Causes of damage to aluminum radiators

Aluminum radiators are not durable compared to bimetallic and cast iron ones. In apartment buildings, they most often leak due to pressure drops in the system and water hammer.

Changes in water or coolant temperature also affect the condition of the batteries. If a liquid hotter than 100 degrees circulates in the heating system, it can damage the gaskets and sealant.

When water or coolant boils, the pressure in the central heating system (central heating system) can rise significantly. This often results in damaged sections. In some cases, an aluminum radiator may simply burst.

Sometimes problems are due to incorrect installation. Moreover, an aluminum radiator can leak several years after installation. In this case, you can only rely on yourself and hope that the other batteries were connected correctly without violating the installation standards.

If you have cheap aluminum batteries installed, there is a risk of manufacturing defects. No one is immune from this and it cannot be determined in advance. Therefore, before you buy a radiator, think about it: isn’t it easier to pay a little extra and buy a good battery than to fix problems?

Battery Features

Despite all its attractiveness, this type of heater is in the least demand among consumers due to the prevailing opinion that the service life of aluminum radiators is short, and they have many shortcomings and “claims”.

This is not entirely true. Aluminum heating radiators have a number of attractive features that have won the hearts of many customers.

Among them:

- They are able to withstand pressure drops of up to 20 atmospheres and above. If they are intended to be installed in a house with centralized heating, then you should carefully study the operating system and, when choosing radiators, familiarize yourself with their technical characteristics specified in the data sheet.

- Aluminum radiators weigh little , so they are easy to both transport and install.

- Their device is so simple that, if necessary, it allows you to repair aluminum heating radiators with your own hands if you have the necessary tools .

- High heat transfer ensures rapid heating of the room while saving energy resources .

- A small volume of coolant provides almost instantaneous heating of the entire radiator area.

- Aluminum radiators have a stylish design and fit perfectly into any environment.

Such a number of advantages could make them leaders in sales on the heating systems market, if not for the fact that they “feel” best in individual heating systems.

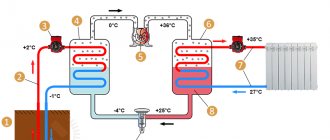

This is due to the fact that aluminum is susceptible to corrosion in the absence of a coolant for a long time (as is known, in centralized systems it is drained in the warm season) and its purity and alkaline balance.

If with autonomous heating the quality of the media can be monitored and left in the system, then in an apartment building with central heating it is very difficult to do this.

If aluminum batteries are installed correctly and operated in the conditions required for them, then their service life significantly exceeds the warranty (10 years) from the manufacturer. Repairing an aluminum heating radiator will not be as difficult as adding additional sections.

Locate the leak

When an aluminum radiator leaks, the most difficult thing is to determine the location of the damage. Believe me, it's not as easy as it seems.

When you see a puddle on the floor under the radiator, you can determine which section the water is coming from. But the shape of the sections is such that it is difficult to look under the outer feathers; the gap between them is usually 4-6 mm. Therefore, you will not be able to determine the real cause and location of the damage.

First of all, inspect the joints at the top of the radiator. They are visible through the gaps between the feathers that remove air. If there are drops of water on the connection or it is wet, you are in luck.

and you are deprived of most of the problems with “making a diagnosis”. You can proceed to the section “How to fix a leak between sections of an aluminum heating radiator.”

The lower joints are difficult to inspect, since you cannot get close to them. You can feel them with your fingers, but it’s better to be smart. Use a small mirror to examine them.

Advice

To better see the inside of the radiator through the mirror, shine a flashlight on it. The light reflected by the mirror will fall on the inner parts of the sections.

If all connections are dry, then the problem is more complex and a crack has appeared on the side wall of the radiator. In this case, water drips onto the floor from one of the feathers.

The easiest option is to simply remove the damaged section. But if you don’t want to do this, you will have to find the leak and fix it.

Repair Tips

Sometimes flushing the system is enough. Then you need to shut off the riser or individual coolant supply point, remove all the elements, and take them outside.

You can try to carefully rinse the pipes at home, but this requires a lot of water.

The jet is supplied under strong pressure, washing away all the dirt. An iron sewer cable is used to clean the space inside the pipes. The action is carried out until the water is clear.

If it is not possible to remove the batteries, then you can use chemical compounds that are pumped into the heating system. To ensure that the product passes through the entire system, a circulation pump is used.

All deposits are gently corroded without damaging the pipes or radiators from the inside. Some compounds create an additional layer of protection that prevents the deposition of rust for a long time: the coating is washed out very slowly, which will last until the next scheduled wash.

Professional cleaning without removing batteries

You can hire a professional to do the washing, who will come with special equipment. He performs cleaning work quickly and without damaging the pipeline, and can immediately check for damage in different places of the heating lines.

If calling a specialist is expensive, then you can limit yourself to diagnostics, which many specialized companies offer to carry out free of charge. In this case, troubleshooting is carried out on your own.

You can see more details on how to properly repair an aluminum radiator in the following video:

Checking the side walls of aluminum radiator sections

Now comes the hardest part...

The problem is that 95% of leaks occur only when water or coolant is under pressure in the radiator. It won't work to remove a section, fill it with water and see where it comes out from.

Unfortunately, at this stage you will have to work hard. To find out exactly where the aluminum radiator is leaking, you will have to dismantle the sections.

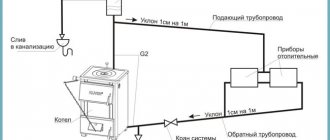

If your radiator is installed and connected correctly, then there are taps on the lower and upper pipes, and they are connected to each other via a bypass. You need to do the following:

- Close the valves on the supply and return pipes;

- Open the bypass;

- Drain the radiator.

To drain the water from the battery, first unscrew the top plug, then the bottom one. When the water has completely drained, you can begin dismantling the sections.

If there is no bypass or taps, you will have to turn off the entire heating system. This is not difficult to do in a private home. In an apartment building, for this, contact the employees of the housing office, housing and communal services or a regular plumber. In some houses (especially new ones) you can turn off the heating only in your apartment.

Options for leaks and searching for section damage

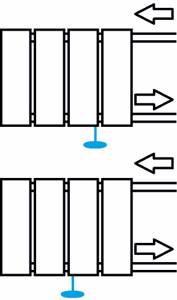

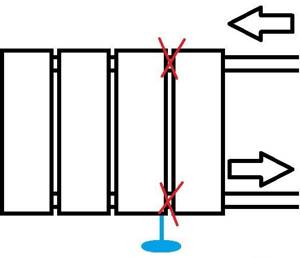

In this situation, two options are possible (see figure).

Options for radiator side wall leaks.

If an aluminum heating radiator leaks from the side of the section that is located further from the supply pipe, you must do the following:

- Using a nipple wrench, unscrew the nuts located between the leaking section and the intact one located further from the pipe (see figure) ;

If a leak appears from the side of the section located closer to the supply pipe, proceed as follows:

- Using a nipple wrench, unscrew the nipple nuts located between the leaking section and the intact one located closer to the pipe (see figure) ;

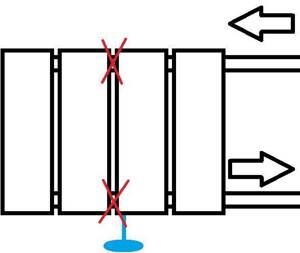

- Unscrew the damaged section;

- Turn it so that the wall on which there is a leak is located further from the pipe;

- Install the damaged section using a nipple nut and wrench.

After these manipulations, you need to completely seal the radiator:

- Screw the bottom plug;

- Install the Mayevsky tap in the upper hole of the radiator and unscrew it two turns;

- Open the water supply and close the bypass slightly.

After this, the radiator will begin to fill with water, and the air will exit through the Mayevsky tap. When water comes out instead, turn off the tap. There is now fluid in the radiator that is under pressure.

At the site of a crack or break in the radiator wall, water will begin to leak out. It's done - you've found a leak.

Important!

If the joints between the nipple nut and the radiator were treated with sealant, you will also need to use it. This also applies to the places into which the plugs and Mayevsky tap are screwed.

Why is there a leak or no heat transfer?

It is not difficult to recognize from the outside that the system is leaking somewhere. Where there are threaded connections, a white coating forms, and when the heating system is running, heat transfer becomes worse. But it’s not so easy to figure out the cause of the breakdown; the cause of the problem can be:

- incorrect installation of the threaded connection;

- pressure changes, increased acidity of water. Acidity promotes metal corrosion;

- As a result of using poor quality water, limescale may appear. Also, plaque heavily clogs the inside of the batteries, thereby narrowing the heating passage;

- wear of the spacer elements between the battery sections;

- The battery type is not suitable for the heating system.

In apartments, at the discretion of the management company, inspections and preventive maintenance of heating devices are carried out by specially trained people.

How to eliminate a leak between sections of an aluminum radiator

There are three reasons why leaks may occur at the joints between sections, namely:

- Gaskets or sealant allow fluid to pass through;

- The nipple nut is cracked or its thread is broken;

- Thread failure in the section mounting hole.

First, completely unscrew the nipple nut and inspect it. If it is cracked, just replace the old one with a new one. If there is damage to the thread of the mounting hole in the section or the nipple nut, you can simply wrap it with fum tape and install it in place.

If there is no visible damage, replace the gaskets. Some radiators (especially cheap ones) use a sealant. Sometimes nothing is installed at the connection points. Be sure to put in a good gasket, even if it wasn't there. Remove any remaining old gasket or sealant completely.

Tools used to repair aluminum radiators

Disassembly, inspection and other preventative work on the radiator are carried out on the floor, and washing is done in the bathroom or outside. To begin work, you need to take care of the safety of the floors and cover the covering with plastic film. When working in the bathroom, the bathtub is also covered with material that protects it from mechanical damage.

We recommend: Is it possible to install bimetallic radiators on central heating?

The following accessories are useful for working with radiators:

- wrenches of different sizes;

- nipple key;

- rubber mallet;

- sandpaper;

- special lubricant;

- silicone gaskets.

During installation work, situations may arise when it is necessary to replace nuts or nipples.

It is better to postpone the start of repair work to weekdays, since it will be possible, if necessary, to go to the store for the necessary spare parts.

When washing, you need to prepare a container to drain the water after cleaning the battery.

Repair of side walls of aluminum radiator sections

If a crack has formed on a section, then only argon soldering will help. Cold welding and sealants are powerless here - they will not be able to penetrate deeply and securely fix in the metal.

If you have an individual heating system whose pressure does not exceed 5 bar, you can use automotive radiator sealant. But this is too expensive an option - the sealant is not cheap, and you will have to pour a lot of it into the system.

If there is a pinhole at the leak site, you can use cold welding. The main thing is that it gets inside the radiator. Then, after hardening, the cold weld will form a kind of plug and will hold well. This option is not suitable for small holes.

Hole on the wall of an aluminum radiator. It can be sealed using cold welding.

- Using cold welding, you can seal holes with a diameter of more than 2 mm. Here is the full algorithm of actions:

- Heat a piece of cold weld under hot water (wrap it in plastic to avoid contact with moisture);

- Knead it;

- Apply cold weld to the hole and push it inward;

- When you are sure that part of the weld is in the internal radiator channel, remove the residue from the outside.

Important!

Before applying cold welding, the radiator must be dry and degreased. To do this, pour a little solvent or white spirit into the hole and wait until it dries.

Advantages and disadvantages of aluminum radiators

First of all, you should consider the distinctive features of this type of device in order to better understand their structure and the fundamental difference from other batteries. Experts highlight some main features as advantages:

- Low weight of batteries, which greatly facilitates transportation and especially installation and dismantling of equipment - even one person can handle it

- High heat transfer, allowing you to quickly heat the room and significantly save on fuel consumption.

- The batteries have a reduced coolant volume, which speeds up the heating of the liquid. This did not affect the heat transfer - it is no lower than that of analogues with a larger volume.

- Radiators work well with any temperature control and maintenance equipment and have low thermal inertia. They respond to all changes very quickly, which allows for significant heat savings.

- A large selection of stylistic solutions and modern design will allow you to choose the best option for any room design.

However, the devices are not without their drawbacks.

Disadvantages of devices

The disadvantages include the following facts:

- Aluminum is soft and has low resistance to deformation. A blow that steel or cast iron can easily withstand will easily damage aluminum. Moreover, damage is not uncommon during the transportation and installation of products. If you do not calculate the force, you can easily break the thread at the point where the nipple is attached.

- Despite its generally high corrosion resistance, the material does not tolerate the presence of copper in the system. If the boiler liner or heat exchanger is copper, and the system contains ordinary water, the process of electrical corrosion is very active, which can completely ruin aluminum batteries within a few years.

- If the coolant is not a special solution with an optimal acidity level, but simple water, then hydrogen is formed during the reaction with aluminum. It can rupture the radiator, so installing a large number of pressure relief valves is highly recommended. The system is also demanding on the quality of the coolant - bad water causes accelerated corrosion.

- Sensitivity to pressure in the system is optimal up to 9 atmospheres. In most multi-storey buildings, the pressure significantly exceeds the strength threshold of aluminum and amounts to 10 atmospheres or even more. Therefore, you need to be prepared for annual repairs, and it is better to purchase radiators made of more durable materials.

- Aluminum is not resistant to water hammer.

What am I doing wrong?

Most people think this: if an aluminum radiator leaks, it’s enough to simply fix the leak. But think about it - if something went wrong, there is a reason for it. Without eliminating it, you risk stepping on the rake a second time.

After repairs, be sure to reduce the pressure in the system. In a private home, this is quite simple to do - adjust the pump or configure the controller on the equipment.

In an apartment building - open the bypass slightly or screw the valve on the supply pipe. If the radiator has a thermostat, lower the temperature.

We hope that the publication was useful, but you will not find it useful. You can ask your questions in the comments. Don't forget to share it on social networks

Dismantling works

Only after the battery is removed from the wall can you begin repair work. Radiators made of aluminum are not very heavy and therefore one person can easily remove them from the wall. Before removal, it is necessary to unscrew the nuts and dismantle the radiator. Everything is done in the following steps:

- the circulating pump stops and the pressure in the system is released;

- The radiators are cooling down. The structure is disconnected from the pipe connections. The couplings are being removed;

- remove the battery from the brackets;

- the remaining water is drained into a previously prepared container. The structure is laid on woven material;

- The filter elements are pulled out and washed with a soapy water solution.

At the next stage, disassembly work into elements begins. The most important point will be to disconnect the nipple. When twisting it, the section moves away.

It is worth paying attention to the letters S and D near the threaded connections. Where the first means left-handed thread, and the second, respectively, right-handed. Do not unscrew with a tearing motion, otherwise you can easily break the threads. Everything is done as carefully as possible. If the threaded connection is difficult to unscrew, it is better to increase the lever.

Disassembly of threaded connections is carried out in stages on both sides. We turn the nipple a turn or two, then do the same with the nut of the opposite side. By gradually weakening both sides, the section will be protected from unexpected breakdowns and other damage.

Sections have been dismantled. The metal seals are removed and washed. If severe mechanical damage is found anywhere, then it is worth replacing spare parts. The silicone gasket must be replaced.

We recommend: Which central heating batteries to choose?

How to deal with a breakdown in a matter of minutes? Do-it-yourself repair of aluminum heating radiators

Aluminum radiators are widely used in heating systems , have reasonable cost, are easy to install and have good heat dissipation.

The stylish appearance and the ability to install radiators even under low-height window sills have made them one of the best options for most houses and apartments.

But, like any other items, radiators can break. Some causes of breakdowns can be easily eliminated at home without the involvement of third-party specialists.