SNiP requirements

Any construction work, including the installation of heating radiators, is carried out in accordance with certain rules and regulations. The technical data sheet of each heating device contains detailed information regarding the type of battery mount. However, it would be a good idea to familiarize yourself with the requirements specified in SNiP 3.05.01-85.

Here are the main standards:

- The location of the heating device is considered optimal if its central point is as close as possible or completely coincides with the central vertical axis of the window. Deviation in one direction or another is allowed no more than 20 mm.

- The width of the heating device should be about 50-75% of the window size. This norm is not strictly mandatory and is rather advisory in nature. The fact is that the reliability of fastening for heating radiator batteries does not depend on their size - it will only affect the amount of heat transfer.

- The distance from the radiator to the floor covering must be at least 60 mm - this is a fire safety requirement.

- There must be a gap of at least 25 mm between the heating radiator and the wall, and even better - 30-50 mm.

- There must also be a gap between the window sill and the battery - at least 50 mm.

- It is important to choose the right number of support points, that is, wall mounts for heating radiators. For a radiator with 6-8 sections you will need two upper and one lower holder. For every subsequent 5-7 sections, you will need to add one more holder at the top and bottom.

- In the same way, the number of floor racks for radiators is selected. A battery of 6-8 teeth is installed on two support points, and with the addition of each subsequent 5-7 sections, another mount is installed.

- The number of heating radiator cells should not be too large. If the system operates in conditions with natural circulation of water, for example in a private house, no more than 12 teeth in a row can be installed there. If we are talking about multi-storey buildings in which the coolant circulates under constant pressure, it is permissible to install a radiator with a total number of sections of up to 24 pieces.

Please note that to reduce heat loss as a result of pointless heating of the external wall, it is recommended to place heat-insulating foil material behind the radiator. It will redirect heat waves indoors.

Preparation for installation

At the stage of preparing cast iron radiators for installation in a heating system, the following tasks are performed:

- selection of a suitable battery, its purchase;

- purchase of additional elements (Maevsky crane, mounting brackets, brackets, paint, sealant, tow);

- preparation of working tools for battery installation.

Heating radiators made of cast iron can withstand operating pressures of up to 9 atmospheres, and before they go on sale they undergo individual hydraulic testing.

For one minute, such a cast iron battery can withstand a pressure of 15 atmospheres, but given the fragility of cast iron products, they should be transported extremely carefully. Sometimes it is even possible to disassemble into sections before transportation.

At the end of the testing, the product is painted and dried. Paint and varnish products are subject to basic conditions that meet the following technical characteristics:

Painting cast iron radiators

- resistance to the influence of corrosive processes;

- resistance to high temperatures. At the same time, the temperature for the radiator according to standards should not exceed 80 degrees;

- The paint should not change color during battery operation.

Enamel paints and varnishes are most suitable for painting cast iron radiators. Such battery paints do not contain harmful components that can evaporate during painting or drying. Acrylic-based paint products are also quite suitable. Its advantages are the ability to withstand high temperatures and the ability not to disturb the structure of the coating, that is, not to crack.

To keep the cold out from the street, cast iron radiators should be installed under a window opening.

This creates a thermal curtain. According to standards, the battery is supposed to occupy a distance not exceeding 70% of the window opening.

For the most efficient heat circulation, the following requirements must be observed:

- the location of the product from its upper part to the window sill and from the floor to its lower part should be approximately 5-10 cm, and a gap of 2-5 cm should be left from the wall;

- The battery fins should be positioned exclusively vertically;

- the center of the device must coincide with the center of the window opening, the maximum possible deviation should not exceed 2 cm;

- it is necessary to connect the radiator only after its installation;

- within the same room, all batteries should be installed at the same level.

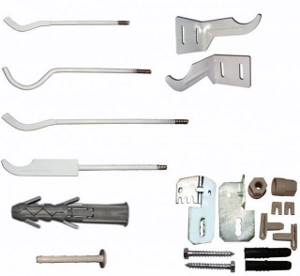

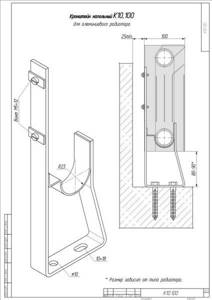

Fasteners for cast iron batteries

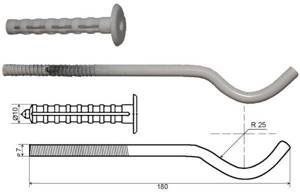

The currently quite popular cast iron radiators are heavy, so the stand for the cast iron radiator must be reliable enough to withstand such a load. As a rule, for cast iron radiators, metal pins are used, bent to the shape of the section.

The installation technology in this case is quite simple. First, a hole of the required diameter is drilled in the brick, then a dowel is inserted into it and the fastening pin is screwed in. If you need to fix the bracket in a reinforced concrete wall, the technology will be slightly different.

Since it is quite difficult to make a hole of great depth in a reinforced concrete slab, the fastening pin is fixed on a small metal plate. It is attached to the slab at four points, but at a shallower depth. The reliability of such fastening in both options is approximately the same.

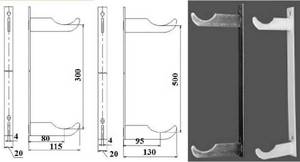

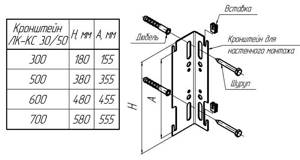

A stand for a cast iron radiator is sometimes a mounting plate with two support points. Such a fastening element is fixed to the wall in such a way that the upper and lower brackets bear approximately the same weight of the radiator. On sale you can find planks with brackets fixed at a certain distance, as well as with adjustable elements.

Quite often, floor mounting racks are used for cast iron batteries. Just like vertical slats, racks are monolithic and adjustable.

Please note that there are two ways to secure the battery to the stand. The standard option is fastening with a metal bracket. Some models use a flexible chain of several links for fastening.

It is worth noting that the markings on the mounts for cast iron radiators indicate that they are reinforced. This information must be taken into account when selecting mounting brackets.

Installation of cast iron radiators

The installation process of heating equipment requires special skills and must be carried out in accordance with European standards. It is better to entrust the installation of cast iron heating radiators to professionals. Specialists will take into account the characteristics of the premises in which the batteries are installed and will carry out the installation in accordance with the standards. The general rules for installing heating systems include the following points:

When installing batteries, it is important to choose fasteners that will support the weight of the product and will not change their properties throughout the entire period of operation.

The most popular ways to mount equipment to the wall are cast iron brackets, steel clamps and pin mounts. If the fastening is incorrectly selected, an emergency situation may be created and the heating system may be deformed. Installation of cast iron products will not cause any difficulties when installed on brick and concrete walls. The fastening process consists of making holes, hammering dowels and installing brackets. If the wall is made of plasterboard or wood, the best option would be to use special stands and props that will transfer the load to the floor.

Installing cast iron appliances in a room allows you to create the most cozy and comfortable microclimate. The price of cast iron batteries is slightly higher than that of similar heating devices made of other materials, but this is justified by the advantages of the products and their resistance to various factors. The price for installing cast iron heating radiators is quite low, and the work of certified craftsmen will ensure the reliability of the heating system for more than twenty years.

Fastenings for steel radiators

Steel batteries are available in several configurations - they can be tubular or panel. In this regard, the holder for the heating radiator must be selected individually, based on the type of fixation.

For mounting panel heating radiators on the wall, special brackets are produced that look like metal corners. One wing of the wall bracket for a heating radiator is fixed to the wall using anchors, and the other is equipped with special hooks for hanging the battery. The panel-type radiator itself has brackets with which it is attached to hooks.

Some models of steel panel radiators do not contain mounting brackets, so they are mounted on vertical strips with clamps. Since such batteries are light in weight, this type of mounting is quite acceptable.

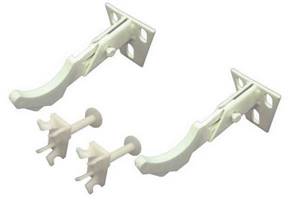

Tubular steel radiators are attached a little differently. Due to the low weight of the structure, only 2 upper supports are sufficient to fix it. Plastic clips are installed at the bottom of the radiator, which rest against the wall to hold the battery in a vertical position.

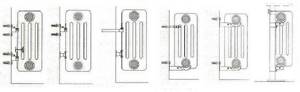

How to fix cast iron radiators

Depending on the individual characteristics of the room, you should select an option for installing products that will ensure uniform distribution of the load and prevent destruction of the wall of the home.

To Wall

Installing wall mounting systems is the most popular method used when installing heating in a home.

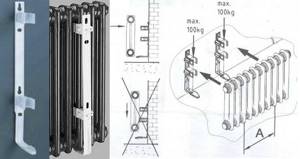

Photo 1. Quick wall mounting of radiators using a special strip with clamps. Maximum load 100 kg.

The fasteners are designed to withstand increased loads from equipment and can provide durable service even under adverse operating conditions. Most systems are used for installation on brick, concrete and wooden walls . Wall mounting of cast iron radiators is not suitable for equipping houses made of plasterboard and lightweight foam blocks .

Floor installation

In cases where the walls are not intended for the installation of cast iron batteries, floor fasteners are an excellent solution. The fasteners transfer the entire mass of the radiators to the floor and relieve the load from the walls. Despite the fact that floor fasteners are quite reliable and stable , sometimes it is necessary to install additional wall clamps to hold the batteries in a certain position.

General recommendations

Recommendations for installation of heating devices:

Fixing bimetallic and aluminum batteries

If we talk about the mass of bimetallic and aluminum radiators, then in terms of this parameter they are almost identical. Therefore, a bracket for a bimetallic radiator can be successfully used to mount an aluminum battery.

A fastening element of this type is practically no different from a stand for a heating radiator made of cast iron. The only difference is the lower load-bearing capacity. As a rule, such clamps are universal corners, one side of which is fixed to the wall, and the other contains recesses on both sides. This configuration allows such fasteners to be mounted in any direction.

It is noteworthy that bimetallic and aluminum batteries do not initially provide for the possibility of floor mounting. However, attaching radiators to surfaces such as glass, plasterboard or sandwich panels is not possible. In this case, a floor bracket for aluminum radiators is used, similar to racks for cast iron batteries.

How to choose the right bracket

The main rule when buying a retainer: it must withstand the weight placed on it. The maximum load is usually indicated in the included instructions. It is easiest to choose a bracket for an aluminum radiator, since it weighs little and any type is suitable for it.

For very powerful batteries, use floor stands. But if the covering in the house is wooden, then you need to make sure that the clamps are equipped with additional fasteners to the wall. This is necessary in order to reduce the load on the boards. For light heating elements that will be located in a deep niche under the window, it is better to buy a long bracket.

For cast iron radiators, it is recommended to use holders with the ability to slightly change the height, otherwise installation difficulties may arise. The price of an adjustable bracket is not so high as to give up installation convenience.

It is important that the alloy contains no toxic substances released when heated. You should not buy parts secondhand, especially without the appropriate accompanying documents. Please note that the lightest one - the corner bracket - is intended only for aluminum and copper radiators.

Work technology

Owners of private houses can replace radiators at any time convenient for them. To do this, just turn off the boiler and drain the water from the heating circuit. But in an apartment in a multi-storey building, the replacement of the radiator will have to be previously agreed upon with the servicing utility organization.

If all installation work is carried out in the summer, when the heating is turned off, there will be fewer difficulties. However, you will still have to clarify whether water was drained from the system or not.

Please note that many experienced mechanics advise replacing radiators while the central heating is running. This is done because when the coolant is supplied to the circuit under pressure, you can immediately check the functionality of the radiator - if the installation was carried out incorrectly, leaks will occur.

The efficiency of their operation will depend on how well the radiators are mounted to the floor or to the wall. The fasteners must be installed absolutely level, since if they are skewed, problems may arise when connecting the system.

Using available means - a pencil, a level, a plumb line and a tape measure - perform the initial markings. Mark the central axis of the window, which should coincide with the middle of the radiator. A horizontal line is drawn through this point along which the upper supports will be attached.

In cases where there is only one lower support element, it is mounted on the central axis. If there are several of them, another horizontal line is drawn parallel to the top line. After marking, begin drilling holes and installing brackets.

Results

Each type of heating radiator requires the use of special fasteners. In some cases, they come complete with a battery. However, they are often difficult to install and are not of high quality. Therefore, it is recommended to make sure that the fastenings are reliable and, if necessary, now purchase modern and high-quality products separately, even if they are more expensive.

The procedure for installing radiators does not depend on their type: the rules remain the same, only the fasteners change. If installation under a window is intended, the following distances must be observed: from the floor should be at least 80-120 mm, to the window sill at least 60-100 mm, to the wall - 30-50 mm. It is also necessary to decide on the quantity and location of fasteners.

The number of brackets (hooks) per battery depends on its length. If there are few sections - up to 8-10 pieces - then two holders are required at the top, and at least one more at the bottom. If there are more than 10 sections, install three supports on top and two below. For each next five to seven sections of cast iron radiators and ten tubular and aluminum ones, the number of fasteners increases: one holder is added at the top and one at the bottom.

Methods of using various types of fasteners for sectional radiators

Rules for floor mounting of the battery

Radiators are rarely installed using floor mounting, and if installed, it is for the following reasons:

- There is not enough space on the wall. For example, a window that is too large does not leave space for a radiator.

- Special requests and aesthetic considerations. Some designer batteries have a special design that requires only floor mounting, or the stylistic design of the room requires mounting the radiator on legs or on a pedestal.

This installation method has the following advantages:

- 100% reliability;

- high installation speed;

- simplicity;

- can be used with all types of batteries (including cast iron).

You need to make marks on the floor, depending on how the future structure will be placed. Using fasteners, each holder is firmly fixed to the floor. If the battery weighs little, then the kit should include small legs, and not large and heavy brackets. They are attached the same way.

The last step remains - attach the radiator to the already installed elements and connect it to the pipes.

Each threaded connection should be tightened sufficiently, but applying too much force is dangerous. It is recommended to use a torque wrench; the corresponding indicator should be indicated in the radiator installation instructions.

Replacing a heating device is not only about saving money. This process requires maximum care and attention. If you do not have confidence in your own abilities, it is better to turn to professionals.

Did you manage to solve your problem using the recommendations from the article?

Yes!

46.61%

No. More answers required. I'll ask in the comments now.

37.17%

Partially. There are still questions. I'll write in the comments now.

16.22%

Voted: 339

Marking the installation locations of the brackets

Since it is better to place the radiator strictly in the middle of the window opening, find the middle on the wall and draw a vertical line. After which there are two options: with the lower wiring, draw a horizontal line that will mark the upper edge of the installed radiator. When replacing a radiator with a side connection, the location of the supply pipes is important. Therefore, in this case, we draw a horizontal line that comes from the upper (usually supply) pipe.

Measure the distances between the fasteners on the battery, and set them aside relative to the marked lines. Sometimes you have to attach fasteners and measure it this way: it depends on the type of heating device and on the type of brackets or holders used.

How to install a radiator correctly, read the article “Installing batteries with your own hands: rules and technology”

To securely fasten the radiator, it is important to choose the right fasteners. There are a large number of brackets designed for different types of radiators.

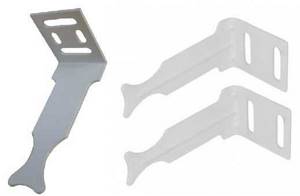

Fasteners for cast iron batteries

Since these are the heaviest heating devices, the holders for them are the most massive: they must hold considerable weight for years. These can be individual or curved pins attached to a bar. In any case, when making mounts for cast iron batteries, thicker metal is used. In price lists it usually comes with the addition of “reinforced”. Can be painted (standard color is white) or not. Some manufacturers paint it in the desired color upon request (when ordering a radiator, specify the type of fastener and its color).

The mount for a cast iron battery is made reinforced: made of thicker metal

When purchasing, you will need to take into account the dimensions: fastenings for sections of different depths are made specially, since it is necessary to ensure a distance to the wall of at least 3-5 cm.

In addition to brackets for cast iron radiators, they also produce hooks. They are sold in pairs with dowels. Installation is standard: a hole is drilled, a dowel is inserted into it, and a hook is screwed into the dowel (there is a thread on one side).

There are mounting strips for cast iron radiators that make installation easier

In addition to wall mounting, there are legs for floor installation. They come with adjustable height or not. The upper arcs that fix the section to the stop are also different: there is an arc made of steel wire, and there is a chain of movably connected links. In both cases, the batteries are fixed to the support using these arcs and bolts.

Types, design and application of fasteners

Wall mounting

Here, manufacturers do not spoil us with variety: wall mounting brackets come in only two varieties.

The product is suitable for lightweight aluminum batteries.

This type of fastener has a greater load-bearing capacity.

Please note: it is better to hang massive cast iron heating devices on pin brackets.

crazy hands

If for some reason you do not have the opportunity to purchase a mounting kit for wall mounting of a radiator, the situation can be saved by ordinary smooth fittings with a diameter of 10 - 12 millimeters.

Floor mounting

Here are the most common types of floor brackets.

This floor mount for aluminum radiators is designed for fixed depth sections (100 millimeters). The heater is installed on a support with the lower manifold; the rear fins of the sections are fixed with a pair of screw clamps.

Methods of fastening aluminum and bimetallic radiators

Products that are very similar in shape are used. Only they are made from thinner metal. In general, brackets for sectional radiators of any type are very similar. There are universal corner brackets for aluminum and bimetallic radiators. They have a recess at the top and bottom for the collector, so they can be mounted on both the right and left.

Special corner brackets for lightweight sectional radiators

There are no floor-standing aluminum or bimetallic radiators. But there are racks that allow you to install any of them on the floor. In this case, the rack is first fixed to the floor, and then the heating device is installed and secured on it.

Floor mounting of aluminum radiators helps if the walls cannot withstand even such a small weight (if they are made of plasterboard or aerated concrete, or other similar materials).

Any sectional radiator can be mounted on such racks

You won’t be able to hang anything on the now fashionable glass wall. But then you need to pay attention to what the entire structure looks like from the reverse side. In this case, for heating it is more advisable to use convectors built into the floor, floor-standing models of tubular radiators (at the same time they can serve as a fence), and cast-iron retro radiators.

Features of mounting a heating battery to the wall

Attaching heating radiators to the wall surface is not a labor-intensive process, but it has its own characteristics and subtleties. Installation of heating radiators to the walls is one of the important stages of work on organizing a heating system. The rules for fixing radiators primarily depend on the material from which they are made. To do this reliably, you should know about the types of these elements of the heating system, fastening options and take into account other subtleties of the work process. Then attaching radiators to the wall will not cause you any difficulties.

Types and features of batteries

- Cast iron radiators are characterized by thick walls and resistance to corrosion. They retain heat for a long time and have a long service life. However, it is the large weight of these products that makes it necessary to make the most durable fastenings and supporting stands for them.

- Steel batteries are light in weight, which makes their installation not difficult at all. But they are short-lived and quickly lose heat.

- Aluminum products for the heating system are attractive in appearance, the installation of which is also simple due to their light weight.

- Bimetallic radiators are considered the most universal, combining the properties of steel and aluminum structures. Their installation is also not labor-intensive.

Mounts for different types of batteries

To attach heavy heating appliances to the wall, you should choose massive holders that can easily hold a lot of weight for many years. For such products, thicker, more solid metal is used, most often marked as “reinforced”. For this purpose, brackets and hooks are available for sale, supplied with dowels. After drilling a hole in the wall, just insert the dowel and screw the hook into it.

Often, cast iron batteries are equipped with legs that can be adjusted in height. In order to hang them on a wall made of concrete or brick, you can use standard dowels, but in the case of plasterboard or wooden walls, it will be necessary to provide an additional floor base. In this case, the legs will come in handy.

To attach bimetallic, aluminum and steel radiators to the wall, similar brackets are used, only made of thinner metal. Convenient in this case are corner fasteners, which are considered universal and equipped with recesses for the collector. Such parts can be fixed on both the right and left. However, for heating radiators of these types, there are also special racks that allow them to be installed on the floor.

Basic subtleties of work

The type of heating system plays an important role in the entire operation. With single-pipe heating, a bypass will be necessary, allowing, if necessary, to turn off individual sections of the heating system. To work on mounting radiators, you will need to prepare all the necessary tools and materials:

- plugs and stoppers;

- dowels;

- taps and brackets;

- construction level and hammer drill.

When attaching radiators to the wall, you should follow some rules to do the job as efficiently as possible. First of all, the following dimensions must be observed:

- Be sure to take into account the distance of the structure from adjacent surfaces. So, the space from the floor to the radiator should remain at least ten centimeters. Approximately the same distance should be maintained from the batteries to the windowsill for uniform air distribution.

- The distance from radiators to walls must be maintained within three centimeters.

In addition, you should take into account other nuances that allow you to correctly fasten the elements of the heating system:

- Square footage of the room. The number of sections of the heating device depends on this parameter, which plays an important role when mounting.

- The number of brackets must be chosen with reserve. It is advisable to use at least three brackets: two on top and one on the bottom. But it is best to use four, two at the bottom and two at the top. If the battery size exceeds 10 sections, it is recommended to increase the number of brackets to six.

Procedure for attaching batteries to the wall

- After carrying out all the necessary calculations and purchasing materials, you can begin fixing the heating devices. Before mounting, the wall surface should be prepared by plastering or wallpapering.

- The space for hooks or brackets is marked. Using a building level and a ruler, all measurements are carefully taken, and only then drilling is carried out.

- Dowels are inserted into the holes made and fasteners are screwed in.

- After hanging the battery, you need to check that it is fixed correctly and make sure that there is no play. After trying on the batteries, it will be clear whether the work was done correctly. If the radiator is seated tightly, immobilized and its weight is distributed among the fasteners, then we can conclude that everything was done technologically correctly. A horizontal level and gaskets of the required thickness, which are installed where they come into contact with the brackets, will help eliminate the possibility of radiator distortions.

- Only after this should you begin connecting radiators to other elements of the heating system.

Problems of insufficient fastening of batteries to the wall

Correct and reliable fastening of heating devices to the wall is a guarantee of peace and well-being of apartment residents. Insufficient fixation of batteries, especially in combination with the following factors, can lead to deformation of the product or depressurization of seams, which will cause leaks. That is why it is very important to install them correctly and reliably.

So, the factors that aggravate the improper fastening of batteries:

- mechanical damage to devices during their operational life;

- distortions of heating radiators when filling them with water.

mr-build.ru

Fasteners for steel heating devices

There are two different types in this group: tubular and panel radiators. They have different designs and, accordingly, different fastenings.

In panel radiators, brackets are welded on the rear wall, with the help of which they are hung on brackets. The shape of this type of fastener is different: it is designed specifically for staples.

In panel radiators, brackets are welded on the rear wall

When installing panel radiators, it is necessary to strictly monitor the vertical position of the brackets. High precision is required: four or six staples must fit exactly onto the hooks. It is also important that the wall is perfectly flat and smooth. In general, using conventional brackets, panel radiators are quite difficult to hang. It is easier to work with other types of holders.

Standard bracket for panel radiator

Since the mass of the heating device is small, it is quite enough to fix it on the upper brackets and install stops at the bottom that will give it direction in the horizontal plane. They are not attached to the wall, but are hooked onto a bracket and simply rest against the wall. For reliability, the part that faces the wall is expanded.

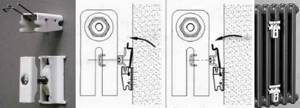

This is what a set of brackets for tubular steel batteries looks like: the upper collector is hung on the hooks, and plastic stops are placed below

There are also special mounting strips for easy installation. They are a strip of metal with plastic clips at the top and bottom. When using this fastener, there is no need for brackets on the rear panel. The slats are fixed to the wall, a radiator is inserted into them, which is held in place by plastic hooks.

Rail for quick installation of panel batteries

Fasteners for tubular radiators are similar to sectional ones: the same hooks, only of a different size, often equipped with plastic covers.

There is also a special fastener with SMB tube grips. This is a strip of steel with plastic clips and a shelf at the bottom that serves as a support for the radiator. This mounting plate can be used if the weight of the device filled with water does not exceed 100 kg. Installation is simple: place the battery on the shelf, bring the top edge closer to the latches. They grab the nearest tube and a click is heard. The radiator is installed, the supply pipes can be connected.

Bar for quick installation of a tubular radiator with shelf and clamps

There is a second option for quick installation: SVD fasteners. It consists of two parts. One is attached to the radiator, the second to the wall. Then they are connected to each other and secured with a steel loop.

Another type of holder for tubular models: two parts, one is attached to the wall, the second is attached to the pipe. They are held together with a wire fastener.

Floor mounting for tubular radiators can be of several types: tubular supports that are welded at the factory, or stands with hooks. Radiators are hung on such racks, and the racks themselves are attached to the floor.

Results

Brackets for radiators are of different types and types: for wall and floor installation. The standard ones that come with the kit are reliable, but they are more difficult to work with. Planks and devices for quick installation save time, but cost a lot.

The heating appliance market is striking in its diversity. But the familiar cast iron radiators are still popular due to their many advantages. They are durable, corrosion resistant, easy to use and very durable. But even the most reliable device may one day require replacement. You can solve the question of how to hang a heating radiator on brackets yourself. The main thing is to have experience, the necessary materials and take into account some installation nuances.

Modern cast iron radiators are an example of style

Advantages and disadvantages

The main advantages of cast iron batteries include:

- Public availability. Cast iron is an inexpensive material for batteries.

- Long lasting thermal effect. Cast iron takes a long time to heat up, but it also retains heat for a long time.

- Multifunctionality. Many people use batteries as additional space for quickly drying things.

The disadvantages of cast iron batteries include the following characteristics:

- Device weight. Cast iron batteries are quite heavy, and this leads to the need for installation by several people, which increases the cost of their installation.

- Long heating time. After connection, due to the long heating time, the house will remain at a cool temperature for some time.

- Appearance. Bulkyness and lack of smoothness in appearance often looks rather unaesthetic.

- Additional care. After installation, the product must still be painted to protect it from corrosive processes.

Features of selection and installation

Before starting work, you need to decide on the installation location. The heating device is placed in the area where the most significant heat losses are observed. As a rule, this is a place near the windows. Heat losses are not excluded, even if you have modern energy-saving double-glazed windows installed. There is no need to even talk about ordinary wooden frames.

If there is no heating device under the window, then the cold air falling along the wall “spreads” across the floor. Attaching cast iron radiators to the wall in this location will change the situation. Rising warm air will prevent the spread of cold currents.

Another area of heat loss is the area near the front door. But this is more often faced by owners of private houses and apartments on the ground floor. In this situation, the heating device is hung as close as possible to the entrance. When choosing a location in accordance with the layout, do not forget about sufficient space for the pipeline.

For the most effective protection, the radiator should account for at least 70% of the width of the window opening. When choosing the appropriate option, keep in mind that a small device will not provide the required comfort. A battery selected correctly in size will avoid cold areas on the sides of the window, condensation and dampness.

When looking at models for installing cast iron batteries, consider the climate of your area. Purchasing a device with high heat transfer will be justified only for very cold regions. For residents of the middle zone, batteries with average performance are sufficient; for residents of southern latitudes, low devices with a minimum number of sections are suitable.