Possibility of combining fuel compositions

Heating systems must be designed for emergency situations when one energy carrier is urgently replaced by another. The market offers equipment for several types of fuel. Let's consider complex heating boilers using several fuel functions that do not require a radical change in the system. The offered heating devices are capable of providing hot water to consumers not only in private homes, but also in office buildings or public utilities.

Combination of wood - gas

Coal, firewood, briquettes, lumber - anything that can be burned - is suitable for the firebox module. The installation consists of one or two separate chambers. In a device with a firebox, only solid materials are used at a time; to switch to gas, a burner is mounted in the chamber.

Units with separate fireboxes have impressive dimensions. Two types of energy resources can be used simultaneously. The heat exchanger is mounted alone on 2 chambers or there is a combination of two separate elements.

Gas/solid fuel units are relatively inexpensive and are in high demand among owners of small cottages.

Combination gas - electricity

Quite common combination boilers are installed in places with a centralized gas supply. Advantages of heating boilers of this type:

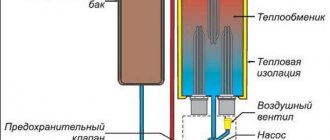

- Small sizes. A heat exchanger with a built-in heater is installed in a relatively small combustion chamber to provide hot water supply.

- Economical energy consumption. The thermoelement turns on only when it is necessary to quickly heat up the water, or in the summer without turning on the gas in the heating system.

- Low price for the model range.

In equipment types without a secondary circuit, a water heater is additionally installed. In case of interruptions in gas supply, heaters with low power will be able to maintain the minimum temperature of the coolant.

Combination of wood and electricity

Solid fuel boilers are installed if it is impossible to connect to the main gas pipeline or fuel in cylinders. They are non-volatile and have great power. Universal factory-made devices are equipped with all safety protection elements with a manufacturer’s warranty.

Features of heating units using a combination of wood/electricity:

- repairability - electrical parts of the system are easy to replace;

- reliability of the design - heating elements are designed to work in a firebox;

- The thermostat provides remote temperature control.

To adjust the power of solid fuel boilers, manufacturers recommend installing and using electronic heat regulators.

Multi-fuel heating equipment

Household equipment performs its functions on several energy sources. In addition to the most common combinations with heating gas, wood, electricity, the device burns pellet granules. In variations of boiler units with a pellet supply hopper, this structural element is removed, and the chambers are used for specific energy carriers. The units are adapted for different fuel fractions, so it is necessary to take into account the creation of special conditions for increased injection pressure and forced draft.

The functionality is expanded by installing an electric heater in the heat exchanger.

To install multi-fuel systems, the following requirements must be met:

- during continuous operation, it is necessary to ensure a supply and storage of energy resources;

- organizing the delivery of consumables to the boiler;

- uninterrupted supply of electricity to the units.

When choosing combination boilers for heating a home, factors should be analyzed for a specific room. The main indicator is economic feasibility. In addition to the increased cost of the device, it is necessary to take into account the additional costs of matching the diameter of the chimney to each fuel material and the availability of the serviced area.

There is no point in buying a powerful boiler unit for small spaces with the hope that the automation will work well. This approach attracts unused capacity, leading to rapid wear of equipment during idle operation of the system.

https://youtube.com/watch?v=G4QwXU_uW6k

The most advantageous aspects of gas-wood heating boilers

If we put aside the requirements for arranging a separate room in the house, combined wood-gas heating boilers will have a whole range of excellent qualities.

- The operation of such a universal heating device does not require special skills. Even options such as combined boilers.

- The cost of combined models is not much higher than analogues that can only work, for example, with coal, pellets and the gas option. You can install it instead of a wood-burning stove; they take up even less space than usual.

- The dimensions of the gas-wood heating model are, of course, larger than gas models, but do not exceed analogues with a wood firebox. The wood-gas-electricity device has the same dimensions.

- High efficiency – up to 90%. The wood-burning method of heating a room is one of the most effective; the main thing is to use dry wood, with no more than 20% humidity.

- Small release of harmful substances into the atmosphere.

Compared to heating with electricity or gas boilers, combined gas and wood heating boilers can provide complete independence from utilities. Wood stoves have always been used as the basis for warm home comfort, because... This type of fuel is the easiest to obtain anywhere.

Rice. 3 Gas-wood boilers are compact in size

Combined boiler electricity + wood

How is it possible to combine two such different types of fuel in one boiler? It's all about the unique and thoughtful design. In addition, as experts say, this is the simplest and most practical design of all combined heating boilers.

If you look closely at multi-fuel boilers of the “electricity + wood” type, you will notice that they are distinguished from solid fuel boilers only by the installation of one device. This is a heating element with the help of which the coolant in the heating system is heated. By the way, heating is carried out by direct action, because the heating element is built into the heat exchanger. So there are no intermediaries between the heating element and the coolant.

Like all modern boilers, this one is equipped with an excellent automation system. It controls and regulates the temperature inside the house by increasing or decreasing the power of the heating unit.

The boiler’s automation allows you to switch to modes where one or another type of fuel is used. Note that manufacturers today offer two transition options:

- Auto.

- Manual.

Combination heating boiler

Which is better, each consumer decides for himself. Let us only note that manual transition is easier, and the boiler will cost less. The automatic option is more convenient, but the price of such boilers is too high. However, these heating devices are very popular today. The fact is that when the power of a wood-burning boiler decreases, the heating element turns on automatically. It supplies the heating system with the necessary thermal energy.

For example, the laying of firewood was done in the evening. Naturally, its warmth will not be enough until the morning, and overnight the temperature may drop to critical. The automation will not wait for someone to turn on the electric heating element manually. She herself will supply current to the heating element. This is the functionality of universal heating boilers.

Combination boilers that use wood are primarily powered by electricity. The firewood has to be rekindled when the electric current is no longer supplied to the line. And in suburban villages in winter this often happens. Therefore, the owner must place firewood inside the firebox in advance in order to be fully prepared. All that remains is to ignite the solid fuel. Since the temperature inside the heating system is normal, a strong flame is not required to maintain it.

Installation Requirements

Compared to conventional heating devices, more stringent requirements are imposed on the installation and maintenance of combined units:

- Firstly, multi-fuel boilers must be installed only in separate rooms. A furnace or small boiler room is allocated for them, which depends on the size and performance of the equipment.

- Secondly, this room must comply with fire safety regulations. It must have a well-functioning chimney and ventilation.

- Thirdly, a foundation must be poured under the universal boiler.

Advantages of a universal boiler: electricity + wood

Combination boiler design

Let us note just some of its advantages:

- This combination allows you to use the most accessible and cheapest type of fuel - wood waste. And versatility is achieved by the presence of two types of energy carrier. They can be used separately or in combination under certain operating conditions.

- Unfortunately, cheap natural gas does not reach all consumers. So electricity is the most accessible type of fuel, and firewood is the cheapest. This combination allows us to talk about both the efficiency of the boiler and its practicality.

- Due to the use of heating elements, the boiler can be classified as an environmentally friendly heating unit.

- A modern approach to creating convenient and comfortable operating conditions, including the installation of an automation unit and programmers. This makes it possible to easily maintain the heating system and save time on these processes.

- The well-thought-out design of the unit allows you to save fuel on heat losses. And this is another plus for the consumer.

Universal boilers: combining different types of fuel

Gas-wood heating boilers combine the ability to operate on two types of fuel: natural gas and solid fuel (wood).

Each type of energy carrier has its own advantages that determine its choice in certain operating conditions.

A wood-burning stove makes it possible to organize autonomous heating, which does not depend on the availability of a central supply and the cost of energy (as happens with gas).

A gas stove, in turn, allows you to operate the heating system without the daily time and physical effort of carrying firewood, placing it in the stove, igniting and heating the room. This fact explains the widespread use of gas heating in the private sector, the construction of gas central stations and the installation of gas equipment in residential buildings.

To keep the boiler at temperature longer, long-burning boilers are used.

Read how to use a hot water boiler here.

A house equipped only with gas heating depends on the availability of the resource in the gas network, on its quality, composition, and pressure inside the pipeline. The economic efficiency of gas heating is determined by the price of energy, which home owners are not able to control. Rather, they have to accept, in fact, an increase in the price of payment for heat in their own home.

The desire to save money and heat the house with firewood (available) leads to the transfer of the gas boiler to an economical maintenance mode, when a low temperature for heating the outlet water is maintained.

The main heating of the house in the evening is transferred to the wood stove.

After the installation of gas equipment in many houses, coal-wood stoves were dismantled, and the new construction of a solid fuel stove requires investment and professional skills. Therefore, a combined design - gas and wood boilers - has become a popular type of heating a gasified house.

Standards for installing a gas-wood heating boiler

The installation of a gas boiler with the possibility of burning wood is subject to higher requirements than for conventional solid fuel equipment. Operating and connection standards are described in SNiP, SP and PPB. In particular, it states:

- Boiler room - a room with a total area of at least 12 m² and a ceiling height of 2.2 m is selected for installing the boiler.

- The walls and floor are lined with non-combustible materials: plaster and ceramic tiles.

- Supply and exhaust ventilation is required. For better air flow, the door frame is installed without a lower threshold.

- The boiler is connected to the electrical network through automatic circuit breakers located outside the boiler room. Modern multi-fuel small-sized boilers (gas, wood and electricity) have protection against power surges. Despite this, manufacturers recommend connecting through an uninterruptible power supply with a built-in stabilizer.

- Natural lighting is a must. The dimensions of window openings are calculated depending on the performance of the boiler.

- Universal heating boilers for gas and wood, with a capacity of up to 40 kW, can be installed in any room used for household needs. A heat generator over 40 kW is installed in a separate room intended exclusively for the needs of the boiler room.

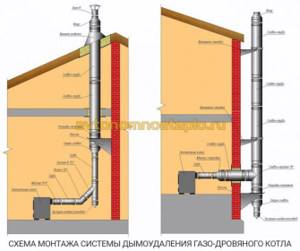

- Where the chimney passes through the floor slabs and roofing pie, fire-proof cuts are provided. The pipe is insulated with a non-flammable mineral sealant.

- A spark arrester and a deflector are installed on the chimney head to increase the draft force.

When connected to the main gas, the first start-up of the boiler is carried out in the presence of an inspector. If there are no violations, the Gas Service inspector will make a note in the equipment passport about its commissioning.

Pros and cons of using wood and gas boilers

Heating boilers for the home, operating on wood, gas and electricity, as practice has shown, are easy to use and easily replace two single-fuel units. The advantages of universal multi-fuel models are:

- Automation of the combustion process.

- Long operating time from one load of firewood.

- Lower cost compared to two boilers operating separately on gas and wood.

- Quick switching to a backup fuel source.

- Ability to work in an unheated building to prevent freezing of the coolant.

- Small dimensions.

- Meeting the needs of hot water supply - floor-mounted double-circuit heating combined gas-wood boilers, operating as a flow-through water heater. Single-circuit analogues, connected to an indirect heating boiler.

Household hot water gas-wood heating boilers have several disadvantages:

- High price.

- Heavy weight due to the fact that several combustion chambers are built into the design.

This is where the disadvantages of universal boilers end. It is clear that domestic equipment has shortcomings, but in general, even Russian units work flawlessly. Multi-fuel boilers are easy to use and in many ways superior to units that run on only one type of fuel.

Calculation of power and temperature of a warm water floor

Distinctive features of gas-wood boilers

The gas-wood combination boiler belongs to the first type.

It is designated by the letters T.G. Solid fuels for it are firewood, coal, briquettes, pellets. The equipment is convenient for those who are just planning to supply gas to the house in which they already live. The materials used to make the boiler firebox are steel and cast iron, so the equipment is placed on the floor. Moreover, for a boiler with a cast iron firebox it is necessary to strengthen the foundation.

There are single-circuit and double-circuit boiler models. Single-circuit ones can only heat the room, double-circuit ones additionally provide the house with hot water. Heat exchange units supply 700 liters of hot water per hour to housing.

A combination boiler can have one or two fireboxes. In two-furnace models, a gas burner is located in the lower firebox, and a chimney is mounted in the upper one. Both fireboxes heat up simultaneously. Combustion products settle on a special tray. This makes cleaning the equipment easier. The pallet is installed only if firewood is used.

Installation Requirements

Combination boilers in accordance with SNiP 41-01-2003 must meet the requirements. At the same time, they have their own characteristics during installation and operation, which distinguish them from similar units operating on a single fuel.

These requirements and recommendations must be known and followed in order for the boiler to operate safely.

Premises requirements

Wood and electric boilers for home heating are produced only in a floor-standing version and are installed in a boiler room with ventilation, and in accordance with other SNiP requirements:

- The walls in the room are made of non-combustible material.

- Equipment in the boiler room is installed no closer than 300 mm from the walls.

Example of boiler installationSource pingru.ru

- The boiler room must be a dry and moisture-proof room.

- Since the boiler is heavy, the platform under it is reinforced with a concrete screed.

Also, the room must meet fire safety standards: there are no flammable objects or flammable liquids near the boiler; A sheet of iron is installed in front of the firebox to prevent fire from falling coal or sparks from the firebox.

Chimney

When installing an electric wood-burning boiler, an indispensable condition is the presence of a chimney like a unit with solid fuel. For uninterrupted operation of the installation, good draft is needed, for which the pipe must rise above the ridge of the roof of the house and have an internal diameter no less than the boiler pipe.

The chimney pipe must be free of mechanical damage and have a hermetically sealed joint. During operation of the heating elements, it is recommended to make a view to preserve heat in the chimney. It is also advisable to insulate the pipe to prevent condensation from forming in sub-zero weather.

Electrical requirements

When installing an electric wood-burning boiler, Gorenergo’s permission is currently not asked. But in any case, it is necessary to have a power supply capable of withstanding the operation of the heating elements without overloads.

For example, if the boiler is supposed to be used by connecting heating elements over 6 kW, then the voltage should be 380 volts.

In any case, connecting the device must be strictly according to the instructions. Wherein:

- It is not allowed to install a combination boiler in a room where there is high humidity or there is likely to be contact between the electrical part of the equipment and water.

- The temperature range in the room should be between 0 and +45 °C.

- The cross-section of the wire is calculated and corresponds to the required power and current.

Despite these seemingly simple requirements, work on installing and connecting a combination boiler must be carried out by certified specialists. In this case, in addition to the quality of the work performed, you receive the right to free warranty repair of the boiler if the breakdown occurred due to defective equipment.

Combination boilers are also called devices that are initially designed to run on solid fuel, but they also provide the ability to connect electric heaters separately:

Requirements for connection and installation of boilers

Heat generators are classified as explosive and fire hazardous equipment. To minimize the risk of emergency incidents, installation and connection are carried out according to specially developed rules.

For solid fuel

The regulations put forward the following requirements:

- The unit is located as close to the center of the building as possible.

- Place it on a foundation or non-combustible base, in plan extending beyond the outline of the boiler by 300 mm from the front side and 100 mm from the side and rear.

- Fuel is stored in a box located at a distance of at least 1 m from the boiler.

- The floor made of wood or other flammable material is covered with sheet iron extending beyond the boundaries of the unit by 600 mm in all directions.

The solid fuel boiler is located as close to the center of the building as possible.

Minimum distance from the heating unit to the walls:

- front - 1 m;

- side and rear - 600 mm.

Premises requirements:

- Availability of natural light.

- The minimum ceiling height is 2.5 m.

- Volume - at least 7.5 cubic meters. m.

- Supply ventilation opening - with an area of 200 sq.m. cm, at a height of 1 m from the floor or below.

- Exhaust - from 140x140 mm in size, under the ceiling.

- Fire resistance of walls and partitions is 0.75 hours.

For gas

The second heater is installed in another room in any part of the building. Location next to the TT unit is not allowed due to the risk of coal dust gas entering the combustion chamber.

A gas boiler can be installed in any room.

Covered with non-flammable materials:

- walls;

- the floor under the boiler and around it extending beyond its boundaries by 500 mm in all directions.

Premises requirements:

- minimum height - 2.5 m;

- volume - at least 7.5 cubic meters. m.

A wall-mounted boiler can be installed in the kitchen. If there is a gas stove in the room, its minimum volume is 15 cubic meters. m.

For a unit with an atmospheric burner, it is necessary to organize a flow of fresh air through an opening with the following parameters:

- area - at least 200 sq. cm;

- height above the floor - no more than 300 mm.

Video description

Combination boilers are also called devices that are initially designed to run on solid fuel, but they also provide the ability to connect electric heaters separately:

Today, electricity and solid fuel are the most popular and affordable energy sources for heating boilers. Boilers, which can heat a house by burning wood or using electricity, are an effective solution and, moreover, no different from conventional devices in terms of reliability.

Using two combi boilers

Devices that can operate on multiple types of fuel are becoming increasingly popular. But the use of such a device only solves the problem of convenience, while the reliability of the system remains low. To correct the situation, you need to install 2 units.

How Sharing Is Possible?

Manufacturers of combination boilers do not prohibit connecting several devices to 1 system. A common chimney can only be used if both devices operate at the same time using the same fuel.

Design and principle of operation

A combi boiler has 2 fireboxes located one below the other. The lower one contains a gas burner, the upper one is used for burning wood or coal.

Switching modes is carried out in 2 ways:

- in budget class models - manually;

- in expensive ones - automatically.

The second option is more practical. A flame sensor or thermostat monitors the state of the firebox and, when firewood reaches it, sends a signal to the controller to start the gas burner.

Combination boiler design.

When using wood, install a tray for combustion products. This makes cleaning the unit much easier.

Some models are additionally equipped with electric heating elements. The heater will prevent freezing of the coolant if all types of fuel are unavailable.

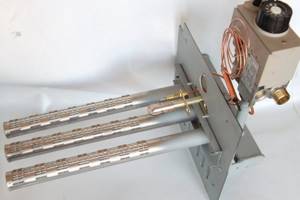

Selection of gas burner

The characteristics of this unit affect the efficiency of fuel combustion, and therefore the efficiency of the boiler.

According to the possibility of regulation, there are 3 types of burners:

- fixed;

- multi-stage;

- modulation.

The first type is characterized by a simple design and low cost. The burner operates at constant power. To adjust the level of heat transfer, the boiler periodically extinguishes it and lights it again. This is the least economical mode.

The selection of a gas burner affects the efficiency of fuel combustion.

2- and 3-stage devices are capable of operating at 40, 70 and 100% of rated power. The optimal one is selected automatically.

The advantages of such burners:

- fuel economy;

- increasing the service life of the device.

Disadvantages: high cost and expensive repairs.

Modulation burners are the most expensive. They smoothly change power in the range from 10 to 100%, which allows the heater to operate without shutdowns. This further extends its service life and saves fuel.

Connection diagram

Combination boilers are connected to the system in the same ways as simple ones:

- consistent;

- parallel;

- with separator;

- with heat accumulator;

- with primary-secondary rings;

- with 3-way valve.

Boiler connection diagram.

The choice depends on the size of the heated object and available finances.

Parallel operation of wood and gas boilers

This option for heating a house from two boilers provides for their separate connection to the circulation system. Each heat source must have its own circulation pump installed at the return line inlet. There is no need to do this for a wall-mounted gas boiler; the pump is already installed by the manufacturer. If solid fuel burns out, the temperature of the coolant will decrease and the gas boiler will automatically turn on.

An important design point is the piping of the solid fuel boiler with metal pipes and the presence of an emergency discharge device with the simultaneous supply of cold water to the return line.

1 scheme (open and closed systems)

This method is convenient because the liquids of the two systems do not mix. This allows the use of different coolants.

Advantages and disadvantages

| pros | Minuses |

| Possibility to use different coolants | A large number of additional equipment |

| Safe operation, the reserve tank will release excess water in case of boiling | Efficiency is lower due to excess water in the system |

| Possibility of use without additional automation |

2 scheme, two closed systems

It uses a closed system, which eliminates the need for a heat accumulator. Control is carried out by thermostats and three-way sensors. Operational safety is ensured by automation.

Here we use the battery for excess heat. Thus, we increase the efficiency of the system and eliminate the need for temperature sensors and automation.

Heat supply via 3-way valve

Each boiler must be equipped with its own circulation pump, and another pump will be required to ensure circulation through the heating system devices. An automatic air vent should be installed at the top point of the hydraulic separator, and a tap for emergency drainage of water at the bottom.

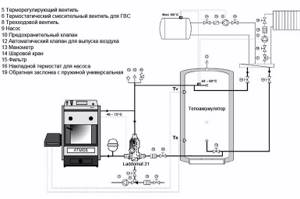

System with a heat accumulator, why is it used?

The heat generated by the wood-burning boiler enters this container. From not, through a coil, heat exchanger or without them, into a gas boiler. The automation of the second understands that the water has the required temperature and turns off the gas. This will continue as long as there is enough temperature in the heat accumulator.

A heat accumulator or a heat-insulated container with a built-in coil, designed to accumulate heated coolant and supply it to the heating system. In this scheme, the gas boiler, heating devices and battery are connected by pipelines into one closed system. The solid fuel boiler is connected to the built-in battery coil and thus heats the coolant in a closed system. The organization of heating operation in this scheme occurs in the following order:

- In a solid fuel boiler, wood burns and the coolant is heated from the coil in the container;

- solid fuel has burned out, the coolant has cooled;

- the gas boiler turns on automatically;

- the firewood is laid again and the solid fuel boiler is ignited;

- The temperature of the water in the battery rises to the same temperature as that set on the gas boiler, which stops automatically.

This scheme requires the greatest costs for the purchase of materials and equipment, but has a number of advantages:

- the solid fuel boiler can operate in an open circuit;

- highest level of security;

- no need to constantly replenish the firebox with wood or coal;

- coolant circulation through a closed system;

- the possibility of simultaneous operation of two boilers simultaneously and each separately.

Additional costs include the purchase of an accumulator tank with a coil, two expansion tanks and an additional circulation pump.

calculate the required volume of container

Features of using universal boilers

Atmos-dc combi boiler

The high thermal power of a boiler running on wood and gas makes such installations popular among those who constantly live in rural areas. Technically, such a plant is considered solid fuel. Firewood is used for the main heating of the room, and gas allows you to maintain the temperature at night and in the absence of the owners of the house. Therefore, when choosing a particular model, it is necessary to take this circumstance into account.

Such a design cannot ensure complete automation of the installation, so human presence remains mandatory. Because of this, the market price of the equipment is lower than analog automatic installations.

Such a universal boiler must be isolated from residential premises. During its operation, wood debris, burning dust or ash often gets into the room where it is installed. It is safer to store firewood separately from the unit, so having an additional utility room is a must.

The automation system operates from the mains, so the equipment described is energy-dependent. For greater operational safety, universal heating boilers must be connected to uninterruptible power supplies and also have a voltage stabilizer.

In addition to electricity, dual-circuit models are also connected to the water supply. Therefore, to install the boiler, you need to find a place where everything is nearby - gas, water and electricity.

Note! To operate the firebox, you can use firewood whose humidity does not exceed 20%. You can install the described units yourself, but turning to specialists for help will provide an additional bonus in the form of after-sales service

It's worth taking advantage of

You can install the described units yourself, but turning to specialists for help will provide an additional bonus in the form of after-sales service. It's worth taking advantage of.

Combination boilers: advantages of operation

The arguments for the use of combination boilers are factors that make it attractive to purchase a universal type of equipment.

Possibility to reduce heating costs (if you use less expensive firewood instead of expensive gas).

You can provide yourself with wood fuel yourself by arming yourself with a chainsaw and going out of town in search of dry trees.

Semi-automation of the process . Automatic operation in gas mode allows you to wake up in a warm room in the morning and come home to a heated living space in the evening.

Modern design and transportability . Unlike capital brick stoves, a metal boiler (if necessary) can be dismantled and moved to an adjacent corner or another room.

Cost of combined heating boilers

There is a direct relationship between the amount of fuel used and the cost of the boiler. This is quite obvious - assembling equipment with a large number of chambers requires more costs, and the boiler itself will be much larger, so the cost of its production will be an order of magnitude higher.

However, there is an exception to the rule - combined heating boilers using solid fuel and electricity hardly change in size. This electric solid fuel boiler is quite popular. Structurally, these boilers differ from wood-burning boilers only in the presence of an electric heating element, which starts automatically when the temperature drops below a certain point.

Considering the insignificance of the alterations, boilers using electricity and wood ultimately cost significantly less than other options. Nevertheless, such equipment turns out to be quite convenient in operation - for example, there is no need to constantly add fuel, because in the event of its absence, the system itself will switch to electricity. However, you need to remember that electric heating in combination boilers has a reduced power, so you cannot count on fully warming up the building - only on maintaining the system in working order.

Combined boilers using coal and electricity have a similar device. They differ from their wood-burning counterparts in that any solid fuel can be used in the firebox. It's all about the features of the firebox - a combustion chamber designed for the use of coal has good resistance to high temperatures, so they are often heated with wood, briquettes or peat. But we should not forget about the volume of fuel - after all, coal, compared to other resources, has the highest energy intensity with a small volume.

An excellent example of such equipment is the Russian-made Warmos-TT combination boiler for a home, which has the following characteristics:

- These boilers, powered by electricity and coal, are characterized by a relatively low efficiency (about 70%), but at the same time they allow, firstly, the use of any solid fuel, and secondly, they are quite suitable for burning very wet wood;

- The thermal insulation of the boiler is made according to a combined scheme - a water jacket is built into it;

- The draft regulator is pre-installed, and optionally you can purchase a heating element with a thermostat, which allows you to maintain the water temperature in the system even in the absence of solid fuel in the chamber.

Boilers of this class are produced mainly by domestic manufacturers, and their cost is often quite low.

How to choose a combi boiler?

Available types of energy carriers are the main criterion for choosing combination boilers. The most popular models are fuel equipment, which necessarily runs on coal or wood. The popularity of pellet boilers is growing; this environmentally friendly fuel is becoming more and more accessible. They show good efficiency, which is no lower than that of a wood-burning boiler.

In addition to choosing the fuel on which the heating equipment will operate, it is necessary to pay attention to important technical characteristics when choosing a boiler. The main parameter of this technique is power

The number of heating circuits is also an important characteristic of the equipment. If you are purchasing a boiler for a permanent home, then the best choice would be a dual-circuit model. It will provide not only heat, but also hot water at minimal cost.

Don’t forget about such a simple but important characteristic of heating equipment as the dimensions of the boiler. Most models have impressive dimensions, which can be a serious problem if there is a limit on usable space.

This is especially true for boilers with multiple fireboxes

It is also worth paying attention to the automation equipment included in the equipment. It is designed to provide the simplest possible control and a high degree of safety, protect against freezing

https://youtube.com/watch?v=G4QwXU_uW6k

Kinds

Combined units are divided into several types.

- Gas-solid fuel appliances for home heating. The main positive features of this heating unit include economy and its independence from the gas supply in case of accidental or deliberate shutdown. This easily includes gas-fired appliances, where you can also actively choose firewood for heating your home. Wood-burning units, in general, have become very popular these days due to the low cost and availability of wood in our country. A combined gas-firewood appliance will allow you not to be afraid of even the most severe frosts. Here, pellets (for this purpose a special burner is built into the device) and coal are often used as combustible materials.

- Gas-liquid fuel devices. One of the most effective installations for any structure, which will allow you to efficiently heat a large space in a short period of time. To quickly transfer from one type of fuel to another, you will need to change the type of burner.

- Gas-electric-liquid-fuel units. To quickly heat the air in the home, gas, diesel fuel and electricity will be used. With the help of gas and diesel fuel, it will be possible to quickly heat all the rooms of a residential building, and the heating element will be able to maintain the desired temperature in it. Gas generator type boilers are usually in demand in homes that are used occasionally.

- Units consuming gas, diesel fuel and solid fuel. These are multi-tasking designs that are often chosen for heating private cottages. These types of devices are very complex in many respects - they need to be maintained and operated specifically.

- Quad-fuel designs. All 4 types of fuel are used here. The devices will help you adapt to any heating conditions of a private building, choosing exactly the type of fuel, which will allow you to save significantly.

Material

All types of this type of heating products are made only in floor-mounted versions. The design of such a boiler necessarily uses cast iron. With additional types of fuel, the product will operate with the release of condensation, which is especially noticeable in the example of choosing diesel fuel. And cast iron has increased resistance to metal corrosion, for this reason cast iron products are called the best options for heating.

Dimensions

Combined structures are quite heavy, are produced in floor form and are often of impressive size.

The most simplified appearance and small sizes are products that run on diesel fuel and gas. Products that run on gas and electricity also have oversized parameters. Such a device consists of a small chamber for combustion of fuel, a heat exchanger with a built-in heating element or other types of heating device.

What is needed to start a universal boiler?

When installing a combination boiler, a number of requirements must be met:

- The gas burner is secured with screws, and the connection to the main line is carried out with the permission of the gas services. Their representatives must come and check compliance with safety standards, as well as install and seal the meter.

Note! The universal gas-wood heating boiler kit does not include a union nut with which the unit is connected to the gas pipeline. Therefore, you must first buy it yourself.

- After connection, it is advisable to check all joints for leaks.

- To connect the automation, a separate electrical cable is installed and grounded.

- It is better to delegate all commissioning work to specialists.

Design features

Multi-fuel units have several fireboxes for different types of fuel. Usually one is loaded with coal or firewood, the other is intended for liquid or gaseous fuel: gas or diesel fuel. Several fireboxes for different fuels are good because several separate independent circuits can be connected to them and the temperature in them can be different. For example, one serves the radiators, the second serves the heated floor. It is possible to divide by floor or according to some other principle

If you like this idea, when purchasing, pay attention to the fact that each firebox has a separate heat exchanger, which is not available in all boilers

Combined heating boilers usually have several fireboxes for different types of fuel, and may also have several independent heat exchangers

If we talk about the developments of recent years, then almost all modern models also have built-in heating elements. It turns out that such equipment makes it possible to work on any currently available energy carrier.

Another interesting novelty: burners have been developed that can use gas or diesel fuel with equal success (at least, that’s what the manufacturers say). With such a spray unit there is no need for even two burners or chambers. The type of fuel used is changed by moving the switch to one of the positions.

For more economical and efficient heating of large areas and reducing the cost of heating, it is advisable to use heat accumulators. This is especially advisable when regularly using firewood and coal as one of the types of fuel. This is due to the peculiarity of multi-fuel boilers: when using solid fuel, the boiler power is not regulated and the room sometimes becomes too hot. If there is a heat accumulator, excess heat is transferred there and is “conserved” there, and if there is a lack of thermal energy, hot water from the heat accumulator is supplied to the system or used for hot water supply. Such a system allows you to fire the boiler much less often (how often depends on many factors, boiler power, heat loss at home, weather, calorific value of the fuel, etc.).

Design Features

The range of heating boilers is represented by different models. Some run on gas, others on electricity, and others on liquid fuel. Each type has its own operational advantages and disadvantages. The disadvantages of using certain installations haunt designers and technicians. So they decided to combine some models, and combined heating devices were born. They can operate, for example, on solid fuel and gas simultaneously.

This combination made it possible to minimize emergency risks and organize the operation of the same solid fuel boiler in autonomous mode. How do such installations work, and where is their use more than justified? As a rule, universal boilers are always equipped with an additional number of pipes. They can be used to connect underfloor heating, heating radiators, a greenhouse control system, heating water in a swimming pool or heating a bathhouse.

The gas burner in such a boiler is located below the combustion chamber, where firewood, briquettes, sawdust or coal are placed. Therefore, if necessary and switching, it allows you to completely burn the remaining solid fuel. If work is switched to solid fuel, the gas burner closes automatically. For ease of use, the steel heat exchanger responsible for heating the room passes through the entire body. All walls are thermally insulated with special mineral wool, so the efficiency of the unit is almost 92%. And this is a very high figure.

The heat exchanger for supplying hot water is made of copper and is located in the upper part of the installation. Copper is not afraid of corrosion, so the service life of the coil is equal to the service life of the entire device as a whole. Universal boilers have lever and air dampers that ensure the supply of the required portion of air.

How the installation works

The operating principle of a gas-wood boiler is extremely simple. The design uses two autonomous cameras. The furnace room is located above the gas room. This feature allows you to use two types of fuel simultaneously. Gas burners can operate at low pressure. Therefore, you can often see models that are connected not to central gas lines, but to liquefied gas cylinders.

Note! If there is a power outage, the gas-wood boiler will not be able to operate on gas. And all because the products of its combustion in this case will not be independently discharged through the chimney to the outside, and condensate instantly accumulates on its walls, clogging the chimney

If there is no light in the house, the boiler is heated exclusively with wood.

Advantages of installations

There are quite a lot of advantages of gas-wood boilers, so we will outline only the most basic ones:

- The main factor is the opportunity to save money and use cheap firewood instead of expensive blue fuel. If you run out of wood, you can switch to gas in automatic mode.

- The combined design allows the use of autonomous heating. Gas ensures operation of the installation at night without additional fuel loading. It’s also nice to come home after work to a well-heated house, knowing that the gas will maintain the desired temperature when there is no one to throw firewood into the stove.

- Universal combi boilers can have one or two circuits, so you can use the installation not only for heating, but also for supplying hot water for technical needs. Today, universal gas-wood boilers are equipped with storage boilers, and there are models that can heat water to the desired temperature using a flow-through method. The choice is great, and that makes me happy.

But before deciding to purchase such installations, experts recommend studying the features of their operation and disadvantages.

When you need a multi-fuel boiler: the pros and cons of the equipment

Universal heating boilers solve the issue of uninterrupted heat supply to a private home. They make it possible to choose the fuel that is suitable for a particular situation. Installing the units will help you switch over time to an economical energy source with minimal financial costs. If in the future it is planned to gasify a populated area or supply electricity to the house, then you should prepare for this in advance. Replacing monofuel equipment is too expensive. Thrifty owners initially install combination boilers for heating their home. The combination of liquid energy carriers, firewood, coal, gas, electricity is determined by the needs of the household. The availability of energy resources in a particular area, their prices, and the design of the building are taken into account.

Advantages of universal units

The advantages of purchasing boilers that operate on a multi-fuel principle outweigh the disadvantages of the equipment. The advantages of multi-fuel devices include:

- The boiler produces heat without interruptions and forced stops

- Automation of processes - switching from one type of fuel to another occurs as the energy carrier is produced

- Savings when using different types of fuel

- Universal heaters supply the house with hot water, heat the room, and help create comfortable living conditions

- Additionally, a boiler is connected

- Environmental friendliness and high efficiency

- The compact dimensions of the unit are a significant advantage of multi-fuel devices

Combination boiler Beretta VR-5 is expensive equipment

The disadvantages of boilers operating simultaneously on many types of fuel include the cost of the equipment. A boiler with a power of 50 kW is considered to be the most efficient. The greater the power, the more modest the functions performed by combination boilers.

The energy dependence of multi-fuel units precludes complete autonomy without installing a backup generator, and fuel storage requires the organization of special storage facilities.

Firewood-pellets-gas

If you are interested in the design of this type of heating, the table below describes the manufacturer of gas, solid fuel and pellet boilers, its most popular model and a brief description.

| Manufacturer and model | Characteristic |

| Atmos DC 18 SP (Czech Republic) | The new series of combined boilers "ATMOS" DC 15EP(L), DC 18SP(L), DC 25SP(L), DC 32SP(L) allows for ecological combustion of wood using the principle of generator gasification in combination with a burner for pellets, natural gas or extra light fuel oils (depending on which burner is built into the boiler). Boiler type: single-circuit. The combustion chamber is open. Installation - floor. Heating area - 300 m². Power - 20.5 kW. Type of solid fuel - firewood, pellets. Display - no. Boiler - external (optional). Boiler volume: 78 l. Heat exchanger material is steel. Overheating protection - yes. Frost protection - yes. Thermostat - yes. Ignition is mechanical. Efficiency - 92%. Weight - 429 kg. The advantage of this model is that the boiler takes up less space compared to a large number of boilers. Regarding environmental operation, the boiler, according to CSN EN 303-5, belongs to class 3. |

Thus, combined boilers for heating a home are an excellent option for obtaining not only heat, but also saving money. Since there is always a choice of fuel and its autonomous switching, in the absence of one specific type of fuel, your home will be heated at any time of the year. Combined boilers for solid fuel and gas are reliability, high performance and versatility.

Types of combined units

Manufacturers of heating equipment try to develop their devices so that the circle of potential customers is as large as possible

Equally important is the environmental characteristics of heating systems. A feature of pyrolysis water heaters is their “omnivorousness”. To produce combustible gas, they can use not only traditional firewood and charcoal, but also cellulose-containing waste, used motor oil and used car tires

To produce combustible gas, they can use not only traditional firewood and charcoal, but also cellulose-containing waste, used motor oil and used car tires.

Most often, mini-boiler houses use complexes designed for combinations: firewood, coal, peat briquettes/electricity, pellets/gas/liquid petroleum products, firewood/electricity/gas/diesel fuel. Very often, boiler equipment that simultaneously operates on sawdust, substandard flax or sunflower husks is installed on farms or small agricultural enterprises. It not only effectively heats homes and technical premises, but also disposes of waste. Natural gas or fusic (substandard) oil is usually used as a backup option.

Solid fuel and electric

The solid fuel/electricity combination remains the most popular in low-rise construction. In this case, electric heaters perform an auxiliary rather than an operational function due to the relative high cost of electricity.

Solid fuel and gas

The combination of a combustion chamber and a gas burner is popular in gasified cottage communities and in rural areas. Heating with natural gas alone, especially a large house, is quite expensive. Based on the prices for firewood or coal in a particular area of residence, you can choose the fuel that will help you avoid unnecessary expenses during the cold season. Gas, if there is a connected pipeline, can always be an excellent insurance during periods of severe cold.

Diesel and gas

Diesel/gas units are designed with a single combustion chamber. In order to convert the device from one type of fuel to another, it is enough to change the burner. If for any reason the gas supply is interrupted, a special nozzle is installed to ensure atomization and combustion of diesel fuel in a housing with a heat exchanger. The fairly simple design of such combined heaters allows all operations to be performed with a minimum set of tools in just a few minutes.

Electricity, solid fuel, gas and diesel (multi-fuel installations)

Multi-fuel complexes are the most versatile, but also the most complex. Their purchase is justified if the user has at his disposal the entire range of fuel at an affordable price. They are also often used in remote or hard-to-reach areas, in which everything that is currently at hand is used for heating. In this case, the issue of survival in harsh conditions may be of paramount importance, and combined heat sources are used for heating and hot water supply.

Finnish combined heating boilers

Finnish boilers occupy a fairly large market share. This is due to several reasons. Firstly, their climate is close to ours, so we can expect that their power will be sufficient in our conditions. Secondly, most campaigns have been working for a long time, and, therefore, have gained experience and have a certain potential. Well, and thirdly, their quality is up to par.

Jäspi Group is one of the Finnish companies operating in this heating equipment sector. Their boilers have a good reputation and are all equipped with heating elements. The basic configuration of the boilers includes one heating element for 6 kW. You can order 2 or 3 pieces.

Finnish combined heating boilers Jäspi

In the Jäspi VPK line you can use wood, pellets, diesel fuel, and gas. Jäspi Tupla has a high efficiency, copper coil, runs on diesel/gas and solid fuel. In this line, the fireboxes are autonomous, only combustion products exit into one pipe, therefore the smoke channels are combined in front of the chimney fitting. Operation on gas or diesel fuel is characterized by high efficiency. When the burner is set correctly, the fuel is burned almost completely, so cleaning this combustion chamber is only required once a year. When using firewood, their size depends on the modification: in Tupla 1 S – 35cm, in Tupla 2 S – 50cm.

Some technical characteristics of Jäspi Tupla and Triplex

Jäspi Triplex boilers are a model with reduced emissions of harmful substances into the atmosphere, equipped with new ceramic grates. It is also possible to use 35 and 50 cm firewood. For modifications with a firewood length of 50cm, top combustion can be implemented.

The Jäspi Biotriplex line uses the latest developments: switching from pellets to firewood and back does not require changing equipment. The two fireboxes are independent of each other.