Thanks to the combination of the positive characteristics of glass and polymers, fiberglass pipes have almost unlimited application prospects - from arranging ventilation ducts to laying petrochemical routes.

In this article, we will consider the main characteristics of fiberglass pipes, markings, manufacturing technologies of polymer composites and the compositions of binding components that determine the scope of operation of the composite.

We will also present important selection criteria, paying attention to the best manufacturers, because an important role in product quality is played by the technical capabilities and reputation of the manufacturer.

Production of fiberglass pipes

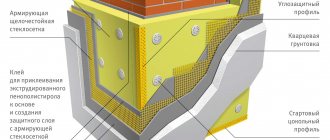

- The first layer is made of fiberglass soaked in polyester oil. It is responsible for resistance to corrosion and abrasion, as well as water resistance.

- The second layer is made of the same fiberglass with oils and sand, guaranteeing resistance to mechanical stress.

- The outer third layer of PVC provides resistance to ultraviolet radiation and temperature changes.

- The inner layer is smooth and therefore has high hydraulic properties.

The production of fiberglass pipes takes place in a continuous mode, and all products meet the requirements of international standards (AWWA, ASTM, ISO, CEN).

Fittings and accessories

Fiberglass pipe accessories are made from epoxy and vinyl ester resins. These adhesives provide the best corrosion resistance and temperature performance.

Fittings include flanges, couplings, tees, reducers, drain pipes, repair kits, fiberglass repair kit and more. Fiberglass pipes are designed for heavy duty applications and are suitable for a wide range of chemicals as specified in the Fiberglass Chemical Resistance Guide.

All fittings come with a pipe or flange connection for easy field installation. Prices for fiberglass pipes include all accessories necessary for installation and range from 4,350 to 47,900 rubles per linear meter, depending on the diameter.

Composite pipe chemical resistance table

| Pos. | Environment name | Normal chemical resistance (X1) | Increased chemical resistance (X2) | ||

| Limit concentration, % | Limit temperature º C | Limit concentration, % | Limit temperature º C | ||

| 1 | Nitric acid | 5 | 25 | 20 | 50 |

| 2 | Phosphoric acid | 54 | 80 | any | 100 |

| 3 | Hydrochloric acid | 10 | 60 | 10 | 85 |

| 4 | Hydrochloric acid | 25 | 40 | 25 | 80 |

| 5 | Hydrochloric acid | up to 25 | — | 37 | 65 |

| 6 | Sulfuric acid | 25 | 50 | 25 | 100 |

| 7 | Sulfuric acid | 70 | 30 | 75 | 40 |

| 8 | Hydrofluoric acid | 25 | 20 | 25 | 35 |

| 9 | Caustic sodium and caustic potassium | 15 | 80 | 50 | 80 |

| 10 | Hexane | 100 | 70 | 100 | 70 |

| 11 | Sea water | — | 60 | — | 80 |

| 12 | Acetic acid | 50 | 40 | 50 | 50 |

| 13 | Chlorine and hydrogen chloride (gas) | — | 50 | — | 100 |

| 14 | Sulphur dioxide | — | 70 | — | 90 |

| 15 | Hydrogen sulfide | — | 80 | — | 80 |

Application of fiberglass pipes

Networks are laid with fiberglass pipes:

- Water intakes and cold water supply – from main to internal networks;

- Sewerage and storm drainage;

- Drainage networks, structures for cleaning, reclamation and irrigation.

Pipes are also used for fire-fighting purposes, for transporting oil and gas (6 pressure classes and 3 strength classes), as well as for assembling light building support and frame structures: so the range of use is very wide. The pipe production process allows for special orders.

Characteristics of fiberglass pipes

The limits of operation of pipes on polyester resins are pressure 32 atm and temperature 90 degrees; for pipes with an epoxy binder - the maximum pressure is an order of magnitude higher (up to 240 atm), the maximum coolant temperature is 130 degrees. At the same time, the thermal conductivity characteristics of fiberglass in some cases make it possible not to insulate the outer walls of the pipes; heat is practically not emitted. Pipes based on epoxy resins are used in industrial construction, in the energy industry (desalination plants and cooling systems of thermal power plants), in the oil and chemical industries. In private homes - for heating systems and hot water supply.

The price difference between glass composites based on epoxy and polyester binders is significant; this is primarily due to the high cost of epoxy raw materials. In a conventional hot water supply system and in the boiler installation of a private house, the use of expensive pipes with an epoxy binder is justified, but for cold water supply and other communications, high strength is not required and the characteristics of pipes with polyester resins are more than sufficient.

In addition to pipelines, fiberglass pipes are an excellent lightweight and durable material for frame structures - purlins and racks, various supporting elements. The prices for these pipes strongly depend not only on the diameter, but also on the type of binder (pipes made with polyester resins are much cheaper than epoxy), so the interest of private developers and summer residents in a lightweight, aesthetic, high-strength pipe with absolute corrosion resistance is understandable - an almost eternal material. In private housing construction, there is currently no rush to widely use fiberglass pipes, but a simple fact speaks in favor of fiberglass composites: when re-equipping and repairing pipeline systems, many enterprises replace metal pipes with fiberglass ones.

What are they?

Fiberglass is a multicomponent material consisting of fiberglass filler and a polymer binder. This combination in the composite leads to the appearance of qualitatively new mechanical properties. Strong glass or plastic fiber is used as a filler in fiberglass; epoxy and polyester resins are most often used as a thermoset binder.

The technological ability to produce fiberglass pipes appeared in the 50s of the twentieth century. But the low price of traditional metal pipes (even copper and stainless steel) prevented the spread of fiberglass products.

In the 60s, the quality of fiberglass improved, and it became possible to use them at high pressures. Simultaneously with the emerging demand for durable, corrosion-resistant materials in the oil and coal industries, metal prices began to rise.

With the increase in technical characteristics, fiberglass plastics have become widespread, especially in North America and Saudi Arabia. In the 80s, fiberglass pipelines began to appear in all countries with developed industry.

Installation of fiberglass pipes

When purchasing fiberglass composite pipes, pay attention to the end - there should be no cracking or delamination, only smooth and even surfaces. Foreign inclusions in the composite may be visually visible - this is most likely a sign of poor quality

In self-assembly, fiberglass pipes can be sawed, end milled, drilled and machined, while a high-quality fiberglass composite does not show any delamination, cracks or chips.

There are a number of installation methods, of which several are the most reliable and simple:

- Socket pipes are installed in the same way as PVC pipes;

- Flange mounting - the connection involves the use of a pipe with a special flange ring at the end, the ring is equipped with holes for bolts;

- Coupling installation of the yoke type - pipes are joined and connected by fasteners (bolts, screws, studs, etc.). When mounting on couplings, both removable connecting elements and an adhesive composition are used - during assembly without the possibility of dismantling and subsequent use of the elements;

- In some cases, both threaded and screw connections are allowed, as for plastic pipes.

A few nuances for storing and installing pipes:

- Store pipes indoors no closer than one meter from the heating device;

- Throwing pipes is not recommended;

- If you brought the pipes in the cold, you need to keep them indoors for a day or two;

- Install fiberglass pipes at positive air temperatures;

- Before installing the pipes, all welding work near the work site must be completed;

- You cannot twist or “bend” any pipe too much, and fiberglass is no exception; manual bending limits - no more than 5 diameters, if permitted by the technical manual. if the bend is more than 30 degrees, then the bend is taken at 45;

- Fiberglass is cut at a right angle relative to the central axis, using special construction scissors with sharp blades. When using fittings with metal, strong tension should be avoided;

- Teflon rather than jute seals are preferred.

During operation, all conditions specified in the technical specifications for glass-composite pipes must be observed: for example, for pipes not protected from UV, provide insulation and protection. External pipelines are protected from freezing using standard insulation.

Physical and operational properties

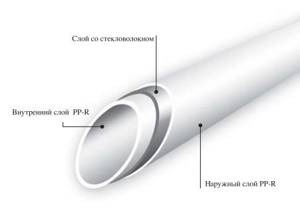

In everyday life, a fiberglass-reinforced PP pipe is used as a heating pipe to supply heating fluid and hot water - this imposes certain restrictions on its physical characteristics and dimensional parameters. Main properties of glass fiber reinforced PP pipes:

- Random polypropylene copolymer PP-R, from which PP heating pipes are mainly made, can withstand temperatures up to 165 °C. In this case, the operating temperature of the environment at which the material can function throughout its entire operational life of 50 years should not exceed 80 °C.

- The polypropylene pipe reinforced with glass fiber is designed for operation at a nominal pressure PN of no more than 20 bar. Some manufacturers (Russian-Italian Valtec) produce PP pipes for 20 bar with a red fiberglass sheath and for 25 bar with sulfur.

- Glass fiber-reinforced PP pipes are connected by soldering, using special soldering irons for polypropylene pipes. The inner and outer shells of the two parts being soldered are heated at a temperature of + 260 °C and joined together. As a result of the mutual diffusion of polymers, a strong and reliable connection is formed. To switch to metal, any production, simultaneously with pipe products, produces a wide range of fittings, many of which are soldered with threaded brass bushings.

- The thermal conductivity coefficient of glass fiber PP pipes is relatively low and amounts to 0.25 W/m °C.

Rice. 5 Areas of application for glass fiber PP pipes from Valtec

- The standard sizes of PP pipes reinforced with glass fiber are determined by their outer diameter from the standard range of 20, 25, 32, 40, 50, 63, 75, 90 and 110 mm.

- The guaranteed and standard service life of PP pipes with fiberglass for heating is at least 50 years, provided they are used in a working environment with the temperature parameters for which they are designed (no more than + 80 ° C).

- The main disadvantage of PP pipes is the high coefficient of linear expansion, reaching up to 9 cm per 100 meters of pure polypropylene. Since the additional layer is a mixture of glass fiber and PP, linear expansion is not significantly affected. Pipe reinforced polypropylene elongates a little less (by 2 - 3 cm) when a 100 m section is heated.

- Like the vast majority of polymers, polypropylene does not tolerate direct solar radiation. To protect against ultraviolet radiation, it is painted in gray, green, and black colors.

- Also, the disadvantages of polypropylene include its high oxygen permeability, which can be harmful for pipelines and heating equipment with parts containing iron alloys.

Rice. 6 Soldering equipment for polypropylene

Production

What does fiberglass pipe production look like?

To date, four main technologies for their production can be distinguished.

| Name | Description |

| Extrusion | The resin is mixed with a hardener and chopped fiberglass, and then pressed through an annular hole with an extruder. Production is cheap and technologically advanced, but the lack of a regular reinforcing frame affects the final strength of the products. |

| Pultrusion | The pipe is formed between the inner and outer mandrels. Both surfaces are perfect; however, a number of technological limitations do not allow the production of pipes of large diameters and high operating pressures in this way. |

| Centrifugal molding | The reinforcement is a ready-made fiberglass sleeve, which is pressed against the surface of the rotating mold by centrifugal forces. They also contribute to the uniform distribution of resin over future walls. The main advantage of the technology is the ability to obtain a smooth outer surface; The main disadvantage is energy consumption and, accordingly, high cost. |

| Winding | Fiberglass impregnated with a binder (thread, tape or fabric) is wound onto a cylindrical mandrel. Equipment for the production of fiberglass pipes using the winding method is the most common due to its relative simplicity and high productivity. |

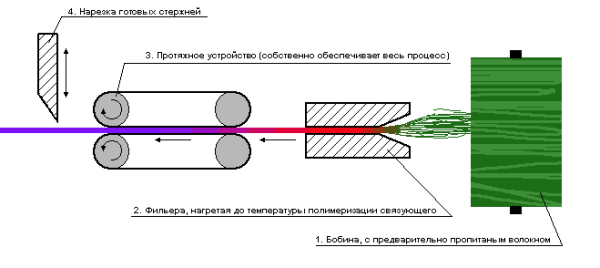

Scheme of production by pultrusion method.

The latter production method has several, so to speak, subspecies. Let's get to know them.

Spiral ring winding

The stacker - a ring with several mechanisms for feeding impregnated thread - makes reciprocating movements along a rotating mandrel. With each pass, a layer of fibers is laid at a constant pitch; The ring laying pattern, as we remember, allows us to achieve maximum tensile strength of the pipe.

The spiral-ring winding method is used to produce pump and compressor pipes designed for high operating pressures, load-bearing structural elements (including composite power line supports) and even… rocket engine housings.

Manufacturing of tubing by spiral-ring winding.

Spiral tape winding

The only difference with the previous method is that in one pass the stacker forms a narrow ribbon of a dozen or two fibers. Accordingly, much more passes are required to form continuous reinforcement; The reinforcement itself turns out to be somewhat less dense. The main advantage of the method is much simpler and, accordingly, cheaper equipment.

Longitudinal-transverse winding

The fundamental difference from previous schemes is that the winding is continuous: the stacker simultaneously lays longitudinal and transverse threads. It would seem that this should simplify and reduce the cost of technology; however, there is a purely mechanical problem here.

The mandrel on which the future pipe is wound rotates; If so, the reels from which the thread of longitudinal reinforcement is unwound must also rotate. Moreover, the larger the diameter of the pipe, the more coils there should be.

Longitudinal-transverse winder.

Oblique-layer transverse-longitudinal winding

This solution was developed during the life of the Soviet Union in Kharkov and was initially used in the production of rocket casings. Later it became widespread throughout the post-Soviet space.

What is the essence of the method?

- The stacker forms a wide ribbon of parallel, binder-impregnated fibers.

- Before winding onto a mandrel, the tape is pre-wound with thread without impregnation, which subsequently forms an axial reinforcement. The threads themselves collected into the tape form, accordingly, transverse reinforcement: the tape is laid across the axis of the mandrel.

- After laying, each layer is rolled with rollers, compacting the reinforcement and displacing excess binder.

What are the benefits of such a scheme?

- Possibility of continuous production. In one pass, you can form arbitrarily thick walls by simply changing the overlap of the tape.

- High performance.

- The ability to produce large-diameter fiberglass pipes (in theory, without any maximum size restrictions). Dimensions are limited only by the size of the mandrel.

- Extremely high fiberglass content in the finished material. It reaches 85% versus 45-65% with alternative methods. This affects both the final strength and flammability of the product.

Oblique-layer transverse - longitudinal winding.

Where can fiberglass pipes be used?

Let’s immediately say that they can be used in a wide variety of industrial and economic sectors. But more specifically, such pipes have proven themselves excellent in the areas listed below.

- Energy. Here, such pipes are actively used when laying pipelines operating at high pressure levels.

- Oil industry. In this case, fiberglass pipes are used both for transporting valuable minerals (we are talking about main lines) and for supporting all other production processes, including gas/oil production.

- In the housing and communal services system. And here the products described in the article are used for laying water supply systems (DHW and cold water supply), as well as for installing heating systems.

- Medical, chemical industries. Due to chemical neutrality, as well as resistance to various types of aggressive influences, fiberglass pipes are simply irreplaceable for transporting alkalis, acids and other mixtures/liquids.

Aluminum reinforced contours

The reinforcement of pipes with aluminum foil deserves special attention. Why was aluminum chosen? A distinctive characteristic of this metal is the protection of the internal walls from the negative effects of chemical elements. Aluminum patina can only be destroyed by mercury salts, which are not used in these systems. That is why the pipes are under reliable protection. Also, contours with aluminum reinforcement are able to combat pressure drops in the water circulating inside. Metals such as platinum, gold and silver have similar properties.

Advantages:

- They have high strength.

- Do not corrode.

- Resistant to bacterial contamination.

- Repel limescale deposits.

- Not subject to mechanical wear.

Flaws:

- The need to strip the mating ends during installation, which, if not handled properly, can damage the system as a whole. But if you do not follow this recommendation, the material may delaminate.

- If exposed to aggressive sun, the material may break.

- They have a small turning radius.

Manufacturing technologies

Now there are four main technologies for manufacturing fiberglass pipes:

- Extrusion.

- Pultrusion is the molding of a product between an outer and an inner mandrel.

- Centrifugal molding (casting) on a technological mandrel (on its inner surface).

- Winding - a fiberglass tape (or fabric, thread) impregnated with an unhardened binder is wound onto a mandrel.

Extrusion

Extrusion is the process of extruding a mixture of fiberglass and resin (or thermoplastic polymers) through a ring-shaped opening. A simple, inexpensive and highly productive technology, but the resulting products do not have high strength. But it is quite sufficient for use in sewer and water supply systems. In this type of fiberglass, sometimes not resins are used, but thermoplastic polymers - HDPE, PP.

Pultrusion

Pultrusion is the drawing of a rod of glass fibers impregnated with a binder through several successively located dies with a decreasing cross-section. The method is continuous; for it, a binder composition is selected with a precisely calculated hardening time and a short initial setting time. Fiberglass roving is passed through a bath of binder, then the workpiece is pre-formed, then drawn, cured, and cut.

The pultrusion method has the highest productivity, it is cheap, and is used for mass production of plumbing and water pipes operating at low operating pressures. The result is fiberglass pipes with very smooth internal and external surfaces. The disadvantage is the impossibility of manufacturing large-diameter pipes operating at very high pressures and the complexity of the technological process. With pultrusion, it is difficult to perform ring reinforcement.

Centrifugal molding

A fairly old method of manufacturing composite structures. The pipe is formed inside a rapidly rotating mold, and materials are fed inside - chopped fiberglass, sometimes fiberglass and uncured resin. Under the influence of centrifugal force, the materials are distributed into shape and harden. The result is a tube with a very smooth outer wall and precise outer diameter, the walls are uniform, without delamination or inclusion of gas bubbles.

The disadvantage is the high cost of the method. Used for the manufacture of thick-walled pipes with increased ring rigidity, for example for microtunnels.

Winding

Manufacturing fiberglass pipes using the winding method is the simplest of all technologies with high productivity. Winding methods: spiral-ring, spiral-tape, longitudinal-transverse, oblique-layer longitudinal-transverse. Manufacturing by winding can be continuous or periodic. For the manufacture of fiberglass products, thermosetting (polyester, epoxy, phenol-formaldehyde resins) and thermoplastic binding materials (PP, PE, polyamide) are used.

When winding threads or tape of fiberglass impregnated with a binder, a very smooth inner and rough outer surface of the pipe is formed.

What to look for when choosing polypropylene pipes

The main criteria for choosing such products should be their technical characteristics.

Operating pressure

Marked on the outer surface in the form of the inscription “PN”. The pressure value is selected in accordance with the individual characteristics of the heating system. If constant water hammer is observed or it will be necessary to frequently compress the pipeline system, the polypropylene product “PN20” will be optimal.

If the heating of the coolant in the heating system exceeds 70 degrees, “PN25” pipes reinforced with fiberglass will be more suitable. When autonomous heating is used, usually the pressure does not exceed 10 atmospheres. To install such a heating system, you can use polypropylene pipelines “PN20” with solid aluminum reinforcement.

Coolant and its normal temperature

Depending on the installed heating system, appropriate polypropylene pipes are selected. Since the coolant temperature in a “warm floor” does not exceed 40 degrees, you can install products with any reinforcement. You can use mono-composition products.

Where radiators are installed, and the heating of the coolant reaches 85 degrees, you can safely install polypropylene pipes with any type of reinforcement.

Pipe diameter

This parameter is very important for the normal operation of the heating system. It must fully satisfy the requirements of the system. The internal opening of the pipe must freely allow the corresponding flow of coolant to pass through for a certain time.

In very large premises, for example, hotels, pipes with a diameter exceeding 200 mm are installed.

In individual buildings, it is enough to install PP pipes with a cross section of 20-32 mm. They are easy to install to form the desired bend.

PP reinforced heating pipes are often installed in hot water supply systems. Polypropylene with a cross section of 20 mm can withstand high temperatures perfectly. The risers are made of polypropylene products with a diameter of 25-32 mm.

When connecting to central heating, 25 mm PP pipes are used.

For normal functioning of the heated floor, 16 mm products are installed.

A prefabricated autonomous heating system is assembled from pipes of different diameters.

The tips described above should be taken as a basis, and before purchasing and installing PP heating pipes, you need to take into account the individual characteristics of the object, and sometimes even the characteristics of individual sections of the system.

For example, when installing a single-pipe heating system, the radiators are connected in series. To mount such a ring, you need to use pipes with a diameter of 32-40 mm. Additional outlets for radiators are made with a diameter of less than 26 mm.

If a two-pipe system is installed, then heating is carried out according to a completely different principle. The supply line, together with the return line, reduces the pressure in the pipeline. Therefore, pipes with a diameter of less than 30 mm can be installed.

General information

Production Features

Polypropylene pipes are made using a special extruder machine, which processes the material in several stages.

The result is a finished pipe. How pipes are made:

- 1.Procure the required amount of raw materials.

- 2. Polypropylene in the form of shavings or granules is placed in a separate chamber, sometimes additional material is added to it.

- 3. Melt the plastic, heating the raw material to 2500 degrees Celsius. The inside of the chamber is coated with Teflon, so the viscous substance does not stick to the walls.

- 4.The machine produces pipes up to two and a half meters long.

- 5.The products are cooled in special containers, maintaining their shape for a long time.

- 6. Label and package products.

The entire production process is automated and takes a small amount of time. The operator monitors the progress of the machine. He also determines manufacturing parameters and, if necessary, repairs equipment.

What is a fiberglass reinforced polypropylene pipe?

These products are 3-layer polypropylene pipes reinforced with FIBER glass fiber.

They differ:

- increased resistance to corrosion processes and chemical influences;

- abrasion resistance;

- hygiene. Thanks to this property, the products have found their application in the installation of drinking water pipelines;

- environmental safety;

- long service life;

- ease of installation.

In addition, the products are universal in their use.

This is manifested in the fact that they are used:

- when installing heated floors, water heating;

- for supplying hot and cold water;

- in the process of arranging drainage and sewer systems.

Due to the design features of the risers, the product practically does not change linear dimensions, which is very important when installing heating and ventilation communications

Advantages of polypropylene products.

Pipelines made of plastic material are widely used for heating and water supply systems. The products are endowed with positive qualities that are not found in analogues made from metal material.

Positive properties:

1. long service life, which can reach 50 years for a cold water pipeline, 25 years for a hot water pipeline and heating network.

2. The products are smooth on the inside, so the pipes are resistant to the formation of dirt deposits, the passage inside the products remains the same throughout their service life.

3.installation of polypropylene pipes can be done quickly without the use of equipment, at home, independently.

Types of fiberglass fillers

“FiberGlass” literally means “fiberglass”. However, everyday speech has transformed this term as the name of glass-filled plastics, in which various glass fiber materials serve as fillers.

By analogy with reinforced concrete, glass fibers act as reinforcement, ensuring the rigidity of the structure and the strength of the SPM, and synthetic resins bind the filler threads into a single matrix, creating a monolithic structure.

The raw material for the production of glass fibers is glass scrap (cullet), the sources for which are:

- broken window glass and glass containers;

- rejected or broken products created under production conditions.

Glass waste is 100% recyclable, which proves the priority of recycling cullet to save primary raw materials and maintain a clean environment.

Broken glass does not fall into the soil and does not pollute landfills.

Virgin glass fiber is formed into a continuous glass filament by drawing elementary fibers called filaments from molten recycled glass raw material.

After further processing, semi-finished products are formed from the filaments:

- complex threads;

- glass rovings are strands of untwisted fibers (analogue of roving).

In this form, glass fiber is practically not used as a filler.

The resulting semi-finished products are subjected to textile processing to create products that will be directly used as a filler in the molding of fiberglass products.

The main types of fiberglass filler are:

- twisted products - cords, plaits, twines;

- woven mesh and special structure;

- fabrics – ribbons, mats, canvases.

Technical qualities of fiberglass

Various types of glass, including cullet, are used as the main components in the manufacture of fiberglass. The technology consists of melting scrap glass and then drawing the resulting mass through a high-strength mold, resulting in glass fibers. To make glass wool, the molten mass is inflated with steam when ejected from a centrifuge.

In this way, manufacturers manage to obtain a material that is characterized by:

- Low heat transfer is the most important parameter for thermal insulation. For example, for glass wool the thermal conductivity is about 0.05 W/m×°C.

- Excellent resistance to aggressive substances even at high concentrations.

- High density. For glass fibers the parameter is 2500 kg/m3. When combining the material with plastic or resins, the indicator decreases.

- Melting point is in the range of 1200-1400°C.

- Absolute fire resistance if the material is not mixed with polymers.

- High degree of protection against stray current.

- Anti-corrosion.

- Bactericidal properties.

- Strength is identical to steel and significantly exceeds nylon in this indicator.

- Various thicknesses of threads - from ultra-thin (D=1 microns) to sizes of 25 microns.

Operational features of fiberglass pipes

Composite materials are traditionally characterized by high strength, and fiberglass is no exception. These products can be used when laying highways for various purposes, regardless of climatic conditions, pressure and aggressiveness of the transported substances. However, pipes should be used taking into account the operational features of a particular model:

- Products based on polyester resins are chemically neutral and therefore indispensable in the oil refining industry. However, at high temperatures and pressure their use is impossible (more than 95 degrees and 32 atmospheres);

- Pipes with epoxy binder - used at pressures up to 240 atmospheres, temperature limit - 130 degrees. Another advantage is the almost complete absence of thermal conductivity, which eliminates the need to install insulation.

Regardless of the characteristics of a particular type of fiberglass pipes, these products are distinguished by high strength, optimal performance characteristics, and their trouble-free service life in domestic conditions exceeds 50 years.

Advantages and disadvantages

Of the many advantages, the most important is the long service life of more than fifty years, which is more than three times the service life of metal pipes.

Plastic products do not change their properties when in contact with moisture, and therefore are not subject to corrosive formations. No harmful or toxic substances are used for their production. The usefulness of these pipes is that they can be made from unnecessary used pipes.

Plastic has low thermal conductivity, so heat loss will be minimal. Such pipes weigh little, which will greatly simplify and reduce the cost of transporting a large number of large pipes. They are easy to install and transport. The cost of such products is quite reasonable and starts from twenty to eight hundred rubles.

The smoothness of the inner surface resists various deposits and growths. This is a guarantee that over time the volume of the pipeline will not decrease and bacteria will not multiply.

The main disadvantage of these products is their lack of stability when working at high temperatures. However, many improved types of plastics are now being produced that can be used in heating and hot water supply systems. Another inconvenience may be caused by the fact that depending on the type of plastic, different types of fastenings are required (using fittings, different melting temperatures).

Also, when laying water pipes made of plastic, one must not forget that certain types of plastics are prone to destruction due to the action of ultraviolet radiation. To preserve the pipeline you will need insulation.