet facade” (plaster) taking into account materials | 1100 — 1500 |

| Installation of an “insulated wet facade” without taking into account materials | 1100 — 1350 |

| Installation of an “insulated wet facade” taking into account materials | 1900 — 2300 |

Video recommendations for applying Ceresit textured plaster

We would like to invite you to study the video material on applying decorative plaster ST 174.

Ceresit plaster will help not only update the facade of your home, but also make it more secure. The quality of the products will allow you not to worry about repairing external walls for a long time. And the work done by yourself will save money that can be spent on other needs. But if you are worried that plastering work is beyond your capabilities, then contact specialists, and our article will help you control the quality of the process.

Technical characteristics of popular material

Ceresite is considered to be a certified product that has passed a huge number of tests. Facade plasters from this manufacturer differ from others by unique characteristics.

- The density of the mixture is 1.7 kg per dm³.

- Repair work can be carried out using decorative plaster at temperatures of 5-30 degrees above zero.

- The drying time of the layer for texture treatment does not exceed 15 minutes.

- The material is resistant to moisture.

- It has fairly stable hydrophobic properties and a low moisture absorption rate.

- The mixture is resistant to various types of contamination.

- A large selection of textures, the “bark beetle” Ceresite is especially popular.

Facade plaster from Ceresit has excellent characteristics when compared with some other manufacturers. For the production of products, only modern equipment and quality-tested components are used to obtain a mixture that will make your home or premises visually attractive and protect it from harmful factors.

What makes Ceresit stand out from its competitors?

In order to make a beautiful exterior coating, it is customary to use facade plaster, which has a grooved structure. The mixture is ideal for treating surfaces made of concrete, cement, gypsum or sand. Thanks to this, decorative plaster from the Ceresit company can be used on different surfaces and at the same time, it will retain its original texture.

Manufacturers make a special composition that allows you to obtain a material with a high elasticity index, especially when compared with other companies.

Ceresit plaster does not fade under the influence of sunlight and is quite resistant to mechanical damage. If we talk about competitors’ products, not all of them divide the mixtures they produce into winter and summer. This parameter is especially important to consider in situations where work is performed at low temperatures, at non-traditional times for repairs.

Facade plaster Ceresit on polystyrene foam (foam)

For external wall insulation with polystyrene foam, special mixtures Ceresit CT 85 and Ceresit CT 85 pro . These are polymer-cement mixtures with mineral filler and organic modifying additives. They are used simultaneously as an adhesive for PPS boards and as facade plaster.

Ceresit CT 85 mixture can be used at any time of the year at a temperature of +1°C ~ +30°C. Ceresit CT 85 pro solution is used during cold periods at temperatures +1°C ~ +15°C.

Characteristics:

- Good adhesion to all wall materials and foam.

- Good plasticity, convenience and ease of application.

- Consumption for gluing is 6 kg/m², consumption for plastering is 5 kg/m².

- High vapor permeability.

- High resistance to precipitation and UV rays.

- Ready for use at sub-zero temperatures 24 hours after application.

Disadvantages of a Ceresit wet facade

With such advantages of this insulation system, it is difficult to talk about the disadvantages. But basically all these shortcomings are associated with the installation work.

- The temperature range for installation work is from -5˚С to +50˚С. This means that in the cold season, in order to prevent the mixture from hardening, you need to make a special polyethylene cover. If the temperatures are negative, then for work you will need a heat gun, the duration of which depends on the thickness of the layer of the applied mixture, which must dry completely. And this means that the energy costs are so high that there can be no talk of any low cost of this method of external insulation of the facade.

- Strict environmental humidity requirements for this type of work are also a significant disadvantage. If the ambient air humidity exceeds 40%, the mixture will dry unevenly and not completely. This means that the surface will be covered with stains of plaster that dried at different times. The same applies to installation work during precipitation.

- Hot weather also does not contribute to high-quality insulation using the Ceresit “wet facade” system. The installation technology does not allow operation in direct sunlight. Uneven heating of areas of the mixture will lead to hardening of the surface in violation of those conditions, which in turn will provoke cracks and delamination of the layers of plaster.

About the manufacturer of facade systems "CERESIT"

The owner of the world-famous brand “CERESIT” is an equally famous German company, which was founded more than 140 years ago. Since then, the company has occupied a leading position in both the consumer and industrial sectors.

Henkel's headquarters are located in Düsseldorf (Germany). The company is represented in more than 120 countries, and its staff includes more than 47 thousand employees. For this reason, Henkel is considered one of the most multinational organizations in the global market, based in Germany.

Henkel has three main business units:

- “Cosmetics and personal care products”;

- “Cleaning and detergents”;

- "Adhesives and technologies."

The most important part of the development and production of materials for construction and repair is occupied by construction adhesives and mixtures under the CERESIT brand, which include 5 product categories:

- for tile cladding;

- for flooring;

- for making screeds;

- for insulation of facades;

- for waterproofing premises.

What is a wet façade?

Today on the Internet you can find many incorrect definitions of “wet facade”, in which this term refers to insulation, for the installation of which water-based glue is used. In reality, things are somewhat different.

Technically, it is correct to call such facades thermal insulation composite systems for insulation with external plaster layers. Slabs of pressed mineral wool or polystyrene foam are used as insulation, the thickness of which is selected taking into account the climatic conditions of the region and the initial thermal conductivity characteristics of the walls.

The “wet facade” consists of the following layers:

- base - a flat facade wall made of brick, wood, foam blocks, OSB sheets or monolithic concrete (if the wall is not level, air will circulate between the insulation and the wall, which will significantly reduce the effectiveness of insulation);

- thermal insulation layer of non-flammable polystyrene foam of facade grades (fixed with glue and disc dowels);

- fiberglass mesh (it is recommended to purchase alkali-resistant material);

- a layer of ordinary or decorative plaster (finishing with light facing facade slabs is allowed).

Facade plaster Ceresit “Bark beetle”

Among decorative plasters, the most popular is the “Bark Beetle” coating. It is applied with Cerezit ST 35 pebble plaster with different-sized granules of 1–3.5 mm. The bark beetle solution is applied to the base in the same way as others.

When grouting with a plastic trowel, large granules move, creating grooves in the binder that look like traces of the activity of bark beetle larvae. The texture pattern is formed by linear, circular or chaotic movements of the master’s hand.

Installation of the Ceresit “wet facade” system

Installation of a ceresit wet facade is carried out in several stages, which include:

- preparatory work;

- installation of insulation;

- securing the reinforcing mesh;

- applying a plaster layer;

- surface painting.

High-quality performance of work at each stage is important for all subsequent ones and affects the final result.

Ceresit plaster insulation system - device sequence

Preparing the wall surface

Work on the installation of a facade system begins with an inspection of the surface of the walls on which the mounted materials will be fixed. At the same time, the outer surface is thoroughly cleaned of any dirt and carefully inspected. Defects in the form of cracks, irregularities, potholes are detected and, if necessary, eliminated.

In some cases, to improve the load-bearing capacity of the walls, they are covered with a rough layer of plaster. After this, the entire bearing surface is primed.

Preparing the wall for the construction of the facade requires special attention - the surface must be smooth

To reliably ensure the stability of the system, a U-shaped metal profile is fixed at the bottom of the wall, which plays the role of a support bar. This element is installed along the entire perimeter of the building, as well as above windows and doors. It protects the lower edge of the structure from moisture and allows the weight of the entire multilayer structure to be properly distributed.

The support profile is installed at a height of 30−40 cm from the ground level or installed on a protruding plinth. A gap of 3-4 mm is left between the individual slats to compensate for possible thermal expansion. For fastening, plastic dowels and screws are used, which are driven in every 15-20 cm.

Installation of insulation

Installing insulation is not a complicated process, but it is responsible

After completing the preparatory work, they begin to install the insulation. First, mineral wool boards or polystyrene are glued to the prepared surface using Ceresit SM-15 or SM-11 wet facade adhesive. The glue is applied with a notched trowel in the form of a wide strip along the entire perimeter of the slab and a dotted area in the center. This allows for reliable fastening of the material while economical use of adhesive. To do it correctly, it is enough to cover 40% of the surface of each slab with glue.

The slabs are installed from the bottom up, starting from the bottom row, which is immediately installed along the entire perimeter. Installation of each row starts from the corner. Wherein:

- vertical joints between slabs in adjacent rows should not coincide;

- adjacent slabs are pressed tightly against each other to minimize the thickness of the seams;

- Excess glue protruding from the seams is immediately removed.

Scheme of fastening the insulation with a disc dowel

Three days later, after the glue has completely dried, fastening plastic dowels are installed, the design of which includes a wide disc-shaped head, a plastic nail and an expanding nail to be driven in.

The length of the dowels used depends on the thickness of the insulation and the wall material. The penetration of a nail into a wall made of porous materials should be at least 9 cm, and for hard materials, at least 5 cm. 6-10 pieces are driven into each slab.

Installation of the reinforcing layer

Reinforcement begins no earlier than one day after installing the insulation. The material used for the reinforcing layer is a façade mesh made of fiberglass with a special alkali-resistant coating. Adjacent mesh strips should overlap each other by 5-8 cm. If it is necessary to strengthen individual sections, the mesh is applied in two layers. A special corner with an edge mesh is installed at corners, doorways, windows and lintels.

The reinforcing layer is applied to the insulation in the plaster layer

The reinforcing material is covered with a layer of adhesive composition 2-3 mm thick, and the total layer thickness can reach up to 5 mm.

Finishing of the facade

The final stage of installing a “wet” Ceresit façade is finishing. It involves applying a layer of plaster to the surface and then painting it. You can begin this work only after the reinforcing layer has completely dried, which lasts 3-5 days.

Finishing of the facade

The material for the plaster layer must have high vapor permeability, good resistance to adverse weather conditions and high mechanical strength. For this purpose, special dry facade mixtures Ceresit are used. Plastering work can be carried out in dry weather at an outside temperature of +5°C to +30°C, while direct sunlight is not allowed on the fresh plaster layer.

The surface is painted with a roller or through a spray bottle with acrylic, silicate or silicone Ceresit paints.

Advantages of the Ceresit facade system

Ceresit facade systems make it possible to reduce the consumption of basic building materials during the construction of walls without increasing heat loss during the cold season. It gives the building a beautiful appearance for a long time and is much cheaper in cost than other structures.

The advantages of this design are:

- provide an attractive appearance of the building;

- low weight with high thermal efficiency

- absence of “cold bridges”;

- shift of the dew point into the thermal insulation layer, which eliminates the formation of wet condensation in the walls;

- complete absence of possible freezing of walls in the event of microcracks;

- providing additional sound insulation of walls.

At the same time, the relatively low cost of the necessary materials makes the plaster facade of the Ceresit system quite affordable for most developers. In addition, it should be noted that it is easy to install, significantly reducing construction time.

Choice of insulation

One of two options can be used as insulation for facades using the wet method:

- polystyrene foam (plate thickness 5-10 cm);

- high-density mineral wool (it is best to use basalt wool).

When choosing a material, you can be guided by four main criteria:

- Price. In this regard, polystyrene foam wins because it is a cheaper material.

- Vapor permeability. This property is inherent in mineral wool, which allows the walls of the house to “breathe”. Polystyrene foam does not have this quality.

- Complexity of work. It is easiest to work with foam plastic, due to the higher rigidity of the material.

- Fire hazard. Foam boards are flammable, so they need to be treated with fire retardants. Basalt wool does not burn and can withstand temperatures up to 1000 degrees.

Decorative plasters

Instead of wallpaper or paintwork, thin-layer decorative plaster can be applied to the leveled base. The cheapest option is to use cement-based dry mineral mixtures, some modifications of which allow you to work in winter conditions. Name of dry mixtures of decorative plasters Ceresit

| Brand name | Volume of mixing water, l | Viability of solution, min | Mixture consumption per sq. m., kg | Approximate price/packaging |

| Decor Plus | 5-5,5 | 60 | Grain 1 – 1.8 Grain 2.5 – 3 | 340 rub. / 25 kg |

| ST 35 and ST 35 “Winter” | Grain 2.5 – 2 Grain 3.5 – 3 | 560-660 rub. / 25 kg | ||

| ST 137 and ST 137 “Winter” | Grain 1 – 1.8 Grain 2.5 – 3 | 700-900 rub. / 25 kg |

How to properly prepare the mixture

To prepare the mixture, you must have a container (bucket) for mixing it (use only stainless steel utensils). The manufacturer most often produces plaster in 25 kg bags.

To correctly calculate the required amount of mixture, it should be taken into account that the recommended mixture consumption per 1 m² is from 2.5 kg to 4 kg.

For 5-6 liters of water you need to add 25 kg (bag) of dry composition. Cold water must be used.

The plaster should be mixed with a mixer or concrete mixer.

The mixture is left for three minutes to completely dissolve, and then it should be mixed again.

IMPORTANT!

The prepared mixture should be used within three hours.

The frozen mixture cannot be used.

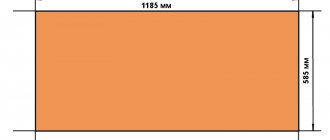

Sanding the insulation planes according to the three-meter rule

Sanding is done using a plywood grater measuring 400 x 600 mm, 500 x 700 mm with sandpaper glued to it with a coarse grain of 100 microns (1 mm). This sanding allows you to smooth out small irregularities that occurred when gluing the insulation due to initial deviations in the geometry of the glued sheets and due to errors during gluing. Small graters should absolutely not be used on large surfaces; small graters create unevenness and depressions when sanding.

Silicone facade plaster Ceresit

The silicone mixture is made on the basis of synthetic resin, to which fillers and modifiers have been added. Advantages of silicone plaster:

- purer colors;

- the best plasticity of the solution;

- maximum resistance to precipitation;

- does not form microcracks;

- does not shrink after drying;

- antiseptic properties prevent the accumulation of dust and dirt;

- synthetic material can be washed with water;

- fungi do not settle on the surface;

- silicone does not react with the chemical composition of the atmosphere and does not form salt stains.

Silicone plaster is more expensive than cement and acrylic plaster. But its consumer characteristics are higher, it lasts longer, and therefore is much more profitable.

Installation of dowels

Dowels additionally secure the insulation sheets to the facade; they are installed either in accordance with the official recommendations of the system holders, two in the middle of the slab and the rest at the joints of the slab with adjacent slabs

or one “star” in the middle and four dowels in the insulation body closer to the edges

If the insulated wall is made of monolithic reinforced concrete, solid brick, expanded clay concrete, then the expansion zone of the dowel should be 50 mm, the total length of the dowel is approximately the thickness of the insulation + 50 mm.

If the insulated wall is made of foam concrete, aerated concrete, slotted brick, multi-slotted blocks, warm ceramics, then the spacer zone is 100 mm, the total length of the dowel is approximately the thickness of the insulation +100 mm.

The top of the dowels must be carefully covered with CeresitST 85 or ST 190 glue; the coating is done after the final sanding of the surfaces to the three-meter rule.

Installation of mineral wool boards and expanded polystyrene

Since slabs of expanded polystyrene and mineral wool have different chemical compositions, different brands of glue are used to glue them to the prepared base:

- for slabs made of facade PPS-16F, extruded EPS or Ceresit polystyrene foam, use cement-based compositions CT 85, CT 83 or budget Termouniversal adhesive. The technological pause after gluing polystyrene foam with cement adhesives is 72 hours;

- when installing polystyrene foam on metal, wood, chipboard, OSB, plastic or on a wall treated with bitumen waterproofing, use a more technologically advanced polyurethane foam adhesive ST 84. After gluing the insulation with this glue, further work can begin after 3 hours, and the period of complete setting limited to 15 minutes. The polyurethane foam composition can also be used on traditional substrates;

- For the installation of Ceresit mineral wool boards, special brands of glue are produced, which are distinguished by a large number of polymers and microfiber. Thanks to the “reinforcing mesh” effect, compositions ST 190 and ST 180 have increased reliability of slab fixation.

Cement compositions are applied to the insulation boards either using a comb 10-12 mm high, or using a layer of glue around the perimeter of the board and several (3-9) spots in the middle of the sheet, depending on its area and the unevenness of the wall.

The polyurethane foam composition ST 84 is applied with an edging around the perimeter and two or three horizontal stripes in the center of the sheet - the amount of glue and the distance between the horizontal stripes depend on the unevenness of the base or the size of the polystyrene foam sheet.

Application of quartz primer Ceresit ST 16

When the base reinforcing layer has completely dried, at least 72 hours after the last re-upholstery, you can begin applying the Ceresit ST 16 quartz primer. The Ceresit ST 16 primer is applied with a paint brush, a wide brush, or a flute. The primer can be white, not a tinted base, or it can be painted to match the color of the future Ceresit decorative plaster.

Facade plaster Ceresit for aerated concrete

Aerated concrete has an open-cell structure, which increases the thermal insulation and vapor permeability of walls. But due to its cellularity, the material has high hygroscopicity, which negatively affects the frost resistance of the wall material. Leveling façade plaster Ceresit ST 24 helps to create walls that are “breathable” and at the same time not afraid of precipitation.

"Ceresit" ST 24 is made from Portland cement with the addition of perlite and polymer fiber. Mixture characteristics:

- Universal, for external and internal work.

- Highly adhesive, adheres well to cellular autoclaved and non-autoclaved concrete. Applied manually and mechanically.

- Low thermal conductivity coefficient 0.3 W.

- High vapor permeability coefficient of more than 0.1 mg.

- Apply a layer of 3–30 mm.

- The working time with the solution before hardening begins is more than 1 hour.

- Air temperature during application +5°C~+30°C.

Installation of abutment elements on blocks of window and door openings

During insulation, the insulation must extend at least 15-20mm onto the window frame to prevent a cold bridge. The abutment element with the mesh is glued to the window frame on three sides, top, right and left.

How to replace "Ceresit" on the facade?

You can find a lot of debate on the Internet about how to replace Ceresite on the facade. Among them there are proposals to use materials from such brands as “Stomix”, “Caparol” and “Bolix”, however, due to its own characteristics, in practice “Ceresit” most often turns out to be the most preferable option.

Installation of facade insulation system

Installation of a façade insulation system consists of five main stages and can be completed within a week. The timing varies and depends both on the area of insulation and on the materials used in the insulation system you have chosen - mineral wool or polystyrene foam

What you should pay attention to during installation:

- non-compliance with application technology or the use of chemically incompatible materials from different manufacturers leads to the appearance of cracks in the protective reinforcing and decorative layers

- If you do not ensure tight joining of the insulation boards when gluing, then cracks and tears may appear in the outer layer

- in addition, the seams between the insulation boards should not be allowed to be filled with an adhesive composition - this leads to the appearance of “cold bridges”, and fungal and mold lesions appear on the inside of the wall

- if you violate the technology and put the reinforcing mesh directly on the insulation boards, “spider web cracks” may appear in the decorative layer

Useful tips

A few words about what is the normal temperature at which installation of thermal insulation is possible. Work should be carried out exclusively in dry weather and temperatures from -5C. Air humidity should not be higher than 80%. If the cold is short-lived, then after a certain time the work can be continued again, but it is worth considering that if you leave the insulation boards without a protective shell (from 2 to 3 weeks), this may adversely affect their quality. Therefore, it is necessary to carefully check their condition. If there are minor changes for the worse, such as yellowing of the slabs or excessive dust content, the surface must be cleaned using sandpaper.

Direct sunlight is one of the main enemies of new mounted layers. It is also worth mentioning increased moisture and wind. Metal sheets used as slopes and ebbs, along with construction mesh, the protrusions of which should not exceed 40-50 mm, act as an additional protector of the plaster. It is also worth considering that if the climatic conditions were difficult during work, then the drying speed of the finishing solution will be significantly lower. When preparing the mixture, it is recommended to adhere to the following rules:

- Take elements contained in one batch;

- uniform dosage of water taken from one source.

Heavy and light wet facade

Today there are two types of insulated wet facade: • heavy, • wet.

“Heavy” wet facade

A wet façade of this type does not involve gluing insulation to the wall. Dowels are inserted into the wall, and insulation is attached to them using special hooks. It is reinforced with a special mesh and pressure plates. This mesh is then plastered and covered with a finishing layer on top.

This technology allows the structure to absorb thermal and seismic deformations. Some builders call this design “floating insulation.”

For a heavy wet facade, a thick layer of plaster up to 40 mm is used. This is necessary in order to cover the metal mesh. At the same time, the wall must withstand heavy loads. A heavy wet facade is more expensive than a light one. This option is suitable for insulating walls in regions with harsh climates.

"Light" wet facade

This wet façade insulation system is used most often. Its cost is very low. At the same time, there is minimal load on the walls. Any surface can be used for light wet facade technology. The wall must be flat. If the masonry is made by hand, then before applying insulation, you need to plaster the wall.

The insulation is attached to the wall using dowels and glue containing cement. Solid mineral wool slabs are suitable as insulation. This material is non-flammable and allows air to pass through well. This is especially true for masonry.

Lightweight technology involves laying finishing layers on top of insulation. The thickness of the finishing plaster should be no more than 8 mm, ideally 4 mm.

Preparatory work before starting the installation of the system and strengthening the insulation

The installation of Ceresit facades involves the removal of the previous cladding if its stability is questionable and it has poor adhesion to the walls.

The wet facade system may require leveling before further work, during which you can use Ceresit ST 29 façade putty.

This composition must be applied to surfaces that are pre-treated; for this, a façade primer of the Ceresit ST 17 brand must be used.

Then, in the area of the border that connects the base and the facade, along the entire perimeter of the building, it is necessary to strengthen the base profile, which will determine the starting point for installing the insulation slabs.

Afterwards, a heat insulator must be strengthened onto the surface of the facades; they can be slabs of expanded polystyrene or mineral wool.

They are perfectly fixed on the walls with adhesive mixtures of the ST 85 or ST 190 brands, produced by the manufacturer Ceresit. You can also use ST 84 polyurethane glue, which is sold in cylinders.

The peculiarity of the technology at this stage is that an adhesive mixture should be applied to the surface of the polystyrene foam insulation board, and it is necessary to form a strip, the width of which should be 6 cm, while its height should be 2 cm.

The composition should be applied along the perimeter of the base, 2 cm away from the edges. The mixture should be applied in the central part of the slab like beacons, the diameter of each of which should be 10 cm and the height 2 cm.

The maximum number of such beacons should be 8 pieces.

If the insulation process is to be carried out using mineral wool slabs, then the adhesive mixture should be applied in a continuous layer. Once the glue has been applied and distributed, the slab can be applied to the wall and pressed. At the stage of strengthening the insulation, the Ceresit system should be built from the base profile; the material should be laid in order, moving upward.

Do not forget that during the installation of insulation, its position should be controlled using a level. Now you should wait until the glue hardens, only after, in order not to change the position of the plates occupied by them during the fastening process, you can grind the base using a polisher equipped with coarse sandpaper.

Then the insulation can be further strengthened, as described above.

Installation of the reinforcing layer

At the next stage of arranging Ceresit facades, a waterproofing mixture should be applied to the surface of the insulation; when using polystyrene foam heat insulator, the ST 85 mixture from Ceresit is used; when using mineral wool, the waterproofing mixture ST 190 is suitable. The mixture solution should be applied to the base in a layer of 3 mm.

The reinforcing mesh should be laid on the freshly applied mortar and recessed into it with a trowel. Arranging a wet facade requires laying a mesh with an overlap, which can vary from 5 to 10 cm.

During this process, the mesh does not need to be stretched too much and deepened all the way to the heat insulator. Then the façade system must be equipped with a layer of mortar, the thickness of which must be 2 mm.

The mixture should be applied so that the mesh is hidden underneath. And then the surface should be leveled using a metal grater.

Arrangement of the decorative layer

The process of insulating facades using the Ceresit system involves applying a finishing decorative layer at the last stage.

To ensure better adhesion of the reinforcing and decorative layers, priming should be done. As a primer solution, you can use ST 16 facade paint, the color of which is close to the color of the facade plaster. It should be applied as evenly as possible, using a brush; one layer will be enough.

When constructing a plaster facade using a silicone or silicate mixture, you should use a primer of the ST 15 silicon or ST 15 brand in tandem.

A thin-layer plaster mixture should be applied to the surface as evenly as possible, the thickness of the layer should be equal to the thickness of the grain, while using a trowel, the tool should be held at a slight angle, after which the surface must be further smoothed.

After the facade plaster stops sticking to the tool, it can be given the desired texture using a plastic trowel, which must be held in a horizontal position.