Classification of facade structures

A high-quality ventilated facade for a house made of timber and wooden cottages can be presented in two types:

- A complete system using insulation. The most common design for timber houses with a timber cross-section up to 150 mm.

- A lightweight version - the essence is the same, but without the use of insulation. Perfect for houses made from recycled materials - the facade will hide unpresentability, and for areas with a warm climate, but long rains - its purpose is to resist humidity. The façade material is attached to a thin frame directly onto wooden surfaces.

It allows you to save on energy resources, so it is in demand in budget buildings and in regions with harsh climates. The system is distinguished by its impressive layers and lathing structure.

Any device for a ventilated facade of a timber house is available for self-installation, subject to all design rules. Next about facade materials.

What are the features

Before choosing a ventilated wooden facade, it is worth taking a look at its features.

The design differs in that free air access is provided to the walls. Due to this, dampness does not accumulate in the wood. Properly dried and treated wood reduces heat loss and also prevents the growth of fungus and mold.

This kind of cladding is not scary:

- precipitation;

- wind;

- Sun rays;

- temperature changes.

When finishing is done with a wooden lath with a gap for ventilation, the service life of the building is significantly increased. There is no problem of rotting, and the need for repairs does not arise soon. In the summer you can turn on the air conditioner less intensively, and in the winter you can save on heating.

Materials for construction and finishing

Since the structure without decoration is a lathing, it can be represented in two options - wooden bars and metal profiles. The latter option is undesirable for a log house, unless the finishing material is corrugated sheet or steel siding.

This is due to the formation of condensation from the temperature difference between the materials, and moisture is always detrimental to wood. Wood for sheathing must meet the following conditions:

- The cross-section of the beam is not less than 50 mm. The width is calculated from the thickness of the insulation + 20 mm.

- Wooden blocks must not have any defects. Firstly, they have a responsible mission - they will carry heavy cladding, and secondly, the damage that has begun will easily transfer to clean elements and the service life of the facade will be reduced.

- All materials must be treated with all kinds of protection - from moisture, parasites and fire.

You can cover a wooden object with anything. Ventilated facades of houses made of timber can be presented in various options - siding, panels, steel sheets, wood.

Why insulate a wooden house?

There is a way out of the situation if you use a layer of polystyrene foam as thermal insulation, but only if the homeowner does not mind having a “non-living” structure made of wood. Polymer material, releasing chemical components due to moisture and heat, remains only a decorative design. Work on the reconstruction of wooden houses, as well as the arrangement of the facade, is usually carried out with hanging systems - siding, PVC panels, block houses, clinker tiles, etc.

An integrated approach to cladding

Installation of a wooden ventilated wooden facade allows you to decide:

- Insulation issue.

- The problem of leveling noticeable wall defects.

- The task of decorating and creating additional strength.

- Problem with sound insulation of wall structures. It also simplifies their care and makes it possible to extend the period until the next repair work and use of the house as a whole.

Pie wall with ventilated façade

This ventilated “pie” turns out to be multi-layered. It consists of a wooden wall surface, an insulating layer, a membrane to protect against moisture, a ventilation gap and a finishing layer of decorative cladding. Each layer plays a specific role in a ventilated facade for a wooden house, so it is impossible to change this “filling” for something else. The choice of insulation material will depend on the financial capabilities of the home owner, as well as climatic conditions in the region. In the northern regions, special attention is paid to insulation.

Note: it is believed that we can talk about effectively saving energy only if the thickness of the insulating material is from 7 to 10 cm. For this, you can use polystyrene foam. It will not absorb moisture, which is an additional plus. The material is also characterized by a low level of vapor permeability, and this is considered a disadvantage. In contrast, mineral insulation is famous for its excellent noise absorption, but at the same time it is afraid of water.

At the same time, the windproof film will protect the structure from the destructive effects of gusts of wind or moisture. A layer of ventilation that prevents the formation of condensation can be created by installing a lattice structure. The lathing has another useful function - finishing parts are attached to it. The ventilated facade of a wooden house allows its residents not to freeze in winter and not to suffer from the summer heat.

How to make a ventilated facade correctly

Before the walls of a wooden house are decorated to the taste of the owners, it is necessary to carry out a number of manipulations related to the protection of the building material of the building itself. That is, the walls under the facade must receive high-quality treatment with all kinds of protection - there will not be another time for such work. If this is neglected, then the damage processes that have begun and undetected will develop, and then the crowns will need to be changed. Further:

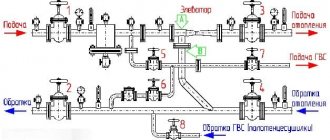

- Sheathing device. The timber is placed on the walls using a building level in only one position - vertical or horizontal.

- The installation step of wooden guides depends on the width of the insulation used, or 50-60 cm if the design does not require it. Cotton mats or styrene slabs should lie in sectors without movement or unnecessary fixation.

- Waterproofing is laid over the laid insulation. This quality is provided by rubber, PVC films, roofing felt or other material offered in variety by the industry.

- If in advance the lathing was not satisfied with the required parameters - the width of the bar is 70-80 cm, then a counter lath is placed on top of the waterproofing. This is easy to do - the contours of the wood protrude under a layer of film or rubber, and fixing the next layer will not be difficult.

This rule is immutable, even if the facade systems are different depending on the type of construction. Only in this way will ventilation be ensured.

Lastly, decorating material is installed. Many owners, in order to preserve the environment, resort to natural lining, imitation timber, and block houses.

However, it is worth noting that all types of wood for ventilated facades must undergo intensive treatment with impregnations, otherwise damage will not take long.

How and with what to insulate timber houses from the outside with your own hands

Due to the severe frosts inherent in most of Russia, when in the winter months the air temperature outside reaches 40 degrees below zero, creating high-quality thermal insulation of walls will require a lot of effort. It is at this time that the pressing question arises about insulating a house built from timber.

Material selection

In order to properly insulate the facade of a wooden house, you need to be extremely careful when choosing a thermal insulation material. Finishing with foam plastic is one of the simplest options, and its cost is somewhat cheaper than analogs made from other raw materials. But it has several significant shortcomings that negatively characterize it in our case. This is a low coefficient of vapor permeability, and also the fact that when exposed to fire, it melts and releases dangerous vapors.

Do-it-yourself external insulation of the facade of a timber building using mineral (basalt) wool will allow you to achieve better vapor barrier of the walls.

External finishing of any wooden facade with polystyrene foam reduces its “breathing” characteristics.

Independent material calculation

You can correctly calculate the required amount of material without much difficulty. For an accurate calculation, you will need the dimensions of all walls that need to be insulated. Using simple mathematical operations, determine their area (length multiplied by width, minus the area of window and door openings) and add to it another 15-20% of the resulting amount for the reserve. This is exactly the amount of thermal insulation required to finish the outside of the house in one layer.

If everything is extremely clear with the calculation of the area, then special calculation programs are used to determine the thickness of the required insulation layer. They use temperature indicators of a specific region, the thickness of the walls of a log house, as well as the thermal insulation coefficients of a specific type of insulation. You can perform the calculation “with your own hands” or with your head based on the following requirements:

- If the thickness of the walls of a wooden building is at least 20 cm and the temperature is not lower than 20 degrees below zero, you can install 5 cm insulation in one layer;

- When frosts are more than 20 degrees below zero, you need to use two or even three layers of thermal insulation.

Wet technology

This technology involves gluing insulation directly to the wall surface. This can be done using special glue. After that, a protective abrasive mesh is applied to the thermal insulation and the facade is plastered or painted. Important! When doing the work yourself, all adhesive and painting mixtures must be vapor-permeable. This is necessary in order not to damage the vapor barrier of the building wall. The “wet method” technology with polystyrene foam as insulation is the most inexpensive way to thermally insulate the facade of timber houses.

Ventilated facade technology

Insulation using a ventilated facade allows you to create a system in which drops of condensation will be discharged outside without causing damage to the structure: load-bearing walls, insulation and finishing materials. This will be done as follows: water vapor settles on the inner surface of the cladding, and thanks to the air space between it and the heat insulator, it will evaporate and be removed outside the structure. This technology is the most optimal for use on timber buildings.

Installation of sheathing

Before insulating the facade from the outside, it is necessary to carry out an antiseptic treatment of the wall surface. This will prevent the formation of fungi and harmful insects in the wood that destroy the material.

In order to properly insulate a log house with your own hands, you need to mark the walls in the horizontal and vertical planes. This is done using a level, level, plumb line, liquid or laser levels.

Choice of insulation

For the complex design of a ventilated curtain facade, it is necessary to determine the thermal insulation material. For “breathing” walls of a wooden building, thermal insulation must support steam movement. Taking into account the requirements, only mineral wool is suitable as insulation. Among its types, we highlight stone wool with the following advantages:

- Low thermal conductivity.

- Density with sufficient rigidity retains a stable shape and does not settle in high humidity.

- Refers to non-combustible materials. This is an important characteristic for a ventilated system, where the ventilation gap works on the exhaust principle and in the event of a fire will contribute to the rapid spread of fire.

- Has good soundproofing properties.

- Environmentally friendly.

The task of wooden ventilation facades

in which the presence of ventilation is provided under the casing. Insulation is also used most often. It is needed to remove steam from the house, and can also be built in a lightweight and full version.

There are two main tasks for a full-fledged ventilated structure. One is to create an air gap for ventilation. The second is for the building to acquire excellent thermal insulation characteristics. This kind of design consists of:

- metal frame;

- insulation layer;

- waterproofing protective film;

- facing material.

Correctly and efficiently made wooden ventilated facades help to save on costs, on heating in winter and on electricity in summer, which the air conditioner consumes. This design is used in places where there are much more cold days a year than warm ones.

A simplified or lightweight ventilation system consists of a frame and a facing layer. Thanks to this device, air circulates and the external walls are protected from environmental influences. If you follow the installation procedure, it is not difficult to make a ventilated façade.

The most common methods of insulation

When choosing insulation for the walls of a house, you first need to take into account its thermal insulation characteristics. In addition, an important factor is the tendency of the material to “slip”. Different installation technologies imply special requirements for thermal insulation.

The structure of the wall insulation is similar to a layer cake. The structure consists of several layers:

- Thermal insulation material;

- sheathing (not required when installing a wet facade);

- vapor-permeable moisture-protective membrane or reinforcing mesh (depending on the chosen technology);

- finishing layer of facing material.

useful in work

The technology of insulating walls using the wet method is what professionals call pie. The thermal insulation material is glued to the facade using adhesives, then treated with decorative plaster.

Wet facade

Ventilated facade

The technology of insulating walls using a ventilated method is usually used in the construction of shopping centers or high-rise residential buildings; in private construction, an analogue of this technology is siding, but more on that later. Ventilated facades are usually installed with mineral wool insulation. A special frame (sheathing) is organized and the cladding is attached to it. It is worth noting that the choice of cladding is very large. From heavy stone to lightweight modern aluminum composite material.

The basic principle is the circulation of air between the insulation and the facing layer. Thus, the dew point from the insulation leaves with the rising currents.

It is important to know

Failure to comply with technical requirements when installing a ventilated facade leads to dire consequences. For example, if there are no special gaps between the vertical posts of the profile necessary to compensate for temperature deformation, the system will “bend”, the facing layer will be damaged, and accordingly the money will be wasted.