Basic insulation mistakes

External insulation of the walls of a country house must be carried out in accordance with the requirements and rules for installing materials. Errors that most often occur during insulation contribute to improper circulation of air flow and the formation of moisture inside the cake, which leads to a weakening of the thermal insulation qualities:

- incorrect calculation of thermal resistance;

- if there is no base strip at the bottom of the wall, the insulation may come into contact with the ground;

- Expanded polystyrene should not be left in the sun for a long time during installation;

- cracks between insulation boards lead to the appearance of cold bridges;

- Expansion dowels should be installed at the corners of the building and around doors and windows to securely fasten the material.

In addition, you should not skimp on materials, since in addition to their correct installation, the low quality of the material should not cause poor-quality insulation.

Thus, when insulating walls, the living space is preserved; careful consideration of details is required to calculate the amount of materials and determine the order of installation work.

Preparing materials

To install insulation for walls under plaster from the outside, you will need:

- materials for facade insulation of appropriate thickness. As a rule, this value varies between five and ten centimeters, and for the northern regions it reaches fifteen;

- adhesive composition. Its choice is determined taking into account the insulation material used. Expanded polystyrene is perfectly glued with foam glue, mineral wool is fixed with Ceresit ct 180. There are special mixtures for installing foam;

- base strips that serve as guide elements for the insulating layer slabs;

- umbrella dowels for additional fixation of slabs;

- primer composition for external work;

- fiberglass reinforcing mesh;

- perforated corners.

Choosing the type of insulation for plaster

The entire list of finishing works is usually planned in advance, so even at the stage of choosing insulation it is worth understanding the properties of different types of material in order to plaster them using the correct technology. The most commonly used materials for insulating facades are polystyrene foam (foam plastic) and mineral wool.

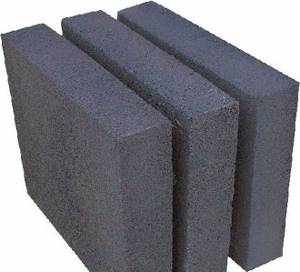

- Expanded polystyrene;

Quite easy to install and inexpensive material with excellent resistance to moisture. Expanded polystyrene insulates the facade well, but is less durable than mineral wool. In addition, polystyrene foam is not fireproof.

It is most reasonable to choose expanded polystyrene for thermal insulation of brick facades, concrete, expanded clay concrete and slag concrete walls.

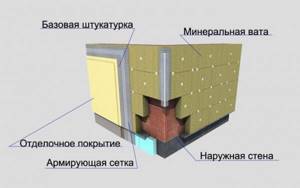

Insulation of house facades with polystyrene foam - view of the structure after completion of installation work

- Mineral wool;

Non-flammable and breathable material with excellent vapor-permeable properties. When planning to install such insulation, you should understand that its weight is greater than that of foam plastic, so to attach it to the facade you will need a stronger sheathing.

It is also recommended not to skimp on the quality of mineral wool and choose two-layer materials in the form of diabase or basalt slabs. They are quite dense and have a hard outer surface.

Mineral wool is used to insulate houses made of timber, expanded clay concrete, as well as walls made of gas silicate and aerated concrete.

Insulation of the facade with mineral wool - installation of the material on the walls was carried out “in a running start”

When choosing plaster, it is necessary to take into account the type of insulation that will be installed on the facade. If you choose expanded polystyrene, the reinforcing mesh should also be special - resistant to alkalis.

What type of insulation is optimal for facade plaster?

So, which insulation to choose? Basic requirements for external insulating materials:

- Convenient form for installation.

- The material is sufficiently rigid to allow its installation without the use of additional equipment.

- High thermal insulation qualities.

- Low price.

NOTE!

These requirements are best met by polystyrene foam and stone wool. Both materials are produced in the form of slabs of various thicknesses, installation is carried out without the use of special equipment, and there is the most successful set of working qualities.

In addition, the installation method of both materials is completely similar, as is the finishing method.

Possible errors when performing work

Most often, beginners make the following mistakes that reduce the quality of their work:

- weak fixation of insulation - causes cracks, detachment and deformation;

- poor preparation of the walls - causes a decrease in adhesion, sliding of the insulation and even a shift in the dew point;

- installation in unsuitable climatic conditions - leads to a reduction in service life;

- loose joining of insulation boards, small overlap of the mesh - provoke cracking of the finish;

- improper treatment of window slopes - allows moisture penetration;

- choosing low-quality plaster is a prerequisite for rapid deterioration of the entire finishing layer.

In order for the home insulation system to serve for a long time and actually cope with the main tasks, it is important to strictly follow the technology and not skimp on materials. Then the house will become beautiful, comfortable and reliable, and will not require repairs for decades!

Insulation for plaster facades

Moscow Change the region if we made a mistake

8 from 9:00 to 18:00 Call back

Send a request

Sale! We are selling the remains of Technoelast EMP for 238 rubles per square meter. The quantity of material is limited!

- Send a request

- Contacts

- Delivery

- Payment

- About company

- DOM TECHNONICOL

0

- Roofing Flexible tiles Tiles

- Ridge-eaves tiles

- Underlay carpets

- Valley carpets

- Slats for flexible tiles

- Nails for flexible tiles

- Pass-through element

- Adhesives and mastics

- Metal tile sheets

- Roof tiles

- Ridge tiles

- Flat slate

- Roof aerators

- Roof ventilation Aero elements

- Gutter

- Window

- TPO membranes

- Thermal insulation Basalt (stone) wool

- Roll waterproofing

- Soundproofing mats

- Roofing waterproofing Rolled roofing waterproofing

- Sealants Acrylic sealant

- Drywall Plasterboard sheet (GKL)

- Plywood

- Aerated concrete blocks

- Formwork for walls Large panel formwork Linear formwork panels

- Waterproofing films

- Facade tiles

- Facing stone

- Vinyl siding

- Soffit

- J-profile

- Terrace board (decking)

- Facade plaster

- Paints

- Plasters Leveling plasters

- Tile adhesives

- Geotextiles

- Bolts Stainless steel bolt

- Construction nails

- Construction staples

Minimum order amount 10,000 ₽

Cart (0) Comparison (0)

Entrance

Minimum order amount 10,000 ₽

- Catalog

- Catalog

- Roofing Flexible tiles Tiles

- Ridge-eaves tiles

- Underlay carpets

- Valley carpets

- Slats for flexible tiles

- Nails for flexible tiles

- Pass-through element

- Adhesives and mastics

- Roof tiles

- Ridge tiles

- Flat slate

- Roof aerators

- Roof ventilation Aero elements

- Gutter

- Window

- TPO membranes

- Thermal insulation Basalt (stone) wool

- Roll waterproofing

- Soundproofing mats

- Roofing waterproofing Rolled roofing waterproofing

- Sealants Acrylic sealant

- Drywall Plasterboard sheet (GKL)

- Plywood

- Aerated concrete blocks

- Formwork for walls Large panel formwork Linear formwork panels

- Waterproofing films

- Facade tiles

- Facing stone

- Vinyl siding

- Soffit

- J-profile

- Terrace board (decking)

- Facade plaster

- Paints

- Plasters Leveling plasters

- Tile adhesives

- Geotextiles

- Bolts Stainless steel bolt

- Construction nails

- Construction staples

- Facade materials

Roof

- Plaster facades

Facade tiles

Plaster facades Insulation for plaster facades

- 120

Show by

- 120

Basalt wool Baswool Facade 140 1200x600x50 mm 6 slabs/pack (6,912) RUB 2,571/pack

Compare In comparison

Basalt wool TechnoNIKOL Technofas Extra 1200x600x100 mm 3 slabs 1,931 RUR/pack

Compare In comparison

Basalt wool TechnoNIKOL Technofas 1200x600x150 mm 2 slabs 3,042 RUR/pack

Compare In comparison

Basalt wool TechnoNIKOL Technofas 1200x600x90 mm 2 slabs 1,831 RUR/pack

Compare In comparison

Basalt wool TechnoNIKOL Technofas 1200x600x100 mm 3 slabs 3,042 RUR/pack

Compare In comparison

Basalt wool TechnoNIKOL Technofas 1200x600x50 mm 6 slabs 3,042 RUR/pack

Compare In comparison

Basalt wool TechnoNIKOL Technofas Extra 1200x600x50 mm 6 slabs 1,931 RUR/pack

Compare In comparison

Basalt wool TechnoNIKOL Technofas Extra 1200x600x130 mm 2 slabs 1,672 RUR/pack

Compare In comparison

Basalt wool TechnoNIKOL Technofas Extra 1200x600x140 mm 2 slabs 1,806 ₽/pack

Compare In comparison

Basalt wool TechnoNIKOL Technofas Extra 1200x600x150 mm 2 slabs 1,931 RUR/pack

Compare In comparison

Basalt wool TechnoNIKOL Technofas Extra 1200x600x80 mm 3 slabs 1,546 RUR/pack

Compare In comparison

Basalt wool TechnoNIKOL Technofas Extra 1200x600x90 mm 3 slabs 1,734 RUR/pack

Compare In comparison

Basalt wool TechnoNIKOL Technofas Cottage 1200x600x100 mm 3 slabs 2,233 ₽/pack

Compare In comparison

Basalt wool TechnoNIKOL Technofas Cottage 1200x600x50 mm 6 slabs 2,233 RUR/pack

Compare In comparison

Basalt wool TechnoNIKOL Technofas Optima 1200x600x100 mm 3 slabs 2,537 RUR/pack

Compare In comparison

Basalt wool Baswool Facade 140 1200x600x50 mm 6 slabs/pack (6,912) RUB 2,571/pack

Compare In comparison

Basalt wool TechnoNIKOL Technofas Extra 1200x600x100 mm 3 slabs 1,931 RUR/pack

Compare In comparison

Basalt wool TechnoNIKOL Technofas 1200x600x150 mm 2 slabs 3,042 RUR/pack

Compare In comparison

Basalt wool TechnoNIKOL Technofas 1200x600x90 mm 2 slabs 1,831 RUR/pack

Compare In comparison

Basalt wool TechnoNIKOL Technofas 1200x600x100 mm 3 slabs 3,042 RUR/pack

Compare In comparison

Basalt wool TechnoNIKOL Technofas 1200x600x50 mm 6 slabs 3,042 RUR/pack

Compare In comparison

Basalt wool TechnoNIKOL Technofas Extra 1200x600x50 mm 6 slabs 1,931 RUR/pack

Compare In comparison

Basalt wool TechnoNIKOL Technofas Extra 1200x600x130 mm 2 slabs 1,672 RUR/pack

Compare In comparison

Basalt wool TechnoNIKOL Technofas Extra 1200x600x140 mm 2 slabs 1,806 ₽/pack

Compare In comparison

Basalt wool TechnoNIKOL Technofas Extra 1200x600x150 mm 2 slabs 1,931 RUR/pack

Compare In comparison

Basalt wool TechnoNIKOL Technofas Extra 1200x600x80 mm 3 slabs 1,546 RUR/pack

Compare In comparison

Basalt wool TechnoNIKOL Technofas Extra 1200x600x90 mm 3 slabs 1,734 RUR/pack

Compare In comparison

Basalt wool TechnoNIKOL Technofas Cottage 1200x600x100 mm 3 slabs 2,233 ₽/pack

Compare In comparison

Basalt wool TechnoNIKOL Technofas Cottage 1200x600x50 mm 6 slabs 2,233 RUR/pack

Compare In comparison

Basalt wool TechnoNIKOL Technofas Optima 1200x600x100 mm 3 slabs 2,537 RUR/pack

Compare In comparison

Basalt wool TechnoNIKOL Technofas Optima 1200x600x50 mm 6 slabs 2,537 RUR/pack

Compare In comparison

Basalt wool Baswool Facade 140 1200x600x50 mm 6 slabs/pack (6,912) RUB 2,571/pack

Compare In comparison

Basalt wool TechnoNIKOL Technofas Extra 1200x600x100 mm 3 slabs 1,931 RUR/pack

Compare In comparison

Basalt wool TechnoNIKOL Technofas 1200x600x150 mm 2 slabs 3,042 RUR/pack

Compare In comparison

Basalt wool TechnoNIKOL Technofas 1200x600x90 mm 2 slabs 1,831 RUR/pack

Compare In comparison

Basalt wool TechnoNIKOL Technofas 1200x600x100 mm 3 slabs 3,042 RUR/pack

Compare In comparison

Basalt wool TechnoNIKOL Technofas 1200x600x50 mm 6 slabs 3,042 RUR/pack

Compare In comparison

Basalt wool TechnoNIKOL Technofas Extra 1200x600x50 mm 6 slabs 1,931 RUR/pack

Compare In comparison

Basalt wool TechnoNIKOL Technofas Extra 1200x600x130 mm 2 slabs 1,672 RUR/pack

Compare In comparison

Basalt wool TechnoNIKOL Technofas Extra 1200x600x140 mm 2 slabs 1,806 ₽/pack

Compare In comparison

Basalt wool TechnoNIKOL Technofas Extra 1200x600x150 mm 2 slabs 1,931 RUR/pack

Compare In comparison

Basalt wool TechnoNIKOL Technofas Extra 1200x600x80 mm 3 slabs 1,546 RUR/pack

Compare In comparison

Basalt wool TechnoNIKOL Technofas Extra 1200x600x90 mm 3 slabs 1,734 RUR/pack

Compare In comparison

Basalt wool TechnoNIKOL Technofas Cottage 1200x600x100 mm 3 slabs 2,233 ₽/pack

Compare In comparison

Basalt wool TechnoNIKOL Technofas Cottage 1200x600x50 mm 6 slabs 2,233 RUR/pack

Compare In comparison

Basalt wool TechnoNIKOL Technofas Optima 1200x600x100 mm 3 slabs 2,537 RUR/pack

Compare In comparison

Basalt wool Baswool Facade 140 1200x600x50 mm 6 slabs/pack (6,912) RUB 2,571/pack

Compare In comparison

Basalt wool TechnoNIKOL Technofas Extra 1200x600x100 mm 3 slabs 1,931 RUR/pack

Compare In comparison

Basalt wool TechnoNIKOL Technofas 1200x600x150 mm 2 slabs 3,042 RUR/pack

Compare In comparison

Basalt wool TechnoNIKOL Technofas 1200x600x90 mm 2 slabs 1,831 RUR/pack

Compare In comparison

Basalt wool TechnoNIKOL Technofas 1200x600x100 mm 3 slabs 3,042 RUR/pack

Compare In comparison

Basalt wool TechnoNIKOL Technofas 1200x600x50 mm 6 slabs 3,042 RUR/pack

Compare In comparison

Basalt wool TechnoNIKOL Technofas Extra 1200x600x50 mm 6 slabs 1,931 RUR/pack

Compare In comparison

Basalt wool TechnoNIKOL Technofas Extra 1200x600x130 mm 2 slabs 1,672 RUR/pack

Compare In comparison

Basalt wool TechnoNIKOL Technofas Extra 1200x600x140 mm 2 slabs 1,806 ₽/pack

Compare In comparison

Basalt wool TechnoNIKOL Technofas Extra 1200x600x150 mm 2 slabs 1,931 RUR/pack

Compare In comparison

Basalt wool TechnoNIKOL Technofas Extra 1200x600x80 mm 3 slabs 1,546 RUR/pack

Compare In comparison

Basalt wool TechnoNIKOL Technofas Extra 1200x600x90 mm 3 slabs 1,734 RUR/pack

Compare In comparison

Basalt wool TechnoNIKOL Technofas Cottage 1200x600x100 mm 3 slabs 2,233 ₽/pack

Compare In comparison

Basalt wool TechnoNIKOL Technofas Cottage 1200x600x50 mm 6 slabs 2,233 RUR/pack

Compare In comparison

Basalt wool TechnoNIKOL Technofas Optima 1200x600x100 mm 3 slabs 2,537 RUR/pack

Compare In comparison

Basalt wool TechnoNIKOL Technofas Optima 1200x600x50 mm 6 slabs 2,537 RUR/pack

Compare In comparison

Basalt wool TechnoNIKOL Technofas Optima 1200x600x150 mm 2 slabs 2,537 ₽/pack

Compare In comparison

Basalt wool TechnoNIKOL Technofas Effect 1200x600x100 mm 3 slabs 2,749 RUR/pack

Compare In comparison

Basalt wool TechnoNIKOL Technofas Optima 1200x600x50 mm 6 slabs 2,537 RUR/pack

Compare In comparison

Basalt wool TechnoNIKOL Technofas Optima 1200x600x150 mm 2 slabs 2,537 ₽/pack

Compare In comparison

Basalt wool TechnoNIKOL Technofas Effect 1200x600x100 mm 3 slabs 2,749 RUR/pack

Compare In comparison

Basalt wool TechnoNIKOL Technofas Cottage 1200x600x150 mm 2 slabs 1,948 ₽/pack

Compare In comparison

Basalt wool TechnoNIKOL Technofas Optima 1200x600x120 mm 2 slabs 2,032 RUR/pack

Compare In comparison

Basalt wool TechnoNIKOL Technofas Optima 1200x600x130 mm 2 slabs 2,196 RUR/pack

Compare In comparison

Basalt wool TechnoNIKOL Technofas Optima 1200x600x140 mm 2 slabs 2,372 RUR/pack

Compare In comparison

Basalt wool TechnoNIKOL Technofas Optima 1200x600x110 mm 3 slabs 2,795 RUR/pack

Compare In comparison

Basalt wool TechnoNIKOL Technofas Optima 1200x600x70 mm 3 slabs 1,773 RUR/pack

Compare In comparison

Basalt wool TechnoNIKOL Technofas Optima 1200x600x80 mm 3 slabs 2,032 RUR/pack

Compare In comparison

Basalt wool TechnoNIKOL Technofas Optima 1200x600x90 mm 3 slabs 2,278 RUR/pack

Compare In comparison

Basalt wool TechnoNIKOL Technofas Optima 1200x600x60 mm 4 slabs 2,032 RUR/pack

Compare In comparison

Basalt wool TechnoNIKOL Technofas Optima 1200x600x200 mm 1 slab 1,691 RUR/pack

Compare In comparison

Basalt wool TechnoNIKOL Technofas Optima 1200x600x160 mm 2 slabs 2,701 RUR/pack

Compare In comparison

Basalt wool TechnoNIKOL Technofas Optima 1200x600x170 mm 2 slabs 2,877 RUR/pack

Compare In comparison

Basalt wool TechnoNIKOL Technofas Optima 1200x600x150 mm 2 slabs 2,537 ₽/pack

Compare In comparison

Basalt wool TechnoNIKOL Technofas Effect 1200x600x100 mm 3 slabs 2,749 RUR/pack

Compare In comparison

Basalt wool TechnoNIKOL Technofas Cottage 1200x600x150 mm 2 slabs 1,948 ₽/pack

Compare In comparison

Basalt wool TechnoNIKOL Technofas Optima 1200x600x120 mm 2 slabs 2,032 RUR/pack

Compare In comparison

Basalt wool TechnoNIKOL Technofas Optima 1200x600x130 mm 2 slabs 2,196 RUR/pack

Compare In comparison

Basalt wool TechnoNIKOL Technofas Optima 1200x600x140 mm 2 slabs 2,372 RUR/pack

Compare In comparison

Basalt wool TechnoNIKOL Technofas Optima 1200x600x110 mm 3 slabs 2,795 RUR/pack

Compare In comparison

Basalt wool TechnoNIKOL Technofas Optima 1200x600x70 mm 3 slabs 1,773 RUR/pack

Compare In comparison

Basalt wool TechnoNIKOL Technofas Optima 1200x600x80 mm 3 slabs 2,032 RUR/pack

Compare In comparison

Basalt wool TechnoNIKOL Technofas Optima 1200x600x90 mm 3 slabs 2,278 RUR/pack

Compare In comparison

Basalt wool TechnoNIKOL Technofas Optima 1200x600x60 mm 4 slabs 2,032 RUR/pack

Compare In comparison

Basalt wool TechnoNIKOL Technofas Optima 1200x600x200 mm 1 slab 1,691 RUR/pack

Compare In comparison

Basalt wool TechnoNIKOL Technofas Optima 1200x600x160 mm 2 slabs 2,701 RUR/pack

Compare In comparison

Basalt wool TechnoNIKOL Technofas Optima 1200x600x170 mm 2 slabs 2,877 RUR/pack

Compare In comparison

Basalt wool TechnoNIKOL Technofas Optima 1200x600x50 mm 6 slabs 2,537 RUR/pack

Compare In comparison

Basalt wool TechnoNIKOL Technofas Optima 1200x600x150 mm 2 slabs 2,537 ₽/pack

Compare In comparison

Basalt wool TechnoNIKOL Technofas Effect 1200x600x100 mm 3 slabs 2,749 RUR/pack

Compare In comparison

Basalt wool TechnoNIKOL Technofas Cottage 1200x600x150 mm 2 slabs 1,948 ₽/pack

Compare In comparison

Basalt wool TechnoNIKOL Technofas Optima 1200x600x120 mm 2 slabs 2,032 RUR/pack

Compare In comparison

Basalt wool TechnoNIKOL Technofas Optima 1200x600x130 mm 2 slabs 2,196 RUR/pack

Compare In comparison

Basalt wool TechnoNIKOL Technofas Optima 1200x600x140 mm 2 slabs 2,372 RUR/pack

Compare In comparison

Basalt wool TechnoNIKOL Technofas Optima 1200x600x110 mm 3 slabs 2,795 RUR/pack

Compare In comparison

Basalt wool TechnoNIKOL Technofas Optima 1200x600x70 mm 3 slabs 1,773 RUR/pack

Compare In comparison

Basalt wool TechnoNIKOL Technofas Optima 1200x600x80 mm 3 slabs 2,032 RUR/pack

Compare In comparison

Basalt wool TechnoNIKOL Technofas Optima 1200x600x90 mm 3 slabs 2,278 RUR/pack

Compare In comparison

Basalt wool TechnoNIKOL Technofas Optima 1200x600x60 mm 4 slabs 2,032 RUR/pack

Compare In comparison

Basalt wool TechnoNIKOL Technofas Optima 1200x600x200 mm 1 slab 1,691 RUR/pack

Compare In comparison

Basalt wool TechnoNIKOL Technofas Optima 1200x600x160 mm 2 slabs 2,701 RUR/pack

Compare In comparison

Basalt wool TechnoNIKOL Technofas Optima 1200x600x170 mm 2 slabs 2,877 RUR/pack

Compare In comparison

Basalt wool TechnoNIKOL Technofas Cottage 1200x600x150 mm 2 slabs 1,948 ₽/pack

Compare In comparison

Basalt wool TechnoNIKOL Technofas Optima 1200x600x120 mm 2 slabs 2,032 RUR/pack

Compare In comparison

Basalt wool TechnoNIKOL Technofas Optima 1200x600x130 mm 2 slabs 2,196 RUR/pack

Compare In comparison

Basalt wool TechnoNIKOL Technofas Optima 1200x600x140 mm 2 slabs 2,372 RUR/pack

Compare In comparison

Basalt wool TechnoNIKOL Technofas Optima 1200x600x110 mm 3 slabs 2,795 RUR/pack

Compare In comparison

Basalt wool TechnoNIKOL Technofas Optima 1200x600x70 mm 3 slabs 1,773 RUR/pack

Compare In comparison

Basalt wool TechnoNIKOL Technofas Optima 1200x600x80 mm 3 slabs 2,032 RUR/pack

Compare In comparison

Basalt wool TechnoNIKOL Technofas Optima 1200x600x90 mm 3 slabs 2,278 RUR/pack

Compare In comparison

Basalt wool TechnoNIKOL Technofas Optima 1200x600x60 mm 4 slabs 2,032 RUR/pack

Compare In comparison

Basalt wool TechnoNIKOL Technofas Optima 1200x600x200 mm 1 slab 1,691 RUR/pack

Compare In comparison

Basalt wool TechnoNIKOL Technofas Optima 1200x600x160 mm 2 slabs 2,701 RUR/pack

Compare In comparison

Basalt wool TechnoNIKOL Technofas Optima 1200x600x170 mm 2 slabs 2,877 RUR/pack

Compare In comparison

Next 30

Next 30

- 120

Show by

- 120

- Contacts

- About company

- Brands

- Delivery

- Payment

- Purchase returns

- Privacy Policy

2021 Roofing and Insulation All rights reserved. The website ts-krovizol.ru is for informational purposes only and is not a public offer. For information on the cost of goods, please contact the sales department of the Roofing and Insulation company

Installation of the selected optimal insulation on the wall

Installation of insulation is carried out in dry weather at temperatures from +5° to +30°. This range is most favorable for adhesives and for people doing installation.

NOTE! It is undesirable to work under the scorching rays of the sun. Mineral wool must have a density of 150 or more, and PPS must be marked “F” (facade). The best options are polystyrene foam or basalt slab mineral wool.

In terms of physical properties (strength, size, etc.), both materials are close to each other, so the installation procedure for them is almost the same:

The best options are polystyrene foam or basalt slab mineral wool. In terms of physical properties (strength, size, etc.), both materials are close to each other, so the installation procedure for them is almost the same:

- The facade is cleaned of external lights, slopes, drainpipes and other hanging elements.

- Old paint or other coating is removed.

- The wall surface is inspected. Detected cracks, dents or other defects must be puttied; in particularly difficult cases, leveling plastering is used. The maximum size of the “wave” of the surface is 1 cm per 1 m of length. If there are crumbling areas, a deep penetration primer is used.

- Installation of insulation begins. It is recommended to install a special profile as a support for the bottom row of slabs, which will make it easier to fix the insulation and ensure horizontal alignment. The slabs are installed using a special adhesive, which is applied to the wall and immediately leveled with a notched trowel. Then the insulation board is pressed against the wall for tight contact and fixed with special dowels - fungi.

- The laying of the slabs is done as tightly as possible; there should be no cracks or gaps between the slabs.

- The next row is laid unevenly so that the joints of the slabs of the first row overlap the entire slab of the next one.

IMPORTANT! Sometimes, to facilitate the subsequent application of plaster, a metal profile is used for installing gypsum boards. The plates are tightly installed between the profile strips on the adhesive layer, the gaps between them (if they appear) can be sealed with the same glue. Subsequently, the metal profile will serve as guides for the plastering rule and ensure an even surface of the coating

This method is used on large facades, where the possibility of errors when applying plaster is very high.

Subsequently, the metal profile will serve as guides for the plaster rule and ensure an even surface of the coating. This method is used on large facades, where the possibility of errors when applying plaster is very high.

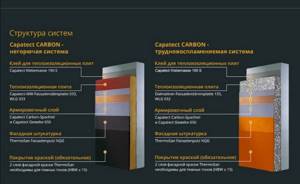

Sectional structure

Laying technology

Plastering technology of the selected insulation

The procedure for applying plaster is the same for almost all types of insulation.

You need to do the following:

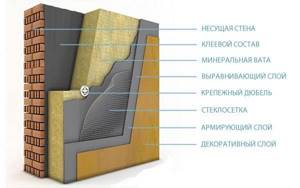

- The surface of the insulation is covered with a layer of glue using a notched trowel. Immediately, a reinforcing mesh is laid on top of the adhesive layer and slightly pressed into the adhesive to ensure complete immersion and tightness of the connection. Additional putty is applied on top for compaction and final strengthening of the reinforcing layer.

- The adhesive composition is allowed to stand for complete hardening.

- A layer of decorative plaster is applied using technology approved for the selected type. Instructions are usually included with the mixture (printed on the packaging or on a separate booklet included).

- If necessary, after the plaster has dried, one- or two-layer painting of the surface is carried out.

Pie device

Reinforcement and plastering

Insulating the outer surface of walls is an important and very useful operation from the point of view of preserving the wall material and improving comfort for the residents of the house. The main task facing the owner is the choice of material for insulation, the appropriate time for work and compliance with the technology for installing insulation and applying decorative plaster.

The option is quite labor-intensive and more expensive compared to “dry” finishing methods, but the result looks very solid and noble, which many times justifies the expense and effort.

Methods and technology of working with mineral wool for plaster and siding

At the moment, there are several common methods of insulating the facades of private houses using mineral wool. Among them, the most popular are:

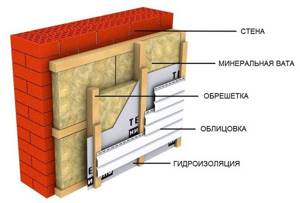

- “Wet” facade (under the plaster layer). Initially, the mineral wool must be attached directly to the building itself. After this, plaster is applied to it, which is subsequently painted or decorated in other ways, depending on the preferences of the building owner.

- "Ventilated facade. Often used for insulation under siding. In this case, an air gap is created between the mineral wool fixed to the wall and the outer cladding layer. Its thickness must be calculated using the appropriate formula. To create a gap, an appropriate metal or wooden structure must be attached to the house. Its main purpose is to fix facing materials. This could be lining, tiles, stone, fiber cement boards, etc.

“Wet” façade

Penoplex is often used in combination with mineral wool. For example, the base is insulated with penoplex, and the walls with mineral wool.

Insulation of the facade of a private house with mineral wool can be done independently without the help of specialists. In order to do this, you need to take a responsible approach to the procedure, prepare all the tools in advance and understand the most important nuances of the work.

Preparation when working with mineral wool with your own hands

The preparatory stage involves performing certain work on the surface of the walls. Be sure to:

- remove peeling plaster;

- remove paint;

- get rid of solution build-up.

Places that have been affected by mold or mildew must be thoroughly cleaned. After this, they need to be treated with appropriate substances.

Preparatory work involves removing window casings, drainpipes and additional decorative elements of facades. After this, the walls must be primed. To do this, use a deep penetration primer.

Surface marking

In order to carry out the insulation process efficiently, it is necessary to mark the surface of the facade. To do this, you should install sags: horizontal, vertical and diagonal. First, pins or nails must be secured at different points on the facades. A nylon cord should be pulled between them as a weight gain. In this case, you should use a level. Weights allow you to identify wall unevenness and install insulation evenly in such places.

Installation of profiles for mini-slabs

Base profiles (or strips) are used as a guide that supports the first row of mineral wool on the facade. In addition, such elements help protect the insulation from rodents penetrating into it from below. For installation of profiles, driven dowels are most often used.

Fixing mineral wool boards

In order to install mineral wool on the facade, you need to use a special construction adhesive designed for such purposes.

It is prepared in accordance with the instructions. The substance should be applied to the mineral wool using a comb spatula. The glue should cover the entire surface of the sheet.

If we are talking about a ventilated façade, then before installing mineral wool on it, you need to secure special brackets in advance, where the guides will subsequently be attached.

The mineral wool itself is attached to disc-shaped dowels or mushroom dowels. Afterwards, holes are cut in the mineral wool so that it can be easily placed on the brackets. And finally, disc-shaped dowels are attached so that the “head” of the dowel holds a couple of mineral wool slabs at once.

For 1 square meter it is necessary to use up to 5-7 disc dowels. It is best to hammer them into the corners of the slabs.

Final work

The roll of mounting mesh must be fixed at the top of the wall. This can be done using pins or mortar. The material sheets must overlap each other by at least 10 centimeters.

It is allowed to perform rough plastering with a thickness of 3 to 5 millimeters. 2-3 days after this, you can begin applying the decorative layer.

Types and brands of mineral wool

Mineral wool is available in three main varieties:

Stone and basalt wool;

Glass wool is a lightweight fibrous material consisting of very thin glass strands, the thickness of which ranges from 5 to 15 microns. The length of the fibers is about 15-50 mm. The raw materials from which glass wool is produced gives the material elasticity and good strength, but when working it is important to take into account the fragility of the fibers, which tend to crumble and dig into the skin. Glass wool is dangerous to the eyes and lungs, so when installing it, be sure to use goggles, a respirator, gloves and appropriate clothing. Such insulation can withstand heating up to 450°C and cooling down to -60°C.

Slag wool is another subtype of mineral wool. This material is made from blast furnace slag, the thickness of its fibers varies from 4 to 12 microns, the length of the fibers is approximately 15-16 mm. Slag wool is not used in the insulation of facades and water pipes, since it has good hygroscopicity, moreover, the material enters into chemical reactions with metal surfaces. As with glass wool, you need to work with slag wool carefully, protecting your eyes, skin and lungs from the microscopic fragile fibers of the material. Slag wool tolerates high temperatures well and can withstand heating up to 300°C.

Stone wool has fibers of the same length and thickness as its previous counterpart, but the advantage of this material is that its fibers are not so fragile, they do not crumble or prick. In addition to good thermal insulation properties, stone wool also has high temperature tolerance and can withstand heating up to 600°C. This material is most often used in insulating the facades of houses. Stone wool contains various components: clay, charge, limestone, blast furnace slag and dolomite. These components give the material a certain fluidity and reduce the percentage of binding components, which, in turn, makes stone wool safer for health, but also less moisture resistant.

Basalt wool is a type of stone wool, which is made from gabbro-diabase. It does not contain any additional impurities and can withstand very high temperatures, which can reach 1000°C. Such cotton wool can be cooled to -190°C, and it will not lose its performance qualities. Basalt wool is available for sale in several versions: in the form of sheets, rolls, mats, and also loose material.

Unlike wool for interior work, façade mineral wool is denser and hydrophobic (repels water). Mineral wool for insulating the outside of a wooden, brick and other house is produced exclusively in the form of slabs with dimensions of 0.6x1.2 m and 0.5x1 m. The thickness of the material can be 5, 10, 15 cm. The most popular type is 10-centimeter mineral wool slabs .

The main brands of mineral wool for insulation:

Mineral wool grade P-75 is often used for thermal insulation of horizontal surfaces. The density of this material for the facade is 75 kg/m³ - this indicator is not enough to withstand heavy mechanical loads. This material is most often used in insulating attics and roofs, as well as gas, oil and district heating pipes.

Material grade P-125 has a density of 125 kg/m³. It is advisable to use this mineral wool in the decoration of interior spaces, namely floors, ceilings, walls and partitions. By the way, mineral wool of this brand, in addition to its ability to retain heat well, also has soundproofing qualities and protects the interior of the room from external noise.

Mineral wool grade PZh-175 has an increased density, which is 175 kg/m³, as well as good rigidity. Its scope of application is insulation of walls and ceilings made of metal or reinforced concrete.

The material of the PPZh-200 brand is considered the most dense among its analogues, because its density is at least 200 kg/m³. Increased rigidity is another distinctive feature of this brand of mineral wool. Like the previous material, PPZh-200 wool is used for insulating reinforced concrete and metal walls and ceilings, and in addition, it can be used as additional fire protection for buildings.

Selecting material density

When selecting insulation for a facade, you need to pay attention to the mass and density of mineral wool. For most buildings, weighting is very undesirable. It is also worth paying attention to the possibility of subsequent finishing, because this indicator also affects this. So:

If the facade is equipped with a ventilated one, then a sufficient density is 45-100 kg m³. Here the cotton wool is laid into the sheathing and there will be virtually no stress. The main tasks for this type are to maintain its shape and not sag under its own weight, and the indicated indicator is enough for this.

If the facade is plastered over insulation, as in our case, then the density should be above 100 kg/m³, optimally from 140 to 175. This will allow the use of any type of plaster mixtures, including bark beetles and mosaics. Since this mineral wool will have to withstand heavy loads during installation, it must be securely fastened; for this, a system with dowels is used in combination with adhesive fastening. Further in the article we will use material with a density of 140 kg/m³.

Facade insulation technology for plaster

Work on thermal insulation of the external walls of a house includes the correct selection of the necessary plaster mixtures, primers, and glue, which is used to fix the insulation on the facade of the house. To finish an insulated wall, several types of finishing coatings are used. The basic rule: when working with mineral wool slabs, it is necessary to plaster the walls in the house with solutions with low vapor barrier properties.

What kind of plaster is used with insulated facades:

- Mineral decorative plasters. It is based on cement and various additives that increase the characteristics of the composition - adhesion to the surface, elasticity and others. This is the most inexpensive type of finishing mixture.

- Acrylic mixtures. This is essentially a solution of acrylic polymer with added mineral fillers. The main advantages are elasticity and durability. Insulating the outside of the house with acrylic plaster allows you to implement interesting solutions for textured finishing - “bark beetle”, “pebble”.

- Silicate-silicone plaster Ceresit CT 174/CT175 is used to create decorative thin-layer coatings on brick, concrete and other wall surfaces. The materials are characterized by good vapor permeability, resistance to pollution, frost resistance and low water absorption. Available in ready-to-use form - 25 kg buckets.

The fourth type is silicone mixtures. Silicone-based facade plaster has absorbed all the positive properties of previous compositions. The coating has high elasticity, which allows it not to react to wall shrinkage. Another plus is the self-cleaning surface. A good coefficient of vapor permeability ensures the removal of condensate from supporting structures.

Having decided on the materials, you can choose the technology for insulating the house from the outside. Let's consider the main stages of work:

- Preparing the base. Before insulating the walls in the house, they must be cleaned of old mortar and any unevenness must be repaired with a cement mixture. If mold and fungi are present, the surface should be treated with an antifungal agent.

- Installation of insulation. The technologies for attaching foam plastic or mineral wool are similar. The only difference is in the glue for fixing the slabs to the surface. For mineral boards, Ceresit CT 180 is used, and for foam plastic, Ceresit CT83 is used. First of all, a support profile is mounted along the perimeter of the external walls - a plinth for the first row of sheets. Next, beacons are placed in the corners, and a cord is pulled to control the plane.

- Fixing the slabs. The adhesive mixture is stirred to a puree consistency and applied to the mounting side of the sheet. After which the slab is mounted on the wall. Laying begins from the corner. During installation, it is necessary to ensure that the vertical joints of the next row are offset by 10 cm relative to the joints of the previous one.

- Mechanical fastening of sheets using disc dowels. Fasteners are installed at the corners of the joints and one or two in the middle.

- Reinforcement of insulation with mesh, leveling. Before applying decorative plasters, the surface of the heat-insulating layer is reinforced with a special mesh. According to the technology, the mesh sheets should be laid on glue with an overlap of 10 cm between each other, so that when the solution dries, the finish does not crack. If the surface has unevenness, they are carefully eliminated by rough plastering and priming.

- Decorative finishing. The final stage of work with the insulated facade of the house includes the application of decorative plaster. If necessary, the plastered surface can be painted. The finishing mixture is applied after the primer has completely dried.

The insulation of facades under plaster must be approached taking into account a number of features. First, you should decide on the thickness of the thermal protection layer of the house. For example, in areas with a temperate climate, a slab thickness of 50-70 mm will be sufficient for facade insulation. For regions with severe winters these values will be higher. Secondly, it is necessary to choose the right finish and always with good vapor conductivity characteristics.

In addition, the technology of thermal insulation of external walls for further plastering should be strictly observed. To work independently, you will need experience and skills, but the best option is to immediately turn to professionals and save time and money.

Installation of insulation

The technology for insulating a facade under plaster includes several steps:

Work order

Next, we will familiarize ourselves with all these stages of work in order.

Preparation of materials

So, to insulate the walls of a house under plaster, you need to prepare:

- facade insulation of suitable thickness. As a rule, slabs 5-10 cm thick are used for these purposes. In the northern regions, thermal insulation 150 mm thick may be needed;

- adhesive for insulation - the choice depends on the type of thermal insulation. For example, for extruded polystyrene foam, adhesive foam should be used. For mineral wool, adhesive such as Ceresit CT180 is used, which is a dry mixture; there are also special compositions for foam plastic;

Adhesive foam for penoplex

- base strip - serves as a guide for insulation boards;

- dowels for insulation (umbrellas);

- façade primer;

- fiberglass mesh;

- perforated corners.

Preparing walls for installation of insulation

External walls are prepared as follows:

- if the property has already been used, there will probably be canopies, drains or other parts on the facade walls that will interfere with further work. Therefore, they all need to be dismantled;

Old finish must be removed

- If there is old plaster on the walls, it must be removed. If this is not done, then after finishing the facade it may begin to peel off. ;

- then the facade should be cleaned of dirt and dust. To do this, the walls can be washed with a hose or wiped with a damp cloth;

Priming the wall with a roller

- after this you need to prime the walls. The liquid can be applied using a roller or brush. Try to ensure that the soil is laid down in a thin, even layer. Once it's dry, apply a second coat of primer.

Example of mounting a plinth strip

Installation of insulation

Now you can begin insulating the facade under the plaster.

This work is done like this:

- Before you begin installing the insulation, you need to secure the base strip to the walls. It is called basement because it is installed at the very bottom of the walls, from which insulation begins.

The position of the bar must be checked with a level

As I said above, this bar serves as a guide, so during its installation you must use a building level;

Preparation of glue

- then prepare the glue, if, of course, it is a dry mixture. To do this, pour it into a bucket, then add water and mix with a mixer or drill with an attachment. The result should be a solution with a dough-like consistency;

Applying glue to mineral wool

- Now the glue needs to be applied correctly to the slab. If the walls are smooth, you can cover the entire back side of the insulation with a thin layer of adhesive solution.

An example of applying adhesive foam to insulation

If the slabs have to be leveled relative to the surface of the slab in order to obtain an even plane, it is better to apply the glue in lumps . In case of insulation of walls with extruded polystyrene foam, adhesive foam is applied along the perimeter of the slab, as well as in the center;

- Now the insulation needs to be inserted into the base strip, and then lightly pressed against the wall with your own hands. To adjust the position of the slab relative to the wall, apply a level to it.

Installation of insulation begins from the corner

According to this scheme, the insulation of the entire first row is glued;

- to ensure that the vertical joints are offset relative to each other, start installing the second row from half the slab , i.e. according to the principle of brickwork. According to this scheme, the entire facade is covered with insulation;

Example of slope insulation

- After the insulation of the facade is completed, it is necessary to insulate the slopes. To do this, use 2 cm thick insulation. Cut it into panels of the required size and cover window and door openings with them;

- Next, you need to wait for the glue to dry, after which you can begin installing the dowels. This process is quite simple - a hole is drilled in the wall through the thermal insulation, after which a dowel with a wide head is inserted and a nail is driven into it.

Dowel installation

The most important thing at this stage is to position the fasteners correctly. They should fix the slab at the corners. In addition, one or two dowels must be installed in the center of each slab.

Keep in mind that the fasteners must be slightly recessed, otherwise it will not be possible to complete further wall finishing..

Filling gaps with adhesive foam

Preparing the surface for plastering

Now you need to prepare the surface of the external walls for plastering.

Instructions for doing this work look like this:

- if there are gaps between the thermal insulation boards, be sure to fill them with scraps of insulation or adhesive foam, as shown in the photo above;

Unevenness can be removed using a grater

- If there are differences at the joints of the slabs or you notice any irregularities on the walls, they must be removed using a special grater . To check how smooth a particular section of the wall is, apply a long rule to it;

- if the walls are covered with extruded polystyrene foam, the surface of the insulation must be made rough. To do this, it can be treated with a metal brush, a needle roller or a grater, which I mentioned above;

Example of surface preparation of extruded polystyrene foam

- after this, the extruded polystyrene foam must be coated with an adhesive primer, which is applied in two layers;

- further, all external corners should be protected with plaster perforated corners, which are glued with insulation adhesive. When installing the corners, use a level so that they do not deviate from the horizontal or vertical;

Installation of plaster corner

- After this, you need to cover the caps of the fasteners with an adhesive solution using a spatula.

After performing all these procedures, you should get a flat and relatively smooth surface.

Cutting fiberglass mesh

Reinforcement

The next stage of work is the rough finishing of the facade using insulation.

It should start with slopes that are reinforced as follows:

- first you need to cut the fiberglass mesh so that the strips can be wrapped at the corners, and at the same time they overlap each other by 10 centimeters;

Slope reinforcement

- then glue with a thickness of 0.3-0.4 mm should be applied to the slope;

Angle alignment

- after that, attach the mesh to the glue-treated slope, align its position, and then smooth it on top with a regular spatula. As a result, the glue should completely cover the canvas. Pay special attention to aligning the corners. If the mesh is rigid, apply glue to the fold line and wait a minute or two until the mesh gets wet. After this it will become much more elastic;

- Reinforce the entire opening using this principle.

If finishing is done using mineral wool, first lightly moisten the surface of the insulation. This will improve the adhesion of the glue and it will not roll off.

Facade wall reinforcement

Now you need to reinforce the surface of the walls by following these steps:

- cover a small section of the wall with glue;

- then attach the pre-prepared mesh to the glue, then level it and run it with a spatula;

- After the mesh is fixed on the wall surface, glue the rest of it. To do this, simply apply glue over the canvas using a spatula, as shown in the photo above. At the same time, make sure that no waves appear on the mesh during the gluing process;

- According to this principle, the entire surface of the facade is reinforced. As with reinforcing slopes, glue the mesh with a turn at the corners and an overlap;

Applying a second layer of glue

- After the walls have dried, apply a second layer of glue several millimeters thick. The purpose of the second layer is to increase the strength of the surface, as well as eliminate minor flaws. Therefore, it should be applied according to the putty principle, i.e. carefully, trying to achieve a perfectly smooth surface.

Do not attempt to correct major wall unevenness by applying a thick layer of adhesive. This will lead to cracking of the surface as the composition dries.

At this point the work is completed, now all we have to do is finish the walls and slopes with façade plaster.

Surface priming

Types of thermal insulation materials

First, let's figure out what kind of facade insulation is used for the exterior of a house.

Mineral wool

It is one of the most popular materials used to insulate facade walls using “wet facade” technology.

Vata has certain benefits, which include:

- environmental Safety;

- vapor permeability;

- excellent thermal insulation qualities;

- ability to resist ignition;

- high strength index.

Developers note some disadvantages:

- mineral wool is more expensive than polystyrene foam;

- the weight of the material is quite large;

- The fibers are fragile and when they get on the skin they cause irritation.

Some experts advise using insulation with a lower density, since it has lower thermal conductivity. But such a statement is erroneous, since the density value is quite an important feature, because the strength of the insulating material depends on it.

If the insulation of the facade is carried out using the “wet” method, then the thermal insulation materials perform load-bearing functions. In addition, the insulation is protected from mechanical stress only by an adhesive layer, the thickness of which is several millimeters, and a fiberglass mesh used for reinforcement.

When using less dense wool, be prepared for the insulation to delaminate under the weight of the finishing material. It should also be noted that the finish will be unstable to mechanical loads.

Styrofoam

For plaster facades it is considered the most popular insulation material.

Polystyrene foam is affordable, lightweight, has excellent thermal insulation properties, and does not cause skin irritation.

Unfortunately, the vapor permeability of polystyrene foam is zero, the walls do not “breathe” after such insulation, and a reliable ventilation system must be provided in the rooms. The material is subject to combustion, during which it releases toxic substances that have a poisonous effect on humans. The strength of polystyrene foam is low, and the surface of the outer wall does not receive adequate resistance to impact loads.

Extruded polystyrene foam

This is one of the types of polystyrene foam, made using a special technology. In this regard, the material has received a number of advantages:

- its strength indicator is ten times greater than that of polystyrene foam. The material based on it is recommended for use on the walls of the first floor and basement;

- expanded polystyrene is considered a low-flammable material, as it contains fire retardants;

- The thermal conductivity index is significantly lower than that of mineral wool and polystyrene foam.

Unfortunately, there are also negative aspects. Expanded polystyrene has a low level of adhesion and requires a special approach when working. The price for such material is quite high, vapor permeability also leaves much to be desired.

Advantages of plaster over other materials

When choosing a finish for facade insulation, the following advantages can be noted:

- Protects the building from precipitation;

- High vapor permeability prevents moisture from accumulating in building materials - it is constantly removed naturally;

- A thin layer of plaster weighs significantly less than other finishing materials, which minimizes the load on the house;

- Using a combination of “thermal insulating materials + plaster” allows you to insulate almost any material from brick to concrete;

- The result of insulation is smooth, smooth or textured surfaces, which guarantees an attractive exterior and the ability to implement a wide variety of architectural solutions.

Manufacturers

It is better to buy cotton wool from trusted manufacturers. Among them are both well-known brands and mineral wool brands that are unfamiliar to the mass consumer.

Rockwool. (Denmark) produces insulation from basalt and gabbro fibers at production facilities located in several countries, including Russia. Features of insulating mats are:

- low thermal conductivity;

- good absorption of air noise;

- resistance to open flame (flammability class NG);

- long service life;

- environmental cleanliness.

Paroc. A manufacturer of basalt wool from Finland () offers consumers mats for residential construction and acoustic insulation of recording studios.

The insulation is characterized by a low thermal conductivity coefficient, fire resistance, and durability. It is almost impossible to find counterfeit products on sale - the company very carefully monitors the market for counterfeits. Unfortunately, for the average consumer the price of insulation is too high.

Isover. The leader in sales of mineral wool in Europe is a transnational company registered in France, which has its production facilities in Russia. The product has the best balance between price and quality.

TechnoNIKOL. The brand of thermal and waterproofing materials "TechnoNIKOL" belongs to Russian business, but is produced in many European countries (Lithuania, Belarus, Czech Republic, England). Among the huge product line, mineral wool insulation occupies a significant place. Modern equipment and careful quality control allowed the company to enter the TOP 5 largest suppliers of mineral wool to the construction market of Europe and the CIS countries.

IZOVOL. produces basalt insulation in Russia. The product has an affordable price and good quality. The line of insulation products includes mats produced separately for facades, roofs, floors, and foundations.

All quality characteristics meet the requirements of EU and Russian standards. A slight shedding of fibers during the installation process blurs the impression of quality. The manufacturer knows about the problem, but cannot fix it yet.

In addition to the listed brands, it is worth paying attention to the products of the brands “KNAUF” and “URSA”. It is very often bought for insulating timber houses.

From the middle price sector, experts note the insulation "Beltep" (Belarus). It has excellent rigidity, good vapor permeability, easy installation, and an affordable price.

The most popular thermal insulators

There are many insulating materials, of which expanded polystyrene, mineral wool slabs and foam glass are popular in the wet facade system. To buy a quality product, contact directly the manufacturer, an official dealer or a specialized retail chain.

Expanded polystyrene

Expanded polystyrene is a synthetic thermal insulation material that has been used for insulating houses since the 50s of the last century, during which time production technology has been improved and new varieties of material have been created. Sometimes illiterate sellers equate polystyrene foam with polystyrene foam, but this is a gross mistake: polystyrene foam is an excellent packaging material, but it cannot be used for insulation - it absorbs moisture and is not resistant, its service life is 2-5 years.

Expanded polystyrene is used as a heat insulator - an effective lightweight insulation with a service life of up to 30 years.

- density 8...35 kg/m3, depending on the brand;

- thermal conductivity 0.037…0.043 W/m°C;

- water absorption 1.8...4.0;

- vapor permeability 0.05 mchPa;

- flammability group G4;

- temperature range -60…+80°С;

- chemical resistance - unstable to acetone, turpentine, drying oil and petroleum products;

- noise absorption 41 dB;

- environmental safety - when burned, it releases phosgene, hydrogen bromide and hydrocyanic acid; in a stable state it is harmless.

The disadvantages of expanded polystyrene include flammability, the “love” of rodents for it - they like to make nests in unprotected layers, destruction in the light and absorption of moisture: the material has a structure with open cells in which moisture is retained, worsening the thermal insulation qualities of the material.

When purchasing slabs of expanded polystyrene, it is important to make sure of the quality of the product - the edges of the slabs must be smooth, as if sealed, without cuts or chips, and the material itself must have a certificate of conformity, since unscrupulous sellers pass off ordinary polystyrene foam as polystyrene foam, which is not insulation.

Penoplex

Penoplex - extruded polystyrene foam with a closed cell structure, has a lot of advantages compared to expanded polystyrene - light, dense, effective, absorbs less moisture, belongs to the G3 flammability group - does not spread flame, self-extinguishes. The durability of the material is up to 50 years. Disadvantages - higher price, comparable to the price of mineral wool slabs, low vapor permeability.

- density 26...35 kg/m3, depending on the brand;

- thermal conductivity 0.028…0.035 W/m°C;

- water absorption 0.2%;

- vapor permeability 0.01...0.05 mchPa;

- flammability group G3...G4;

- temperature range -70…+75°С;

- chemical resistance - unstable to acetone, turpentine, drying oil and petroleum products;

- noise absorption;

- environmental safety - when burned, it releases phosgene, hydrogen bromide and hydrocyanic acid; in a stable state it is harmless.

The most famous manufacturers of penoplex are the TechnoNIKOL corporation and the plant in Kirishi, Leningrad Region. In any case, the color of the material must be orange-red and have a certificate of conformity.

Mineral wool

Under the general name "mineral wool" are collected thermal insulation materials created on the basis of fibers obtained from melts of mineral substances:

- slag wool - from waste blast furnace slag, the cheapest option, however, it is rarely used for insulating houses, since it is produced only in the form of soft mats, unsuitable for plastering, and it may also have a residual radiation background;

- glass wool - made from broken glass and quartz sand, produced in the form of soft mats and hard slabs, not the best choice for insulating a residential building, since during cutting and operation it releases fine glass fiber dust, which can cause serious problems with the respiratory system and human skin;

- stone wool - from the melt of gabbro and dolomite minerals, various manufacturers have launched the production of various types of heat insulators and soundproofing materials from stone wool;

- basalt wool is made from the basalt rock, but we’ll talk about it separately.

The general characteristics of thermal insulators made of mineral wool are light weight, vapor permeability, low thermal conductivity, and durability. A common disadvantage is that mineral wool absorbs moisture, so increased attention is paid to hydro- and vapor barriers in structures.

Of all the materials described above, stone wool is popular for insulating facades: its thermal conductivity is close to expanded polystyrene, but does not burn, is vapor-permeable, and is a good sound insulator.

The final paint and plaster on mineral wool insulation must be vapor-permeable in order to release the moisture that the thermal insulation will pick up during plastering.

Basalt slabs

Basalt slabs are the most effective mineral wool insulation; they have the lowest thermal conductivity and greater vapor permeability. The disadvantage is the higher cost relative to stone wool.

- density 30...180 kg/m3, depending on the brand;

- thermal conductivity 0.0326…0.048 W/m°C;

- water absorption 1.5%;

- vapor permeability 0.3 mchPa;

- flammability group N/G;

- temperature range up to +600°C;

- chemical resistance - stable;

- noise absorption 0.75...0.99 dB;

- environmental safety - harmless.

Popular brands of basalt slabs are rockwool (often mistakenly written rockwool), nobasil, techno light, park, knauf.

Foam glass

Like glass wool, foam glass is based on broken glass, however, during the production process, the thinnest threads are not pulled out of the molten mass, but rather it is foamed, obtaining a closed cell structure, and then molded into slabs measuring 450x600 mm and a thickness of 80 to 250 mm. Main properties of foam glass:

- density - 120–150 kg/m3;

- low thermal conductivity 0.04 W/m°C;

- low water absorption (2% of volume) and vapor permeability;

- fire safety - N/G;

- resistance to low and high temperatures;

- chemical resistance;

- noise absorption;

- durability - the material is inert to all aggressive compounds, almost eternal;

- environmental safety - safe, recyclable and recyclable.

Before the advent of more effective materials, foam glass was used for thermal insulation of saunas and baths; now, due to its relatively high cost, foam glass is used less frequently.

Foam glass is a Russian-made material; the slabs are black or dark gray. When purchasing, request a certificate of conformity.

Rockwool mineral wool slabs for ventilated facades and their installation techniques

Curtain facades are characterized by convenient and quick installation and the absence of excessive additional loads on the foundation of the building. Also, this system is highly maintainable - you can replace the Rockwool insulation for the facade even during operation, you just need to dismantle several panels of external finishing.

The process of installing a ventilated façade using Rockwool mineral wool boards consists of the following steps:

- Careful surface preparation.

- Vapor barrier membrane flooring.

- Installation of supporting profiles made of metal or wood.

- Laying mineral wool slabs.

- Protection of Rockwool material with waterproofing film.

- Organization of the air gap - bars up to 30 mm thick are packed perpendicular to the supporting profiles, on top of them.

- Fastening of decorative finishing materials.

According to expert assessments of the staff, the most suitable material for organizing systems of ventilated suspended structures is basalt wool in Rockwool VENTI BATTS Optima slabs. You can order high-quality insulation at an affordable price from our company.

Why she?

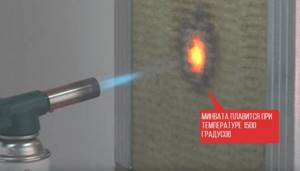

Stone wool for facade insulation (another name for mineral wool) is a non-flammable insulation material. For example, according to the manufacturer Rokwool, their mineral wool slabs can withstand temperatures of 1500 degrees WITHOUT FIREING or MELTING!

Alas, cheaper foam plastic cannot boast of this. There is a second important nuance. Vapor permeability. Mineral wool allows steam to pass through better, which means that in a sense it can be called a breathable insulation. Of course, insulation with mineral wool will cost more. You can see more about the properties of this material in the video on the topic: how to insulate the facade of a house with mineral wool.

Mineral wool for plaster is produced by different companies:

To insulate the facility, the customer provided TechnoNikol mineral wool for façade insulation.

According to the manufacturer Rokwool, their mineral wool boards can withstand temperatures of 1500 degrees.

How to calculate the thickness of insulation

Calculating the thickness of insulation is not an easy task.

First, the thermal resistance of the outer wall is determined using the formula:

R ex.=(1/α (in)) + R1 + R2 + R3 + (1/α (n))

R1, R2, R3 are the heat transfer resistances of all layers of the wall (we conventionally assume that there are three of them, although in practice there may be more or less).

α(в) and α(н) - the amount of heat transfer from the inner and outer surface of the wall, respectively.

Then the minimum value of thermal resistance is calculated using the formula:

R min = δ/λ

δ—layer thickness.

λ is the thermal conductivity of the material.

After this, the results obtained should be compared. If Rmin is less than (or equal to) Rpr, then the wall does not need insulation. If it turns out the other way around, the minimum value is greater than the calculated value, then the difference - ΔR - is the determining value for determining the thickness of the insulation (δS), which is found by the formula:

δS = ΔR · λу, where λу is the thermal conductivity of the insulation.

The calculation method is quite complicated due to the need to look for specific data and values for each region, use SNiPs or other reference materials. All this is quite difficult for an unprepared person, which gives rise to errors that reduce all efforts to nothing.

It’s easier to turn to online calculators, which will quickly give the required value; you just need to enter a few data on the wall material and the selected insulation.

If you have absolutely no desire to engage in such calculations, then you can resort to the simplest (and most commonly used) method: simply use insulation 5 cm thick. This value is the most common, it is suitable for almost all regions (with the exception of the northern ones or those characterized by severe frosts).

Calculation of material thickness

We figured out which façade insulation is better. Now it remains to determine the optimal thickness of the material, which depends on certain conditions:

- the building material from which the walls are built and its thickness;

- climate features of your region;

- thermal performance indicators of insulation material;

- features of the interior finishing - installed insulation layer, plaster or facing material.

The thickness of the outer plaster layer is not taken into account, because seven to eight millimeters will not play a special role.

It is best to determine the thickness of the insulating material for finishing the facade using calculators on special websites. By entering information about the walls, insulation material and area of construction work, you will get the desired result, which can be double-checked on another construction site. If the data matches, the result is considered correct.

You can take a more complicated route and perform calculations in accordance with the recommendations of the joint venture “Thermal Protection of Buildings”. True, this will require the help of experienced specialists.

Having received certain information, it is recommended to increase the thickness of the insulating material by ten to twenty percent, because the requirements for thermal insulation become more stringent from time to time.

Remember that the thickness of the thermal insulation material should not be less than five centimeters. Otherwise, you will not get a positive effect.

Types of plasters

When selecting facade plaster for work, certain difficulties may arise - the choice is very large. There are four types of plasters in total:

- Mineral (cement).

- Silicate.

- Acrylic.

- Silicone.

Each of these types differs from each other in the composition of the components, application methods, and properties of the resulting coating.

Mineral mixtures

The main components in the composition are cement and active additives that increase adhesion and give some elasticity to the final coating. To give a particular color shade, pigments are additionally introduced.

The mineral coating is highly durable. However, at the same time, it is the least elastic and in cases where significant mechanical stress is possible (washing the facade with a stream of water under pressure, shrinkage of the house) its use is not recommended.

Plaster is produced in the form of dry mixtures in bags. Before use, a certain amount of time is required to prepare and mature the solution.

Acrylic plaster

The main component is an aqueous solution of acrylic polymer with a small amount of mineral fillers. Coatings obtained from such compositions are characterized by high elasticity and durability.

Wall surfaces treated with acrylic plasters easily accumulate dirt and require regular cleaning. The compositions are produced completely ready for use.

Silicate compounds

In terms of their properties, silicate plasters occupy an intermediate position between mineral and acrylic compositions. The main binding component is potassium silicate (liquid glass). Acrylic resins are additionally introduced as plasticizers.

The coating is strong and durable, with medium elasticity. The combined use of mineral plaster and fiber insulation is almost ideal from the point of view of vapor permeability. Contaminants are practically not retained on the surface of the plaster layer.

The silicate mixture is produced in polyethylene buckets of various packaging. The composition is completely ready for use.

Silicone plaster

Silicone-based plaster compositions are distinguished by a combination of the positive qualities of all other groups:

- the coating is elastic, able to withstand small movements of the facade;

- the surface has self-cleaning properties. Dust does not stick to it and is easily washed away by rain or blown away by strong winds;

- The vapor permeability of the coating is somewhat worse than that of mineral compositions, but still sufficient for the free removal of moisture from the walls.

The only significant drawback is the high cost of the material.

Plastering works

The rules for applying plaster mortar are the same for almost any insulating material. The actions are performed in the following sequence:

- the entire surface of the insulating layer is covered with an adhesive solution, for which a notched trowel is used;

- a reinforcing mesh is applied to the freshly applied glue and lightly pressed into the mortar mass until it is completely sunk and a tight connection is created;

- additional putty is performed on top to compact and further strengthen the reinforcing base;

- you should wait some time for the glue to completely harden;

- Apply a layer of plaster material, observing the requirements of the accompanying instructions for a specific type. As a rule, such information is attached to the mixture by the manufacturer, and you just have to study it carefully;

- if necessary, the dried plaster solution is covered with one or two layers of paint.

Types of facade insulation and features of their use

Insulating the facade has obvious goals: increasing the level of comfort for residents, optimizing the temperature in the premises and reducing heating costs. In fact, the use of thermal insulation solves another important issue. If the walls are cold, condensation inevitably appears on them, which gradually penetrates into the thickness of the material, freezes, and then tears it apart from the inside. Sooner or later such walls will begin to collapse. If you increase the temperature on the surface and inside, condensation will not appear, therefore, the dew point will be displayed.

The essence of using insulation under plaster is to attach any heat-insulating material to the wall of the house and then plaster it. A special construction mixture will protect the insulation from atmospheric and other negative factors and create the basis for applying a decorative coating. There are different types of insulation on sale, each of which has its own pros and cons.

Types of insulation for plaster

Mineral wool boards

The basis for the production of this insulation is basalt or other silicate rocks, as well as metallurgical slag. They melt and stretch into fibers with a large number of air channels. The fibers are then formed into slabs with different densities and a certain number of layers.

The best mineral wool insulation for the walls of a house is a two-layer slab with a density of 100–125 kg/cu. m, where the soft inner layer firmly adheres to the wall, adapts to its relief, and the hard outer layer is the basis for the plaster. Mineral wool slabs (mats) have many advantages:

- strength and vapor permeability;

- excellent heat-saving properties;

- environmental friendliness, safety;

- lack of flammability.

The disadvantage of such insulation is significant - it is not able to withstand moisture, as a result, water literally saturates it, changing its performance properties for the worse. The problem will have to be solved by impregnating the cotton wool with water-repellent compounds. Also among the disadvantages is the large weight of the insulation and the ability to cause irritation on the skin.

Ecowool

This material is also called cellulose insulation, because it is made on the basis of cellulose. Its price is quite low, it provides excellent thermal insulation, is breathable, and environmentally friendly. However, ecowool is used quite rarely for wall insulation. It strongly absorbs moisture, as a result of which mold and mildew begin to multiply on its natural fibers. You need to apply insulation to walls using special equipment, which also reduces its popularity.

Insulating the facade of a house with ecowool

Glass wool

Glass wool is a well-known fibrous wall insulation, which is a type of mineral wool. It is made from glass fiber obtained from waste from the glass industry. The insulation is characterized by high chemical resistance, increased elasticity, strength, and vibration resistance. It has optimal thermal conductivity, which allows it to serve as a heat and sound insulating material.

Glass wool is available in slabs and rolls. It can be used as facade insulation under plaster, as well as for thermal insulation of internal partitions and roofs. Disadvantages of the material:

- the need to use respirators and gloves when working (otherwise small fibers will harm health);

- crumbling and large shrinkage.

Isover fiberglass insulation

Styrofoam

Expanded polystyrene, or polystyrene foam, is a rigid polymer board consisting of small air-filled granules. The insulation on top is impregnated with fire retardants, so it does not support independent combustion, but when smoldering from another source it emits toxic fumes. The main advantage of polystyrene foam is its resistance to moisture and lightness, due to which the load on the foundation almost does not increase.

Insulating the facade with foam plastic

Polystyrene foam is a popular material for difficult climatic conditions. It does not lose properties during 80 cycles of freezing and thawing. This foam insulation is ideally combined with plaster. By itself, it is afraid of ultraviolet radiation, collapsing under the rays of the sun, and rodents can also live in it. After plastering, the material will fully demonstrate its performance characteristics, because it will be reliably protected from negative factors. The durability of such a combined insulation will increase, as will its resistance to weathering, cracks, dents, and scratches.

Extruded polystyrene foam

This insulation is a type of conventional polystyrene foam with a more uniform fine-porous structure. It has better technical parameters, but costs an order of magnitude more. The advantages of the material over conventional polystyrene foam are obvious:

- the strength is tens of times higher, so it can be used for cladding plinths and basement floors;

- the flammability of polystyrene foam is reduced;

- the thermal conductivity of extruded slabs is less than that of foam plastic and mineral wool;

- Thanks to the profiled edges, installation of the slabs is easy, and there are no seams on the finished coating.

Penoplex slabs made of extruded polystyrene foam

Extruded polystyrene foam does not allow vapors and gases to pass through, so the vapor permeability of the walls may be impaired. The adhesion of insulation to plaster mixtures is quite low, as a result of which its installation requires a special approach.

Sprayed thermal insulation materials

A separate group of insulation materials includes liquid sprayed materials. The most famous and popular among them is polyurethane foam in the form of foam, which is obtained by mixing two main components. It is easy to apply such insulation, the work goes quickly, and there are no seams left on the surface. It firmly adheres to all types of substrates: wood, brick, metal, concrete.

Sprayed insulation materials are very lightweight and can withstand humidity, temperature changes, and exposure to chemicals. They must be protected from direct rays of the sun, otherwise they begin to deteriorate from the action of ultraviolet radiation. In addition, sprayed insulation supports smoldering, which occurs upon contact with an open fire.

Household sprayed polyurethane insulation Polynor

Insulation for facade plaster - choosing the best option

When choosing a specific insulation for your home, you need to be guided by its durability, resistance to adverse factors, and fire safety. Many people also take into account the affordability of insulation and its availability in stores. However, these are not all the criteria that need to be taken into account. The shape of the insulation should be convenient for installation. It’s good if the material is hard enough and can be secured without much effort. The higher the thermal insulation qualities of the insulation in slabs or rolls, the better the result will be. It is important to know the load-bearing characteristics of the walls so that the finishing done does not spoil their properties.

Tips for selecting insulation for the exterior of a house are as follows: