Advantages and disadvantages

Before you start making heating registers, you need to evaluate all the pros and cons of these heaters, so that your expectations are not disappointed later. So, first about the advantages:

- low cost and ease of manufacture;

- low hydraulic resistance: thanks to this, the heater can be used in the “tail” of any system;

- reliability and durability: a register, qualitatively welded from ordinary pipes, will quietly serve for at least 20 years;

- resistance to pressure drops and water hammer;

- The smooth surface facilitates easy removal of dust when cleaning premises.

Unfortunately, a home-made heating register also has a lot of disadvantages. The main one is low heat transfer with a significant mass of the device. That is, in order to provide a comfortable temperature in a medium-sized room, the register must be of decent size. Let's give a simple example taken from technical literature. If the temperature difference between the coolant and the room is 65 ºС (DT), a register welded from 4 DN32 pipes 1 m long will deliver only 453 W, and from 4 DN100 pipes – 855 W. It turns out that, based on heat transfer per 1 m of length, any panel or sectional radiator is at least twice as powerful.

Other negative aspects of smooth-tube registers are not so critical, although significant:

- holds a large volume of water: the disadvantage does not play a big role if there are 1-2 such heating devices for the entire system;

- During operation, it is very difficult to increase or decrease the power of registers made of smooth pipes. You can’t do without dismantling the welding machine;

- are susceptible to corrosion and require periodic maintenance with painting;

- They have an unpresentable appearance: the defect can be corrected; if necessary, the heater is hidden behind a decorative screen.

Having analyzed the advantages and disadvantages of smooth-tube devices, we can conclude that their scope of application in private housing construction is very limited. As already mentioned, registers can be used for heating various rooms with low requirements for comfort and interior design.

When selecting materials, you need to decide what pipe diameters to take and what their total length should be. All these parameters are arbitrary; you can make a heater from any pipes, and take its length convenient for placement in the room. But in order to supply the required amount of heat, it is necessary to ensure a sufficient heat exchange area. To do this, it is recommended to perform an approximate calculation of the register based on the surface area.

Making such a calculation is quite simple. It is necessary to calculate the outer surface area of all sections in m2 and multiply the resulting value by 330 W. Proposing this method, we proceed from the statement that 1 m2 of register surface will give off 330 W of heat at a coolant temperature of 60 ºС and room air temperature of 18 ºС.

For a person who has welding skills, it will not be difficult to independently weld the register according to the available drawings. It is necessary to prepare and cut pipes into sections and lintels, and cut plugs from a steel sheet. The assembly sequence is arbitrary; after welding, the heater should be checked for leaks. When manufacturing and installing registers, consider the following recommendations:

- you should not take pipes with too thin or thick walls: the former will cool faster and last less, and the latter will take a long time to warm up and are difficult to adjust;

- do not forget to build a Mayevsky valve into the end of the upper section for bleeding air;

- when welding coils, the rotating section can be made from two ready-made elbows if it is not possible to use a pipe bender;

- Place a tap at the coolant inlet and a valve at the outlet;

- remember that the registers are installed with an invisible bias towards the connection of the supply pipe. Then Mayevsky's crane will be at the highest point.

Calculation of heating registers

To prevent the house from being cold and the heating to evenly warm all rooms, it is important to calculate the number of registers for each room. For purchased devices, their power is looked at in the passport and the number of devices is calculated; for homemade tubular heaters, the length of the pipes will have to be determined by yourself

Calculation of the required thermal power to heat the room

If your house is built according to a project, then data on the required power of heating devices is available in the documents - you need to find and use them.

If there is no design of engineering systems, then use traditional approximate data on heat loss:

- 100 W per 1 m² of room area with one external wall and one window.

- 120 W per 1 m² of room area with two external walls and one window.

- 130 W per 1 m² of room area with two external walls and two windows.

The total heat losses are calculated, the resulting power is increased by 20% (multiplied by 1.2) and the total power of all heating devices is obtained. In the northern regions of Russia, it is desirable to increase the resulting power by another 20 percent.

The power of the appliances in each room is calculated based on the above data (heat loss in the room multiplied by 1.2).

The exact method for calculating the heat loss of a house is very complex and is used by design organizations.

Calculation of register thermal power

The amount of heat (W) supplied from the pipe to the room is determined by the formula:

Where:

- K is the heat transfer coefficient, W/(m2 0С), taken depending on the pipe material and coolant parameters.

- F is the surface area, m2, calculated as the product of π·d·l.

- where π = 3.14, and d and l are the diameter and length of the pipe, respectively, m.

∆t – temperature difference, 0С, determined in turn by the formula:

- Where: t1 and t2 are the temperatures at the inlet and outlet of the boiler, respectively.

- tk is the temperature in the heated room.

- 0.9 is a reduction factor for a multi-row device.

For a steel structure, the heat transfer coefficient to air is 11.3 W/(m2 0C). For a multi-row register, a reduction factor of 0.9 is accepted for each row.

For calculations, you can use a calculation calculator - there are many of them on the Internet, but manually is more reliable.

Heat transfer of registers made of smooth pipes. Table

The values of heat transfer coefficients for steel smooth-tube registers are given in the table.

In private homes, the temperature difference is usually 60-70 °C.

How to calculate the required number of register sections

The number of purchased registers is determined by dividing the required power by the rated power of the device.

For homemade registers, divide the required power in each room by the heat transfer of one linear meter of pipes used. The required total length of pipes is obtained. Then this length is distributed between the devices, divided by the number of pipes - their length is obtained. There are options here - there may be several short devices or one long one.

What other parameters should be taken into account

If there is a need to increase the power of the device, then it is necessary to increase the length of the pipes, and not their diameter. The efficiency of the system decreases with increasing pipe diameter.

If the system uses oil or antifreeze, it should be noted that they have a lower heat capacity than water. When using them, heating devices must have a larger area than devices in a water system.

Device characteristics

Heating registers have several qualities that distinguish them from other heating devices:

- Thanks to effective heat exchange with the surrounding space, small-sized devices are able to heat large rooms.

- Making a heat exchanger is quite simple - you only need a welding machine and an angle grinder with a cutting disc.

- You can use any available materials - pipes made of cast iron, stainless steel or steel.

- The devices are able to withstand high pressure (10 kgf/m2) and can operate on any coolant - water, oil, other liquids, steam.

- The device can be assembled either according to ready-made drawings or according to those drawn up independently. Various configuration options, plugs, additional elements and finishing materials are allowed.

- The final cost of a heat exchanger made of smooth pipes will be lower than that of other devices with a similar level of efficiency.

It is worth noting that the larger the total surface area of the device, the higher its heat transfer. In turn, the area depends on the cross-section of the pipe and the length of the section.

Please note that the efficiency of the equipment will depend on the number of levels and the space between them, the configuration of the device (S-shaped or sectional), the type of material used, as well as the presence of insulation and the properties of the coolant.

In most cases, heating registers have the following characteristics:

- Electric-welded carbon steel pipes are used for the heat exchanger.

- The pipes are connected in one of the following ways: flanged, external threaded, and welded.

- The maximum pressure value is 10 kgf/m2.

- The cross-section of pipes in sections is 32-219 mm.

- The minimum distance between levels is 50 mm.

- The cross-section of the connecting jumpers is from 32mm.

Types of heating registers

Heating registers are a group of pipelines located parallel to each other and communicating with each other. They may differ in material, shape and design.

Materials for production

Most often, heating registers are made of smooth steel pipes in accordance with GOST 3262-75 or GOST 10704-91. The use of electric welded pipes is preferable due to their ability to withstand higher pressures. However, in practice, water and gas pipes are also quite common, and they are operated no less successfully. Such heating devices can easily withstand all kinds of mechanical damage and loads, as well as work with any coolant.

There are also stainless steel models. They are installed in rooms with increased requirements for aesthetics and durability. Due to the increased cost, the use of stainless steel registers is most justified in bathrooms. The high corrosion resistance and variety of configurations of stainless steel heated towel rails allow them to be used even in the most modern bathroom interiors.

Aluminum and bimetallic registers are more efficient in terms of heat transfer. They are lightweight and aesthetically pleasing, and work perfectly in individual heating systems with well-organized water treatment. In other cases, low quality coolant leads to rapid failure of devices.

Sometimes you can find registers made of copper. They are usually used in systems where the main wiring is copper. They are easy to work with, very attractive and durable. In addition, the thermal conductivity of copper is approximately 8 times higher than steel, which makes it possible to significantly reduce the size of the heating surface. A common disadvantage of all devices made of non-ferrous metals - sensitivity to operating conditions - limits the scope of application of copper registers.

Design

The most characteristic designs of traditional steel registers can be divided into 2 types:

- Sectional;

- Serpentine.

The first is characterized by a horizontal arrangement of pipelines and the use of vertical narrow jumpers between them. The second involves the use of straight and arcuate elements of the same diameter, which are connected by a snake using welding. When using stainless steel or non-ferrous metals, the pipes are simply bent to give the required configuration.

There are three options for connecting pipes:

- Threaded;

- Flanged;

- For welding.

They can be located either on one side of the device or on different ones. The coolant outlet is provided under the supply or diagonally from it. Sometimes there is a lower connection of lines, but in this case the heat transfer is significantly reduced.

In sectional registers, there are 2 types of connections depending on the method of arranging jumpers:

- "Thread";

- "Column".

Plain tube registers can be used as registers for the main heating system or as separate heaters. For autonomous operation, a heating element of the required power is installed inside the device and connected to the network. Antifreeze or oil is often used as a coolant for portable electrical registers made of steel, because... it does not freeze during storage or during a power outage.

When used separately from the general heating system, it is necessary to additionally place the expansion tank in the upper part of the device. This avoids pressure increases due to volume expansion during heating. The size of the container is selected based on the ability to accommodate about 10% of the total amount of liquid in the heater.

For autonomous use of the register made of steel pipes, legs with a height of 200 - 250 mm are welded to it. If the device is part of a heating circuit, its movement is not planned and the walls are strong enough, then a stationary mount is used using brackets. Sometimes for very massive registers a combined installation option is used, i.e. The device is placed on stands and additionally fixed on the wall.

Sectional

Sectional steel heating registers made of smooth pipes can consist of either one or several sections, the ends of which are closed with plugs. The incoming coolant pipe cuts into the upper part of the section. Moving from side to side, water gradually fills the entire section.

To manufacture this type of heat exchanger, smooth steel pipes with a cross section of 25-400 mm are used. The most commonly used pipes are 76, 89, 108 and 159 mm in diameter. The insertion of inlet and outlet pipes can be done with a thread, flange connection or welding.

Additionally, the equipment is equipped with a threaded fitting into which an air vent is connected. Such steel registers are designed for a maximum coolant pressure within 10 kgf/cm2 or 1 MPa.

The plugs installed on the sides of the pipe are flat or elliptical. They try to make transitions between pipes as close to the edges as possible in order to increase the heat transfer of the equipment.

Types of registers

Heating registers are divided into three types:

- aluminum;

- cast iron;

- steel.

Aluminum registers are in great demand due to their low specific gravity, good heat transfer rates, excellent corrosion resistance, long service life, and the absence of joints and welds.

Aluminum pipes are produced by monolithic casting. Aluminum registers are used in residential and administrative premises. The main disadvantage of aluminum devices is their high price.

Cast iron registers are easy to install because they have a monolithic flange connection. During installation, a second flange is welded to the heating pipeline, and then a strong connection is made using bolts.

Steel registers are installed into the heating system by welding. High-quality welding is a guarantee of long service life of the entire heating system.

Stationary and mobile registers

To heat the coolant in stationary registers, heating boilers are needed. To heat the coolant in mobile registers, an electric heating element is used, operating from a network with a voltage of 220 V. This type of registers is used for work houses of builders, premises where finishing work is carried out.

Installing registers indoors has a number of undeniable advantages over installing batteries in a heating system:

- long service life, pipes made of steel do not need repairs, at least 25 years;

- the heating system is characterized by a high degree of reliability; the main requirement for ensuring such reliability is high-quality welding seams;

- an open heating system can be installed in large areas; low resistance to the movement of the coolant ensures the large diameter of the pipes used for the register.

Recently, registers are installed much less often, choosing more alternative modern heating devices. The disadvantages of this type of device include:

- The appearance of the register is not the most attractive; a thick steel pipe is laid along the wall throughout the room;

- a small area of contact with the air in the room leads to a low heat transfer rate, zero use of convection;

- supplying a heating system with registers is high in cost and difficult to install; large-diameter steel pipes on the construction market are quite expensive; it is necessary to use welding during installation.

Advantages of the equipment

The main advantages of this type of heat exchanger can be considered:

- ease of use;

- ease of maintenance (cleaning);

- the presence of a large heat-transfer area with small dimensions;

- high fire safety;

- economical energy consumption in the presence of a heating element;

- Possibility of use as a heated towel rail;

- Wide range of applications - can be installed in warehouses, production workshops, trade pavilions and office buildings, as well as in hospitals and clinics.

conclusions

If you decide to equip your home with this type of heating device, we advise you to carefully understand the features of its operation, as well as study the intricacies of creating and installing registers. Additional reference literature will greatly help you with this.

Find out the cost of repairs

Repair work?

Why do clients choose us?

Heating and Repair

We have the best prices!

In absolutely any part of our country it is necessary to heat the house during the cold season. Any sane person can figure out what to do to improve the apartment system. It is difficult to imagine the life of a person living in Russia without a cottage heating system. Everyone knows that heat sources are constantly becoming more expensive. The website Sistema-Otopleniya.ru presents many apartment heating complexes that use exclusively different methods of heat extraction. It is recommended to install each heat generation system hybridly or independently.

A register is a pipe of sufficiently large diameter stretched along the walls of a heated room.

This is one of the main elements of the heating system. There may be more than one pipe. If the number of pipes is from 2 to 5, then they are connected in parallel into batteries by welding. Registers for a heating system are usually made of pipes with a diameter of 25 mm and above. This design is very reliable: with high-quality welding work, it can last up to 30 years without repair, and is capable of heating large areas. The disadvantages are: unpresentable appearance, low heat transfer, installation complexity due to the use of welding, high cost of materials.

Heating registers are either coil or sectional. Coil ones consist of one pipe, sectional ones - of several. The distance between individual sections must exceed the diameter of the pipes by 50 mm.

These devices are quite effective and are not inferior in terms of heat transfer to a conventional convector. Their surface is easy to clean.

The word “convection” is often found in the description of the technical characteristics of heating devices. The higher the convection level, the lower the comfort level. The higher the coolant temperature, the higher the wear of the system. It is better to choose those devices that have a lower level of convention.

Calculation of heating registers

To prevent the house from being cold and the heating to evenly warm all rooms, it is important to calculate the number of registers for each room. For purchased devices, their power is looked at in the passport and the number of devices is calculated; for homemade tubular heaters, the length of the pipes will have to be determined by yourself

Calculation of the required thermal power to heat the room

If your house is built according to a project, then data on the required power of heating devices is available in the documents - you need to find and use them.

If there is no design of engineering systems, then use traditional approximate data on heat loss:

- 100 W per 1 m² of room area with one external wall and one window.

- 120 W per 1 m² of room area with two external walls and one window.

- 130 W per 1 m² of room area with two external walls and two windows.

The total heat losses are calculated, the resulting power is increased by 20% (multiplied by 1.2) and the total power of all heating devices is obtained. In the northern regions of Russia, it is desirable to increase the resulting power by another 20 percent.

The power of the appliances in each room is calculated based on the above data (heat loss in the room multiplied by 1.2).

The exact method for calculating the heat loss of a house is very complex and is used by design organizations.

Calculation of register thermal power

The amount of heat (W) supplied from the pipe to the room is determined by the formula:

Where:

- K is the heat transfer coefficient, W/(m2 0С), taken depending on the pipe material and coolant parameters.

- F is the surface area, m2, calculated as the product of π·d·l.

- where π = 3.14, and d and l are the diameter and length of the pipe, respectively, m.

∆t – temperature difference, 0С, determined in turn by the formula:

- Where: t1 and t2 are the temperatures at the inlet and outlet of the boiler, respectively.

- tk is the temperature in the heated room.

- 0.9 is a reduction factor for a multi-row device.

For a steel structure, the heat transfer coefficient to air is 11.3 W/(m2 0C). For a multi-row register, a reduction factor of 0.9 is accepted for each row.

For calculations, you can use a calculation calculator - there are many of them on the Internet, but manually is more reliable.

Heat transfer of registers made of smooth pipes. Table

The values of heat transfer coefficients for steel smooth-tube registers are given in the table.

In private homes, the temperature difference is usually 60-70 °C.

How to calculate the required number of register sections

The number of purchased registers is determined by dividing the required power by the rated power of the device.

For homemade registers, divide the required power in each room by the heat transfer of one linear meter of pipes used. The required total length of pipes is obtained. Then this length is distributed between the devices, divided by the number of pipes - their length is obtained. There are options here - there may be several short devices or one long one.

What other parameters should be taken into account

If there is a need to increase the power of the device, then it is necessary to increase the length of the pipes, and not their diameter. The efficiency of the system decreases with increasing pipe diameter.

If the system uses oil or antifreeze, it should be noted that they have a lower heat capacity than water. When using them, heating devices must have a larger area than devices in a water system.

Gas heating

A double-circuit boiler is a very convenient device

Gas heating is one of the best today. Natural gas is an economical, efficient, safe, environmentally friendly fuel.

Gas and electric heating are similar in their efficiency, safety and a number of other advantages. But a detailed examination reveals its specific shortcomings.

A comparison with electric boilers reveals the following. Electric boilers are more expensive than gas boilers, but in some cases their performance is higher, control is more convenient and simpler, and their use is safer. An electric boiler only requires a power connection, while gas analogues additionally require the purchase of a mounted burner and regular cleaning of burning and soot. Electric boilers are easy to install, which is another advantage.

Gas heating requires permission to install it, prepare a site for its installation, lay out the system for it, connect and install all the necessary equipment, which in total is quite expensive. But the monthly heating fee will be lower than for electricity, although it also depends on the efficiency of the purchased gas system. Otherwise, the gas system has the disadvantages of a water system within the intra-house space, as a system that uses a coolant.

When comparing gas heating with heating by direct electric heaters, the advantages of electric heating are the absence of installation permission, much lower capital investments, and ease of installation and maintenance. The disadvantage is a more expensive source of energy - electric.

Selecting a heating device configuration

Homemade radiator designs are mainly made on the basis of metal pipes with a diameter of 80 - 150 mm.

Design features are limited to two versions:

- Lattice.

- Snake.

The lattice design of the heating battery differs from the “snake” in a slightly different circuit design, and, depending on the variations in such batteries, the distribution of the coolant may be different.

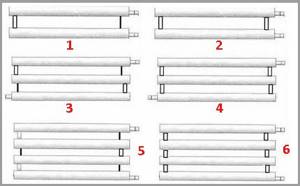

Options for circuit design of heating registers for their own production: 1 – one jumper and one-sided power supply; 2 – two jumpers and one-sided power supply; 3 – two-way power supply and 2 jumpers; 4 – two-way power supply and 4 jumpers; 5, 6 – multi-pipe

Coil structures actually have a monotonous design, implying strictly sequential movement of the coolant.

Lattice registers are constructed according to different schematics:

- with one or two jumpers and one-way power supply;

- with one or two jumpers and versatile power supply;

- parallel connection of pipes;

- sequential connection of pipes.

The number of pipes in one assembly can range from two to four or more. Rarely, there is also the practice of making single-pipe registers.

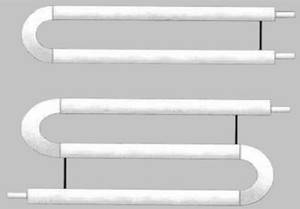

A coil assembly usually contains at least two pipes connected on one side by a blind jumper and on the other by a through jumper, which are made from two pipe bends (2x45º). It should be noted that the design of heating registers in the form of a coil is used much less frequently than “grid” designs.

Options for the possible manufacture of “snake” type registers. For coil-type register battery designs, the choice of manufacturing options is limited compared to lattice-type designs.

Both manufacturing options - lattice and coil - can be made not only on the basis of classic round pipes, but also on the basis of profile pipes.

Profile pipes seem to be a somewhat specific material, since they require a slightly different approach when assembling heating radiators. However, registers made from a profile pipe are more compact and take up less usable space, and this factor is also important.

Scope of registers

Scheme of a sectional register made of steel pipes.

In recent years, such registers have become the basis of the heating system in various enterprises. They are easy to install, very reliable and durable, and have high heat transfer. If necessary, a single heating system is welded from several pipes. It is best to connect individual pipes into a system using metal-plastic pipes with a diameter of 25 to 32 mm.

Heating registers are used for heating residential, warehouse and industrial premises. Most often they are installed in places with high requirements for sanitary and fire safety.

Heating registers are used to heat apartments and individual rooms. In private homes they are used less frequently, as many alternative heating devices have appeared that fit better into the interior.

Heat exchanger installation

Considering the large weight of the heating register, you need to use appropriate brackets for mounting, or better yet, place it on the floor. As you understand, there are two installation methods:

- hang on the wall;

- put it on the floor.

The main thing is that the structure is very strong. The distance to the walls is also important, which is 20–25 cm. The same distance should be to the floor, while maintaining the intended slope angle for circulation. The distance between the heating register pipes must be at least five centimeters. It doesn’t matter whether the heat exchanger is autonomous or connected to a network.

Radiators of any type are installed around the perimeter of the room on the external walls. That is why in apartments the battery is always under the window. The heat exchanger not only heats the air, it also heats the walls

It is very important to paint the registers so that they do not rust

Portable registers

Schemes of tubular radiators.

To heat not very large rooms, registers, popularly called samovars, are sometimes used. They operate autonomously due to the heating elements installed in them. Such registers are intended for temporary heating and maintaining the temperature in a garage, dressing room, or other outbuilding. They are filled with transformer oil, antifreeze and other non-freezing liquids. Such a system can be stationary or portable.

How to make a register with your own hands

The easiest way to assemble such a heating device yourself is to use the following technology:

- pipes are cut into sections according to the calculations performed;

- at the ends of the segments, closer to the edge, marks are made for the location of the jumpers;

- The jumpers themselves are cut out of a pipe with a diameter equal to the supply;

- the pipes are laid out on a flat horizontal surface parallel to each other;

- by welding in three places, all jumper sections are grabbed;

- jumpers are welded to the sections.

When assembling a heating radiator, jumpers should be installed as close as possible to the edge of the horizontal sections. In this case, the heat transfer of the register will subsequently be higher. At the final stage:

- plugs for sections are cut from sheet metal;

- all plugs are grabbed to the ends pointwise or diagonally;

- the elements are welded into place.

The plugs should be cut in such a way that when they are installed, a small “chamfer” remains along the edge of each section. This “chamfer” is subsequently filled with a weld.

It is advisable to additionally equip registers welded in this way with air vents. Simply put, in each upper section of such a device it is worth installing a standard Mayevsky tap.

Calculation of the required number of registers in the house

When choosing registers for heating, you need to pay special attention to the pipes used in the design and their diameter. The most suitable option for this parameter is considered to be a size of 31-32 mm

Experts do not recommend installing registers from pipes whose diameter exceeds 82 mm. This is due to the fact that heating boilers will not be able to provide the required amount of coolant.

In terms of heat transfer, aluminum radiators are better than steel ones.

For each individual building, it is necessary to very accurately determine the number of pipes and their diameter in the register. Therefore, installing these heating systems in a house requires taking into account the following factors:

- The number of doors and windows in the building.

- Wall thickness.

- Materials from which windows and doors are made.

To calculate the required number of pipes, one main indicator should be taken into account - the heat transfer of 1 m of pipeline. The cost of installing a heating system using radiators and registers is not much different. The differences in price depend only on the number of joints, the cost of welding work and pipes, and the size of the devices. In multi-story and one-story buildings, it is best to use registers for lower pipe routing.