- home

- Services

- Residential insulation

- Insulation of the pool - stages of work on installing thermal insulation

—

—

—

When constructing a swimming pool, its thermal insulation plays a key role, because the main problem of such structures located in open areas is large heat loss. In this regard, the question arises: How to insulate a pool to avoid excessively rapid cooling of the water?

The need for insulation work is caused by several reasons. Firstly, due to the difference in temperature between the bowl and the ground, the water will cool down in the shortest possible time, and secondly, without insulation, energy costs will significantly increase, which will be used to heat the water to the desired temperature.

Why is thermal insulation needed?

Insulation helps to increase the service life of artificial reservoirs. The walls and bottom of swimming pools are thermally insulated. Thermal insulation is performed for two reasons:

- The difference in temperature conditions between the bowl and the soil leads to rapid cooling of the water;

- Due to intense cooling, a lot of electricity is spent heating the water in the pool.

To insulate artificial reservoirs, materials with a high thermal conductivity coefficient should be used. This is due to the large temperature difference between the soil and the pool.

The need for thermal insulation of the pool

One way to extend the life of a pool is to insulate it. There are two types: wall insulation and bottom insulation.

Pool insulation is done for two reasons:

- The temperature difference between the pool bowl and the ground, the water will cool quickly;

- The second reason follows from the first. The energy costs for heating the water in the bowl are too high.

It is necessary to insulate the pool with a material whose thermal conductivity coefficient is quite high. Because the ground temperature is about 5 degrees Celsius, and the pool temperature is 25 degrees. The difference is too great.

What are the requirements for a swimming pool site?

Most temporary pools are very, very demanding when it comes to foundation preparation. And the larger the capacity of the container, the more pronounced these requirements are.

What is most important is the presence of a perfectly flat plane lying in the absolute horizon with a deviation of no more than 2–5 mm per meter. Almost all modular pools are self-supporting, but this property only manifests itself when the load is evenly distributed. Otherwise, the walls will be deformed, and the difference in levels can lead to malfunctions of the water treatment plant.

Both inflatable and frame pools are flexible containers made of water-resistant fabric. A load of several tons of liquid is not a problem for such a tank, but the smallest pebble with sharp edges on the litter may well become one. Of course, in case of minor damage there is a repair kit, but draining 3–5 cubic meters of water is a below average pleasure.

Frame pools are more complex and, in addition to a flat and smooth base, require proper installation of supporting profiles and their fastening in the ground. This may introduce some peculiarities into the foundation preparation process.

Finish options

There are not so many materials suitable for use in such difficult conditions. Taking into account high humidity and general requirements for the external design of coatings, the following finishing options will be optimal in terms of their characteristics:

- Tension fabric.

- Hanging solutions made of plastic or metal.

- Painted surfaces.

The last type of design can be excluded from the list of suitable options, since the ceilings will look too ordinary and ordinary. This finish can be used, but, as a rule, everyone strives to get a coating that is more interesting in terms of appearance. Therefore, you will have to choose from the two remaining types of finishes.

Preparing the site - removing the turf and planning the soil

While small pools up to two tons can simply be placed on the lawn, this will not work with larger swimming pools. A massive “puck” will sink unevenly, and besides, the walls of the pool will almost always be damp and slippery.

Let’s start marking the area and first determine what shape “in plan” the base will take. For round pools, markings are made along a string tied to a peg in the center. Pools in the shape of a capsule are marked by two such circles connected tangentially by straight lines. Bowls with a contour close to an ellipse are drawn with three circles: one large in the center and two small ones at diametrically opposite points, then the conjugation is made manually.

The markings should outline an area that is 30–50 cm wider than the pool on each side. First, we go along the contour and undermine the turf with a shovel, driving it into the whole bayonet. We remove the top layer and take away the resulting “bumps” - good material for creating a new lawn. Using a long rule and a level, we prepare a preliminary horizontal plane, and remove the soil deposits with a shovel.

In the center of each of the holes on which the marking is based, we drive a 20 mm tube about 300 mm long so that its upper edge is at a level of minus 5 cm from the plane of the adjacent territory. For further alignment, you should prepare a radius rail - a block, through one edge of which a pin is screwed, inserted into the tube in the center. We tape the rack level tightly on top with tape, and screw a spacer board 100 mm wide from below.

Basic rules of insulation

Before you begin insulating a frame pool, you need to take into account the nuances of the procedure:

- The surface on which the structure is installed must be either cemented or with tightly compacted soil.

- The insulation procedure is carried out when installing the structure in a permanent place. The sides of the pool can be insulated later.

- Lay the insulation material so that the number of joints is minimal. If there are any, seal them.

Construction of a rigid and level platform

For good load distribution, we prepare a dry mixture of 10 parts of “dirty” crushed stone (PGS) and one part of grade 300 cement, which can be replaced with light crumbly clay, increasing the binder content by 1.5 times. Pour a layer of about 5–6 cm, then level it in a circle with a lath. We compact it with our feet, add more mixture and level it again.

Please note that if the pool frame requires embeddings in the ground, they must be installed before pouring the bottom layer. You just need to trim the edges a little so that the difference in the level of diametrically opposite points does not exceed 10 mm.

Now you need to twist the spacer board from the lath and pour washed quarry sand into the pit to a level of minus five centimeters to the block. Afterwards, the sand needs to be compacted with a hand tamper, the missing amount must be added, compacted again, then spilled with a small amount of water. To level, you need to stock up on a second 50 mm shorter block, which will scrape off excess sand in a circle. After alignment, do not forget to pull out the centering tube.

A damper lining is placed on top of the sand cushion. For it, most manufacturers recommend extruded polystyrene boards with a thickness of 30–50 mm. Laying should begin from the center, gluing the joints with reinforced tape. At the edges, where the contour of the pool forms roundings, the slabs are cut with a knife with an outlet 7–10 cm from the bottom of the bowl.

Next, the issue of dynamic compensation is resolved: the water in the pool works as a counter-balancer, swinging the bowl from side to side. In the plane of contact, where the pressure is very high, such vibrations can undock the substrate plates, and if there is a small pebble or sand on the surface, they will eventually wear out the bottom. Therefore, an EPS bed is covered with a slippery synthetic lining. Some people use banner fabric for this, others make do with plastic film.

Hanging solutions made of metal or plastic

This is a completely different type of design. The installation principle and the appearance of the assembled surface are different here. This is not to say that such a ceiling will be less beautiful or functional, but it looks completely different. The main advantage of this design method will be the ability to independently assemble and install the composition.

The covering is assembled on a frame and this, as in the previous case, will take up some space above your head. However, this will be the only similarity with tension structures. Everything else will be very different. The installation of the composition is carried out in two stages: the first is the assembly of the frame, and the second is the installation of the coating itself from individual fragments.

The surface may consist of square metal panels or slats, which in turn may be made of steel or aluminum. They are fixed on the frame with latches or simply laid without additional fastening. Plastic parts most often are long narrow strips connected into one plane using the tongue and groove method.

Semi-inground pool option

There are other options for foundation construction. For example, a pit for a frame pool can be dug up to one and a half meters deep so that the walls protrude only partially above the ground. Of course, such projects cannot be described as typical, because in different situations different methods of excavating soil and strengthening the walls of the pit are applicable.

By deepening the pool, you can do without an inconvenient ladder (most important for deep bowls), and in general the font looks neater and more proportional. Also, and no less important, a heavy tank will rest on a more dense layer of soil, therefore, large-volume in-ground pools are less susceptible to squeezing and tilting on soft soils.

If the preparation station has a heating function, then the pool should definitely be deepened, even if it is small in volume. It is quite easy to lay a small amount of thermal insulation near the walls of the pit, which, together with the bottom substrate, will create the effect of a thermos at least at the border of dense media, where the outflow of heat is most pronounced.

How to insulate a pool?

Having a swimming pool on your own personal plot is no longer a luxury, but still the cost of its construction is not cheap. Therefore, every owner wants to extend its service life. This can be done at the stage of its construction, taking care of good waterproofing, proper installation and selection of quality materials. But so that the operation of a backyard pool is not accompanied by a number of problems, it is also necessary to insulate it.

Insulated pool walls will help retain heat better.

Insulation of swimming pools is an important attribute in their operation.

Foam insulation is considered the most economical and simplest method.

Thermal insulation is necessary for a number of reasons related to both weather conditions and energy. It is a known fact that the soil, even at the peak of the heat, warms up to a maximum of 12°C, which contributes to large heat losses in the absence of thermal insulation. But what about things in winter? Insulation of the pool in winter is simply necessary to avoid cracking of the walls of the bowl in extremely low temperatures. And also if thermal insulation has not been carried out, a large amount of heat loss promises an increase in the cost of electricity used to heat water. To reduce the risk of pool damage and energy costs, it is necessary to insulate it.

Types of pools

Swimming pools come in various types, from special sports and recreational pools to stationary and stationary ones installed at the dacha.

Stationary

Such a pool cannot be moved around the site; a pit is dug under it and formwork is poured for the pool bowl. A place for drainage and water intake is arranged. But there are times when there is no water on the site with which to constantly fill the bowl. In this case, resort to the following solution. At the owner's request, a fire truck is brought in to fill the pool bowl with water. But what about water purification you ask? That's how. A skimmer cleaning system is installed, which, with proper care and proper use of water in the pool throughout the year, the water can not be changed for several years.

Stationary pool

Mobile

This type of pool costs the owner less than a stationary one and does not require year-round maintenance. Only for the summer swimming season. In addition, this type of pool can be moved by the owner to different parts of the summer cottage. In turn, there are several subtypes of mobile pools: inflatable and frame. The first one is one of the simplest. But it is easy to perforate if handled carelessly. The second type is more durable and durable. The water in it can not be changed all season long if a good filter is installed. But unfortunately, you have to face the following problem: many insects, in search of water, find your pool and often drown there. The most unpleasant thing is that wasps can fly in on a hot afternoon and interfere with your rest.

How to insulate a pool?

Having a swimming pool on your own personal plot is no longer a luxury, but still the cost of its construction is not cheap. Therefore, every owner wants to extend its service life. This can be done at the stage of its construction, taking care of good waterproofing, proper installation and selection of quality materials. But so that the operation of a backyard pool is not accompanied by a number of problems, it is also necessary to insulate it.

Insulated pool walls will help retain heat better.

Insulation of swimming pools is an important attribute in their operation.

Foam insulation is considered the most economical and simplest method.

Thermal insulation is necessary for a number of reasons related to both weather conditions and energy. It is a known fact that the soil, even at the peak of the heat, warms up to a maximum of 12°C, which contributes to large heat losses in the absence of thermal insulation. But what about things in winter? Insulation of the pool in winter is simply necessary to avoid cracking of the walls of the bowl in extremely low temperatures. And also if thermal insulation has not been carried out, a large amount of heat loss promises an increase in the cost of electricity used to heat water. To reduce the risk of pool damage and energy costs, it is necessary to insulate it.

Insulation of a concrete pool

It can withstand the delights of the “Russian winter”, the accompanying temperature changes, mechanical stress, and is also durable and strong. It is poured into excavated soil, after which it is subject to hydro- and thermal insulation, since concrete has high thermal conductivity. If the pool is located in an area of wet soil, then the underground flow must be additionally diverted. As a result, the entire structure of the pool is safe.

Insulation options

Experts recommend using foam concrete, expanded clay concrete, foam plastic, expanded clay and foamed polyethylene to insulate the bottom of the pool.

Foam concrete

Foam blocks are convenient to use for insulation due to the fact that it is impossible to make a foam concrete mixture on site. This requires special equipment. Foam concrete is also not transported in the mixer.

Among the advantages of the material it should be noted:

High thermal insulation ability.- Light weight.

- Easy to install.

- Low cost.

- Mechanical strength (grades D500 and higher). If the blocks have a lower grade, then in a few years they will be destroyed by the soil. This will be especially affected by frost heaving of the soil.

Among the negative aspects, there is a high degree of water absorption due to wetting of cement joints. Foam blocks cannot serve as a waterproofing material.

Important! You should resort to insulating the bottom of a pool using foam concrete only in cases where the bowl is located in a heated room. Foam blocks do not like melt and rain water; it is not recommended to use them in outdoor pools.

Expanded clay concrete

A lightweight material produced by mixing concrete with expanded clay.

Pros:

- Light weight.

- Quick installation.

- Resistant to temperature changes.

- Small price.

The disadvantages of expanded clay concrete are as follows:

- Weak frost resistance due to the porous structure.

- Doesn't like moisture.

It is advisable to use it for insulation in pools where the ingress of moisture from outside is minimized.

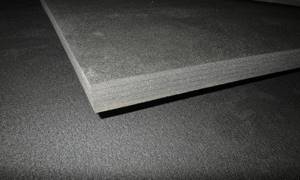

Styrofoam

A universal material for pool insulation that can be used in any type of bowl.

Foam is chosen for the following advantages:

High mechanical strength that can withstand small soil movements.- The material is an ideal hydro- and vapor barrier.

- Little weight.

- Availability and low cost of material.

- Easy to install and does not require special equipment.

Attention! The only disadvantage of polystyrene foam is the insulation of structures that have the correct shape. The material has a sheet structure, so covering a bowl with rounded or non-standard bends will be problematic.

Expanded clay

The material is obtained by firing ceramic pellets.

It is chosen as insulation because of:

- Low price.

- Good thermal insulation.

- Durability.

- Resistant to temperature changes. Expanded clay is not afraid of cold weather.

- Light weight.

- Strength.

- Easy to install.

- Environmentally friendly.

Among the disadvantages of expanded clay it is worth noting:

- High level of water absorption. Due to its structure, it can take months to dry. Wet expanded clay conducts heat poorly and does not tolerate frost.

- Dust formation due to pellets.

It is best to use expanded clay to insulate a pool indoors, where it will not be disturbed by rain or melt water.

Foamed polyethylene

A modern material that has gained wide recognition in many areas of the national economy.

Advantages of foamed polyethylene:

- High moisture resistance, heat and vapor insulation.

- Does not corrode.

- Light weight.

- Eco-friendly and hygienic.

- Relatively low cost.

Reference! The material usually lasts a couple of seasons and then breaks.

It has no other disadvantages. Suitable for outdoor bowls and indoors.

Insulation of a polypropylene pool

Such artificial reservoirs made of polypropylene have become more popular because of their tightness, which every owner of this structure strives for. In addition, a propylene pool is resistant to ultraviolet rays, can be installed in the shortest possible time and is relatively cheap. Insulation reduces the heat exchange between water and slabs, which has a beneficial effect on thermometer readings. In addition, the cracks and holes that formed during the pouring of the foundation are sealed. If this is not done, then liquid from the ground or sediment will penetrate into them, which will increase during frost and render the structure unusable.

Material selection

Scheme of a polypropylene pool.

There is a wide selection of materials for pool insulation on the market. The most commonly used are: foam concrete, polystyrene foam, expanded clay concrete, thermal insulation membranes, expanded clay and so on. But all of the above materials for thermal insulation have one common disadvantage - the presence of seams through which large heat losses occur. And then there is a need to seal them, otherwise the thermal insulation will have little effectiveness.

Experienced builders consider polyurethane foam to be the most suitable material for thermal insulation of swimming pools of all types. This material is easy to use, so insulating even the most complex structure will not be difficult. Using polyurethane foam as insulation for swimming pools will save money, since this material does not have a high price.

Pool system using a skimmer.

Polyurethane foam, compared to other materials, has a number of advantages:

- Polyurethane foam is also waterproofing, which will reduce costs for the latter.

- Has reduced flammability.

- Resistant to temperatures from -100 to 130°C.

- It does not additionally load the structure, as it has a small mass.

- Seamless surface of the insulating layer.

- High adhesion to various types of surfaces.

- Wide range of applications.

- Ease of transportation and storage conditions.

- Chemical resistance to industrial hydrocarbons and weakly acidic sediments.

- Maintainability.

Insulation of an indoor pool

This pool does not clog or bloom, and all because it is under the roof. The building itself is insulated with waterproof components, since high humidity will lead to a deterioration in the performance of the insulation over time. But this does not mean that the room does not need hydro- and steam insulation. On the contrary, the floor, walls and ceiling of a room with a swimming pool need additional insulation from moisture and excessive dampness. And since such buildings are built with thin walls, thermal insulation of the pool area is also required in order to maintain the desired microclimate.

Insulated pool room

Features of insulation of a pool room

To make it pleasant to be in the room where the pool is located, the air temperature should be several degrees higher than the water temperature. On average, the water temperature in the pool is maintained at about 26 degrees, so the air needs to be heated to 28-29 degrees. At the same time, heating requires significant costs, and heaters cannot always provide the desired temperature. The way out of the situation is to make an insulated room for the pool.

Due to the fact that water regularly evaporates from the pool, the humidity in the room is always high. Its level is reduced by organized ventilation, dehumidifiers, etc., but due to the special microclimate of the pool, it is necessary to purchase moisture-resistant materials, both for finishing and for insulation.

Heat loss must be prevented through the following areas:

Basically, walls are insulated from the outside. The construction of internal insulation is extremely labor-intensive; it is necessary to take into account the power of ventilation, heaters, dehumidifiers, climate zone, etc. An error in calculations or a change in the operation of any device for regulating the microclimate leads to condensation between the wall and the insulation. The result is a gradual destruction of the walls and a decrease in heat-insulating properties.

Insulation of pool bowl walls

Heating is required during severe frosts in winter and when there is movement of groundwater. Heat loss is up to 30% through this area. In addition, this method protects the concrete base from freezing and subsequent thawing. The insulation is laid without gaps; if any are formed, they are sealed with sealants.

Recessed or non-recessed tank

To properly insulate an in-ground pool, it must be properly deepened.

To do this you need:

- Measure the perimeter of the pool and dig a pit that will be 1 m wider than the perimeter. The depth of the pit should be no more than 2/3 of the height of the frame pool.

- Make sure that the soil or sand at the bottom of the pit is thoroughly compacted. The best option would be to concrete the surface. Before laying the insulation, make sure that the pit is perfectly level.

Only after such measures have been carried out can you proceed to the procedure for insulating the pool structure. If the pool is buried in the ground, it is additionally recommended to insulate not only the bottom, but also the sides of the pit.

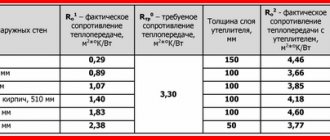

Thermal insulation materials for swimming pools

You cannot insulate a pool with any material you like. This will be wasted money. Because it may not be suitable and may not provide the necessary parameters. Let's figure out which material is best.

Thermal insulation membrane

The advantages of this material include:

- Mechanically strong and elastic;

- Meets all hygienic requirements;

- Very little water shedding;

- Easy to install and weld by hand;

- The welding seams are very durable and double thickened;

- Environmentally safe;

- Easy to repair;

- Can be sent for recycling.

Foam concrete

This type of material waterproofs the pool well, as it has:

- low water permeability;

- resists high pressure;

- withstands impact in aggressive water environments;

- is one of the most budget-friendly waterproofers.

Foam concrete - material for pool insulation

Styrofoam

Polystyrene foam is one of the most accessible and inexpensive types of insulation for a swimming pool, which will stop the transfer of heat from the water to the ground. Its advantages include:

- availability;

- little weight;

- environmental friendliness;

- low price;

- high thermal insulation and waterproofing properties;

- does not promote corrosion.

In addition, this material is easy to install and does not require special installations or machines.

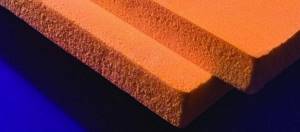

Spray polyurethane foam

This material for thermal insulation of swimming pools is becoming popular. Suitable for most ready-made pools made of polymer and composite materials. Quick and simple surface treatment before installation in a pit provides protection from the effects of groundwater and increases the thermal insulation properties of the walls and bottom of the structure.

Note that insulation with the usual spray foam will be expensive. And this material itself is not very suitable for insulation work. In this area, low expansion polyurethane foam is used. It is characterized by greater mechanical strength, which ensures resistance to mechanical influences from the soil.

The advantages of sprayed polyurethane foam include:

- Possibility of forming an insulating coating without seams or joints. This prevents the formation of cold bridges.

- The shape of the bowl does not matter; polyurethane foam is sprayed onto curved surfaces.

- It has good adhesive properties and has stable adhesion to polymer substrates.

- The material is hygroscopic and performs waterproofing functions.

- Polyurethane foam belongs to the category of fireproof materials; it does not support flaming combustion and goes out without an open source of fire.

Let us note an important point - polyurethane foam is not resistant to ultraviolet radiation, therefore it must be isolated from sunlight. But in the case of processing a surface that is located underground, this problem is no longer relevant.

Foam spraying is also used for the outer surfaces of concrete pool bowls. But after this, the coating is reinforced and plastered using compounds that are resistant to moisture. Often this technology is used as a preliminary step before laying mosaic tiles.

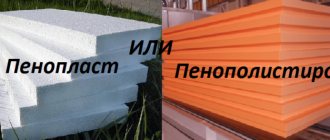

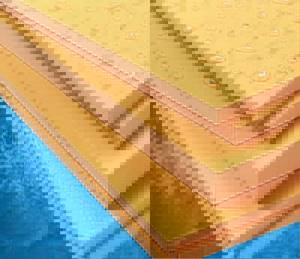

What is penoplex?

The most famous of polystyrenes is polystyrene foam. Everyone knows its characteristics well, and it consists of inflated polystyrene balls, firmly glued to each other using high-temperature treatment. Penoplex is extruded polystyrene foam - a solid mass that is obtained by pressing through an extruder. Penoplex does not crumble, has a high density, is bendable and, unlike polystyrene foam, does not crumble into small pieces from external influences.

What is penoplex?

The most famous of polystyrenes is polystyrene foam. Everyone knows its characteristics well, and it consists of inflated polystyrene balls, firmly glued to each other using high-temperature treatment. Penoplex is extruded polystyrene foam - a solid mass that is obtained by pressing through an extruder. Penoplex does not crumble, has a high density, is bendable and, unlike polystyrene foam, does not crumble into small pieces from external influences.

It is this material that is most suitable for insulating the bottom of a concrete pool.

IMPORTANT! When choosing penoplex, take slabs marked “FOUNDATION”. Since this type of penoplex is used in the construction of basements, foundations, as well as insulating septic tanks. The slabs have increased strength and practically zero water absorption coefficient. The density of the slabs should be 29-33 kg/m3.

Step-by-step instruction

Insulation of the bottom of a concrete pool with penoplex should be included in the design documentation and carried out in stages during construction work. After digging a pit:

- We pour 3 layers onto the bottom: sand, crushed stone, gravel (15-20 cm each).

- We produce cement screed.

- We make reinforcement (periodic profile reinforcement with anti-corrosion properties).

- We install embedded elements on the bottom: skimmers, water level regulator, flow pipe, outlets from the overflow tray, bottom drain, nozzles, etc.

- We fasten them with anti-corrosion wire. We fence with formwork.

- We cast a concrete slab - the base for the pool.

- Let it dry.

- We lay penoplex.

- We seal and connect with mastic.

- We concrete the base.

- We install the frame bowl or start finishing the concrete bowl.

It must be taken into account that the water in the pool is in constant motion, which entails vibration and influence on the bottom of the pool. Therefore, it is necessary to secure the foam blocks very hermetically and in a highly technological manner. It is better to entrust this function to craftsmen who will insulate the bottom in such a way that you do not have to “re-insulate” the bottom of the concrete pool after a couple of seasons.

The cost of penoplex starts from 150 rubles. per sheet.

Types of insulation

The choice of materials and methods for insulating a pool is very large - from economical to highly costly. The most popular are:

- expanded clay concrete,

- foam plastic or penoplex,

- foam concrete,

- expanded clay,

- foamed polyethylene.

These materials have been tested by time and have confirmed their qualities:

- reliability,

- strength,

- high thermal insulation,

- non-susceptibility to outside influence,

- water resistance,

- environmental friendliness,

- a light weight,

- ease of installation.

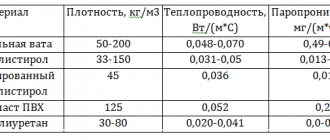

Table of thermal insulation properties of materials:

| Material | Density in kg/m3 | Minimum layer, cm | Thermal conductivity | Hygroscopicity | |

| Bulk | Slag | 1000 | 30 | A | B |

| Expanded clay | 500 | 20 | B | G | |

| Perlite, vermiculite | 40-100 | 10 | D | A | |

| Basalt fiber | 130 | 15 | G | B | |

| Roll | Glass wool | 75-175 | 10-15 | G | B |

| Minvata | 35-125 | 10-15 | G | B | |

| Stitched mats | 75-150 | 10-15 | G | B | |

| Plastif | 50-60 | 2 | G | D | |

| Izover, URSA | 35-125 | 10-15 | G | B | |

| Penofol | 60-70 | 5 | G | IN | |

| Expanded polystyrene | 30-40 | 10 | D | IN | |

| Polyurethane foam | 30-60 | 10 | D | IN | |

| Plate-sheet | Styrofoam | 35-50 | 10 | d | IN |

| Mipora | 25-40 | 10 | D | IN | |

| From mineral wool and glass wool | 75-250 | 10-15 | G | B | |

| Wood fiber | 250 | 1.5-3 | B | A | |

| Foam blocks | Expanded clay concrete | 1000 | 40 | A | IN |

| Foam concrete | 600 | 25 | B | B | |

| Aerated concrete | 400-800 | 20-40 | B | B | |

| Cellular concrete | 400-800 | 20-40 | B | B | |

| Gas silicate blocks | 400-800 | 20-40 | B | B |

Designations:

A - Very high

B. - High

V. - Average

G. - Low

D. - Very low

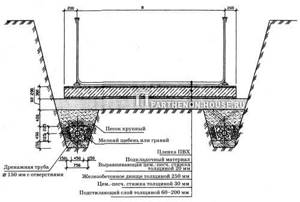

External waterproofing

Groundwater can have a negative impact on the pool bowl, even to the point of its destruction. To protect pools from the destructive effects of hydrostatic pressure, groundwater is removed using drainage systems. Lowering the groundwater level is the most reliable method of protecting swimming pool bowls . A diagram of the drainage arrangement in the presence of groundwater for the pool is shown in Fig. 1.

|

| Rice. 1. Swimming pool drainage diagram (cross section) |

In some cases, when the groundwater level is low, external waterproofing is used. It does not allow groundwater to penetrate through the capillaries of the reinforced concrete bottom and sides into the bowl. For the manufacture of external waterproofing, various materials are used : steel, PVC films, hydroglass insulation, mastics, cement-polymer mixtures and polymer-based roll materials, clay castles, as well as various waterproofing mixtures . When performing waterproofing work, the choice of method of protection against groundwater, as well as the materials used, is very important. The price of the structure and its durability will depend on this. In addition, the quality of execution is especially important. Further, the cheapest materials can accomplish the task if performed well. But if funds allow, then it is better not to save money and purchase special roll-type membranes. They are reliable, durable and easy to install. Installation of such membranes is carried out using hot air welding using industrial hair dryers.

Material selection

Scheme of a polypropylene pool.

There is a wide selection of materials for pool insulation on the market. The most commonly used are: foam concrete, polystyrene foam, expanded clay concrete, thermal insulation membranes, expanded clay and so on. But all of the above materials for thermal insulation have one common disadvantage - the presence of seams through which large heat losses occur. And then there is a need to seal them, otherwise the thermal insulation will have little effectiveness.

Experienced builders consider polyurethane foam to be the most suitable material for thermal insulation of swimming pools of all types. This material is easy to use, so insulating even the most complex structure will not be difficult. Using polyurethane foam as insulation for swimming pools will save money, since this material does not have a high price.

Pool system using a skimmer.

Polyurethane foam, compared to other materials, has a number of advantages:

- Polyurethane foam is also waterproofing, which will reduce costs for the latter.

- Has reduced flammability.

- Resistant to temperatures from -100 to 130°C.

- It does not additionally load the structure, as it has a small mass.

- Seamless surface of the insulating layer.

- High adhesion to various types of surfaces.

- Wide range of applications.

- Ease of transportation and storage conditions.

- Chemical resistance to industrial hydrocarbons and weakly acidic sediments.

- Maintainability.

Modern technologies for insulating swimming pools

One of the most popular thermal insulation technologies for swimming pools is the foam spraying method. Polyurethane foam has all the properties that a high-quality insulation should have. It does an excellent job of preventing the water in the bowl from cooling down.

Inside the artificial reservoir, polyurethane foam is polished, reinforced, and cement mortar is applied on top of it. After this, the walls and bottom of the pool are laid out with mosaics.

The bowl and pipeline are thermally insulated exclusively in stationary reservoirs; in other cases it makes no sense to do this. Mobile models do not require insulation.

The simplest option for insulating a concrete pool using polystyrene foam. Such thermal insulation does not take much time and does not require significant financial investments. Sheets of foam are usually placed around the concrete during the pouring stage. In most cases, the bottom is not insulated. In medium-depth pools with such insulation, the water does not freeze. Polystyrene foam protects the structural material from contact with moisture. Sometimes foam sheets are supplemented with expanded clay backfill, the thickness of which is 20-30 cm. It is preferable to insulate pipelines with basalt mineral wool or foil shells. A sand cushion must be poured under the heat insulator.

Insulated concrete pools are durable and the water in them does not freeze.

Thermal insulation of bowl and pipeline

It only makes sense to insulate the bowl and pipeline in stationary pools. Mobile models simply do not need this. The simplest option for thermal insulation of a bowl is the use of polystyrene foam. Sheets of insulation are simply laid around the concrete during pouring.

As a rule, the bottom is not insulated. The average depth of the pool is enough to prevent the water from freezing. Insulating the pool with foam plastic will also protect the structural material from moisture.

Ultimately, this will save the concrete from the freeze-thaw cycle when moisture enters. Polystyrene foam performs an additional function of moisture protection. Sometimes, in addition to polystyrene foam or instead of it, they use expanded clay backfill with a layer 20-30 cm thick.

For thermal insulation of the pipeline, it is better to use shells made of foil and basalt mineral wool. The shell has already been formed to the size of the pipe; all that remains is to insert the pipe into the insulation and seal the joint with foil tape.

You cannot immediately cover the insulation with earth, since fallen clods of dirt and stones can damage the insulating layer. Therefore, a sand cushion is always poured under the bottom of the insulation. Ideally, the pipes should also be filled with sand until the main part is hidden under its layer.

Pool insulation is an important part of the installation work. Thanks to which you can further save money on electricity, and the water in the pool bowl will always be at the same set temperature.

Natural materials

If you carefully close all the joints between the logs, you can really achieve a noticeable effect.

In ancient Rus' it was customary to caulk the bathhouse. Moss, felt, and tow were tightly packed between the logs. Many people still use this method today. A modern type of inter-crown insulation is jute fibers. This is a natural material, devoid of any “chemistry”. This insulation ensures good air exchange and retains heat. If you carefully close all the joints between the logs, you can really achieve a noticeable effect.

The main advantage of jute is its environmental friendliness. For pennies you can buy biodegradable material that is completely safe for humans and the environment. It does not emit unpleasant odors when heated, and thanks to modern flame retardant impregnations, it is able to withstand fire. With such insulation, going to the bathhouse will be a truly healing procedure.

Attractive to insects. Bugs often settle in the inter-crown space and gradually eat the fibers.

And now about the disadvantages of all natural insulation materials in general and jute in particular:

- Attractive to insects. Bugs often settle in the inter-crown space and gradually eat the fibers. And using a bathhouse infested with insects is not very pleasant.

- Attractive to birds. Magpies and jackdaws pull out moss and take it to their nests. In a few years, such wall insulation may simply disappear.

- Sensitivity to moisture. Before starting work, the material is thoroughly dried. If water gets between the logs, the insulation will quickly rot. And after it, the entire log house will begin to deteriorate.

- Duration of work. All manipulations with fibers take a lot of time.

- Fire hazard. Materials in their pure form smolder and burn beautifully.

Some points can be eliminated if you use combined products: flax batting, jute felt, pine or spruce wood in fluffy form. They are produced in rolls and are impregnated with antiseptics and fire retardants. The performance and durability of such inter-crown insulation is much higher.

Possible alternatives

The following have similar properties to sheet expanded polystyrene:

branded underlays supplied by pool manufacturers;- polyurethane mats;

- rolled materials (linoleum, waterproofing membranes, polyethylene film folded in several layers, penofol, geotextiles);

- sheets of wood-polymer or mineral-based composites;

- flooring made of boards or pallets.

Materials for working with a swimming pool

In addition to concrete, the following basic materials will be required to fill the pool:

- Reinforcement for strengthening the bottom and walls. 12 mm rods are suitable, which are laid out in the form of a grid with 20x20 cm cells. To strengthen the corners, stock up on reinforcement with a diameter of 14 mm, and also purchase wire for tying the rods.

- Waterproofing coating (film, coating composition, membrane, etc.). You also need roofing felt for the primary waterproofing of the pool.

- Thermal insulation. Typically, polystyrene foam, polyurethane foam or polyethylene foam are used.

- Finishing material. Most often, pool bowls are decorated with glass, ceramic or stone tiles.

- Lumber. Needed for making formwork.

- Primer, epoxy resin and other auxiliary materials.

Concrete grade

Concrete is the main building material, so its quality is given the utmost attention. It must be durable, waterproof (from W8), frost-resistant (from F200), and must easily withstand high loads and temperature changes

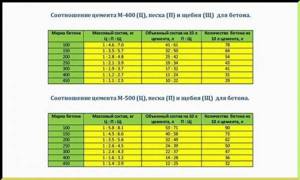

Types of concrete grades M350–M400 have similar properties. They are suitable for the manufacture of slabs, floors, foundations and are no less suitable for filling a swimming pool bowl. Special plasticizers and hydrophobic substances must be added to concrete. The ideal option is to order ready-mixed concrete from a factory, although you can make it yourself.

Composition of the solution

If the remote location of the site or other factors do not allow you to buy freshly prepared concrete, you will need to make it yourself. For 1 m³ of the finished composition you need to take:

- 600 kg of cement;

- 1500 kg of clean sand of medium fraction;

- 800 kg of chopped fiber (glass fiber);

- 3 liters of plasticizer.

Another option for preparing concrete contains sand and crushed stone and consists of the following components:

- 380 kg of cement;

- 1250 kg of medium fraction crushed stone;

- 630 kg of sand;

- 1 kg of plasticizer.

Proportions of components for concrete mortar

Calculation of costs for making a swimming pool

Even if you carry out the work yourself, the process of making a pool will require considerable financial expenses. The biggest expense item is the purchase of concrete or its components.

Advice! Fiber, sealants, boards and timber, finishing materials are quite expensive. But you can save on them, for example, if you use thick PVC film instead of ceramic tiles or mosaics.

According to the standards, for 1 m² of concrete surface when building flat and box-shaped structures, at least 81 kg of reinforcement is needed. Thus, to reinforce a standard pool, several tons of this material will be required, which is quite expensive.

You will also need to purchase other equipment:

- pump;

- filter;

- heater.

You cannot save on it, otherwise the circulating system will not work correctly and will not be able to cope with a large volume of water. Usually up to 100-150 thousand rubles are spent on equipment, and about the same amount will be needed for other materials. This figure decreases as the area of the pool decreases.

Insulation of a frame pool: what to choose?

Insulation of a frame pool: what to choose?

When the swimming season ends and autumn comes, pool owners wonder how to insulate and how to cover such a structure https://intex-dom.com.ua/g571169-karkasnye-bassejny-intex? After all, the aquatic environment itself retains heat well, but it is necessary to promote its accumulation and preservation. To do this, you can cover the pool; this will additionally protect it from contamination and significantly reduce evaporation. This makes it possible to significantly preserve chemistry.

Cover for frame pools

There are several types of coverings:

In the first case, a solar heat-saving film with a bubble structure is laid on the pool. There are light and dark films, the light one is used only to save heat, and the dark one is used for slightly heating the water, since it absorbs the sun's rays well. As a result of this covering, the water does not evaporate, heat is retained, and the bowl itself is reliably protected from various debris, including sand, getting inside.

Trampoline covers also retain heat in the water. The canvas needs to be attached around the perimeter of the entire structure with special fixing bolts, which is quite labor-intensive work.

The classic form of cover for an outdoor pool is a tarpaulin or floating blanket. Floating is very convenient in the summer, and even one person can handle it. Tarpaulin is most often laid for the winter or if you want to completely protect the pool from various flying debris.

Polycarbonate, or “pavilion”

The polycarbonate cover is represented by an arched aluminum structure with polycarbonate walls. This cover can be applied to any pool – according to size, shape and volume, you can even choose the desired color. The finished structure can be moved on specially built-in rails, which are located along the pool. This “pavilion” also has built-in doors that can be locked. This cover has many advantages - for example, it is possible, regardless of the weather, if you install additional water heating, to carry out swimming in the cold season. Also, this design will protect the pool not only from debris, dirt and dust, but also from the penetration of various animals and even strangers.

The main disadvantage of a polycarbonate covering is its bulkiness and the need for the presence, and that is, the preparation of a special surface on which the rails will need to be placed. The cost of such a pavilion is quite high.

If you are choosing a pool cover, you need to decide what functions you need it for. In principle, any of its varieties can protect the water structure from dust and dirt and warm up the water a little. For example, using a pavilion, you create a greenhouse effect. The modern variety of shapes, colors and types of protective coating allows you to choose exactly the option that is harmoniously suitable for the design of the pool.