The procedure for calculating the material for roof insulation

Roof insulation plays a significant role in shaping the microclimate of the room.

It affects not only temperature conditions and fire safety, but also provides sound insulation, protection against fungi and rodents. Therefore, the selection and calculation of insulation must be approached with the utmost care. Roof insulation not only affects temperature conditions and fire safety, but also provides sound insulation and protection against fungi and rodents.

To calculate the amount of material required for roof insulation, you need to determine what type of roof you need to work with and what room you want to protect from heat loss. The thickness and amount of thermal insulation, as well as the type of insulation you will use, greatly depend on these conditions.

The roof design may or may not imply a load on the insulation (flat roof) (pitched roof - usually used to create attics and living quarters). This means that to insulate a flat roof, a denser material with increased rigidity is required; in this case, basalt insulation with a density of at least 130 kg/m3 is recommended.

m, or, if low fire safety requirements are presented, polystyrene foam and polystyrene foam with a density of 30-38 kg/cub.m. In the case of a pitched roof, a material with a lower density is recommended: basalt insulation (25-35 kg/m3), fiberglass-based mineral wool. (14-16 kg/cub.m).

Flat roof: how and how to insulate it

A roof with a slope of up to 12 degrees is considered flat. Covering it is the easiest way - you don’t have to bother with additional elements and tricky things with the sheathing. It can be either unexploited or exploited. In the latter case, the roof is equipped with a rigid and durable base - after all, it takes on considerable loads.

When choosing insulation for a flat roof, you first need to decide whether it will be used. If this is the case, then we take a heat insulator with high moisture resistance and a load limit of up to 250 kilograms per square meter. For a roof that is not in use, the load limit may be lower, but the requirement for moisture resistance must be observed. As a rule, a flat roof is insulated with polystyrene foam (ordinary or extruded type); less often, basalt fiber mats are used for these purposes.

Insulation of a flat roof with slabs of extruded polystyrene foam.

An example of insulating a flat roof with basalt wool mats.

- Installation of flat roofs of various types

Expanded polystyrene weighs little and is somewhat cheaper. It is also easy to process, and you don’t even need a special tool. Expanded polystyrene retains heat simply remarkably, since almost all of it consists of air. Among the disadvantages of this insulation, flammability should be noted. Therefore, on a flat roof, on top of this heat insulator, non-flammable protection is applied in the form of a sand-cement screed.

Popular brands of insulation for flat roofs

We found out above that it is best to use expanded polystyrene boards for insulating a flat roof; now we will consider the most popular manufacturers producing various types of insulation based on expanded polystyrene.

#1. Penoplex Roofing.

The older name of the insulation is PENOPLEX 35. Manufactured by a Russian company of the same name, it is nothing more than extruded polystyrene foam. It is produced in the form of slabs with a thickness of 2 to 10 centimeters, measuring 0.6 by 1.2 meters. And the density of this roof insulation is 28-33 kilograms per cubic meter.

#2. EPPS TechnoNIKOL.

And again the products of the Russian company - TechnoNIKOL. Extruded polystyrene foam, produced under this brand, has several varieties. The following are applicable for roof insulation.

- XPS TECHNONICOL CARBON ECO – suitable for the roof of a low-rise building or a country mansion.

- XPS TECHNONICOL CARBON ECO DRAIN – differs from the previous material by the presence of drainage grooves on the slabs. They help ventilate a flat roof.

- CARBON PROF is an especially durable polystyrene foam. Excellent for roofs of high-rise buildings, shops and warehouses. This rigid roof insulation can withstand enormous loads.

- CARBON PROF SLOPE is as strong as the previous material, but has a special “trick”. It is a set of five slabs with different surface inclinations. With their help, a slope is made on a flat roof.

- More information about these insulation materials: Extruded polystyrene foam TechnoNIKOL

#3. Expanded polystyrene brand URSA XPS.

The manufacturer (the international holding URALITA) guarantees excellent quality to this insulation. The flame retardants included in its composition help to increase fire resistance. This material is good for an inverted roof. Its slabs have a cutout on the side, ensuring perfect joining and no gaps.

Variety of thermal insulation materials

Before you begin calculating the thickness of the material, you need to select insulation.

Three types of material are mainly used:

- glass wool;

- stone wool (basalt);

- expanded polystyrene.

Glass wool is a fibrous insulation material that is one of the subtypes of mineral wool. It is made from the remains of glass production, which is how it gets its name.

Glass wool fibers are thinner than stone wool and twice as long. These fibers are formed into slabs, which subsequently serve as insulating material.

Glass wool is the cheapest option for roof insulation. At the same time, it has such important advantages as safety, fire resistance, low heat transfer, good vapor permeability and lack of toxicity.

If you plan to insulate the attic, then glass wool is ideal for pitched roofs.

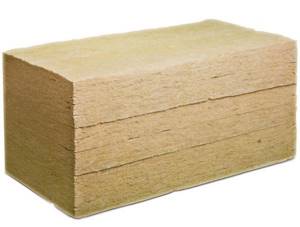

Stone wool (basalt) is another type of mineral wool. This insulation is produced by melting basalt in a furnace, the temperature inside of which reaches 1500 degrees Celsius.

After melting, the mass is drawn into fibers, which are then treated with a binding solution, shaped and heated to 180-230 degrees Celsius.

After cooling, the material is cut to the required sizes. Stone wool has a number of important characteristics: good sound and heat insulation, fire resistance, durability and environmental friendliness.

When insulating roofs, it is recommended to use it in the form of blocks installed between the rafters.

Expanded polystyrene is insulation in the form of slabs, which are 98% composed of natural gas air. Air and gas are contained in a huge number of thin-walled cells of the foam material.

This structure allows us to call polystyrene foam the best option; moreover, it has the lowest thermal conductivity.

The main disadvantage of this option is its cost. Also, polystyrene foam is quite flammable and when exposed to ultraviolet radiation or fire, it can release toxic compounds.

At the same time, we should not forget about its advantages: strength, very long service life, good vapor permeability and sound absorption, the formation of fungi and mold is excluded, and there is no moisture absorption.

Sometimes they try to use foam plastic in roof insulation, which is strictly prohibited by the current SNiP.

This is due to flammability, possible harm to human health and the fragility of the material.

Mineral insulation

This type of heat-insulating materials is most in demand. The material does not rot, it is not afraid of moisture, it is fireproof and will last for many years. In most cases, this insulation is a compressed slab made of mineral wool.

It is obtained at the moment of cooling of the mineral alloy. There are two types of mineral wool:

Slag is obtained from waste from the metallurgical industry, and stone from waste:

Scheme of insulating a tile roof with mineral wool slabs.

To insulate houses, it is better to use stone wool.

The main positive properties of mineral wool are its fire safety and excellent thermal insulation properties. Vata is indifferent to humidity, fungi do not grow in it, and it is environmentally friendly. Each slab has standard dimensions.

Glass wool also has the properties of stone wool. It is made from glass waste. This material has great strength and high elasticity.

Long thin fibers give it such qualities. The sizes of glass wool have standard values specified in GOST.

Return to contents

Calculate the thickness of the insulation

The thickness of the roof insulation is calculated using a special formula:

And the insulation. = (R – 0.16)*λut ,

wherein:

- And the insulation. – required insulation thickness in m;

- R – heat transfer resistance in sq.m*°C/W;

- λth is the value of the thermal conductivity of the insulation in W/(m*°C).

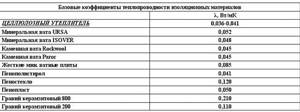

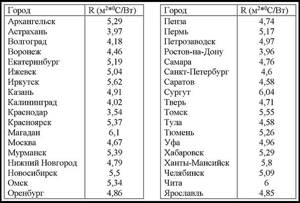

The value of R must be looked at in a specialized table of heat transfer resistance data; for each region the value will be different. Information about the thermal conductivity value of the material is contained on its packaging. For the three types of materials given in the article, this value averages 0.04 W/(m*°C).

It is logical that in more northern regions the thickness of the insulation will be significantly greater than in the southern ones. Let's give an example of how thick basalt wool will be in different cities of Russia:

- the thickness of basalt wool in Moscow or St. Petersburg will be around 20 cm;

- for Izhevsk or Omsk this value will be 25 cm;

- Northern cities such as Vorkuta or Chita will need a 30 cm layer of basalt wool;

- More northern areas require the use of a 35 cm layer.

Insulation of the attic room

Ecowool attic insulation scheme.

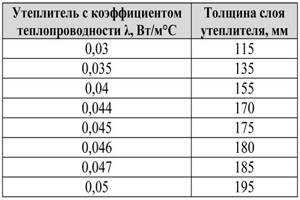

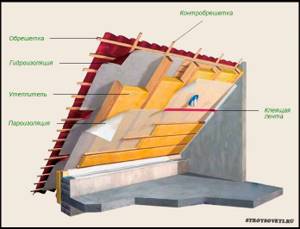

An attic roof usually consists of a rafter system covered with roofing material. The rafters are installed every 60-100 cm. These gaps are filled with insulation. It is recommended to use mineral wool or fiberglass as insulation material. This material is available in the form of slabs or mats. They are laid in layers, the number of which depends on their thickness. What should it be like? The thickness of the insulation is calculated based on the thermal conductivity coefficient, which is indicated in the quality certificates. You can rely on the following data:

Coefficient Insulation thickness

- 0.035 150 mm;

- 0.04 180 mm;

- 0.044 200 mm;

- 0.045 205 mm;

- 0.046 210 mm;

- 0.047 215 mm;

- 0.05 225 mm.

With a thermal conductivity coefficient of 0.04, the calculation of the average thickness of the insulation layer for different cities in Russia will be as follows:

City Thermal Insulation Thickness (mm):

Table for calculating the average thickness of the insulation layer for different cities of Russia.

- Arkhangelsk 220;

- Astrakhan 160;

- Anadyr 290;

- Barnaul 210;

- Belgorod 170;

- Blagoveshchensk 230;

- Bryansk 190;

- Volgograd 160;

- Vologda 210;

- Voronezh 180;

- Vladimir 200;

- Vladivostok 190;

- Vladikavkaz 150;

- Grozny 150;

- Ekaterinburg 210;

- Ivanovo 200;

- Igarka 290;

- Irkutsk 220;

- Izhevsk 210;

- Yoshkar-Ola 210;

- Kazan 200;

- Kaliningrad 170;

- Kaluga 190;

- Kemerovo 220;

- Kirov 210;

- Kostroma 200;

- Krasnodar 140;

- Krasnoyarsk 210;

- Kurgan 210;

- Kursk 180;

- Kyzyl 240;

- Lipetsk 180;

- Magadan 250;

- Makhachkala 130;

- Moscow 190;

- Murmansk 220

- Nalchik 150

- Nizhny Novgorod 200;

- Novgorod 190;

- Novosibirsk 220;

- Omsk 210;

- Orenburg 190;

- Eagle 190;

- Penza 190;

- Perm 210;

- Petrozavodsk 210;

- Petropavlovsk-Kamchatsky 190;

- Pskov 190;

- Rostov-on-Don 160;

- Ryazan 190;

- Samara 200;

- St. Petersburg 190;

- Saransk 190;

- Saratov 180;

- Salekhard 280;

- Smolensk 190;

- Stavropol 150;

- Syktyvkar 220;

- Tambov 180;

- Tver 200;

- Tomsk 230;

- Tula 190;

- Tyumen 210;

- Ulyanovsk 190;

- Ulan-Ude 230;

- Ufa 200;

- Khabarovsk 220;

- Cheboksary 200;

- Chelyabinsk 200;

- Chita 240;

- Elista 160;

- Yuzhno-Sakhalinsk 210;

- Yakutsk 290;

- Yaroslavl 200.

If the cross-section of the rafter legs is smaller than the thickness of the layer of insulating material, additional wooden blocks are attached to them using nails, screws or self-tapping screws. They must be treated with an antiseptic composition. There should be ventilation in the form of an air gap between the insulation layer and the roof. The air gap is 25-50 mm. The insulation is protected on top by a windproof membrane. It is better to use Tyvek HD, Monaperm 450 VM, and Monarflex VM 310 films for this purpose.

The bottom layer of insulation for the attic is covered with a vapor barrier film and a finishing cladding is installed from lining, plasterboard or other materials.

To create comfortable conditions in the attic room, thermal insulation is needed. Then you need to insulate the roof and gables. A wide variety of materials can be used for these purposes. It is best to use mineral wool. It has excellent characteristics and is easy to install.

The thickness of the thermal insulation layer is calculated according to the region of residence.

The colder the climate, the larger the insulation layer should be. Properly installed thermal insulation significantly reduces building heating costs.

Calculate the thickness of the insulation

The thickness of the roof insulation is calculated using a special formula:

And the insulation. = (R – 0.16)*λut ,

wherein:

- And the insulation. – required insulation thickness in m;

- λth is the value of the thermal conductivity of the insulation in W/(m*°C).

It is logical that in more northern regions the thickness of the insulation will be significantly greater than in the southern ones. Let's give an example of how thick basalt wool will be in different cities of Russia:

- the thickness of basalt wool in Moscow or St. Petersburg will be around 20 cm;

- for Izhevsk or Omsk this value will be 25 cm;

- Northern cities such as Vorkuta or Chita will need a 30 cm layer of basalt wool;

- More northern areas require the use of a 35 cm layer.

Where to buy roof insulation in Moscow

In our online store you can buy insulation of the following brands:

| ROCKWOOL insulation | |

| ROCKWOOL Light BUTTS | ROCKWOOL Facade BUTTS |

| ROCKWOOL ROCKFACADE | ROCKWOOL Light BUTTS SCANDIC |

| TECHNONICOL insulation | |

| TECHNONICOL GREENGUARD Station wagon | TECHNONICOL ROCKLITE |

| TECHNOLITE EXTRA | |

| PAROC insulation | |

| PAROC UNS-37/EXTRA | |

Our managers will be happy to answer all your questions and help you purchase insulation for your roof. By the way, you can buy roof insulation from us with delivery throughout Moscow and the Moscow region.

Still have questions? - Ask!

Natural fibers: features

This type includes:

- moss;

- tow;

- felt.

- jute.

The main advantage is compliance with environmental requirements. However, such material for roof insulation has a number of disadvantages. It allows oxygen to pass through, resulting in precious heat being lost. Jute is considered the best insulation. It never rots and does not require additional chemical treatment. One bag of such insulation is estimated at 300 rubles. Such a low price allowed this material to become quite popular among the population.

Table of characteristics of roof insulation.

This group also includes insulation made from:

- peat;

- reeds;

- sawdust;

- reed slabs.

Natural thermal insulation materials are:

- fiberboard;

- wood concrete;

- kostramit.

These heat insulators are necessarily treated with special fire-fighting compounds, but the possibility of fire does not disappear. The thickness of the insulation made from reed stone reaches 10 cm. A cube of wood concrete costs approximately 4,500 rubles.

How to decide on thickness

After selecting the required material for the roof, you should determine the required thickness.

In order to understand how to calculate the required layer, you should take into account the requirements of SNiP 02/23/2003 related to thermal protection of buildings. Based on these rules, selection must be carried out in accordance with the geographical coordinates of the object being built.

For example, you can study the table with the sizes of basalt heat insulators in individual regional centers.

These values are given taking into account the multiplicity of the slabs, since they have a thickness of 5 and 10 cm. Basalt slabs have increased thermal conductivity. It is equal to the conductivity of glass fiber-based mineral wool or polystyrene foam boards. Therefore, the data presented can be applied to them as well.

Material requirements

Any insulation for the roof and attic must have the following parameters:

- Fire safety. The product must not be exposed to combustion.

- Sound insulation properties. Required to minimize the penetration of external noise.

- Vapor permeable. This will ensure an optimal microclimate in the room.

- Comply with environmental and sanitary safety, as well as SNiP.

- Must be strong and durable.

- Resistant to deformation influences.

Expert recommendations suggest that the thickness of the attic roof insulation should be approximately 250-300 mm. When arranging, it is best to create double or triple layers. Due to this, it is possible to eliminate the occurrence of cold bridges. When insulating attic rooms, it should be remembered that gables are walls. Moreover, in a wooden version they require a larger layer than in a brick version.

How to calculate the amount of material

Thermal insulation of the roof increases comfort and the microclimate in the room. Insulation also improves the thermal resistance of the structure and reduces heat losses. Thermal insulation does not heat the building, but only retains heat inside the house

Therefore, it is important to calculate how many layers of insulation are needed for the roof, what width is needed and what material to buy

All calculation work is carried out at the design stage. It is necessary to take into account the individual characteristics of the structure, climatic conditions, characteristics of the heat insulator and the purpose of the rooms. Calculations are made in advance taking into account the type of roof and its dimensions.

The roofing insulation is laid on the rafters. It is necessary to calculate how many slabs will be placed along and across the roof slope. To do this, it is necessary to take into account the distance between the rafters, the number of steps and the length of the slope.

An example of calculating the amount of mineral wool for a gable roof

The roof is symmetrical, the number of rafters is 7, the distance is 60 cm, the length of the slope is 5 m. Slabs with dimensions of 1.17 × 61 × 25 cm were chosen for installation. You can also take rolled mineral wool.

First of all, the number of slabs that will be laid in a row is determined. To do this, the length of the slope (5 m) is divided by 1.17 and the result is 4.27 pieces. This value is multiplied by step (7) and the result is 29.89 slabs per slope and 59.78 for the entire symmetrical roof. The result obtained is rounded up and a margin of 15-20% is added. As a result, the entire roof will require about 70 slabs.

Calculation of the thickness of thermal insulation material

After choosing insulation, you need to calculate how thick it will be. This is explained by the fact that each heat insulator has its own characteristics that must be taken into account when choosing.

The calculation will help not only to approach insulation as competently as possible, but also to optimize material consumption.

Calculation of insulation thickness begins with determining the minimum permissible heat transfer resistance of roofing structures.

These data depend on the region of location and are specified in SNiP 02/23/2003 “Thermal protection of buildings”. After finding out this parameter, you can be confident in the future comfort inside the house.

This measurement shows how much heat, calculated in W, is transmitted by 1 square meter of roof of calculated thickness with a temperature difference of 1 degree Celsius outside and inside per unit time.

Calculating this value is not easy, so there are tables that show calculated heat loss rates for large cities. For example, for Moscow the R indicator will be 4.67 m²*°C / W.

Next, you need to find out the coefficient of thermal conductivity of the material, which is denoted λ and measured in W/ (m °C).

This number demonstrates how much heat in W is transmitted by one square meter of heat insulator, one meter thick, in one hour with a temperature difference of 1 degree on both surfaces of the material.

This indicator assesses the retaining properties of the thermal insulation material. The lower the insulation has a thermal conductivity coefficient, the better it retains heat.

This indicator serves as a technical characteristic of the material and does not depend on its thickness. Typically, the manufacturer indicates the coefficient value on the material packaging.

This indicator can also be found in special construction tables. For example, the coefficient of polystyrene foam with a density of 25 kg/mᶟ = 0.034 W/ (m °C).

Knowing these indicators, you can calculate the thickness of the insulation layer with which the roof will be insulated.

To do this, you need to apply the formula δ = R * λ, where δ is the thickness of the insulation material in meters.

Using these example values, you can calculate a layer of polystyrene foam insulation with a density of 25 kg/mᶟ for roof insulation in Moscow: 4.67 * 0.034 = 0.15878 m.

We round this number, it turns out to be 160 mm. This value is the minimum acceptable and, in order to sufficiently match the thickness of the insulation, it is recommended to add 10% to the obtained value.

The result will be 185 mm - this is exactly what the insulation layer should be.

From the above we can conclude that roof insulation is a process that needs to be approached competently and thoughtfully.

In addition to formulas, there are specialized calculators that are designed to simplify the calculation of thickness.

The main thing to remember is that a properly insulated top of a building is the key to comfort, health and reliability of the house as a whole.

Determining the thickness of the insulation layer

The thickness of the insulation layer laid in the enclosing structures is determined by calculation, taking into account the requirements of regulatory documentation:

- SNiP 23-02-2003 – Thermal protection of buildings;

- SNiP23-01-99 – Construction climatology;

- SP 23-101-2004 – Design of thermal protection of buildings.

Comparative table on the effectiveness of using various insulation materials in building structures.

When carrying out independent construction, the calculation of the thickness of the insulation can be carried out on its own, naturally, with some assumptions and errors.

A simplified calculation formula will look like:

H – thickness of the insulation layer, m;

R – heat transfer resistance, (m²*°С)/W;

λ – coefficient of specific thermal conductivity, W/(m*°С).

The use of this formula involves a number of assumptions:

- the enclosing structure is considered as a single layer of monolithic insulation;

- The presence and material of the interior decoration of the attic space (if any) is not taken into account.

How thick should roof insulation be?

In order for the conditions in the house to be at the highest level during the cold season, it is necessary not only to take care of the immediate heating system, but also to minimize the leakage of this heat through external structures

It is important to note that this includes not only walls, but also the ceiling and other similar elements

As practice shows, a large amount of heat is lost due to overlap between floors. In this case, it is quite possible to easily solve this problem. All that is required is simply to use high quality material to insulate the heat. In this case, heat loss will be minimal, and this will significantly increase the efficiency of the heating system in the house. The optimal thickness of thermal insulation for the roof is necessary.

If an under-roof space is used in housing, the circuit in this room must be insulated

It is important to note that such insulation should be installed not only in the structure of the immediate roof, but also in the walls of a given room. In the same case, if the attic is non-residential, then the need for thermal insulation is almost completely eliminated

The role of additional insulation in this case is played by the volume of air. But in this case, it is necessary to select the optimal thickness of insulation for the roof.

Ursa insulation: characteristics

Without a doubt, URSA insulation is one of the best in a group of similar insulation materials.

- High thermal insulation capacity provides effective protection of insulated structures from the effects of low and high temperatures, which has a beneficial effect on the condition of both individual building structures and the building as a whole, and increases its service life.

- The softness and flexibility of staple fiberglass makes it easy to install any shaped structure and ensures a tight fit to the surface of the base.

- The non-combustibility of mineral thermal insulation contributes to the fire protection of the building.

- Moisture resistance extends the effective service life of the insulation.

- Environmental cleanliness is determined by the naturalness of the materials used for the production of thermal insulation and a significant reduction in harmful emissions into the atmosphere during heating operation.

- High sound insulation properties ensure protection of personal space from extraneous noise.

- The resistance to stress of Ursa foam polystyrene boards expands the scope of application of this company’s insulation materials.

How to choose the right insulation thickness for a roof

The process of roof insulation plays a significant role in ensuring a comfortable microclimate in the house. It is this that influences the internal temperature and fire resistance of the roof. In addition, it has soundproofing properties and also protects the rafter system from rodents and fungal growths. One of the main roles in this process is played by the thickness of the roof insulation. The calculation and selection process should be approached with the utmost seriousness.

To understand how thick the insulation material should be, you need to understand what type of roof will be insulated. The quantity and type of product to be laid will depend on the type.

Thus, the design features of the roof may place some load on the heat-insulating layer (in the case of flat roofs) or not, as in the case of attic roofs. Based on this, a flat roof is insulated with materials on a denser basis and with increased rigidity. Basalt insulation with a density of 130 kg/m3 is mainly used. However, if minimum fire safety requirements are met, polystyrene foam or polystyrene foam boards with a density of 30 kg/m3 or more can be used. Pitched roofs are treated with lower density options - basalt from 25 kg/m3, mineral wool - from 14 kg/m3.

Which insulation is better: types of insulation

Isover Classic insulation - used for insulating horizontal surfaces, vertical, curved and inclined roof parts.

And also for ventilated facades and for insulating floors, partitions and walls of buildings.

- Density – 10-12 kg/m3, thermal conductivity coefficient – 0.040-0.041 W/m*S.

- Produced in the form of rolls.

- Has excellent soundproofing characteristics.

| Thermal conductivity of IsoverClassic insulation | Vapor permeability of Isover insulation | Fire safety of Isover insulation | Geometric dimensions |

| λ = 0.041 W/(m*K) | 0.55 mg/(m*h*Pa) | NG – group of non-combustible materials | Length – 820 cm Width – 122 cm Thickness – 5+5 cm |

PBS-S foam plastic of various thicknesses and densities. Available in sheets. The sheet size is 100x100 cm, the thickness of the roof insulation is 20-100 mm. Specific gravity – 8-35 kg/m3.

Insulation Ursa M11.

- The base is fiberglass.

- Density – 10-11 kg/m3.

- The thermal conductivity coefficient of Ursa M11 insulation is 0.040 W/(m*K).

Calculation example

Let's try to calculate the amount of insulation based on the following data:

- the perimeter of the house is 8+7+8+7=30 m (here 8 is the size of the long wall, 7 is the short one);

- wall height 3 m;

- the pediment (the triangular upper part of the smaller facade, formed when installing a gable roof) has a width of 7 m and a height of 2 m;

- the number of windows is 10, of which 6 have dimensions of 1500x1500 mm, 4 – 1000x1500 mm;

- there is one door, dimensions 1200x2100 mm.

Important: when calculating insulation (online calculator or manually), the area of the gable is calculated as the area of a rectangle, not a triangle, since a significant part of the thermal insulation material for it is wasted due to cutting slabs or rolls. When calculating the pediment as a triangle, the required insulation area is reduced, but it is necessary to clad the surface with joined fragments of slabs/rolls. Accordingly, the cladding area, taking into account the pediment and openings, will be:

Accordingly, the cladding area, taking into account the pediment and openings, will be:

Let's take Ursa XPS N-III-G4 extruded polystyrene foam as a heat insulator, which is sold in sizes 1180x600x50 mm (7 slabs/4.956 m2). For the calculated cladding area, you will need (taking into account how many squares are in the insulation, one slab has an area of 1.08 sq. m.) 89 slabs or 13 packages. With a packaging cost of 1000...1100 rubles. (data for Moscow, as of August 13, 2018) insulating a house will cost 14 thousand rubles. Calculations are carried out similarly for other insulation materials (how many squares of mineral wool in the form of a roll or slab occupies or how much insulation in a cube is calculated depending on the manufacturer’s data).

Video description

Should you trust online calculators, watch the video:

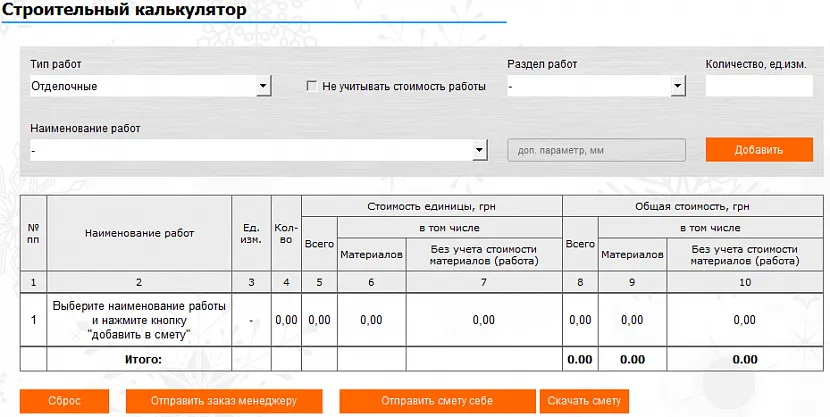

The calculator helps estimate the cost of work Source www.strojmag.ua

Using the calculator, you can calculate the number of bricks for masonry, the cost of finishing, the dependence of insulation consumption on the width of the material, and many other parameters.

It is important to remember that the calculator does not provide exact numbers that can be used when designing or purchasing materials. It only helps to understand the principle of calculations and determine how much the same work will cost using different materials or projects. Full construction calculations can only be performed by qualified specialists.

What material is used to form slopes on a flat roof?

To form a slope-forming layer, slabs of stone wool TECHNOROOF N30 WEDGE 1.7%, TECHNOROOF N EXTRA WEDGE 1.7%, TECHNOROOF N OPTIMA WEDGE 1.7%, TECHNOROOF N PROF WEDGE 1.7% are used to make a slope to the funnels in the valley on the roof and at the parapet, a set of wedge-shaped slabs made of stone wool TECHNOROOF N30 WEDGE 4.2%, TECHNOROOF N EXTRA WEDGE 4.2%, TECHNOROOF N OPTIMA WEDGE 4.2%, TECHNOROOF N PROF WEDGE 4.2% is used.

Recommendations for laying out wedge-shaped thermal insulation from TECHNONICOL stone wool can be found on the website www.teplo.tn.ru in the section “Advertising materials” “Catalogue of building systems. Wedge-shaped thermal insulation”, or in the video section you can watch a visual 3D video! The program for calculating the amount of material is located in the “calculation programs” section.

Results

For roof insulation with mineral wool, soft glass wool and dense stone wool with a soft end are suitable. The materials are laid spaced between the rafters. The thermal insulation density must be at least 55 kg/m. cube, but you shouldn’t take too heavy wool, it will still put an additional load on the rafter system. For flat concrete roofs, heavy and dense stone wool is suitable. It is important to calculate the thickness of the thermal insulation; for this you can use an online calculator, it’s easier. In tandem with mineral wool, vapor and waterproofing are used, which prevent the entry and retention of moisture in the thermal insulation cake.

Preparation for installation

Before installing the insulation, you need to prepare the surface. First of all, you need to check the wooden rafters for mold, rot or mildew. If such defects were found in small quantities, you can use sandpaper and clean them. After this, the materials are treated with antiseptics and painted. In this way, the destructive effects on wood from the environment are blocked. When the rafters are severely damaged, they will have to be replaced.

Checking the electrical wiring for serviceability is considered the next stage of preparatory work before installing a roof insulation system in a private house. All damaged elements will have to be repaired, worn wires will have to be replaced, try to ring each switch, perform a detailed check of each connector, joints and fastening elements, and connection points. If the electrical wiring is unsuitable, it is better to re-equip it.

Before installing thermal insulation on the roof, electrical wiring must be installed with the support of professionals. This way you can avoid serious difficulties in the future.

In existing construction practice, several methods of installing insulating roofing are considered:

- Internal insulation.

- External insulation.

Internal roof insulation is considered the most common installation option for a thermal insulation system, used for flat or pitched roofs. They are manufactured using the following technology:

- First of all, the internal lining of the building is equipped;

- After this, a vapor barrier is provided;

- It is equipped with thermal insulation, as well as protection from moisture and wind.

The last layer of thermal insulation is the roofing material.

The insulation must be provided with a specific width that adapts to certain climate conditions. The main requirement for such material is considered to be minimal weighting of the roof. When installing, you need to leave special gaps through which moisture will escape from the structure.

External insulation is carried out using rigid slabs on flat roofs. The materials are pressed down with special concrete slabs or ordinary pebbles. It is imperative to determine the strength of the roofing when carrying out such installation work.

How can you partially or fully compensate for the thickness of roof insulation?

In the simplest version, a significant amount of insulation can be placed in the space between the rafters.

If the height of the rafters is insufficient, the remainder of the insulation is placed in an additional frame, which is stuffed on top of the main one.

In another option, the problem is solved by using a more compact insulation material, which allows reducing the volume loss of the insulated room to a minimum.

Order installation of thermal insulation from our company and your home will be comfortable and warm all year round!

Varieties and forms

Styrofoam

In its shape, it consists of air-filled polystyrene bubbles, which are then pressed into slabs of standard sizes: 500x1000, 1000x1000 and 2000x1000 mm. Packaging of the material is in the form of plates of fixed sizes. Polystyrene foam is a white slab material with a rigid foam structure, containing 2% polystyrene and 98% air. The thickness of this material varies from 20 to 1000 mm.

The material has the following advantages:

The long-term use of polystyrene foam as insulation also revealed its disadvantages:

- Quite low quality material is found on sale;

- the material is subject to combustion;

- polystyrene foam serves as insulation for only 10-15 years (depending on its manufacturer and quality);

- the material does not “breathe”.

In order to start working with insulation, it is necessary to perform a number of actions that distinguish this type of material from products for other purposes. First of all, it is necessary to carefully prepare the surface that needs to be insulated. To do this, it needs to be cleaned, leveled and primed. After this, you need to make marks with a plumb line to ensure that the foam slabs are evenly spaced. Then the foam is thoroughly lubricated with an adhesive solution and carefully applied to the wall.

There is no need to put too much pressure on the foam when laying it - it is quite fragile, so damage may occur. Foam boards are laid close to each other. Gaps can be filled with foam. To securely fasten the slabs, it is best to secure them with dowels. A reinforcing mesh is glued on top of such insulation - the final finishing is carried out over it.

Penoplex

This material is better than foam plastic in all its properties, and its installation is simple and convenient for self-installation.

This insulation looks like a waterproof tile with a thickness of 20 mm. The basis of the material is styrofoam, its granules are processed under pressure at high temperatures. The walls inside the house for the installation of penoplex are prepared in the same way as for the installation of polystyrene foam (you need to remove dirt and clean, level and prime the surface).

Finishing work:

- primer for facade work;

- basic finishing (a variety of plasters can be used, both acrylic and silicone);

- choice of final texture;

- painting.

The easiest way: the surface is leveled, finishing putty is applied, primed, and painting is carried out. In construction, material with a thickness of 20-100 mm, a width of 600 mm and a length of 1200-2400 mm is used.

Mineral wool

All types of mineral wool are also suitable for thermal insulation.

Properties of mineral wool:

- not flammable;

- heat conductivity is very low;

- Rodents do not eat mineral wool, but they love to live in it;

- service life from 30 to 80 years.

Thermal insulators of this class come in three types:

The material is available in several varieties:

- in the form of slabs (mats);

- rolls;

- in a formless form.

Insulation is required in every building structure. Without insulating material, no building will exist. Insulation protects the building from the cold, it conserves heat and prevents it from disappearing. In addition, keeping the building warm allows you to save on heating costs. Today there are many different types of insulation. Moreover, different sizes of roof insulation are offered. Therefore, choosing the right insulation and the appropriate dimensions is not difficult.

Roof insulation scheme.

In accordance with this, the type of insulation, its size and shape are selected. The selected material must reliably protect the building from the penetration of cold air.

Tips for choosing insulation

It is worth approaching the choice of material for roof insulation with all responsibility.

There are a number of standard rules that will be useful in this case: The mass of insulating materials should be minimal. This will not only make the insulation process much easier, but will also reduce the load on the roof structure as a whole, which is extremely important. The environmental performance of the material is also one of the the most important factors when choosing. Due to the fact that the roof is constantly exposed to various climatic influences and temperature changes, the release of toxic substances cannot be avoided. Particular attention should be paid to the warranty period of the insulating material. Experts consider the optimal period to be 50 years. Increased noise absorption and heat resistance will be a significant plus. This is especially important when they plan to cover the roof with metal tiles. Moisture absorption is also considered one of the main indicators.

When a material actively absorbs moisture, its service life is noticeably reduced compared to more moisture-repellent insulation materials. Sooner or later, it will definitely develop fungi and mold, which can ultimately destroy the entire roof structure. Important! It is advisable to insulate flat roofs with environmentally friendly and styrene materials, while for pitched roofs, cotton wool insulation is more suitable. Insulating a roof is an extremely responsible matter. The final result of this process depends not only on the correct actions of the builders, but also on the correct choice of building materials.

Suitable insulation will allow you to build an excellent roof that will serve reliably for many years and will help avoid unnecessary costs for repairs and alterations. Anyone will be pleased with the prospect of a thirty percent reduction in home heating costs. This is quite realistic - this is exactly the result that can be obtained by choosing the right insulation for the roof. In addition, we will receive other additional benefits. More on this later.

Let's calculate what the presence of insulation under the roof will give to our house. Let us emphasize - not just any kind of insulation, but good insulation. So, we get: Additional protection from dust and moisture; the ability to live in the attic, i.e.

equip living space in the attic; escape from the summer heat; optimal humidity in the house; saving on heating; reducing external noise. Perhaps it is now clear that insulation for the roof is necessary. But for different types of roofs and design solutions, different types of insulation are used. We will talk about this further.

Construction calculator for calculating the amount of consumables

Many construction-related websites contain construction calculators, the main task of which is to help the future homeowner make approximate calculations related to the purchase of materials, understand the scale of the upcoming work and the cost of everything necessary.

Although building a house is a complex process with many nuances, the final cost largely depends on the materials used and their quantity. This means that even a simple online calculator will help you figure out the approximate cost of construction and figure out which material is more profitable to use.

Calculation of materialsSource dcgate.pp.ua

In their calculations, calculators use several calculation options:

- Based on the total area of the building

. The user specifies the linear dimensions of the house, the number of floors and the material used for the walls. The calculator determines the approximate cost. This type of calculation has a large error.

- Based on project type

. The calculation is carried out in several steps based on architectural, as well as structural and engineering designs. The cost of building each “box”, the cost of finishing and communications are calculated separately. The more templates the calculator uses, the more accurate the calculation will be.

- Foundation calculators

determine the amount of concrete, formwork material and reinforcement for constructing the foundation of a house with the given parameters.

The accuracy of the result is also affected by the number of templatesSource stroimdom.com.ua

The universal calculator takes into account the type of floor, material of manufacture and other nuances in the calculation.

Some calculators give the total cost of the house, others - a specific part of the work. Depending on his needs, the site visitor himself chooses a convenient option.

What is a construction calculator for and how to use it

When using a calculator, it is important to understand that its methods are not flexible and do not take into account all construction nuances. If you need to perform a calculation for which the fields in the calculator are not provided, then this can only be done by specialists

Also, the user is not able to understand how correctly the calculator makes calculations, because he sees only the final result and does not know what formulas and templates were used.

Free online construction calculators and calculations

Foundations

Calculation of strip foundation

Slab foundation calculation

Calculation of a columnar foundation

Soil freezing depth

Wall materials

Calculation of a frame house

Calculation of building blocks

Calculation of aerated concrete blocks

Calculation of ceramic blocks

Calculation of rounded logs

Roof

Calculation of a pitched roof

Calculation of a gable roof

Calculation of the attic roof

Hip roof calculation

Thermal engineering

Calculation of the number of radiator sections

Calculation of water heated floor

Materials

Calculation of a fence made of corrugated sheets

Calculation of heavy concrete

Calculation of lightweight concrete

Calculation of mortar

Calculation of the amount of laminate

Before starting actual construction, it is necessary to calculate the characteristics and costs of building materials for a particular structure. This stage will allow you to avoid destruction of the building, deformation of its elements and other negative factors. In addition, the speed of construction work also depends on the quality of the calculations made, since a shortage of any material can slow down the process, and slow down for an indefinite period, due to the fact that additional material, at the height of the construction season, is very difficult to find.

For your convenience and prompt preparation of everything you need, a special website of construction calculators has been presented, with the help of which it is easy to avoid problems with the preliminary purchase of materials and, accordingly, the subsequent shortage of the latter.

The online calculator will help you make the following calculations:

- Consumption of materials necessary for the construction of all main elements of the building;

- Calculation of the required dimensions and parameters of elements;

- Calculation of the required characteristics of building materials.

The multifunctionality of the online service is an undoubted advantage of the site. The online construction calculator allows you to make a huge number of all kinds of construction calculations without leaving your home. Moreover, calculations can be not only of a technical nature, but also of an economic nature, which plays a positive role at the preparatory stage of construction work.

Getting started with the online calculator

To get started, you need to select the required section from the list located on the left side of the screen. For each calculation, it is necessary to enter the required indicators and data, such as the dimensions of the proposed building, the required strength characteristics, location area, and so on. Most calculations involve several directions, that is, in addition to the main calculation of building materials, it is possible to simultaneously calculate the size of the structure. Each calculation is provided with additional reference materials and is also illustratively supported by a convenient drawing.

Some calculations allow you to calculate the economic component of the proposed work, for example, by indicating the cost of one unit of material, the calculator will calculate the total cost of the entire required quantity. Additional indicators are calculated when the checkbox next to the item of interest is checked. The calculation result instantly appears on the screen after pressing the “Calculate” button. The “Print” button is conveniently located at the bottom of the result.

Construction calculator, or the positive aspects of using it

The calculators presented on the site reduce the task of lengthy calculations to a minimum, which significantly saves time.

Each section and subsection of the site allows you to:

- Select the proposed types of work;

- Calculate the necessary costs and the amount of material required for the work;

- Read the detailed drawing;

- Calculate the total amount needed to purchase building materials;

- Read reference materials and recommendations;

- Print the calculation result;

- specialist.

Without exception, such calculators imply a small error. In this regard, preliminary calculations must be coordinated with experts in this field or they must check the calculations already carried out.

The website is currently being finalized. New calculators and calculations are constantly being developed. Please report any errors found via feedback.

Insulation thickness for attic roof

A well-insulated roof is the best way to keep your home warm and save on heating costs. This is also an opportunity to expand the usable area of the house and create a residential attic under the roof, the heating of which will not cost large sums. In matters of roof insulation, numerous nuances associated with insulation and its installation under the roof are of great importance.

Not only the microclimate under the roof, but the integrity and safety of all roofing elements depends on the correctly selected material and its proper installation, observing the order of all layers of the roofing pie. Today we’ll look at what thickness of insulation is needed for a roof and how to calculate it yourself.

Bathhouse roof insulation calculator

If you decide to build your own bathhouse, then special attention will have to be paid to issues of thermal insulation. In this building, it is necessary to maintain a specific microclimate; its premises must warm up quickly at any time of the year and retain heat for a long time to ensure the comfort of bathing procedures. At the same time, the insulation of a bathhouse should be closely related to issues of hydro- and vapor barrier, since direct contact with water and high humidity are normal operating conditions for building structures of such a structure.

Bathhouse roof insulation calculator

A large percentage of heat loss occurs on the roof and ceilings, and their high-quality thermal insulation is one of the main tasks. How to determine the thickness of the insulating layer, depending on the design features of the bathhouse and the thermal insulation material used? A calculator for calculating the insulation of a bathhouse roof will help us in this matter.

The calculator is comprehensive, allowing you to calculate the insulation of both roof slopes and attic floors. Its use requires some explanation, which will be given below.

Bathhouse roof insulation calculator

Explanations for performing calculations

The calculator's operating algorithm is based on the principle that in order to prevent heat loss through building structures, their resistance to heat transfer must be no lower than the standard indicators established by the current SNiP. These values are easy to find on the map below. In our calculations, two indicators can be used - “for coatings” and “for floors” .

Bulk insulation for roofing

This type of insulating materials for the roof of a house attracts many people for three reasons:

- Low price;

- Environmental safety;

- Lack of interest in rodents.

It is immediately worth noting that the roof can be insulated using bulk thermal insulation materials only on the floor. They are poured into the frame. Therefore, the material is suitable for covering an attic. Most often used:

Sawdust

Sawdust itself is a fairly inexpensive material. Its advantage is its absolute naturalness. But there are two problems with using it:

Both solve in the same way. Adding lime to sawdust. Gypsum is also used to impart viscosity to the mass. It is added in an amount of no more than 5% by weight of sawdust. The resulting mass becomes viscous and is perfectly applied and keeps its shape.

Expanded clay

Expanded clay is small crushed pebbles of different fractions (sizes). It is filled between the joists. Expanded clay is not afraid of either steam or rodents. In a sense, it is an ideal insulating material for roofing.

In addition, it is not quite expensive. We will talk in more detail about the use of this type of thermal insulation for roofing in a separate article. Here the mention was necessary to understand the general picture of possible insulation options.

Spraying and blowing

There are two main representatives in this family of roofing materials:

Polyurethane foam is one of the most effective thermal insulation materials. It is sprayed or blown in the form of white foam. To blow in polyurethane foam you need a special suit and a compressor. This material does not allow steam to pass through and you need to use a lathing to blow it in.

PPU is a synthetic material, ecowool is environmentally friendly. Both of these materials are rodent resistant and require special equipment to blow them out. A specially trained technician can apply polyurethane foam correctly.

Ecowool

Ecowool has been used in Western countries for about 50 years. This roof insulation came to the territory of the CIS relatively recently. Ecowool is a cellulose fiber and is made from waste paper. There are special machines for crushing raw materials and “cooking” such cotton wool. Using special pneumatic transport, the cotton wool is delivered to the blowing point, where, for example, it is placed between the lags.

Another obvious advantage of ecowool for roof insulation is that it is easy to blow into the narrow space between the rafters. Laying even rolls of mineral wool in this area is very problematic.

Plastic insulation

This type of heat-insulating materials is represented by:

Such roof insulation materials are not afraid of high humidity, they are light in weight and have excellent thermal insulation properties. Representatives of this group also include foam glass. The material has increased water resistance, does not burn, and is an excellent sound insulator.

Before purchasing insulation material for a roof, it is necessary to determine for which building the insulation is being purchased. Foam plastic is not suitable for the roof of a bathhouse. It can be used in places where there is no high temperature. Therefore, to make the right choice, you must read the description of the material and determine where it can be used.

Return to contents

Basalt insulation

Basalt insulation is characterized by the following features:

- Resistance to mechanical deformation.

- Noise insulation.

- Hydrophobicity.

- Energy saving.

- Non-flammability.

- Durability.

When calculating the optimal thickness, it is necessary to take into account all its characteristics in order to select a layer sufficient for insulation. Typically, for any of the Russian regions, the best thickness is considered to be 150 - 200 mm. For areas with severe frosts, a two-layer laying of basalt slabs will be required.

What does a house with good roof insulation look like?

In the summer, it is quite difficult to determine whether a house is sufficiently insulated. But in winter (with the heating running) this is much easier to do; just choose one of the methods suggested below:

Option one (paid) - invite a specialist to perform a thermal imaging survey of your building, that is, take a photograph of heat loss. In the image it will be quite easy to see where the greatest heat loss occurs - they will appear in red and white, while the cold areas will be colored black and blue. Option two (free) - as soon as the temperature drops to 3-5 degrees below zero, after a small snowstorm, feel free to go outside and look at the building under study from the side

Pay attention to the roof of the building: if there is snow on it (provided that the roof slope is at least 30 degrees), then the insulation for the roof was selected correctly. If the roof pleases you with clearly visible roofing material, it means that the insulation allows warm air from the room to pass through and heats the snow that falls on the roof, which rolls off it like from a water slide.

Materials for insulating the walls of a frame house

To insulate the walls of a frame house, several types of thermal insulation material are used - mineral wool and all its varieties, polystyrene foam or extruded polystyrene foam, bulk insulation materials - sawdust, expanded clay. Let's consider all types in detail.

Stone wool

Produced from basalt rocks with the addition of carbonate, which regulates the level of acid content. To bind the fibers together, binding elements are used - bitumen, bentonite and synthetic origin.

Stone wool does not absorb moisture

Insulation according to SNiP, or how to reduce heating costs

Why does one house consume 1500 kW of electricity to heat 100 m² in the winter month, and 3000 kW in another? What does this depend on, besides the heating system? Is it possible to improve the situation and reduce heating costs? Of course, everything is in your hands! To do this, you need to calculate the heat loss at home and try to minimize it.

A house in Sochi and a house in Yakutsk can spend energy for heating the same way during the heating season, provided that they are built in accordance with SNiP 02/23/2003 - building codes and regulations for each region, developed by the Ministry of Regional Development.

Heat loss at home

The air in the house cools due to the loss of thermal energy through the building envelope, ventilation and sewerage.

The main heat loss of 60-80% goes through the enclosing structures.

Let's check whether the thickness of the enclosing structures of your house (external walls) meet construction standards for living in the winter. And if not, we’ll find out how to fix it. And for those who are just planning to build a house, decide what and how thick the outer walls should be to make the house warm and cozy, and at the same time pay much less for heating.

What numbers are needed to calculate the heat loss of a wall?

Firstly, it is the resistance to heat transfer of external walls

for residential buildings (Rreg) - how well the external walls “retain” heat inside the house. Each region has its own, depending on the temperature inside the house, the average temperature outside the house, and the number of days of the heating period.

Below are the minimum values of heat transfer resistance of external walls Rreg for residential buildings for some cities in Russia:

Secondly, the thermal conductivity coefficient of the wall material

λ and its thickness - d. Thermal conductivity is the ability of a material to transfer heat from its warm part to the cold part. Each material has its own, and differs quite significantly.

So, for example, a 20 cm mineral wool insulation is equivalent in thermal insulation to a 1.5 meter brick wall. Also, thermal conductivity may vary depending on the humidity of some building materials.

This is worth paying attention to, since in a dry state building materials are not used when calculating the thermal conductivity of enclosing structures, and “normal A” and “wet B” building conditions can differ significantly, and a mistake can be made. “Wet” is not only a bathhouse and a sauna.

For example, aerated concrete in a dry state has a thermal conductivity coefficient that differs from normal construction conditions from 0.03 to 0.16, depending on the density. It seems that the numbers are scanty, but the thickness of the wall has already changed significantly: from 15 to 50 cm!

We present the thermal conductivity coefficients of popular building materials, depending on operating conditions, in a comparative table, which can be downloaded from the link

Does the wall thickness comply with SNiP standards?

Let's give an example for a house in Nizhny Novgorod, built from hollow bricks with a density of 1300 kg/m³ on cement-lime mortar with a thickness of 2.5 bricks - 640 cm. Nizhny Novgorod belongs to humidity zone 2 - "Normal", the humidity regime in the house is - “normal”, so we select the thermal conductivity coefficient from column “B”.

Let's calculate the heat transfer resistance of the external wall of the house Ro:

d—material thickness, m

λ is the thermal conductivity coefficient of the material, conditions A or B.

The recommended value of Rreg for Nizhny Novgorod is 3.36 m²x°C/W, which our calculation does not satisfy at all. In such a house it will be cold in winter, more powerful heating devices will be required and the bills will be significantly higher than for an insulated house according to SNiP.

Let's check then, what should be the thickness of the wall so that it meets the standards?

d = R reg

* λ

d = 3.36 * 0.58 = 1.95 m

This is the wall! But only this thickness of brickwork will allow you to have a warm home. Brick has a very high thermal conductivity, and in order for the house to retain heat much longer, it is necessary to fence such walls. It is clear that few people will dare to build such a “bomb shelter.”

This means we will insulate the walls with another material whose thermal conductivity is low, and accordingly the wall thickness will be much less. There are a lot of materials for insulation, the pros and cons of which are a different story, but now we will decide to insulate the wall with stone wool.

What thickness should I choose for a layer of cotton wool? The recommended heat transfer resistance value in Nizhny Novgorod is 3.36, we already have a wall with a resistance value of 1.1. It remains to “get” 2.26.

From the table of thermal conductivity of materials, we take the value of the coefficient for stone wool, with a density of 25 kg/m³ - 0.045, and calculate how thick the insulation should be:

d = 2.26 * 0.045 = 0.10 m

0.1 meters - 10 cm is the minimum thickness of insulation that will make the house warm.

Conclusion: we insulate the walls of the house to the required SNiP standards, and also do not forget about the floor and ceiling, because Large heat losses also occur through them. The greater the thickness of the insulation, the less heat loss, the less energy costs will have to be spent on heating the room.

We won’t bore you with calculations, but let’s say right away that at least 20 cm of stone wool is needed for the floor and ceiling as insulation – for the Central part of Russia. For the North - 25-30 cm. Then your house will keep warm for a very long time, heating costs will be pleasing, and you will choose heating devices not at the rate of 1 kW per 10 m², but, for example, KOUZI 450 W per 10 m². Read in the following articles why one “COZI” will be enough for such an area.

Mineral wool - density and thickness of mineral wool

Mineral wool is perhaps the most common insulation material for attic roofs due to its low cost and good thermal insulation qualities. In addition, the advantages of this material are also fire resistance, good breathability and low hygroscopicity. On the other hand, the thermal insulation characteristics of mineral wool are significantly reduced when wet, which makes it mandatory to equip it with waterproofing and vapor barrier membranes.

Mineral wool has several varieties:

- glass wool;

- slag;

- basalt or stone wool.

Glass wool is made from the finest glass fibers 5-15 microns thick and 15-50 millimeters long. It has an elastic and durable structure, and requires great care when working: to avoid irritation, when laying it, wear a protective suit, gloves, goggles and a respirator. Resistant to temperatures from minus 60 to plus 450-500 °C.

Slag wool, made from blast furnace slag, contains fibers 4-12 microns thick and approximately 16 millimeters long. This material can withstand heating up to 300 °C, but is ineffective when arranging thermal insulation of the attic due to its high hygroscopicity. In addition, slags with residual acidity can have an aggressive effect on metal surfaces, which is also a significant disadvantage. The disadvantages of slag wool are also its fragility and “prickliness”, which creates inconvenience when working with it with bare hands.

Basalt (stone) wool is made from gabbro-basalt or diabase with composite and binder additives. Its fibers are approximately the same size as those of slag wool. In terms of technological characteristics, this material is superior to all other types of mineral wool, and therefore is especially often used for thermal insulation of attic roofs. Stable when heated up to 600 °C (some types - up to 1000 °C). When using this type, the elasticity and density of mineral wool for attic insulation are sufficient so that the material does not wrinkle or settle when installed on slopes.

Types of insulation for roofs, comparison of properties and installation technologies

In this article we will tell you how to choose the right insulation for your roof.

What parameters need to be paid attention to, the stages of proper assembly of a heat-insulating pie on a roofing structure. After reading the article, you will be able to communicate “on the same wavelength” with the foreman about choosing the right material, and, if necessary, supervise the workers performing thermal insulation of the roofing system

Roof insulation

Requirements for insulation

Let us immediately note that there are many criteria for thermal insulation materials. And each of them does not meet all the criteria. Different insulation materials have pros and cons. And the consumer always faces a choice, giving preference to one or another characteristic.

So, if we talk about ideal roof insulation, it must meet the following criteria:

Low thermal conductivity. Here the question is posed like this: the lower, the better. But there is an upper limit - no more than 0.05 W/m K.

Density. Excessive loads on the roof structure are not necessary. Therefore, the less the thermal insulation material weighs, the better.

Low hygroscopicity. This is the property of a material to absorb moisture. As humidity increases, the thermal properties of insulation decrease. And although today the problem is solved by the use of protective films, it is better to give preference to those products that have a low characteristic.

Fire safety indicator. Unfortunately, it must be said that a large number of thermal insulation materials cannot correspond to the maximum value of this parameter. But among them there are those that do not burn and do not support combustion.

Many insulation materials burn well

Stable condition. That is, during operation, the insulation should not change its shape and size.

It should not be a place where harmful microorganisms, rodents, insects or birds would appear.

The insulation must not be dangerous to humans.

On our website you can find contacts of construction companies that offer the service of calculating and carrying out turnkey insulation work for a private house. You can communicate directly with representatives by visiting the “Low-Rise Country” exhibition of houses.

The best insulation

The criteria have been outlined, let’s try them on with different roof insulation materials and decide which one is the best. This article will not discuss bulk-type materials that are used to insulate flat roofs. Let's consider slab and sprayed types.

Board insulation is a material with a fibrous or gas-filled porous structure. Sprayed ones also belong to porous materials, but their method of application is foam, which in air turns into a durable heat-insulating mass.

It should be noted that fibrous insulation, of which mineral wool is a prominent representative, are hygroscopic products. Therefore, they are covered with protective membranes on both sides. Today, many manufacturers offer mineral wool, in which this parameter is greatly reduced. But experts recommend not to abandon protective films when mineral wool is chosen as insulation for the roof.

Mineral wool must be covered with protective films

Characteristics of thermal insulation materials

To choose the best thermal insulation material for a roof, you need to compare the characteristics between them. Let's put them in one table. But let’s first indicate that we will compare three materials: mineral wool, polystyrene foam boards, polyurethane foam. They are most often used for thermal insulation of pitched roofs. That is, the dispute - roof insulation: which one is better - will be resolved between them.