Modern, reliable and practical plastic pipes are an excellent solution for arranging a water supply system in a country house or in a private home. Their advantage is quick installation and low weight of the pipeline system, ease of system modernization and pipe repair. The disadvantage of plastic pipes is that a poorly soldered joint inevitably loses its tightness, and the pipes themselves (with the exception of reinforced ones) are poorly resistant to mechanical damage.

A leak can appear in any type of plastic pipe.

Timely repairs

You can still see steel or cast iron pipes in many residential areas.

Of course, they have high strength and reliability characteristics.

But they also have one significant drawback - a tendency to corrosion.

For this reason, many ordinary people deal with such an unpleasant situation as a leak in a pipe.

And, in the end, you will have to change a large section of the pipe or, possibly, the entire system (you can read about couplings for connecting HDPE pipes here).

And this, as you understand, is a labor-intensive and costly option. The predominant causes of leaks in communication systems are listed below.

- Illiterate installation of joints (read how to properly connect HDPE pipes with fittings here).

- Incorrect connection of plumbing fixtures, for example, a children's urinal for boys.

- Mechanical loads.

Leaks occur in metal pipes much more often than in plastic products. In this case, we are not talking about corrosion, of course.

The main reason for the occurrence of leaks in plastic pipes at the joints may be an error in choosing the material for arranging the heating system.

For example, you cannot use polypropylene pipes for heating (how to connect without soldering) intended for cold water.

Do you know how to correctly calculate heating batteries for a private home using a calculator? The method for calculating the number of radiators for a separate room, house or apartment is described in a useful article.

What fines have been introduced in Russia for wells from September 1, 2021 is written on this page.

Because due to high temperatures and increased pressure, they can become deformed, and leaks will appear in these places.

When installing a water supply system, many owners of private houses prefer modern, reliable and practical plastic pipes.

Their advantage is undeniable:

- Quick and easy installation, for example, with brass fittings for HDPE pipes.

- Relatively light weight.

- Convenient repair.

There are also disadvantages , and the main one is that if the joint is soldered poorly, it will not be airtight.

And hollow products themselves (except reinforced ones) will not be able to withstand mechanical damage.

Polypropylene solder leaked

mediatok wrote: in order to redo everything, you will have to dismantle the wall on the other side, and then redo it. Do you think I'm just asking about other options? The wall is emphasized with plasterboard.

Before you worry, show what's behind your drywall. How and where does the pipe go in the wall? Perhaps the drywall does not need to be dismantled. Maybe the pipe can be re-soldered with minor damage. But you will have to resolder. Otherwise you are at great risk.

mediatok wrote: when soldering polypropylene in one connection, a small leak started. Is it possible to eliminate it without breaking the adhesions?

It is forbidden. Polypropylene water supply does NOT require any patches or seals. What to do: The corner must be cut off (to do this, use scissors for plastic/polymer pipes). And put another corner (use a soldering iron/iron for polypropylene). Moreover, on both sides of the corner, you will have to lengthen the pipes (to restore the length that was cut off with the corner). To do this, you will have to solder a must with a piece of pipe between the corner and the pipe. And this is without options (if done correctly).

If you are confident in yourself, then you can try to solder the corner yourself. An iron for polypropylene can be rented from plumbing stores that sell polypropylene pipes. Usually, scissors are included with the iron. If you rent an iron, be sure to ask about scissors, otherwise they will almost certainly not be included in the kit. (I had to separately ask for the scissors to be put down.) Scissors for polypropylene pipes may not be included in the kit. They quickly fail. But don't be upset. You can go to another store where scissors are included with the iron. Or just buy separately scissors for polymer pipes (suitable for cutting plastic, metal-plastic and polypropylene). Inexpensive scissors cost about 200-300 rubles. (I took the cheapest ones for 230 rubles / made by Fit. The new scissors cut very well. But I had a hard time with rented old ones.) Moreover, you may need such scissors for other household chores.

If you have no experience in soldering polypropylene, then it is better to contact a specialist so that a specialist can resolder the corner for you.

If you want to experiment and get even bigger problems after you finish the repair, then please take the risk. However, remember, it will be much more expensive to redo everything later. I’m telling you this like a shot sparrow who just recently walked through this rake. I resoldered the pipes twice, even three times. The fact that I resoldered it right away was done with less hassle and expense. Where I decided not to resolder right away, I didn’t get off so easily. As a result, I had to gut the plaster (grooves, pipes, water sockets) and still suffer with resoldering, and then again tinker with installing and walling up the water sockets. Costly and labor-intensive, but reliable and good. That’s why I’m glad that I decided to redo it, even if it was a little late. But there are no potential problems in the future (another unscheduled repair).

Think carefully before taking any risks. Maybe get local plumbers to re-solder the corner. (I’m not sure that a third-party plumber would bother with just one corner). Anyway, have a local plumber take a look and tell you what he can do. Maybe, indeed, it will cost without significant destruction. And if it doesn't work out, maybe it's worth it, like, a new piece of drywall and rebuilding the wall. (I think reliable running water is worth it.)

Characteristic features of leaks and options for eliminating them

- The appearance of droplets of “dew” on the pipes in the area of fastening elements,

- wet hollow products,

- lack of normal pressure in the system,

- all this suggests that the apartment owner needs to pay close attention to the water main.

And, as soon as possible, start fixing the leak before it turns into a small flood.

All work can be done with your own hands, without involving specialists from the housing office.

If you do not get rid of the leakage, then even a minimal fountain, falling on electrical appliances, an electrical line or simply on the floor, will harm not only you, but also the neighbors living on the floor below (or even two).

In order to repair a water supply or heating main, you will need the simplest practical skills and special tools (about crimping tools for metal-plastic pipes is written on this page).

Even an amateur can perform basic repairs to plastic pipes And a professional will repair an unexpectedly formed hole in a few minutes.

Worth knowing! The main thing that a repairman must do is to select the best option for eliminating the breakdown, and this must be done in record time.

The first actions the installer must take when performing repair work are as follows:

- If there is such a possibility, turn off the flow of liquid substance into the system or, at least, to the area that needs to be restored (read how to eliminate a water leak in the toilet in this article).

After completing the water supply or limiting the location of the leak, it is worth starting active actions to eliminate the emergency situation. - The next step is to choose the most suitable option for removing leaks in a plastic pipe.

At the same time, one main condition must be fulfilled - the detected crack must be sealed as efficiently as possible, so that an even larger hole does not form in this place.

What do you know about the operating principle of an air-to-water heat pump for heating a house? Read the proposal about the feasibility of installing the equipment.

How to drain water from the roof of a house is written here.

On the page: it is written how the autonomous sewage system of a private house works.

Remember! Water should temporarily not flow into the area where a leak was discovered (how to fix a leak in a pipe with pressurized water).

If the system is multi-circuit, it is enough to shut off the flow of liquid substance directly to the line being repaired.

This can be done by closing the diverter valve of a limited section of the water main.

Recommendations for repairing sewer systems made of plastic and cast iron

When repairing a plastic sewer system, it is important to correctly localize the breakdown and choose the optimal material for repair. Most often this involves repairing cracks or holes in the pipes themselves using some kind of sealant. The second option is to repair pipe joints. Typically, replacement of gaskets, connection and sealing of the seam is required. No special equipment required.

If cast iron pipes break, professional help may be required. Finding a leak is more difficult, since the pipes may be rusty and constantly covered with condensation. It is recommended to cool the air in the room to 15 degrees before starting work to minimize fogging of the pipes. The choice of repair method should also be based on experience and skill. If possible, a rational solution would be to replace cast iron pipes with plastic ones. Large-scale, but one-time expenses will be worth it for years of trouble-free operation.

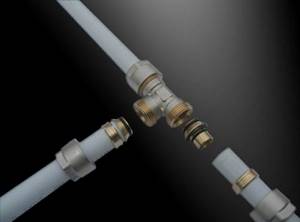

The most difficult repair option is connecting pipes from different materials. To install such a joint, it is recommended to use special adapters that provide good protection of the seam from leaks.

How to caulk a leak

Causes and repair options for leaks.

Homeowners whose plumbing is made of plastic often encounter a problem - a lack of tightness at the joints of the pipes.

A leak can form for various reasons.

Much depends on the method of laying the networks, on the fittings used and on the qualifications of the technician who installed the system.

What could be the cause of a leak??

- Error when selecting temperature conditions in the process of soldering plastic pipes. And this contributes to the violation of the solidity of the transition point: pipe/fastener/pipe.

As a result, a small gap appears.And in order to repair the system, you need to remove the old unit and replace it with completely new components.

If you think that you will get rid of the problem with the help of a sealant, then this is a misconception. By covering the problematic joint with a sealing compound, a malfunction cannot be avoided.

- The nut may have become loose. You can get rid of a leak in the tightening fitting by simply tightening the nut with your own hands.

This will not be difficult to do, provided that the integrity of the internal gasket is not damaged and the lock nut is not damaged.In this case, it is not a good solution to seal the fitting with sealant. If it fails, it means it needs to be replaced.

- The clamp type fitting is poorly pressed .

It can be used in combination with a plastic pipe. And, if it happens that the joint leaks, you need to press on a new connecting element.

Strong recommendation! The same shrink ring cannot be clamped with special pliers two or more times.

- Insufficiently well prepared pipe.

If, during installation of the product, the cut was made uneven, then the place where the pipe is connected using push-in fittings will definitely leak (methods for connecting polypropylene pipes are described here). - Joints of plastic pipes made using the adhesive connection method will leak in the following cases:

- the type of adhesive composition is not accurately selected,

- Not enough time has passed since the installation work was completed before commissioning activities. During this period, the glue did not have time to dry, and the joints did not harden to complete sealing.

The most durable and major way to repair a faulty system is to replace a poor-quality section of pipe with a new plastic product by soldering it through fittings to the main line.

Unfortunately, it is not always possible to use the high-temperature interface method. In this case, repairs are carried out using other known methods:

What not to do if pipes are leaking

But what you can’t do if PVC pipes are leaking at the joint is try to seal the joint. Short-term headache relief is possible in this case. But this is only avoiding the problem, not solving it. Indeed, in this case, the risks of repeated rupture of the material are very high.

If a plastic pipe is leaking at a joint, it is reasonable to seal the joint only for a short period of time (immediately after the accident), if it is not possible to turn off the water. To get the job done, it is recommended to take a rubber clamp with clamps.

7 life hacks that will help when connecting pipe joints

- To make it easier to work with pipes when fixing leaking joints, make marks with a marker.

- Remember, in order for the threaded connection to be perfect, the thread length must be identical to half the length of the coupling. Processing the ends with a thread cutter helps ensure this condition.

- If the connection is made by welding (soldering), do not squeeze the parts together with full force (molten plastic can be pressed inward and reduce the diameter of the fitting involved in connecting the pipe to the system).

- Preliminary heating of the device for ten minutes helps to take full control of the soldering process. In this case, the equipment behaves more predictably.

- After each manipulation during the soldering process, do not be lazy to clean the nozzles. This procedure will help avoid intense carbon formation.

- If carbon deposits have already begun to appear, it is best to use wooden sticks to remove it.

- The surfaces to be welded must be clean. In order for the work to go quickly and the seam to be of high quality, it is important to degrease the ends.

So, to seal leaks at sewer and water pipe joints, you can use both a butt joint and a threaded joint. When connecting by welding, it is important to carefully monitor the temperature conditions and not be lazy in cleaning the nozzles used. When making a threaded connection, it is important not to make the mistake of insulating with sealants.

Clamp bandage

You can eliminate a leak at the junction of plastic pipes using clamping fasteners. This is, of course, a temporary solution.

To work, you will need a clamp with clamps , inside of which there is waterproof plastic rubber.

The good thing about this method is that it allows water to move easily through the plumbing system. This method is fast and reliable.

It is much more effective than the taping method or applying sealant. When performing work, there is no need to shut off the water supply.

But there is one drawback - the fastening points of the clamp weaken over time and the connection loses its tightness.

Cold welding method

Before you begin, you need to prepare the required amount of ingredients.

To do this, mix all the components in the proper ratio.

Then apply the mixture to the damaged area and wait until the composition completely hardens under natural conditions.

Glue method.

We take a pair of clamping devices, material impregnated with a special composition, which includes: bandage or rubber intended for polypropylene + two-component glue + cement.

With the help of an adhesive bandage, you can eliminate the leak on your own.

It is not necessary to turn off the water . Disadvantage of the method:

- it cannot be used for systems with high water pressure.

Sealing tape

This is considered a good option if you need to get repairs done in record time.

We simply wrap several layers of fly over the damaged area.

Eliminating leaks at the junction of other types of pipes

To eliminate leaks at the joints of a pipe made of metal, plastic or metal-plastic, you can use one of the following methods:

- replacement of fitting;

- cold cooking;

- adhesive bandage.

Replacing fittings

The following can be installed on pipelines:

- welded fittings. Mainly used for connecting plastic pipes;

Connecting element installed by welding

- compression fittings. Can be used for joining both plastic and metal-plastic pipes. Unlike a welded fitting, the connection is more reliable and durable;

Element for forming a permanent connection

- threaded fittings. They are used for various types of pipes if it is necessary to arrange a detachable connection.

Element for creating a detachable connection

If a pipe connection is leaking and it is necessary to replace the welded fitting, proceed as follows:

- disconnect the pipeline from the water supply;

- cut the connecting element with special scissors;

When cutting the connecting element, it is important to take into account that the total length of the pipeline is reduced.

- prepare a pipe section of the required length and two new fittings;

- sequentially weld the elements using special equipment.

Installing a new fitting by welding

You can use the finished pipe after the pipes have completely cooled. This time is required to strengthen the newly created connection.

If there is a leak at the junction of pipes with compression fittings, then the connecting element is replaced according to the following scheme:

- the connecting element that has become unusable is removed;

- the pipes that need to be connected are chamfered and calibrated;

- crimp rings and nuts are put on the ends of the pipes, which act as clamps;

- the pipe is inserted into the fitting until it stops and the fixing elements are tightened.

Compression fitting installation diagram

You can use the repaired pipeline immediately after replacing the compression fitting.

The process of correctly installing a compression fitting is presented in the video.

If a pipe is leaking at a joint equipped with a threaded fitting, then you must proceed in the following order:

- first of all, you can try to simply tighten the thread with a wrench, since in some cases a simple loosening of the tightening occurs;

- if tightening does not help, then the connecting fitting is completely removed;

- the thread is treated with FUM tape or any other insulating material;

Sealing the threaded connection before fixing

The insulating tape is wound along the thread in the direction of twisting.

- the new fitting is tightened into its original place.

Fixing the connecting element on pipes

Cold welding

If a leak is detected in pipe connections that are not equipped with a fitting, then the pipeline can be repaired using the cold welding method. To fix the joint, you need to purchase a special compound.

Mixture for quick repair of leaks

This tool must be used according to the following scheme:

- the fragment of the pipeline in which the leak has formed is cleaned of contamination. If the composition needs to be applied to a metal pipe, then the damaged area is first cleaned with sandpaper;

- the mixture in the package is mixed until smooth and applied to the damaged area and carefully leveled.

Using cold welding to eliminate leaks

Until complete drying, which occurs after approximately 3 hours, the pipeline cannot be used.

Sealant

This solution is considered temporary, and cannot be called a repair.

Take into account! Regardless of which method of eliminating a leak you choose, it is possible to eliminate the tightness of the damaged area only after careful preliminary preparation of the pipe section.

The hollow product must be degreased, cleaned and well treated at the junction of the pipe and fitting.

There are several types of sealing mixtures:

- Neutral . It is applicable to all types of pipes. Apply the composition only using a mounting gun.

- Acid. It is not used on pipelines that transport acid or on fragile pipes.

- Silicone . This is a universal composition. It is necessary for sealing socket joints of sewer pipes.

If a leak has formed in the plastic pipes of the heating system, it will be much more difficult to get rid of it.

Most often, such a highway is laid using a hidden method.

Therefore, if you need to eliminate a leak in a plastic pipe, you first need to make sure where exactly it is leaking.

In this case, you will not be able to do without dismantling decorative panels or other wall coverings.

Has a plastic pipe leaked at the junction ? Most likely, low quality pipes and components were used when installing the system.

Therefore, it may be worth considering replacing as much of the pipeline as possible, or even the entire system.

Because otherwise you will not be able to protect yourself from regularly occurring leaks.