It may seem to the average person that the system for removing toxic combustion products is a simple mechanism that is not particularly difficult to create.

The chimney is a seemingly ordinary pipe through which flue gases are removed, and nothing at all depends on it. However, this opinion is wrong.

In fact, the vertical channel is an important design that affects the following parameters:

- fuel consumption;

- boiler efficiency;

- efficiency of the heating system.

Before proceeding with the installation of a device for removing combustion products, it is necessary to resolve in advance several important technological issues regarding:

- heights;

- material;

- sections;

- location;

- ease of maintenance.

In this article we will talk in detail about how high the chimney should be.

Why is it necessary to accurately calculate the channel height?

- It is required to increase the efficiency of the heating system. If the elevation of the pipe device above the roof is done correctly, this guarantees maximum heat transfer with less fuel consumption.

- It is important to ensure complete safety of the structure. If the calculation of the channel height was made incorrectly, toxic combustion products will begin to penetrate into the room. To prevent this from happening, you need to create good traction.

- The risk of fire must be completely eliminated. When the height of the chimney above the roof is less than normal, the cooling of hot gases occurs much more slowly, which increases the likelihood of a fire several times.

What should the chimney duct be like?

When constructing a chimney, it is extremely important that all dimensions are calculated and the material is selected correctly. And these parameters, in turn, will depend on the fuel that is planned to be used. Thus, the brick structure is suitable for gas and solid fuel appliances

Its cross-section and height must be carefully calculated (more on this a little later) so that the entire heating system functions normally. If the dimensions are incorrectly selected, the boiler efficiency will decrease and the required draft will be absent, which can lead to the most unexpected consequences

Thus, the brick structure is suitable for gas and solid fuel appliances. Its cross-section and height must be carefully calculated (more on this a little later) so that the entire heating system functions normally. If the dimensions are incorrectly selected, the efficiency of the boiler will decrease, and the required draft will be absent, which can lead to the most unexpected consequences.

Note! All this is especially important in cases where the chimney is being installed for several devices at once - here it is better to entrust the calculations to professionals, since the risk of making a mistake is quite high. In accordance with generally accepted requirements, 1 chimney is capable of serving no more than 2 heating devices, but only when its internal dimensions allow both of them to operate simultaneously. And the height of the cutting channel in this case should be about 0.8 meters

And the height of the cutting channel in this case should be about 0.8 meters

In the case of large parameters, the efficiency of the device will decrease, and with smaller parameters, the draft will deteriorate, and combustion products may penetrate into the room

And the height of the cutting channel in this case should be about 0.8 meters. If the parameters are large, the efficiency of the device will decrease, and if the parameters are smaller, the draft will deteriorate, and combustion products may penetrate into the room

In accordance with generally accepted requirements, 1 chimney is capable of serving no more than 2 heating devices, but only when its internal dimensions allow both of them to operate simultaneously. And the height of the cutting channel in this case should be about 0.8 meters. If the parameters are large, the efficiency of the device will decrease, and if the parameters are smaller, the draft will deteriorate, and combustion products may penetrate into the room.

As for the shape of the chimney, the cylinder is definitely considered the best. The height of the chimney relative to the roof ridge does not affect this, nor does the material used. And even pipes of the required diameter are built into brick channels. This is explained by the fact that combustion products rise in a spiral, so the optimal shape is a cylinder. Only under such conditions is maximum traction achieved.

Chimney pipe cap

Previously, we talked about how to make and install a cap on a chimney pipe on your own. In addition to this article, we advise you to read this guide

And modern boiler models that operate on a “stop-start” basis cannot do without such a pipe. After all, the main thing for them is to quickly heat the system to the required level and put it into standby mode, which is why, in fact, such boilers are considered the most economical.

In square chimneys, turbulence will be created, which again will lead to poor draft. But for wood-burning heating boilers, this form is suitable, as it increases their efficiency by slowing down the output of thermal energy.

What parameters influence the height of the chimney pipe?

Every master should know how to calculate the height of a vertical channel. Professionals advise making calculations using the formula below:

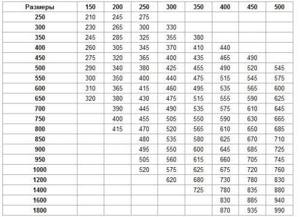

Based on similar mathematical values, it is possible to obtain specific data on which the indicator of the height of the channel above the roof depends:

- Meteorological conditions of the area in which the chimney will be installed (A). In the northern regions this coefficient is 160, while in others it is taken from descriptive documents.

- The amount of substance that passes through the pipe in a certain time (Mi). Such data is given in the heating equipment instructions.

- At what speed does the settling of small particles that are formed during fuel combustion occur (F). When burning wood, ash appears, for which the coefficient is 25. If an electric heating device is used, the value of F is equal to one.

- Concentration of various substances in carbon monoxide that require prompt removal (Spdki and Sfi). These parameters can be found in the descriptive documentation of the heating device.

- Gas outlet volume (V).

- Temperature difference between outlet and inlet air (T).

Not everyone can perform such calculations on their own, since they are quite complex and require special knowledge. For this purpose, it is recommended to turn to professionals.

The meaning of chimney parameter calculations

If the boiler equipment is incorrectly calculated, a reverse draft effect will occur when flue gases are not discharged into the atmosphere, but enter the living rooms. In such a situation, there is even the possibility of creating a fire hazard if hot smoke enters the room. As a result, when building a chimney, it is important to accurately calculate its geometric characteristics, which guarantee the creation of a working draft sufficient to completely remove flue gases and ensure a high efficiency of a heating unit running on natural fuel.

The operation of a thermal energy source operating on solid, liquid or gaseous fuel depends entirely on the following parameters of the chimney:

Pipe length. First, you will need to establish the greatest height of the building, as well as the size in meters to the roof ridge at the point where the design chimney is planned to be installed. As a result, all the most important parameters of the chimney system under construction are associated with this indicator. It must be taken into account that excessively high smoke channels will literally “eat up” the vacuum in the smoke ventilation tract; as a result, the source of thermal energy will not be able to efficiently burn the fuel from the pipe and black smoke will pour out of all the cracks. Exorbitantly low pipes in relation to the roof are no less dangerous. Chimney diameter for wood stove

With regard to this size, it is not the specific number that will need to be taken into account, but rather the geometry of the chimney. Experts - stove makers say that a high-quality smoke exhaust system, functioning according to all the laws of aerodynamics and heat engineering, has a circular cross-section

In this case, soot deposits are not retained in the channels to such an extent, so such a system requires less cleaning. Regarding the specific size, it should be selected according to the cross-section of the main outlet pipe of the boiler or other heat source. The use of larger or smaller pipes is not recommended by the manufacturer due to the high risk of depressurization. In addition to determining the D of the pipe, it is necessary to take into account the traction force. To do this, Bernoulli's law is used, data on the temperature of the external and internal air, as well as the pressure of the environment, is entered into the formula. The final calculation takes into account the total loss of air pressure at two points: in the combustion chamber and at the exit from the chimney. The final size of the draft for furnaces must exceed all pressure losses in the gas-air path.

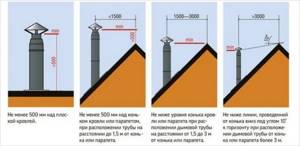

Optimal chimney height on the roof

The value of this value, taking into account the shape of the upper structure of the building, is standardized and prescribed in SNiP 2.04.05-91. This parameter is calculated in a certain order.

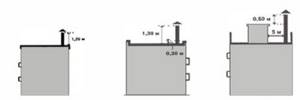

Flat roof

In the absence of parapets or other similar devices, the minimum height of the chimney above the roof should be 120 cm.

If there are protective curbs or similar equipment, the length of the chimney pipe must be increased. It is quite possible to calculate the height by first adding one meter to the maximum length of the heating equipment itself.

When there is a ventilation pipe on the roof, the chimney structure is installed half a meter above the height of the air duct. Moreover, the structure for removing combustion products must be fixed at a distance of 5 m from the installed ventilation shaft.

Pitched roof

When calculating the height, the location of the chimney is taken into account, namely the height of the pipe from the roof ridge.

If the distance between the vertical channel and the upper horizontal line of intersection of two planes does not exceed 1.5 m, the minimum height value is taken equal to 0.5 m.

The height of the channel above the ridge should correspond to the maximum height of the roof if the structure is located 1.5-3 m from the horizontal line of intersection of two slopes.

When the chimney pipe is located on the roof and the ridge is more than 3 m away from it, an angle of 10 degrees must be created between the end of the pipe and the horizontal guide of the building's upper structure element.

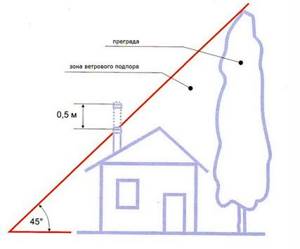

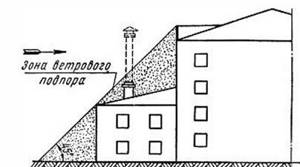

In addition, when determining the height of the chimney, some additional factors are taken into account, for example, the placement of trees or any buildings near the building.

In the presence of foreign elements, a special zone is formed, called “wind backup”. In this area it is impossible to create the necessary draft for the normal functioning of the heating device.

To speed up the movement of gases up the pipe, you need to increase the height of the chimney structure by 0.5 m. As a result, it will leave the wind zone.

Approximately the same situation arises when installing heating equipment in an extension to a building.

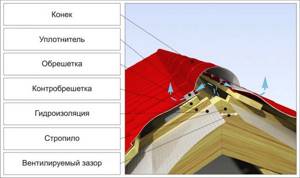

What is a skate?

The ridge is the top edge of the roof structure. This element connects the roof slopes, the planes of which converge on it in one line. Since the ridge is the top point of the roof, the height of the roof is determined by its location .

NOTE!

This element performs the functions of protection and ventilation . It closes the joints of the slopes, preventing moisture and dirt from entering the interior of the roofing pie. In this case, circulating air masses exit through the ridge.

Determining the height of the roof is important not only for the purposes of ensuring wind and snow resistance. Most roofing materials have clear ranges of possible pitch angles for their installation . When installing heavy materials, it is necessary to minimize the load per unit area of the roof base; for this, the slope angle (and, accordingly, the height of the ridge) increases.

Roof ridge

If it is planned to equip an attic space in a house, then the range of possible slope angles is limited by the requirements for the maintenance capabilities of the room and its fire safety. For residential attics, requirements for ease of movement around the room are added, depending on the height of the residents.

Ventilation height

Calculation of the height of the ventilation pipe is carried out similarly to the chimney. For this purpose, standard values are taken from regulatory documents. The main requirement for this design is its location. If the chimney and air duct are located closer than 3 m to each other, it is allowed to make them the same height.

The dimensions of the ventilation pipe and its diameter should not interfere with the ventilation of the boiler room. To do this, it is necessary to take into account the amount of oxygen in the room.

The volume of heated air entering the building heated by the boiler is taken at the rate of 3 m³ per 1 m² of area per hour. For boiler rooms, this parameter should be 180 m³ per hour.

Calculations of strength and stability of the structure

The regulations for gas boilers differ depending on the type of burner. The following standards and regulations apply to chimney systems installed on open-type boilers:

- the pipe has no more than 3 bends (45-90°);

- only non-flammable material is used;

- pipes must be protected with thermal insulation;

- a hole with a damper is provided through which the chimney is cleaned;

- the height and cross-sectional parameters of the chimney comply with the requirements recommended by the boiler manufacturer;

- there is another hole in the pipe to collect condensate;

- To protect the chimney from dirt, leaves, etc., a special umbrella is provided.

Requirements for chimneys on boilers with closed air exchange:

- the diameter of the outlet pipe is less than the diameter of the pipe itself;

- the minimum distance of the horizontal chimney from the ground surface is 2 m;

- the chimney pipe is located at least 2 meters from windows, doors, ventilation holes;

- the minimum vertical distance from the pipe to the window openings is 1 m;

- there should be no walls, fences or other obstacles closer than 1.5 m near the pipe;

- When installing, you should maintain a pipe inclination angle of 6-12° for natural removal of condensate.

It may be useful for many to know the requirements regarding chimneys for solid fuel boilers:

- it is allowed to use one outlet channel for two heating devices if the distance between them is at least 750 mm;

- pipes must be completely sealed;

- the optimal type of section is round;

- perfectly smooth inner walls (finished with galvanized or stainless steel).

Sandwich chimney installation diagram.

The draft is affected not only by the height, but also by the diameter of the chimney of the boiler room, the size of which depends on the amount of fuel burned per unit of time.

Depending on the dimensions of the smoke exhaust structure, the foundation is calculated, namely, it is determined:

- its design;

- required depth;

- sufficient sole area, etc.

The range of diameters of chimneys constructed of brick and reinforced concrete varies from 1.2 m to 9.6 m. It should be noted that the minimum diameter of reinforced concrete pipes is 3.6 m.

Aerodynamic calculation

To carry out such a calculation, you cannot do without special knowledge. In this case, you need to resort to using rather complex formulas.

Of course, such a calculation can be performed using a computer program, but it is recommended to entrust such work to a competent specialist.

But before you turn to a professional, think about how necessary these calculations are. The above recommendations make it possible not to use the aerodynamic calculation of the chimney.

General provisions

The instantaneous throughput of the chimney determines how high the chimney pipe should be above the roof. Household heating units with a power of up to 7 kW are operated only at a height from the grate to the edge of the top of more than 5.0 m.

Communication smoke exhaust ducts are made without scuffing and gas-tight, from structural components that are resistant to mechanical loads, temperature changes, and resistant to the corrosive action of combustion products.

Insulation of chimneys where the operating conditions exceed 105 C is made from heat-resistant insulation. Source sl.aviarydecor.com

See also: Catalog of companies that specialize in roof design and repair.

The parameters of the cuts and offsets of the chimneys of heating units are used in accordance with the manufacturer’s technical regulations.

It is advisable to install smoke vents inside walls and partitions from non-combustible components. External walls made of non-combustible components are allowed to be used only when insulated to prevent condensation.

If it is impossible to arrange communication ducts for smoke exhaust in the walls, mounted and root pipes are used.

Root pipes are structures with their own foundation located not far from the heating unit.

Mounted pipes are installed on top of the heater. It is necessary to take into account the pressure created by the chimney. In earthquake-prone areas, the construction of mounted gas ducts is prohibited.

The gap between the chimney and the rafters, lathing and other parts of the roof made of flammable components is taken to be at least 13 cm, to uninsulated ceramic flues - 25 cm, and when insulated with heat-resistant or poorly flammable components - 13 cm.

The gap between chimneys and roof structures made of non-combustible and poorly combustible components is equipped with heat-resistant roofing materials Source skvb-nn.com

It is important to protect the chimney head from atmospheric influences. The protection must allow combustion products to pass freely.

The chimneys of units using wood and peat, on buildings with roofs made of flammable components, are covered with spark arresters made of metal mesh with a size of no more than 5 × 5 mm.

If the flue length is more than 1.5 meters from the roof plane, the chimney must be equipped with additional guys to resist wind.

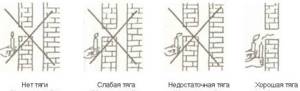

Thrust calculation

Any ventilation system will not be able to function normally without good draft, which is created by the difference in pressure inside and outside the room.

To calculate the draft of a chimney, you need to multiply the height of the channel by the difference in the density of the internal and external air.

The calculation is carried out using the following formula:

F= A(pв - pд)h,

- F – thrust;

- A – coefficient;

- pв – density of outside air;

- pd – density of flue gases;

- h – pipe height.

Example

When fuel burns in the firebox, heated gases are removed. Natural draft occurs due to the difference in temperatures inside and outside the room.

Air density and temperature are directly related. When calculating, dynamic pressure is not taken into account, since the process speeds are very low.

All data is substituted into the famous Bernoulli equation. Next, the pressure loss values are found, then they are compared with the thrust parameter.

If the same indicators are obtained, further calculation does not make sense. The system will work normally, combustion products will begin to be completely removed.

If equality is not maintained, you need to increase the level of traction or reduce the number of losses. To implement the first method, you can:

- lengthen the chimney pipe;

- increase the temperature difference.

To reduce pressure loss, it is recommended to use the following methods:

- make the canal walls smoother;

- reduce the path of removed gases;

- reduce the number of turns;

- increase the cross section.

Using the same method, natural ventilation indoors is calculated.

Types of chimneys

The chimney is another functional element of the building, the location and height of which is regulated by building codes.

There are several ways to classify chimneys.

Chimneys are distinguished by location:

- wall (located inside the main walls);

- indigenous (not connected to the wall and located at a distance from it in the interior of the building);

- external (pass through the facade of the building).

The main method of classification is to distinguish types of chimneys according to the material of manufacture:

- Brick . They are fireproof and have high heat capacity, but their maintenance requires a lot of time and effort, and the draft of a brick chimney is relatively low.

- Steel single-circuit . Inexpensive and easy to maintain, but wear out quickly and require additional fire safety.

- Sandwiches . A more advanced and expensive version of single-circuit chimneys, where there is a layer of non-combustible material between the layers of steel.

- Ceramic . Fire-resistant, durable, easy to install and maintain, but very expensive.

- Asbestos-cement . The cheapest variation, but its performance indicators are low: asbestos-cement chimneys quickly become clogged with soot and burn out. To avoid a house fire due to soot ignition, you need to constantly clean your pipes.

- Polymer . Inexpensive, but not fire-resistant chimneys.

Types of chimneys

At what price can I buy a TV wall mount at a good price?

The device can withstand a load of up to 40 kg and allows you to fix large diagonal TVs - 32-55 inches. Its body is made of durable metal and has a stylish design. Thanks to this mechanism, the screen can rotate around its axis by 120°. It is possible to change the angle of inclination. The price of the model is 1600 rubles.

If you need to buy a swivel TV mount, you should pay attention to the KSL WM227T model. It is a universal mounting device for flat screens.

Using the VESA system, you can mount models with mounting sizes: 75x75 and 200x200 mm. The design is designed to install flat screens with a diagonal of 19-43 inches. The maximum load is 25 kg. The cost of the model is 1120 rubles.

Features of a sandwich chimney

A type of round pipe is a sandwich chimney. It consists of two pipes of different diameters, between which there is a heat-resistant thermal insulation material. They are made of stainless steel. The sandwich chimney is in great demand because it provides stable draft, does not heat up, is easy to install and looks beautiful in appearance.

The passage through the roof of a sandwich chimney can also be done using an elastic adapter. However, it may not be in harmony with its mirror surface. In this case, a metal adapter is used, the material of which is also stainless steel. It is not flexible, so you must take into account the diameter of the pipe and the angle of the roof slope.

A special feature of organizing the passage of a sandwich chimney is the installation of a PPU - ceiling-passage unit. This device protects all wooden elements through which the chimney passes from high temperatures. It is a metal structure with a certain diameter through which a pipe must be passed. The material of its manufacture is galvanized steel or mineralite. The inner surface of the unit is lined with thermal insulation.

Ceiling-passage unit for a round pipe On our website you can get acquainted with the most popular sites in the Moscow region for the construction of a country house. In the filters you can set the desired direction, the presence of gas, water, electricity and other communications.

Channel requirements

The location of the chimney relative to the ridge is not the only issue during construction. It is important to take into account the recommendations and pay attention to the following:

- The material is selected depending on the fuel the boiler runs on. For a gas, stove or solid fuel unit, a stainless steel pipeline would be a good option.

- The number of heating devices should not exceed two per chimney. Otherwise, there is a high risk of incorrect diameter calculation. When using two heating devices, one type of fuel must be used, and the diameter of the pipes can be no larger than the chord of the chimney itself.

- It is preferable to construct a cylindrical or round pipe. This design allows you to create ideal draft, preventing smoke from returning to the room.

By following these simple rules, you can achieve efficient operation of your heating system.

Summarizing

Of course, the warmth in the house depends on the heating boiler, which heats the coolant in the pipes and radiators. However, not a single stove, even the most wonderful one, is capable of functioning with a chimney pipe of the proper height. The height of the chimney affects not only the draft of the stove, but also matters for the health of the inhabitants of the house.

If the height is insufficient, a backdraft may form, in which combustion products and carbon monoxide will flow into the room. According to statistics, during fires, in most cases people die from carbon monoxide, and not from fire. Therefore, before proceeding with the installation of a chimney, it is necessary to study all available information.

Checking the planned pipe for the amount of natural draft

In fact, we have already determined the main parameters of the chimney - the sufficient cross-section of its channel and height. But for devices with natural draft, it is never a bad idea to check the strength of this very draft. So that it does not happen that the constructed chimney suddenly refuses to perform its main functions.

Draft is essentially the difference in pressure between hot gases in the pipe and the outside air. It is this difference that stimulates the movement of gas flow through the chimney channel.

It is believed that for normal operation of a chimney with natural draft, this difference must be at least 4 pascals for each meter of pipe height (0.408 mm of water column or 0.03 mm of mercury). That is, for a five-meter pipe (our minimum), the thrust should be at least 20 Pa. This ensures both normal gas removal and the necessary air flow for continuous combustion of the fuel.

How to calculate this thrust. Naturally, it largely depends on the densities of gases, which, in turn, are closely related to temperature. You can verify this by looking at the formula with which we will work:

ΔP = Htr × g × Patm × (1 / TV – 1 / Tds) / 287.1

ΔP is the natural draft in the pipe, Pa.

Htr—chimney height, m.

g—gravitational acceleration (9.8 m/s²);

Patm - atmospheric pressure. A value of 750 mmHg is considered normal. However, the area for which the calculation is carried out may have its own specifics. We must understand correctly that sea level is considered the norm. And with increasing altitude, this rate begins to decrease. And quite significantly. So when making calculations you will need to be guided by the norm for your region of residence.

Atmospheric pressure is usually measured in millimeters of mercury. However, to calculate in the SI system it is necessary to convert it to pascals. This is not difficult if you know that 1 mm Hg. Art. = 133.3 Pa.

TV - outside air temperature. Moreover, reduced to the Kelvin scale, that is, C° + 273.

Tds is the average temperature of gases in the chimney. Defined as the arithmetic average of the input and output indicators, followed by conversion to the Kelvin scale.

287.1 is the gas constant of air. It would be more correct to select this value for the specific chemical composition of the exhaust gases. But in our case, the error will not be significant, greatly affecting the final result.

A few important notes on inlet and outlet temperatures.

You should always strive for its optimal values. Statistics show that most fires occur with sauna stoves, into which there is practically no heat removal; the heat in the steam room builds up in a short time, and the chimney usually heats up to dangerous temperatures. Therefore, you need to be able to control the temperatures in the pipe using available means - gate valves, valves, additional heat recovery devices (for example, water heating tanks).

In household and heating stoves this is easier, but control is still necessary. In boilers, where the very essence of the work is the constant transfer of heat to the circulating coolant, these issues are not so pressing.

The 900 ÷ 600 ℃ (input and output) mode, found on some sauna stoves, is extremely dangerous in all respects, and should not even be considered! Reasonable limits (and even then their upper limit) are 600 ÷ 400 degrees for household brick and metal stoves. Usually they try to maintain it in the range of 400 ÷ 200 ℃. For gas equipment, the lower limit can fall below 100 degrees.

If all the initial values for substitution into the formula are known, you can proceed to the calculation. To do this, we again suggest using the capabilities of a special online calculator.

Calculator for calculating the natural draft of a chimney.

If the resulting pressure difference falls within the norm (more than 4 Pa per meter of pipe height), then the test can be called successful.

The main parameters of the chimney have been obtained - you can proceed to the selection of materials and detailed design.

This video will tell you about many other subtleties of independent chimney design:

Pipe section

This design parameter is critical to ensuring the efficiency of the heating system. It is determined primarily by the shape of the chimney.

When using a classic cylindrical or round channel, it is enough to follow a simple rule: the cross-section of the pipeline should be proportional to the combustion chamber in the amount of 1 to 10. If a square shape is used during construction, the proportions should be 1 to 1.5.

If the requirements are met, the heat output will be sufficiently effective to ensure proper operation of the stove heating. In this case, the boiler itself will not be overloaded, working at 100%, but without wear.

Types of pipes for stoves and fireplaces

The following types of chimneys are distinguished:

- Brick mounted pipes are massive objects resting on the stove masonry; they must be laid out at least half a brick thick.

- Root pipes are free-standing structures in the form of risers; they should be made from an asbestos-cement pipe with a diameter of 15-20 cm.

- Precast pipes are individual blocks made of heat-resistant concrete.

- Wall pipes are structures mounted in a solid load-bearing wall, which saves space in the room.

Obtaining high efficiency from a furnace with this type of pipe is not possible. If no other method of locating the wall chimney is provided, appropriate types of work are carried out to arrange a pilaster with a protrusion extending into the room. Installation is carried out with maintaining the required distances from the chimney to the outer wall:

- 2.5 bricks (from 20 to 30 - 650 mm);

- 2.0 bricks (from 20 and above - 510 mm);

- 1.5 bricks (from 20 and below - 380 mm).

The location of the chimney is determined strictly vertically without any indentations inside. If there is a bend in the structure, its dimensions should not be more than 1 m. A brick pipe often has an internal cross-section of at least 140x140 mm. Normal chimney draft is achieved due to a pipe height of at least 5 m. If it is less than 5 m, draft is provided using a deflector-diffuser.

Having equipped your house with stove and fireplace heating, you should install 2 chimneys. Different drafts of one of the sources can lead to smoke. In a wooden house, in places where there is an adjacent brick chimney, a thickening of 1-1.5 bricks is provided. A flammable structure near the chimney must be protected from it with asbestos-cement or metal sheets.

Installing a chimney through corrugated sheeting

Corrugated sheeting is a sheet of metal produced by cold rolling and then profiled. Mainly made of steel, but can be made of copper and aluminum. The sheet has ribs of oval, square, trapezoidal or polygonal shape. A special coating is made on top, which gives it anti-corrosion properties. Corrugated sheeting is often used as a roofing material.

To pass the chimney through the roof, in the case of a square or rectangular pipe, a device in the form of two aprons and a tie is used. The method is the same as for a metal roof. Installing round pipes in corrugated sheeting is not recommended, because it is difficult to cut the correct circular section into it. But if you still make a round chimney, the pipe is insulated using a universal elastic adapter.

Accessories for round pipes

What to do if the chimney cross-section is square?

Cylindrical chimneys, especially after the advent of sandwich pipes, are the most common types of devices. But when building a brick kiln, you have to lay out a square or rectangular shape.

In such chimneys, turbulence is formed, which prevents the normal passage of exhaust gases and reduces draft. But for wood stoves or fireplaces, rectangular pipes remain the most popular shape. Such devices do not require an increased level of exhaust gas extraction.

The calculation of a chimney for a wood-burning stove with a square or rectangular cross-section is made taking into account the ratio of the dimensions of the pipe to the size of the blower hole on the stove. This proportion is 1/1.5, where 1 is the internal cross-section of the pipeline, and 1.5 is the dimensions of the blower or ash pan.

Chimney size for gas boiler

Gas boilers come with open and closed combustion chambers. Units with a closed combustion chamber are equipped with coaxial chimneys. The rules for placing them are quite simple:

- The chimney rotates 90 degrees and ideally should immediately exit horizontally behind the wall

- The outlet should be made at a slight slope towards the street so that condensate does not enter the boiler.

- If the pipe is mounted vertically, then a condensate drain must be provided.

- The height of the chimney for a gas boiler with a closed chamber is regulated by each manufacturer in its own way, because the power of the smoke exhauster into the boiler may vary. Therefore, please read the instructions before installation.

- There is no need to install a chimney above the roof and ridge.

For boilers with an open combustion chamber, the height of the chimney is calculated similarly to the method described above.

Service life of the external chimney

The service life of the structure depends on the material of its manufacture and correct installation. When used correctly, ceramic pipes will perform their function for up to 40 years. A brick chimney can be used for more than 50 years. Stainless steel will have to be replaced after 15-20 years, but it all depends on the thickness of the metal. Galvanization has the shortest service life: up to 10 years.

The durability of the structure is affected by the heating temperature of the exhaust gases. A high-quality sandwich system will last up to 20 years. Structures last longer if heating equipment runs on gas or pellets.

Protecting the roof from heat coming from the pipe

When organizing a pipe passage through the roof, it is important to insulate the roof from it. After all, the pipe gets very hot, which increases the fire hazard. The roof is protected using a separate box, the beams and rafters of which are located taking into account the requirements of SNiP. The minimum distance standard from the chimney to the load-bearing beams and rafters is from 130 to 250 mm. The inside of the box is filled with some material that does not burn. For example, it could be basalt or stone wool.

The chimney must never touch the roofing directly.

Further organization of the pipe outlet depends on what shape it is and what it is made of. The shape of the chimney can be made either as a regular square or round, or in the form of a rectangle or oval. And pipes can be brick, metal, asbestos-cement or ceramic. The material from which the roof is made is also taken into account. This can be slate, metal tiles, corrugated sheets, ondulin, roofing felt or bitumen shingles. Each case has its own characteristics.

Where is the best place to route the pipe through the roof?

The most convenient and best option for the pipe to reach the roof is a ridge. Passing through the roof in the ridge area has many advantages:

- firstly, the minimum distance from the top point of the roof guarantees ease of calculating the length of the outer part of the pipe;

- secondly, installing a chimney in close proximity to the ridge is the simplest from a technical point of view;

- thirdly, such an arrangement of the chimney guarantees ease of insulation work.

Of course, this arrangement of the chimney duct also has its disadvantages. The main one is that the rafter system should not have a ridge beam, because the distance between the pipe and the highest point of the roof is practically zero. A solution to the problem may be to bypass the chimney duct with two beams, the distance between which is equal to or slightly greater than the diameter of the pipe, but this option is quite complicated from a technical point of view, and sometimes is completely impossible.

The worst option is to place the chimney in the valley. This is due to the fact that a large amount of snow accumulates here, and water flows down from two slopes. Thus, even carefully executed waterproofing will not last long in the presence of penetration. The roof will probably leak. It's only a matter of time.

Based on the foregoing, it becomes clear that the most optimal option is one in which the distance from the pipe to the ridge is small, but at the same time the chimney is slightly shifted below the highest point of the roof. The advantages of this option are as follows:

- installation has no technical difficulties;

- in this place a lot of snow falls on the roof, but it accumulates lower, so there is no need to install snow retention devices;

- since the passage through the roof is located near the ridge, the height of the pipe will be small, so there is no need to strengthen it with guy wires.

Inexperienced builders often wonder how to properly install a chimney on a pitched roof. The right solution in such a situation may be to arrange the street part of the chimney duct in close proximity to the highest point of the roof.

What should be the height of the chimney above the roof ridge?

Unfortunately, manufacturers and even trading organizations rarely explain what height the pipe should be relative to the roof ridge. In the accompanying documentation, you can often find the phrase “installation of heating equipment and chimney must be carried out by specialized organizations” or “to install a chimney pipe, please refer to the relevant SNiP.”

The recommendations are certainly correct, but difficult to implement. A house or dacha is often located far from the city, and just the visit of the relevant specialists will cost a tidy sum, not to mention the work itself. SNiPs are written for anyone, but not for ordinary citizens. Even professional builders are sometimes unable to understand specific terms.

Features and Requirements

In large cities, there is a poor environment and high levels of pollution, so pipe installation should be carried out at a level slightly above established standards and indicators. In small towns you can use standard standards.

According to fire safety requirements for a boiler room, the height of the pipe through the roof should be set as follows:

- if the chimney is located 1500 mm from the roof ridge, it must be installed at least 500 mm from the highest point of the roof;

- if the pipe is placed 1500–3000 mm from the roof ridge, its level must correspond to the level of the roof;

- when the chimney is located above 3000 mm from the ridge, it is installed lower at a 10-degree angle relative to the top point of the roof;

- the chimney must be at least 1 m higher than the roof.

Some more tips

In addition to height, the draft force is influenced by the shape of the internal section of the chimney.

An oval passage is considered optimal, since as you gain altitude, the smoke begins to twist into a spiral and nothing prevents it from accelerating. Square and rectangular sections themselves become an obstacle due to the internal corners, so the surface must be smoothed as carefully as possible. Some masons select and lay bricks with the smooth side inward, while removing the mortar buildup. Another important point is the size of the chimney diameter. Oval passages are made according to the size of one tenth of the area of this firebox parameter. Square pipes require an area size of one fifteenth of the firebox area. The general rule for all smoke ducts is that their diameter should not be less than the width of the upper exit from the ash pit.

In addition to the height of the pipe relative to the ridge, you should take into account its height from the location of the ventilation ducts. Ventilation located nearby requires raising the height of the chimney by 20–25 cm from its horizon. If there is insufficient draft in the pipe, then the method of increasing the pipe height is used. But at the same time, you should remember the rule of relevance, that is, you should not make the height too large or insufficient.

Installation of a chimney in a soft roof

Soft roofing is a flammable material, so it is important here that there is a gap of 13 to 25 mm between the pipe and the covering. The passage of the chimney through the roof is organized depending on its shape - flat or pitched. The material from which the pipe is made also plays a role. If the roof is flat, consisting of a concrete slab and the pipe is not made of brick, the passage is made as follows:

Around the pipe at a distance of about 15 cm along the perimeter, everything is removed, right down to the concrete.

Concrete is poured so that a side is formed, the height of which is 15 cm.

The roofing covering is applied to the walls.

Where the roofing material connects to the side, a metal strip is installed. Fastening is done using dowels.

An ebb tide is installed on the side.

If the pipe is brick, there is no concrete side. In this case, roofing material is placed on it and a metal apron is installed on top. A groove is made in the wall of the pipe (depth 1.5 cm), into which the edge of the apron is inserted.

When passing a pipe through a soft roof, many nuances must be taken into account

The junction is filled with sealant. In the case of a pitched roof, waterproofing is carried out as on other coverings, that is, using aprons (for square and rectangular pipes), as well as flexible or metal adapters (for round ones).