| Name | Key Features |

| Liquid | The most common. It is used for thermal insulation of various structures and for repairs. Fills cracks and gaps. Can be prepared at a construction site. |

| Granular (thermal wool) | It is made by crushing the polymer into fractions of 10-15 mm. Economical during installation. Penoizol in granules in volume is 2 times greater than the amount of sheet polymer obtained during production. It is used to fill cavities between walls when laying floors. |

| Sheet | The insulation is poured into a special mold, cut, dried and further processed when ready. It is mounted on the outside of the walls of houses, secured with dowels. It can also be laid on the floor (between joists). |

Indicators and advantages of penoizol

The popularity of urea foam is explained by its low price and characteristics:

- Low thermal conductivity (0.041 W/m2*K). To ensure good thermal insulation, a thin layer of foam insulation is sufficient (minimum 10 cm).

- High noise absorption reaching 65%. Even a narrow layer of building material solves the issue of sound insulation.

- Good fire resistance. The insulation belongs to the G-1 flammability group with the B-2 flammability category. The polymer does not melt, but evaporates without releasing harmful toxins. Smokes weakly.

- Hygroscopicity. Air can pass through the foam; the vapor permeability property allows the walls to “breathe.”

- Chemical neutrality towards various components, including organic solvents.

- Biostability. Fungus and mold do not grow on penoizol, and mice/rats do not gnaw it.

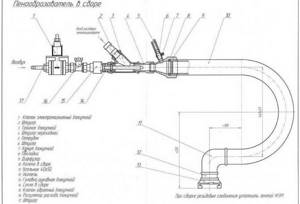

installation of gas and foam generator

- The first thing we will look at in the video instructions is a schematic diagram of the technology and drawings of equipment for the production of urea foam (penoizol and its analogues).

- I will tell you about important technical nuances, mistakes or misunderstandings of unscrupulous manufacturers, including those who may call their urea foam plastic foam insulation

. What you absolutely cannot save on. - From many years of experience, I will demonstrate the design of a simple, but reliable and efficient foam generator; visual photos, videos, diagrams, drawings and instructions will help you easily make such a device with your own hands. My foam generator is easy and quick to maintain and clean if necessary. If it gets clogged, you can disassemble and reassemble it in 10 minutes!

- How to make simple and reliable dispensers for accurate supply of solution and quick adjustment of the amount of resin for the production of foam plastic of different densities and characteristics.

- Required installation maintenance.

Flaws

Penoizol has the following disadvantages.

Firstly, it absorbs moisture and does not release it. Penoizol is quite resistant to moisture, but this feature does not allow the use of insulation when screeding the foundation.

Secondly, the material produces sediment in the range of 0.1-5%.

Thirdly, penoizol breaks easily - it has low tensile strength.

Fourthly, insulation can only be installed at above-zero temperatures (at least +5°C). Only in this case will you get high-quality foam for filling cavities.

If sheet and granular penoizol does not emit hazardous substances, then in liquid form it can evaporate harmful toxins. It is better for workers to have protective equipment.

Characteristic features of the equipment

The technology for producing penoizol is not very expensive. However, the purchased equipment is characterized by high productivity, efficiency and ease of installation. In addition, it is quite compact in size. It is thanks to this factor that the size of the production site may not be too large. All you need to do is find a warehouse.

The penoizol production technology also has a high payback rate. Based on calculations, we can say that the cost of all equipment will quickly pay off even in the situation if the material is used in a small house.

Penoizol manufacturing technology

- In a separate container, mix 3 ingredients: water, a foaming agent and a reaction catalyst. Urea-formaldehyde resin is poured into the second container. Subsequently, it enters the mixture under the influence of compressed air.

- The components are thoroughly mixed until a mixture is formed that is similar in consistency to a soufflé. The resulting material is called liquid foam insulation, which means it is already suitable for use on construction sites.

- The liquid mass is poured into molds of different sizes. Hardening takes place at room temperature, lasts up to 3 hours (depending on the shape, size and specific recipe), on average - 30-40 minutes.

- The resulting insulation sheets are cut into separate slabs in accordance with the required dimensions.

- Urea foam is coated with a protective compound that increases strength and fire resistance.

- The finished product is packaged and stored.

Features and description of the material

The material is a modified foam. Its main characteristics are:

- resistance to fire;

- good thermal insulation characteristics;

- installation by spraying.

It is based on three components. This is orthophosphoric acid, urea resin and a substance with foaming properties. The specified ingredients are mixed in exact proportions and the device is installed. A mixture resembling jelly is formed. It has a white tint. Under the influence of compressed air, it moves outward. She:

- fills any space;

- ensures tightness;

- forms a lush foam after hardening.

Curing requires several steps. After application, the composition sets slowly. This takes approximately 15 minutes. After 3 hours the foam becomes a little hard. But this is not enough for it to fulfill its functions. The material takes its final form after 3 days.

In its finished form, it is not solid, but liquid penoizol that is formed. Some home craftsmen are trying to make it with their own hands, since it has good technical characteristics and is considered easy to manufacture. The material is elastic and easily restores its shape after any mechanical stress. It contains up to 90% air. Outwardly, it resembles expanded polystyrene, but differs from it in its fine cell structure.

The improved properties of penoizol have made it popular in the field of insulation of private houses. It is used in thermal insulation of complex structures, interfloor ceilings and floors.

What you need to get started

A penoizol manufacturing business can be started without major investment. The equipment is inexpensive, and the main expenses each month will be spent on purchasing raw materials and paying staff.

Table 1. The amount of initial costs for the penoizol production business.

| Expense item | price, rub. |

| Registration | 20 thousand |

| Premises for rent, 90 sq. m | 25 thousand |

| Equipment | 200 thousand |

| Raw materials (for a month at full load) | 230 thousand |

| Salary, 6 people. | 190 thousand |

| Additional expenses | 100 thousand |

| Total | 765 thousand |

The calculations are relevant for a city with a population of up to 1-1.5 million people. Additional costs include the costs of utility bills, advertising promotion, premises preparation, etc. The amount of tax deductions is not taken into account in the calculation.

Additional Features Worth Paying Attention to

Additional characteristics that the equipment must have include the type of pump that is connected directly to the container with the main components. Pumps can be centrifugal, plunger, vortex, gear. They are all characterized by their advantages and disadvantages, so the choice should be made only after a complete review of all their advantages.

You should also pay attention to the generation that is typical for the equipment. Some devices that are commercially available today were produced back in the 90s. New samples are produced taking into account previously made errors in use.

Documentation

First you need to register your activity form. You can work as an individual (IP) or legal entity (LLC). It all depends on the plans of the entrepreneur and the scale of production. Each form has its own capabilities and limitations, but working in the LLC form will allow you to cooperate even with large construction companies and wholesale and retail chains.

When registering, OKVED-2 codes are indicated.

23.99.6 “Production of mineral heat- and sound-insulating materials and products.”

22.23 “Production of plastic products used in construction.”

22.29 “Production of other plastic products.”

32.9 “Production of products not included in other groups.”

To start a business project, you do not need certification. The polymer is produced according to TU 2254-001-33000727-99 “Heat-insulating foam insulation. Technical conditions".

Practical instructions for insulating houses with foam insulation

Video of equipment operation and home insulation

There will only be practical information on how to insulate a house with any urea foam without consequences. Even when you order home insulation with foam insulation

officially, it is important to understand for yourself how this is done correctly. After all, private houses and walls are different, the size of the layer, the strength of the masonry are different, and you need to immediately navigate and adapt to each house. I have heard questions on the phone many times... - Aren’t you going to destroy the house?! I have never destroyed a single house. Sometimes, it was necessary to carefully pour penoizol into walls that were swayed by hand. How to do it? All in

(unipora):

- Polymer resin (PS), type KFTM-15

or

KF-P

; - Foaming agent (FO) - alkylbenzenesulfonic acid ABSA

; - Hardening catalyst (CO) - phosphoric acid

; - Water.

Polymer resin

(PS) - a homogeneous suspension of white or light brown color with a dry matter fraction of 51-56%, formaldehyde up to 0.25%, pH - 7.5-8.5, viscosity 17-25 sec according to VZ-246, nozzle diameter 4 mm, mixes with water 1:2, with a slight sediment.

PS is a non-flammable aqueous suspension, usually supplied in metal or plastic barrels of 200 liters or more or in tanks. Storage at +5 ... +25 °C, shelf life - 2 months.

Foaming agent

(PO) - a viscous solution of brown color, non-volatile, low-flammability substance, up to 2% sulfuric acid (in case of contact with skin, rinse with water). Storage is usually in closed polyethylene containers. Shelf life - 1 year.

Curing catalyst

(KO) - liquid according to GOST 12.1.007 belongs to substances of hazard class II, orthophosphoric acid is usually stored in closed polyethylene containers (canisters), shelf life is more than 1 year. Diluted with natural or tap water.

Equipment for penoizol

For industrial production of insulation you need to buy the following equipment:

- compressor and power supply;

- gas-liquid installation for liquefied gas, including a pump system for supplying foam and solution;

- collapsible molds for filling;

- containers for making the mixture;

- large table for packing material.

In this configuration, sheet and liquid foam insulation can be produced.

There are equipment for sale from Russian, Ukrainian and foreign manufacturers. Models differ from each other in price and technical characteristics, including the degree of automation of the process. There are mobile and stationary installations.

Equipment and components for the production of penoizol. UPG units, VPS-G resin, ABSC foaming agent, orthophosphoric acid.

The price is negotiable. buy

the equipment yourself - the necessary drawings and diagrams are on sale.

When choosing equipment, it is better to look for a seller who trains the customer’s personnel to work on the installation. The equipment must have a warranty.

Selection criteria and equipment purchase

In most cases, liquid penoizol is chosen when it comes to domestic use. It is applied using special equipment. You can rent it to save money.

To apply penoizol, a special installation is required; it can be rented in order to save

To produce penoizol with your own hands at home, you will need to equip the installation. You can arrange it from scrap materials. You will also need a compressor, molds for finished products, and additional equipment for lighting and ventilation. Budget installation options involve a combination of:

- gas-liquid equipment;

- supply hose;

- set of taps;

- plastic barrels;

- compressor.

Urea resins and catalyst are mixed in the plant. They are placed there using a pump. There is compressed air here. The main attention should be paid to the purchase of a pump, since it plays the role of a key element in production. Errors in dosage are especially important. A vortex or plunger pump is the most profitable and effective option. But in any case, foreign particles should not be allowed to get inside, as this will ruin the whole process.

More information about liquid foam:

Raw materials

The product is produced by foaming a polymer resin according to a developed recipe. Depending on the formula, additives may be added to the composition, but the main components are the same.

- Synthetic urea-formaldehyde resin.

- Foaming agent. Necessary for the formation of stable foam.

- Catalyst (hardener). Accelerates the hardening process.

- Water with a temperature not lower than +20°C.

Finding and purchasing the necessary raw materials will not be a problem.

There are generally accepted standards regarding the recipe, but a businessman may well create his own insulation formula. It is better to contact a construction expert, although you can find the information yourself - there are enough online resources and forums on this topic on the RuNet.

Self-installation of the installation

(Click to enlarge) On the websites of manufacturers involved in the manufacture of equipment for the production of penoizol, you can purchase installation drawings and learn the production technology.

By purchasing such a package of documents, you can assemble this device yourself, especially since spare parts are always available.

A budget option would be a self-assembled structure consisting of:

- gas-liquid installation;

- set of taps;

- supply hose;

- compressor for producing compressed air;

- plastic barrels up to 300 l.

The process of obtaining insulation is based on the principle of foaming solutions with a catalyst and mixing it with urea resin. Using a pump, the components enter the installation, where they foam under the influence of compressed air.

One of the main system components in a gas-liquid installation is the pump, so it is better to purchase a quality pump.

We do not recommend pumps of type NSh 6 (gear pump) and NSh 10, as they can fail in dosages when supplying one of the components - resin.

These pumps also have problems with the electric motor. The declared power may not be enough to supply the finished product to fill voids.

Please take into account: when choosing pumps for installation, it is necessary to take into account errors in dosage, errors in engine speed instability depending on voltage and load. It is more profitable to use plunger pumps or vortex pumps

Here it will no longer be possible to make a mistake with the dosage, but if solid particles enter, the entire work process may be disrupted, from a failure in dosage to breakdown of the unit

It is more profitable to use plunger pumps or vortex pumps. Here it is no longer possible to make a mistake with the dosage, but if solid particles enter, the entire work process may be disrupted, from a failure in the dosage to a breakdown of the unit.

Keep in mind: when choosing a plunger or vortex pump, you must consult about the material from which the internal parts are made. It is desirable that it be nickel plated, stainless steel, ceramic or plastic.

It is also advisable to purchase a high-quality plunger pump for supplying foam. Foam is formed using a high expansion foam generator at low pressure. The output is foam with a beautiful fine-cell structure.

The most effective method today is double foaming. At the outlet, Penoizol appears as a dry mass, which makes it possible for it not to leak out of the cavity being filled.

The compressor on the equipment must be installed with a certain capacity

Be sure to pay attention to the resin consumption, it should be no more than 25 kg to get a quality product

In an installation for the production of penoizol, it is necessary to create an optimal ratio of all components to distribute the insulation throughout the entire filling volume.

The final product should be white and, when pressed, should return to its original shape.

As an insulating material with low cost and high insulating properties, penoizol is beneficial for your own production.

Having assembled the equipment according to the drawings, you can open your own small business and start earning money. With the expansion of the scope of penoizol, its production can be called promising.

Watch the video, which shows in detail the stages of working on equipment for penoizol with your own hands:

Penoizol production workshop

To organize a business you will need a room with an area of 70-90 square meters. m, divided into a production workshop, warehouse, staff room, administrative room and bathroom. It should be located away from residential areas. Communications need to be installed on the territory of the mini-factory.

The workshop is equipped with a 220V power supply and a good ventilation system. The latter is necessary, because when drying insulation sheets, substances harmful to health are released (phenol-formaldehyde is present in the synthetic resin).

The warehouse will store raw materials and finished goods. It is worth placing metal shelving in the room.

The premises must be equipped with vehicular access for unloading and loading operations.

Manufacturing facility

To begin with, you will need a room no larger than 100 square meters. It will be possible to place equipment and a warehouse for finished products. During the production of penoizol, harmful substances are released, so good ventilation must be provided. In addition, the workshop must have electricity, water, heating and sewerage. The average cost of renting such a workshop greatly depends on the region and ranges from 20 to 70 thousand rubles/month.

The production of liquid penoizol immediately on construction sites will allow you to avoid expenses on the workshop. The equipment can be stored, for example, in a garage, and the workshop can be opened later, after the initial investment has paid off.

Staff

To service the production, you need to hire 3 people, one of whom will be a senior person in the workshop. The latter’s responsibilities include coordinating the rest of the workers, monitoring their activity and training. It is the senior worker who needs to be sent for an internship to the equipment seller.

To organize sales, you will need a sales manager. He will meet and negotiate supplies with representatives of construction and wholesale and retail companies.

A driver is needed to deliver raw materials to the factory and finished goods to customers.

The accountant will handle the document flow and prepare papers for the tax authorities. It is better to hire one through outsourcing (by contacting an accounting firm).

Material consumption rates

The table shows the material consumption rates for producing polystyrene foam with a density of 15 kg/m 3, obtained with a uniform (1:1) consumption of components in RESIN and FOAM containers.

| № | Characteristics | FOAM 3000/10UM | FOAM 2000DMU |

| 1 | Capacity for penoizol, [m3/hour] | ||

| 2 | Pump type: resin / solution | Gear Screw | Centrifugal Centrifugal |

| 3 | Air consumption, [l/min] | ||

| 4 | Power consumption (without compressor), [kW] | ||

| 5 | Supply voltage, [V] | ||

| 6 | Operating air pressure, [atm] | ||

| 7 | Component ratios, resin/solution | ||

| 8 | Adjusting the density of penoizol | Air pressure | Selection of nozzles |

| 9 | Penoizol density in dry condition, [kg/m3] | ||

| 10 | Operating pressure of components (before mixing chamber), [atm] | ||

| 11 | Hose length, [m] to mixer | ||

| 12 | Overall dimensions, mm] | ||

| 13 | Weight, [kg] | ||

| 14 | Guarantee | 1 year | |

Installation PENA-3000/10UM

PENA-3000/10UM is equipment for business+ class penoizol. An ideal solution for small businesses and construction organizations. It can be used both for pouring thermofoam on site and for producing sheets. Penoizol productivity is up to 29 cubic meters/hour. The installation is carried out at 220 V (possibly 380 V).

PENA-3000/10UM allows you to obtain a material of excellent structure, elastic, non-flowing, odorless, fine- and closed-cell, with low water absorption.

Advantages of the PENA-3000/10UM installation for pouring penoizol:

- Both pumps pump according to “volume”, exact dosage and ratio of components are guaranteed from the beginning to the end of filling, regardless of the viscosity and temperature of the components, regardless of the height of lifting of the components through the hoses;

- The radius of filling horizontally is increased to 50 m, vertically - to 30 m;

- The pump along the “resin” line is self-priming. Therefore, it is enough to throw the suction pipeline with a removable filter at the end into the container barrel from above and get to work. In other words, there is no need for a separate resin working container;

- A compressor with a capacity of 200 l/min is sufficient for operation, i.e. The supply voltage for both the installation and the compressor is 220 V, i.e. PENA-3000/10UM can be widely used in the private sector;

- The pump along the “foam” line has 3 working channels, of which only one is used, and the other two are reserve. In other words, the service life of the pump is practically unlimited;

- There is no need to configure the foam insulation installation. Regardless of the density, viscosity, temperature of the components, the flow of the pumps has already been adjusted by us in the best ratio and will remain so under any conditions;

- Installation management is simplified as much as possible. The “human factor” is almost completely eliminated;

- Equipment for penoizol Pena-3000 is equipped with a modified foaming system, which allows you to get more and better foam from the same amount of foam solution. It is possible to adjust the density of the foam mass and the productivity of penoizol directly from the control panel of the installation during operation.

The advantages listed above are interesting, first of all, to those who do not want to experiment. In this case, PENA-3000/10UM is very convenient. It was initially built on a 1:1 “resin”: “solution” ratio, which allows you to obtain good material. However, in some cases, the conditions for using penoizol require changing the proportion, increasing either the consumption of resin or solution. PENA-3000/10UM has such an opportunity. The solution pump capacity is set rigidly and remains constant. But the resin pump’s performance can “smoothly” change due to the fact that the motor of this pump is controlled through a frequency electronic regulator. This is very important and convenient when it is necessary to obtain a “resin”: “solution” ratio, for example, 1 to 0.8 or, conversely, 1 to 1.2, etc.

The pump performance is changed directly from the control panel by rotating the handle of the frequency converter. Clockwise - resin consumption increases, counterclockwise - decreases.

Who should you sell the finished products to?

3 main groups of consumers of urea foam:

- construction companies, repair and construction companies;

- retail stores and wholesale and retail networks for the sale of construction products, construction markets;

- private individuals.

At the initial stage, it is important to use all possible sales channels - it is necessary to attract the attention of potential buyers to the new product. However, the most convenient option is to obtain a contract for large supplies of insulation. Therefore, great attention must be paid to negotiations with construction companies.

The penoizol production business is seasonal. Construction is actively carried out during the warm season. Of course, large construction projects are carried out in winter, but in general the volume of construction work drops noticeably in cold weather.

Production of urea foam plastic

In the video lesson we will discuss the necessary components and raw materials. The correct recipe for preparing a solution for foam. Because even here there are very important points and mistakes that novice manufacturers or defectors make. Which urea resin and hardener to choose in order to obtain the highest quality polystyrene foam. After all, there is a strong odor and discharge that absolutely cannot be used. It’s not just that there are various rumors and rumors, after the work of hacks, penoizol is harmful

Let me remind you, as with any other production, anything, it is important to correctly and accurately follow the technology. Only in this case there will always be positive reviews about penoizol

The influence of different proportions of components, including compressed air, on the characteristics of liquid foam (penoizol and any other brands of urea foam). Solving possible problems with electricity or inappropriate water on site at the customer.

Sales markets

The main market for penoizol is construction organizations. You can sell products through retail chains. It is necessary to effectively advertise your products using:

- Internet;

- free advertisements in print;

- other sources.

Peak sales occur in the summer. In winter, the demand for these products decreases; this is not a winter business, although large construction projects take place all year round and they also need penoizol. It is necessary to begin sales in April to obtain greater profits. It should be taken into account that construction organizations make non-cash payments, which can be credited to the account within 90 days. With individuals, cash payments are made upon receipt of products.

| Name | Consumption rate | price, rub. | Total |

| Urea-formaldehyde resin, kg. | 25 | 12,5 | 312,5 |

| Foaming agent (ABSC), ml. | 0,5 | 75 | 37,5 |

| Orthophosphoric acid, ml. | 1 | 30 | 30 |

| Water, l. | 40 | 1 | 40 |

| Electricity, kW per hour | 8 | 3,5 | 28 |

The costs will pay off in about 7–8 months.