Surface preparation

Both the strength of the fastening and the durability of the façade stucco molding depend on the quality of surface preparation. Therefore, be sure to check the load-bearing properties of the facade wall on which the architectural details will be attached. The wall must be completely cleaned of mortar, mold, efflorescence, dust, dirt, grease and oil.

The wall is cleaned of mortar residues with a spatula, and of dust with a wide brush and rag. If you find hard-to-remove oil stains, efflorescence and mold on the wall, treat these areas with appropriate special compounds. Glued architectural parts must also be cleaned of dust and dirt.

The old plaster must be tapped over the entire surface - and knocked down in those places where voids are found or the plaster is loose and peels off. The surface of the wall must be strong, dry and level - therefore, plaster or putty any resulting irregularities larger than 10 mm. You can also use fiberglass mesh to restore the wall surface. In this case, wall unevenness should not exceed ±10 mm per 1 m2.

If the facade walls are brick, it is recommended to apply a layer of plaster 3–5 mm thick to the places where the products are glued.

Never carry out installation in bad weather. Base humidity of more than 5% interferes with high-quality fastening of architectural details - therefore, at the place of fastening, the wall must be dry and protected from moisture. Also keep in mind that installation should be performed at a temperature not lower than +5 ºC.

Foam stucco

Facade stucco is usually made of gypsum and is considered a very common decorative element. Recently, stucco foam has become a worthy competitor to such parts. It is light in weight, so it can be easily mounted on the wall. The facade of a house with similar decor looks no worse than with a classic design.

Of course, facade stucco molding is more complex to manufacture, since it is a three-dimensional figure. It is best to use finished products that are made by pressing in the factory. However, you can do it yourself, but for this you should use the densest foam plastic - PSB-S-35. Such figures as curls, three-dimensional flowers, bas-reliefs, etc. are cut out of it.

Decorating the facade of a house with polystyrene foam has gained wide popularity. The simplicity of manufacturing and installation allows you to do everything yourself, while the decor is difficult to distinguish from the classic options - plaster, natural stone.

Mounting options

Architectural parts can be attached to the base either with one glue or, in addition to the glue, with the help of anchor devices (dowels, mushrooms) or embedded parts. In this case, it is the glue that ensures a tight, gap-free connection of the parts to the base.

Installation of facade decorative products using adhesive mixture

Installation of façade stucco molding on mushroom-type dowels and nails and adhesive mixture

Installation of facade decor using dowel-nails and adhesive mixture

Installation of a window sill made of façade stucco molding

Installation of window frames with facade decor

Stucco molding on the facade of the house

Before installation work begins, our steeplejacks carefully prepare the surface of the facade for attaching decorative elements. Installation of facade stucco molding is carried out using high-quality construction adhesive and sealant. Treatment of stucco molding with hydrophobic compounds provides reliable protection from moisture and a long service life.

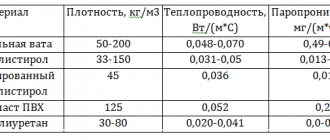

The materials used to create decorative façade elements are polystyrene foam, polyurethane, stone, fiber-reinforced concrete and gypsum, which is used most often than others.

By covering the facade with gypsum stucco, decorative elements can be attached directly to the facade. Before installing the decor, the walls of the building are checked for strength.

Gypsum stucco is covered with waterproofing solutions or covered with a canopy

The facade stucco molding is covered with paint and varnish material. The coating makes decorative elements more attractive and serves as excellent protection from precipitation.

When installing façade stucco, the following work is performed:

Execution of work

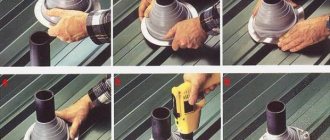

Using horizontal and vertical levels, mark the mounting locations for architectural details with a thin, sharp pencil (not a marker or felt-tip pen). Using an angle cutter or a miter box with a hacksaw, an iron ruler and a square, adjust the parts to the required dimensions for further installation. After adjusting the products to size, proceed to their correct installation.

To do this, take the product, place it on the gluing site and, using a drill or hammer drill, drill holes in the part and the wall where the dowel-nail or “mushroom” will be inserted. Number of holes for fastenings – 3–4 pcs. for 2 linear meters (for fastening iso-siding - 6 pieces per panel). In solid brick or concrete, the hole must be at least 50 mm deep, for all other materials - at least 90 mm. On the product, in the places where the fasteners are installed, it is necessary to drill out the protective layer along the diameter of the heads of the dowel-nails or “fungi” so that the heads do not deform the coating when pulled to the wall.

Using a spatula-comb, we apply the adhesive composition completely to the entire surface of the back side of the part (we use Ceresit CT 83 or Ceresit CT 85 adhesive solution, but they can be replaced with other adhesives of similar properties). We place the part on the gluing site and fasten it with a screwdriver or hammer onto the dowel-nails or “fungi”. The joints between the part and the wall are sealed with adhesive, squeezed out as a result of the part being pulled to the wall. We repeat all the above operations with the next product, leaving a gap of 2–3 mm between them (for parts over 350 mm in height or depth we leave a gap of 3–5 mm, for iso-siding – 5–6 mm).

If the dimensions of the decorative elements are very large, they can be secured using ordinary dowels (without a cap). The fasteners should be installed in the wall before gluing, so as not to damage the protective layer of the stucco elements. In this case, holes for putting on dowels are made from the inside of the element so that they do not reach the outer protective shell by 20–30 mm and do not damage the shell.

With such a dowel fastening, it is also necessary to ensure that the part is firmly pressed against the wall until the glue sets - secure the part with temporary supports.

The joints between the parts are sealed only 1–2 days after the final gluing of the parts to the facade.

If the parts are small (up to 350 mm), take façade assembly adhesive for gluing polystyrene foam (Ceresit CT 84, Penosil Fix&Go Montage or TYTAN Styro 753) and carefully fill all the seams until the adhesive composition comes out outside the part.

If the size is over 350 mm, we drill through holes on the part on the right and left (according to the diameter of the nozzle on the can of mounting adhesive) at an angle of 45º towards the seam. Then we push the adhesive composition through these holes so that it comes out from the outside of the part along the entire seam, including the holes made (as a result, after the glue dries, a so-called “lock” is obtained).

A day after it has completely dried, the glue that has come out of the seams is cut off with a stationery knife along the contour of the part.

At the place where two parts are glued on the right and left, a chamfer is cut at an angle of 45º to the thickness of the part’s coating, cleaned of dust and, using a spatula, sealed with elastic putty CMC Izolasyon (the putty can be purchased directly when ordering façade stucco).

After the putty has completely dried, the seams and previously sealed holes for dowel-nails and “fungi” must be sanded and cleaned of dust.

Again, the joints between the parts are sealed only 1–2 days after the parts are finally glued to the facade.

Material capabilities

Firstly, the possibility of using finishing materials for decorating a private home. Numerous elements are shown on the façade of the large two-story structure. However, this does not mean that foam facade decor can only be used on mansions. In any building you can install individual elements or other details, including those of an exclusive nature.

The following are the most common decorative elements made of polystyrene foam for the facade:

When performing them, different techniques can be used:

Secondly, the cladding can be made from standard parts, exclusive elements, purchased ready-made or made by hand.

Coloring

After the treated joints have completely dried, the architectural detail is ready for painting with any silicone or acrylic facade paints - or for coating with water-based decorative plaster.

The acrylic coating on LEPNINAPLAST decorative parts does not necessarily require priming of the surfaces (but in our climatic conditions it is better to prime).

Paint and primer are applied to products with a brush or using a spray gun.

Acrylic paints must be used, or even better, water-based silicone paints.

WARNING : Paints and primers MUST NOT contain solvent or acetone. If the paint or primer you use contains solvent or acetone, cracks (webs) will appear along the surface of the product.

Note:

If the upper surface of the architectural details does not have a slope that ensures natural removal of water, it is highly advisable to install a drain made of galvanized steel or other metal along the entire length of the decor. The junction of the drain with the wall is sealed with sealant. When the thickness of the part exceeds 300 mm, it is better to mount the drain on its own supporting structure - it should not rest on the architectural part.

Required tools:

— level 2–2.5 m long; - angle cutter (carpenter's miter box); — painting chop cord; — metal tape measure, ruler; - plumb line; - pencil; - fine-toothed hacksaw; - hammer; - drill; — hammer drill; - mounting gun; - screwdriver; - breadboard knife.

Recommended Adhesives

Elements of architectural decor LEPNINAPLAST are mounted to the facade using mounting adhesive for facades. We recommend using the following adhesives: - Ceresit solution (CT 83); — Ceresit solution (CT 85); For gluing architectural parts together we recommend: - Ceresit assembly adhesive (CT 84); — Penosil Fix&Go Montage mounting adhesive; — assembly adhesive Tytan Styro 753.

Storage conditions for façade decor:

- It is not allowed to store products on an uneven surface, leaning against a wall, or on surfaces whose dimensions are smaller than the products being stored.

- It is not allowed for uninstalled products to be exposed to atmospheric precipitation.

- To perform high-quality installation, it is necessary to use working tools: a hacksaw, an assortment of spatulas, a breadboard knife, a foam glue gun, a paint roller and tray, a screwdriver; measuring and marking tools: level, square, ruler, painting cord; consumables: masking tape, foam glue, foam glue remover, screws, protective equipment: gloves, etc.

How to paint external slopes and foam trim.

First of all, expanded polystyrene must be reinforced or plastered, they are called both, the meaning does not change from the name.

There are many ways; in principle, two ways to protect polystyrene foam decor can be distinguished:

- in production conditions

- directly on the facade

After applying the protective layer, you can paint with anything, but you should not use paints containing acetone or alcohol, perhaps the reinforced platband will not be damaged, but it’s still not worth the risk, since polystyrene foam dissolves in acetone and alcohol. The best solution for painting facade decor is rubber paint, which can withstand temperature deformations that are inevitable in our climate.

However, any other facade paint will do.

Features of installation of arched and round platbands.

Arched openings are more difficult to finish than rectangular ones. In order to accurately and beautifully design an arched window on the facade of a house, you need to order the platband along with the slope, then everything will turn out very neatly. If you order just the frame, you will have to level the round slopes with putty, which is somewhat more laborious.

Design options for window and door slopes.

It is impossible to analyze the decorative elements of the facade abstractly from the architectural style, even if we take the classification of windows invented by the current generation of plastic window sellers, which migrates from site to site, it is clear that the names in this classification are associated with certain places on Earth or historical periods. This classification lacks any logic and system; order systems are mixed, selected partially without any visible principle; the styles and time periods by which architecture is classified are not taken into account. But since this list is the most common, we decided to illustrate it. There are serious doubts about some positions. If readers have more reliable information, we would be very grateful if you leave it in the comments.

- The Berlin window is a wide three-leaf window, usually located in the inner corner and used to illuminate the rooms formed by the intersection of two wings of the house. There is a description of this window, but the author of the article could not find any pictures illustrating this type of window. Moreover, under this type of window there was always a simple three-part window. This type of window was not found in English-language sources. The source where this term came from on Wikipedia has also not been found. This façade probably fits the description.

- Biforium is a double-leaf arched window or opening divided by a column or column. Such a window was widespread in Western European medieval Romanesque and then Gothic architecture. From the definition of this type of window one can already read the link to a certain time period, location and style.

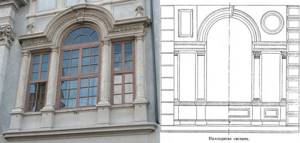

- Bramante window - An arched semicircular window inscribed in a rectangle, appeared in Italy during the High Renaissance Cinquecento late XV - 1527 and was named after the architect Donato Bramante.

- Frame window of Palazzo Cancelleria, Rome

- Fan window is a window, the upper part of which consists of sectors arranged like a fan. This type of window can be found in architecture of different periods and styles. But the first thing that comes before your eyes when you hear “Running Window” is the windows of London. Actually, the so-called type of window, in this case, concerns exclusively glazing and does not affect the external frame; it can be anything, for example, “Bramantine”. Which again speaks to the unsystematic nature of this classification.

Fan glazing in the style of "Liberty" or historical "Modern"

2 examples that show how different a window can be in shape and how different stucco molding can surround a window with the same type of glazing.

- A Venetian window is a double arched window with a column in the middle. This definition raises the greatest doubts, since it essentially echoes the definition of Biforium. Of course, Venice is a city with a unique style, and in the selection of Andre Goncalves windows it is not difficult to recognize Venetian windows even without a signature, but rather by the details of style, color and characteristic stucco elements.

Windows Venice Italy window frames photo.

- Red (slanting) window - the name SKYASCHATOE (not to be confused with jamb, although previously it was the same thing) speaks for itself - that is, framed by jambs. Windows with beautiful carved frames in Russian villages are still called red. The name “red” window was given not only because of its beauty, but also because a lot of light entered the house through such windows. This classification relates to Russian architecture and does not intersect in any way with the order system.

Window trims

Platbands for the windows of the Palace of Alexei Mikhailovich. (photo Red Window)

- A dormer window is a window cut directly into the roof slope and designed to illuminate the attic. This classification refers to the classification of windows by function. A skylight can come in a wide variety of looks in terms of style. Today in cottage construction it is very popular to use the space under the roof, and moreover, modern insulation systems allow this. In modern houses, attic windows are cut directly into the roof; previously, to install lighting in the attic, a small separate house was built, the slopes of which were adjacent to the roof, the window was cut vertically into the central facade of this “birdhouse”. If the attic was located in some castle or palace, such a birdhouse was decorated very elegantly.

- Mezzanine window - a window of the upper mezzanine (Mezzanine), located above the main row of high mezzanine windows. The mezzanine often has a balcony. In Russia, the mezzanine became widespread in the 19th century. Usually this is an element of the architecture of a small house or estate, both stone and wooden.

Russian house with a mezzanine and carved frames on the windows.

Shakhmatovo, A. Blok's estate, mezzanine window. Window trims with a simple profile; wooden shutters also serve as decor for the windows.

The Bolshoi Theater has a row of mezzanine windows on the top floor, a typical example of the Classical style of architecture.

- A second-light window is a window in a dark room through which light falls from a lit room.

Styrofoam trim for a double-height window.

- An enveloping window is a corner window. Since the word “kut” used to mean a corner, now it is more often found in the root of the word “nook”. Why the modern architectural dictionary offers the term “Envelop window” as a definition of a corner window is not entirely clear. After all, it is obvious that for the modern Russian language the term “Corner Window” is more obvious. Corner windows are a modern, technologically complex solution, when choosing which when designing your home you need to understand that this is not a cheap solution, and in Russia it is also impractical. In the history of architecture, such windows are found mainly in southern countries, where there was no need to think about retaining heat in winter and freezing the corners of the house.

The corner window has a brick casing and a stone supporting column.

- Palladium window- a three-part window in which the central arched opening is flanked by two side rectangular openings, separated from the central one by small columns or pilasters. The entire composition is united by a common arch and a rectangular frame. This principle of window construction is named after the Italian architect of the second half of the 16th century. A. Palladio.

The compositionally complex platband of the Palladium window has pilasters in the form of semi-columns and a complex sandstone.

- A panoramic window in large rooms can replace a wall, offering a beautiful view. The latest modification of an antique French window.

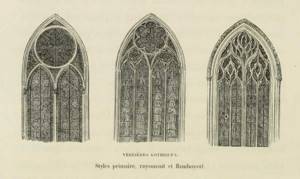

- Rose is a poetic name for a large round window in the western facade of a Gothic cathedral with an openwork interweaving of stone lace filled with colored stained glass. Small roses were also placed on the end walls of the transept.

Sometimes “Roses” were made without glass filling; they served as openwork openings in the walls.

- “Fish bubble” is an arched window opening with a complex curvilinear sash inside in late Gothic architecture. The arched opening has an increased number of branches, while the rule to strengthen the concave parts of the arches remains in force. The fish bubble is formed by a weave of curved lines, reminiscent of a flame of fire in the wind, such Gothic is sometimes called “Flaming Gothic”. Why this particular Gothic style was chosen in this classification is not entirely clear, because there are several styles united by the concept “Gothic”.

Windows in different Gothic styles. The one on the far right is “Fish Bubble” or “Flaming Gothic”, also “Lancet” and “Ray Gothic”.

At that time, the platbands on cathedrals and palaces were made of the same material as the walls, stone or brick.

- Serliana - a three-part window, treated with columns or pilasters and having a semicircular segment above the middle part. Named after the Italian architect of the second half of the 16th century. S. Serlio. Actually, this is the same as the Bramant window. It’s just that a different era gave it a new name.

- A blind window is a niche in the wall that imitates a window opening.

A rare example of a corner blind window with an adjacent thermal window decorated with grotesques.

- A dormer window is a window in the roof of a building intended for natural lighting and ventilation of attic spaces, and sometimes for access to the roof.

The dormer window very often does not have glazing, since it is intended for ventilation; it can also be located on the gable of the house. Sometimes has the appearance of Lucarne.

- Lukarns are called dormers in the form of a protrusion on the roof of a round or oval shape. Lucarnes can also be glazed and serve as roof windows.

The window frame is in the form of a lucarne.

- A Florentine window is a double or triple window with arched ends united by one large arch. Modification of a Venetian window.

- A French window is a tall, floor-to-ceiling window with shallow glass, an arched or rectangular finish and a French balcony at the bottom. A characteristic element of 17th century French architecture

32 windows of Paris in the photo, collected on one sheet.

- And the English window is a term that defines a window with single glass glazing. This window opens by moving the frame up and fixing it. The sash of an ordinary English window is formed from small squares.

- Thermal or Diocletian window is a window that is divided by two vertical pillars (middles) into three compartments - the central one is wider and the side ones are narrower. Such windows are typical of the Roman baths of Diocletian, now rebuilt into the church of Santa Maria degli Angeli e dei Martiri. The photo shows the facade of the Baths of Diocletian with such windows.

500 classic window design options in the photo, examples from different countries:

Production of expanded polystyrene elements

To produce parts for the façade finishing of houses, foam plastic is used that meets stringent technological requirements. The contours are cut out and burned using computer graphics technology. To cut contours, it uses a so-called string, heated to working condition.

Modern production methods make it possible to create products of different sizes and shapes. During the production process, information from computers is constantly transferred to the digital control of machine tools. Thanks to this, the parts fit perfectly together during installation. Fit accuracy is measured in microns.

Manufactured products are reinforced with acrylic fiberglass mesh. Then it is sprayed with a fixing composition. This treatment protects the decor from high humidity and sudden temperature changes. The next stage is drying the workpieces at a strictly defined temperature. Dried products are thoroughly cleaned and polished.

After processing, foam decorations give the impression of being plastered, making them ideal for wall decoration.