Advantages of facade panels with insulation

By choosing insulated facade panels, you get several advantages:

- The load on the foundation will be small, because thermal panels weigh little (10 times less than brickwork of the same area). You don't have to worry about the reliability of the foundation and the strength of the walls.

- Installation can be carried out all year round - there are no restrictions.

- The palette of colors and variety of textures will please even the discerning homeowner.

- In winter, the figures in housing and communal services calculations will be up to 40% lower. This means that after overwintering for several winters, you will recoup the cost of the cladding.

- The fastening of the panels to each other is so strong that the facade is not afraid of slanting rain.

- The panels do not burn and do not support the growth of mold and fungi.

- The service life of such panels is at least 50 years, and if you choose products from the ABC-Klinkergruppe concern, the warranty on the panels will be 100 years.

Scope of application

Sheathing is used for exterior finishing of buildings or structures. These can be residential, industrial or public buildings, single- and multi-storey. The material is suitable both for direct installation on the wall and for forming a ventilated façade, i.e. as a protective layer for external insulation.

The material of the walls does not matter; the low weight of the cladding allows you not to strengthen the foundation. Some samples can be used for interior cladding of walls in residential apartments, premises, shopping centers, and public buildings. This versatility has become the reason for the wide distribution of the material among homeowners or entrepreneurs with large buildings.

Fiber cement siding

This is another type of artificial facade board in the literal sense of the word.

The composition is lightweight concrete made from a mixture of cement, cellulose fibers, dyes and additives. In most cases, the shape is a board with the texture of natural wood, but there are other solutions. Including at the coverage level. Therefore, the properties and cost of this siding depend on the manufacturer.

Fiber cement siding without coating

This type was created as a replacement for traditional siding, so its installation method is classic - from bottom to top, in a herringbone pattern with the top board overhanging the bottom board.

Fiber cement board is easy to cut and drill. Thanks to micro-reinforcement at the composition level, the strength of the skin is quite high. And coloring with pigments in volume (to the entire depth of the board) gives high resistance to solar ultraviolet radiation.

In our video we will talk about Japanese facades. Let's take a closer look at what errors happen during the installation process:

Fiber cement panels with herringbone fasteningSource sv.decorexpro.com

Fiber cement siding with coating

Recently, new types of siding for finishing the outside of a house have appeared on the market of finishing materials - fiber cement panels with a protective coating and a multi-layer structure. The authors of this new product are Japanese manufacturers of facade systems. Each company has its own recipe, but the properties and cost are equivalent. And all modifications have a layer with a solar ultraviolet absorber, which increases resistance to fading.

The simplest option is acrylic paint with the addition of silicone copolymers as a protective layer. Estimated cost is about 1500 rubles/m2.

A little more expensive is painted fiber cement siding with the addition of a hydrophilic layer. This is a kind of sorbent that absorbs moisture from the air, which creates a microscopic film of water with self-cleaning properties - dirt is easily washed off by rain. Price – around 2000 rubles/m2.

Another step higher is ceramic siding with a hydrophilic layer. The basis of these panels is still fiber cement, but with a ceramic coating and a high degree of protection of pigments from destruction when exposed to UV. Price – from 2500 rub/m2.

House finished with fiber cement ceramic sidingSource pinterest.com

And at the very top of the fiber cement siding hierarchy are panels with a protective layer of photoceramics. In addition to blocking ultraviolet radiation and the ability to self-clean, there is a disinfection and air purification function. Photocatalysts, when exposed to light, kill some of the bacteria that are on the surface. Price – from 4000 rub./m2.

Both parts of the house are finished with fiber cement sidingSource eternit.ru

Vinyl and metal siding

Metal and vinyl siding for exterior decoration are different types of siding in materials, but similar in profile and decorative capabilities. The proximity is so close that the installation technologies are largely similar - it is also necessary to take into account the thermal expansion of the panels when attaching them to the sheathing and joining with additional profiles. They also have almost the same range of colors and textures.

Based on the type of profile, single- and double-fracture panels are distinguished. By type of front surface - shiplap, herringbone and block house.

The cost of standard “wall” panels varies slightly. But in both cases, you can find domestically produced panels within 300 rubles/m2. And imported siding from Europe will cost from 800 rubles/m2.

In addition, vinyl panels have a denser design:

- basement siding, which is often used for cladding the entire facade (costs from 500 rubles/m2 to 1500 rubles/m2);

- siding made of foamed PVC with good sound and heat insulation properties (price about 1000 rubles/m2).

For a clear overview of siding, watch the following video:

Siding as panels for the exterior decoration of a house is chosen as part of a curtain wall system, which makes it possible to comprehensively solve the problem of protecting walls, insulating the house and decorative finishing. But most of all it is attractive because of the widest range of materials, texture and cost.

Varieties by material

Various raw materials are used as the basis for facade panels. Each option has its pros and cons, so let’s look at the most common ones.

Metal

Not long ago it was believed that metal products were not suitable for exterior decoration. But technology has stepped forward, and now these panels have acquired significant advantages: laminated coating, imitation of a 3D pattern, etc. For the production of metal panels, aluminum, stainless or galvanized steel is used. Although it should be noted that the last two types are subject to deformation and accumulation of static charge.

The aluminum base is more stable, but at the same time more expensive.

Polymer

The basis for these plates is polyvinyl chloride, thanks to which they are quite resistant to atmospheric influences. Typically, such plates are divided into two types: for the base and for the wall. An important feature of the former is the imitation of the texture and color of natural stone. Those that are mounted on the wall are additionally equipped with decorative junction points. This makes it possible to conveniently finish hard-to-reach places (openings, turns, drains, etc.).

Polymer panels are characterized by quick installation and minimal amount of construction waste that can be generated during the work. And what is very important, PVC plates are practically not subject to atmospheric influences.

Composite

Composite materials include a whole group of finishing materials that differ in technical characteristics and appearance. The basis of such slabs is:

- porcelain stoneware (Characterized by high strength, resistant to moisture, UV radiation and detergents);

- aluminum composite (Expensive finish, consisting of two aluminum sheets and a polymer material between them. Characterized by increased mechanical strength and resistance to adverse environmental factors);

- clinker (has a heat-insulating layer in the structure. The weak side of these slabs is their significant weight);

- fiber cement (Produced on the basis of cement mortar and polymer fibers).

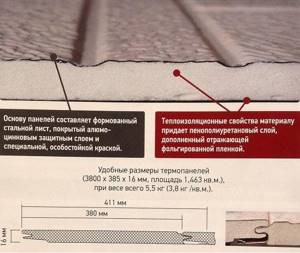

Features of thermal facade panels

Thermal facade panel consists of a facing layer, behind which the insulation is hidden

Structurally, all types of thermal facade slabs are identical: they consist of two or three layers of facing building material, which hides the insulation from the inside. The front side is usually decoratively finished. The greatest interest from home owners is in panels designed to look like clinker tiles, bricks, and natural stone.

Advantages and disadvantages of application

Thermal facade panels keep you warm in cold weather and cool in the summer heat. The insulating effect of such cladding implies significant savings in energy resources. High thermal insulation properties make it possible to recoup costs within three to four heating seasons.

Another advantage is the low weight of façade thermal insulation panels. They do not exert a significant load on the foundation. Lightweight elements are also easier to install: most products are attached manually without the use of special equipment.

Thermal facade slabs also have other advantages:

- long service life;

- mechanical strength;

- resistance to temperature changes and exposure to sunlight;

- moisture resistance;

- immunity to mold and mildew;

- fire safety;

- environmental friendliness.

The wall surface must be thoroughly prepared before fixing the slabs.

Properties and characteristics

The facade panel can be selected according to three parameters - temperature range, length and width

Cladding panels have the following parameters:

- length – 100–125 cm;

- width – 42–46 cm;

- temperature range - from minus 50 to plus 60 degrees.

The thickness of the products depends on the number of layers and insulation. Wall panels for insulation are durable. According to the manufacturers, they will last for more than fifty years without loss of useful qualities and original shade.

Types of thermal panels: which one to choose

There are different types of thermal panels. To make the right choice, you need to consider what they are.

Plastic

Made of plastic, due to the design of the air cells, heat is retained. Installation of such thermal panels is carried out by inserting products into one another. Plastic panels are moisture resistant and resistant to low temperatures. In addition, they can last for quite a long period.

The biggest disadvantage is that plastic will release toxic gases during combustion. Therefore, they are rarely used for residential premises, mainly for warehouses, change houses, etc.

Clay

Such thermal panels look extremely impressive when facing the facade. In addition to their appearance, they provide high-quality insulation to the home. Clay is moisture resistant and resistant to low temperatures. In addition, ceramic products will not lose their appearance due to solar radiation. They have high strength and durability.

Clinker

It is a multilayer material. There is only an option made from polystyrene foam and clinker. Available as a rectangular block with jagged edges. The material is expensive, but at the same time it has a bright appearance and is characterized by long-term operation. In addition, along with the finishing, thermal insulation performance will improve. The only material that comes with insulation.

Fiber cement

Quite a budget solution for cladding a home. Includes 90% cement and 10% cellulose, plastic or fiberglass. Such cladding lasts for quite a long time and is characterized by increased resistance to temperature changes and solar radiation. Living in a house with such panels becomes more comfortable. There is no need to wash, they are cleaned thanks to rain and snow.

Metal

Galvanized steel and aluminum are used as materials for metal panels. Products are mounted on nails or self-tapping screws, which is quite simple. The developers claim that the product's service life will be about 30 years.

The indicated operating temperature range is –50 +50 degrees, but it should be taken into account that the panels themselves do not protect from the cold. It is mandatory to use insulation. Its metal panels protect against adverse factors.

SIP panels

The structural insulation panel includes 2 wood panels containing insulation. Such plates are designed to provide rigidity to the device. They are characterized by increased thermal efficiency and proper sound insulation.

Builders choose this material due to its ease of installation and the absence of non-working seasons - private houses from SIP panels can be built throughout the year.

One of the disadvantages is the increased fire hazard of the material. Obstructing the flow of air is also considered an advantage, so you should think about the ventilation system in cottages at the design stage.

Sandwich panels

The panels are similar in structure to the previous type of product. They also include 3 layers, but the top ones are made of metal and there is insulation inside. Thanks to the use of an auxiliary layer of plasterboard or stone wool, fire resistance indicators increase.

Polyurethane

Proper insulation and sound insulation parameters of such products will be achieved due to the cavities filled with air. Capable of operating in a temperature range of -70 +120 degrees. Polyurethane panels are quite flexible, therefore they are used to design a curved surface. Significant distribution is ensured by low price.

Wooden

Wood panels are one of the favorite tools of designers. When used correctly, it is possible to achieve extraordinary results. Wood is a malleable material, and therefore the panels have a variety of shapes. The most common type of wood panels is ordinary lining.

We recommend: A cap for a chimney pipe: the difference from a chimney, a canopy and a weather vane, drawings and diagrams, how to make it yourself

Composite

The main materials of the products in question are aluminum and plastic. The rule of multi-layering is also observed here, which increases noise and thermal insulation characteristics. The outer side is coated with special paint; such panels have numerous color options. In expensive panels, the texture of natural and artificial materials is sometimes imitated. The paint coating can have dirt-repellent properties, which will make it possible to ensure comfort during the operation of such a building.

In the process of selecting panels, it is necessary to take into account that such a decision is made for many years to come. They determine the external appearance of the building; resistance to external factors - cold, heat, solar radiation, rain and snow - will depend on them.

The best manufacturers

Depending on the type of slabs chosen, experienced craftsmen advise purchasing products from trusted brands. Such material has been tested by time, as evidenced by numerous reviews. Excellent quality was demonstrated by both domestic brands and imported manufacturers. You should choose based on your financial capabilities.

Table 1. The best manufacturers of PVC plates.

Manufacturer Features Docke The company offers a huge range of designs. Among the forms there are both wooden textures and stone slabs

Popular options include imitation ship planks and timber. Vox An excellent brand that pays attention not only to appearance, but also to functionality. The product from Vox has a stain-resistant coating

The author's locking fastening system has also been thought out to prevent moisture from entering. Alta-profile Domestic product of reference quality. The materials are manufactured according to GOST, and the Institute of the Russian Academy of Sciences took part in their development. The products withstand extreme temperatures and have a spectacular appearance. Yu-plast is a Belarusian brand with a good reputation. The manufacturer is known for its affordable prices and careful imitation of textures. Yu-plast brickwork is especially popular. They also note high resistance to atmospheric conditions, since MasterTec pigments are used in production. FineBer In addition to GOST, production is guided by the American ASTM quality assessment. The brand cares about the appearance of the coating, which is why its wood imitations are called the most realistic. Novik is a Canadian company that craftsmen love for its good stone imitation. The range of designs is huge. The manufacturer has improved the slabs by increasing their thickness. Dolomite High-quality products from a domestic brand. The range includes river stone, rock reef, slate and other wild stones. Service life exceeds 50 years. The durability of the material is high, as are the performance qualities. The coating can be washed and repaired.

The best manufacturers and costs of thermal panels

If we talk about the highest quality, durable and safe products, then it is worth considering several companies:

- MFM. This company uses extruded polystyrene foam for production. Insulation thickness up to 100 mm. Buyers are presented with a wide selection of clinker panels or products made to look like natural stone and other types of masonry. A standard one-and-a-half laminated brick measuring 1250x600x60 will cost at least 1,600 rubles per m2.

- FTP Europe. According to the manufacturer himself, clinker tile models are of German quality, and porcelain stoneware coverings are delivered from Europe. The company also offers a wide selection of polyurethane foam and polystyrene foam products. The cheapest slab measuring 1000x650x60 will cost about 1,100 rubles per “square”. More expensive products will cost at least 3,600 rubles per m2.

- Termosit. The products of this company inspire great confidence, since all slabs are accompanied by patents and quality certificates. During the production process, products go through a full technological cycle. Only modern equipment is used. All products are checked for compliance with the stated parameters. And their prices are quite affordable. The cheapest option will cost about 1,000 rubles per square meter.

Some companies use only natural materials as finishing coatings. For example, products are covered with real stone. Expanded polystyrene and polyurethane foam are used as insulation. It’s true that such panels cost at least 2,300 rubles per m2.

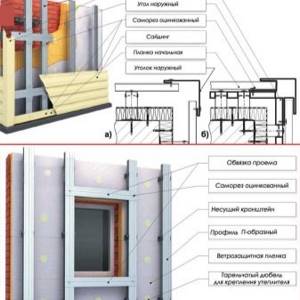

Technology of finishing the facade of a house with cladding panels

Installation work consists of three main stages (photo below):

- Preparation.

- Installation of subsystem and insulation.

- Installation of panels.

These works are carried out sequentially; it is impossible to exclude or skip any stage. Procedure:

Preparation

The surface of the walls is freed from all hanging and foreign objects, elements of the drainage system, platbands and other components. The old casing is removed; if there was a layer of paint, it is cleaned and all peeling or shedding is removed. All potholes or cracks are opened and filled with putty or plaster. The surface is primed.

NOTE! In the most advanced cases, you have to do continuous plastering of the walls. This may be necessary when there is excessive curvature, large deep potholes or cracks.

Insulation and subsystem

The prepared surface is marked, and brackets for installing the sheathing strips are installed at the designated points. Then a thick layer of insulating material is installed on the surface of the wall - mineral wool, polystyrene foam, etc. In the places where the brackets pass, cuts or holes are made, which are subsequently carefully tucked in. The insulation boards are installed on the adhesive layer, additionally secured with disc-shaped screws.

Two extreme strips are installed on the protruding ends of the brackets - lower and upper. They are carefully aligned horizontally and according to the amount of lag from the wall surface. Then a cord is stretched between them, along which the remaining planks are mounted.

Panel installation

Installation is carried out from bottom to top and from left to right. The sheets are attached to the sheathing using self-tapping screws. The sides are connected according to the standard pattern - using special cutouts along the joint lines of the pattern and the sockets on the side faces. The end panel in the row is trimmed to create a straight, even edge.

The first row from the bottom rests on the starting strip, the subsequent ones on the same profile available on the upper edges of the panels. After installing all the panels, additional elements are installed and window and door openings are formed.

CAREFULLY! The basic rule of installation is to fasten each element with loose screws. When thermal expansion occurs, panels or extensions must be able to move freely

Otherwise, the canvas will begin to become covered with waves due to thermal expansion.

Facade panels are an inexpensive and very effective way to decorate a house. Having high decorative capabilities, the material allows for independent installation, which requires virtually no qualifications. At the same time, all the functional qualities of the cladding fully meet all the requirements, and in some moments even surpass them. Durability, solidity and style that is created in a previously unremarkable house - this is the result of installing façade panels.

Wall condition assessment

In order for the panels to be securely attached to the facade, there should be no weak spots on the walls - peeling of old plaster, karst depressions, deep cracks, loose areas, etc. - everything that will not allow you to reliably strengthen the dowels.

If necessary, minor repair work will be required.

The evenness of the walls is assessed – vertically, horizontally and diagonally.

Thermal panels can be mounted directly on the facade if local level differences do not exceed 50 mm.

In cases where small bulges in the wall can be eliminated, this should be done in advance. If the differences are significant, and their elimination will involve large-scale plastering work, it will be easier to level the level using lathing.

Types of facade panels for finishing the house outside.

Panels with insulation are produced in the form of blocks, which are installed on the facade without installing sheathing. The thickness of the products ranges from 6–12 cm. In addition to the finishing layer and material that provides thermal insulation, they can have a hard layer and built-in fasteners at the bottom.

The following is used as a decorating surface:

- clinker, glazed or porcelain tiles with marble chips for grouting;

- corrugated sheets with patterns of natural materials or metal samples made of aluminum;

- wood chips;

- imitation stone or marble.

Finishing the house with sandwich panels.

These are three-layer panels for insulating the facade of a house, which include insulation and cladding on both sides. Manufacturers use samples made from shavings or metal as finishing. Such panels need additional coating, as they do not look presentable. Such panels can be used to completely build new houses or insulate existing ones.

Insulated facade panels for the exterior of a house using sandwich panels can be described as lightweight, durable, and heat-saving. They are produced by pressing insulation and outer skin. The dimensions of such panels are 12 cm wide, 1–12 m long, 0.5–2.5 cm thick. Installation is facilitated by the presence of special locks.

Finishing with thermal panels.

They are also durable, with a service life of up to 50 years. Mineral wool cannot be used as insulation in facade tiles with insulation. They are produced in different thicknesses - 6–8 cm, so when choosing, be guided by the climate of the place where the house is located.

The optimal thickness of the panels will prevent the destruction of the house due to negative environmental factors or biological influences. Their main advantage is ease of maintenance, because brick panels do not require much attention and are low in price compared to the cost of natural brick.

Thermal panel with plaster for exterior finishing of the facade of the house.

The façade panels, which look like plaster, are made from a foam board as insulation and 0.4–0.5 cm of marble chips. Their thickness varies between 5–10 cm.

Thanks to their structure, insulated wall panels successfully withstand aggressive environments and are glued to external walls using ordinary foam plastic adhesive.

There are two similar ways to install panels, which end with sealing the seams:

- Standard grout with marble chips to match the sample.

- By gluing the profile pieces onto the sealant.

What are panels for facade insulation?

Firstly, it is a multilayer slab-type material. But there are three main layers: insulation, which is represented by two materials: polystyrene foam and polyurethane foam, a decorative panel and a base. Some models of thermal panels do not have a base. Today, manufacturers offer a huge amount of cladding in terms of their decorative content: color, shape, pattern, imitations.

But as for the material, there are only four positions:

- Clinker tiles. It is simply glued to the insulation in a checkerboard pattern. OSB boards are used as the base, which give the material additional rigidity. This variety has a stylish design, which is very popular among country developers.

- Decorative plaster applied to a polystyrene foam board. There are a huge number of decoration variations; there are even thermal insulation boards on the market, the finishing of which includes quartz or marble chips. A distinctive feature of this type is the ability to create a seamless surface on the facade.

Thermal panels with decorative plaster applied to them Source bg.decorexpro.com

- Metal coating. In essence, these are standard sandwich panels, only small in size. This is a three-layer material in which insulation is laid between two sheets of metal. Sheets of either aluminum alloys or galvanized iron, painted or coated with a polymer layer, are used as metal cladding. Today on the market you can buy thermal panels sheathed on both sides with corrugated board.

- Artificial stone in the form of concrete mortar, decorated to resemble torn stone. These are heavy slabs, but among all types of the presented category they are the cheapest. Water-repellent and strengthening additives are added to concrete, so they feel great on the facades of houses.

Decorating a house with panels of the “torn stone” model Source da.everaoh.com

Characteristics of thermal panels

Considering the characteristics of thermal panels for exterior decoration of a house, you begin to understand that this finishing material is in no way inferior to other technologies for insulating and decorating facades. And if in some positions he is not superior, then, in any case, he is no worse. Therefore, it is worth wondering why it is not used so actively in private housing construction.

Judge for yourself:

- Thermal conductivity corresponds to the characteristics of the insulation used in thermal panels. And since foamed polypropylene and polyurethane are placed in this material, it is impossible to find the best option today. For information: thermal conductivity of polystyrene foam is 0.25 W/m K, polyurethane foam is 0.19 W/m K.

What are the advantages of facing material?

Advantages of facade thermal panels:

A wide selection of thermal panels makes it possible to make any façade unique

- There are no restrictions on the use of heat finishing. The material is used for covering brick, concrete, plastered and unplastered walls. If the geometry of the working surface is damaged, a sheathing is installed before installation work.

- Installation can be performed at any time of the year and in any weather.

- Considering that the façade thermal panel is responsible for heat retention and the appearance of the room, it can be safely attributed to multifunctional materials.

- Together with façade thermal panels, you can make any design fantasy come true, since the finishing has a huge variety of shapes and shades.

- Thanks to excellent thermal conductivity, insulating a house with thermal panels will allow you to significantly save on heating costs in winter.

- The environmental friendliness of the material allows the use of thermal panels for interior decoration.

- The cladding is durable. With proper installation work, the cladding can last up to 50 years without interruption.

- Wall decoration does not require periodic repair work, as is the case with foam plastic.

- The decorative layer protects the entire structure from mold, mildew, and corrosion.

- The light weight of the material eliminates the need to strengthen the existing foundation.

- Installation of thermal panels can be done with your own hands without the involvement of professional force.

How to make a panel yourself?

To try to make a panel yourself, you will need special equipment - machines similar to those used to produce polystyrene foam (by foaming polystyrene granules). In addition, it is necessary to create a material from which thermal panels can be made. Thus, in a handicraft workshop two directions must be carried out at once: the production of foam plastic and clinker tiles.

Tools required for foam production:

- raw material dispenser;

- special pump;

- forms;

- vacuum installation;

- steam generator;

- pre-foaming unit.

To produce clinker tiles you need:

- kiln;

- Press form.

Expensive units are capable of producing more than 300 parts in one day. Homemade equipment will be less productive and will be able to produce up to 100 elements.

If you only need to finish your own home, it is wiser to buy ready-made panels.

Have you chosen? Are we editing?

Insulated facade panels are mounted on an adhesive mixture or guides. But, before this, you must brush the side edges of the panel with a brush. This is done for better grip. If you have chosen an adhesive mixture, apply it to the back side of the panel, making sure that one thin layer covers the entire panel, as well as in several places - in the corners and in accordance with the facade relief. Place the panel against the wall and let it stand for 5-10 minutes. After the panel has hardened, you can begin making adjustments. Align the panel using horizontal and vertical levels.

You need to start installation from the corner of the bottom row, and it is worth mentioning that there are special corner panels. Carefully level them even before applying the adhesive mixture - estimate it, and only then mount it more thoroughly on the glue.

A day after shrinking onto the glue, the panels with insulation are fastened with umbrella dowels into pre-drilled holes between the seams.

The video below shows how guys from one Sumy company deftly handle the installation process:

Features of installing thermal panels

You can install thermal panels yourself in several stages. First you need to take care of the tools that you will need for your work. It is recommended to prepare:

Cladding the façade of a building with thermal panels must be done using a level

- hacksaw;

- hammer;

- screwdriver;

- perforator;

- grinder;

- construction level;

- sealant;

- Master OK;

- pencil or marker for marking.

Algorithm for installing facade thermal panels:

- Pre-insulation solves the problem of unevenness on the walls. If necessary, install a sheathing. It should be noted that the best option involves attaching one panel to three adjacent vertical bars. The frame elements are treated with an antiseptic.

- Insulation with facade thermal panels begins from the corner of the house from bottom to top, moving from left to right. The lowest row rests on the starting bar, each subsequent row rests on the previous one. Docking occurs using a tongue-and-groove system to ensure maximum tightness.

IMPORTANT! The starting corner is mounted with the obligatory use of a level.

- Difficulties may arise when facing openings and corners if you do not use ready-made corner components. In the case of self-covering corners, the joining edges of the thermal panels are cut at 45°, and the resulting gap is masked with polyurethane foam.

IMPORTANT! Experts strongly recommend using fittings from the manufacturer, which guarantees maximum tightness.

Thermal panels for the facade are attached with special dowels

- Facade thermal panels are attached to the walls or frame with self-tapping screws or dowels. When the installation work is completed, they begin grouting the joints, which is preferably carried out in warm weather. It is estimated that about 3-5 kg of grouting agent should be used per 1 m² of cladding. Subsequently, the treated seams dry for two days.

- The final step is to treat the façade with a special agent to protect against moisture penetration.

We recommend: Drip furnace: do-it-yourself testing, drawings, options

Why choose wall panels for exterior decoration of a house?

The development of the construction industry has given rise to the emergence of new modern materials for external cladding, characterized by excellent physical properties and reasonable prices. This is exactly what wall panels are, reducing the cost of building houses, extending its service life, and, at the same time, acting as a protective barrier from rain, snow, ultraviolet radiation, which negatively affects the surface of walls made from almost any building material.

Facade panels for exterior finishing of houses are widely used for treating the external surface of public buildings, private houses and cottages, shopping complexes, entertainment and sports centers, medical and educational institutions.

Wall panels have the following advantages:

- strength;

- frost resistance;

- soundproofing;

- long service life;

- a light weight;

- environmental friendliness;

- affordable price;

- variety of types, textures and colors.

- do not fade in the sun and do not lose color from rain;

- do not require special care or treatment;

- do not rot, are not attractive to insects and rodents;

House finished with facade slabsSource domcom.ru

Cladding panels for the facade of a house are suitable not only for new buildings, but also for finishing old buildings, regardless of the material of the building.

Decorative slabs for exterior wall decoration are divided into several types, according to material and design:

- Sandwich panels. They consist of several layers of materials glued together. Each layer has different characteristics. The top one is a galvanized metal coating and has a protective function, and the bottom one acts as insulation.

- Composite panels. They are made on a cement base with a fiber filler or a thin layer of metal. This material protects walls well from external environmental influences that contribute to their destruction.

- Plates made of polyvinyl chloride and pressed wood pulp, externally made to look like wood, stone or brick.

Decorative panels for the external walls of a house, belonging to any of these categories, do not put pressure on the load-bearing walls of the building and the foundation.

Installing the entire house with facade slabs does not take much time. The work is completed within a period of two days to two weeks, depending on the area of the facade.

Decorating the wall of a house with facade slabsSource recon-stroi.ru

Beautiful examples in the exterior

Polyurethane foam is the most advanced material for insulating the facades of buildings and structures. Panels with ceramic tiles act as effective thermal insulation and have a decorative function. The panel consists of two components: decorative outer side, insulation.

In modern architecture, there are many options for how you can transform the facade of a building using polyurethane slabs. A wide variety of colours, finishes and special effects provide a huge range of creative possibilities for creating the perfect façade. The unique cellular structure of the finishing systems ensures uniform diffusion of natural light and creates excellent thermal insulation, providing maximum resistance to impact and hail.

Building design professionals can hide different building elements or create intriguing visual contrasts by combining panels with conventional glazing. By offering together enhanced, superior UV protection, façade systems guarantee a long building life.

Insulated panels provide unlimited design options while controlling moisture and reducing energy consumption. Modern manufacturers produce universal, ventilated systems that accommodate a wide range of cladding options.

Recently, it has become popular to use slabs with stone finishes or various types of brickwork. Several types of such finishes look especially impressive, allowing one to highlight several basic elements on the façade, including corners and foundations. An interesting design solution creates a unique and inimitable style of the building, conveys the special mood of the residents or adds respectability.

For information about the features of choosing façade thermal panels, see the following video:

Sources

- https://uytchasndom.ru/uteplenie-doma/uteplenie-fasada-doma-snaruzhi-termopanelyami

- https://uteplenieplus.ru/kak-uteplit/fasady/uteplenie-termopanelyami/

- https://x-teplo.ru/uteplenie/fasady/termopaneljami.html

- https://fasad-exp.ru/uteplenie/fasadnye-termopaneli-dlya-naruzhnoj-otdelki-doma.html

- https://stroy-podskazka.ru/dom/fasad/termopaneli/

- https://fasadevision.ru/fasadnye-paneli/termopaneli/montazh-i-oblikovka.html

- https://fasadwiki.ru/fasadnye-paneli/montazh-i-rabota/termopaneli-dlya-naruzhnoj-otdelki-derevyannogo-doma

- https://zamesbetona.ru/obrabotka/fasadnye-termopaneli.html

How do you like the article?

Sergey Vladimirovich

Ask a Question

Properties and characteristics of thermal panels

Let's start with the most interesting thing - the characteristics of the hero of our review. What is his highlight, and is there any point in getting involved with him? Here's what we know:

1. It consists of several layers, each of which performs its own functions. We will analyze the detailed structure a little later, but for now we will say that there are usually three or two layers: the base, thermal insulation and the decorative part.

Instant transformation of an old building

2. The panels have a very low level of thermal conductivity.

3. Depending on the type of insulating material involved, such panels can improve the soundproofing characteristics of the room quite well.

4. The material is quite durable and dense, which allows it to be used even in harsh atmospheric conditions. It withstands static and small shock loads well.

Facade thermal panels

5. Manufacturers of such panels promise a maximum service life of thermal panels of 50 years. At first glance, this is a lot, but let’s not rush to conclusions, since this does not apply to all products, and a number of questions also arise that simply need to be answered, which we will do in the next chapter.

6. The material is inert to the biological effects of bacteria, fungi and insects.

7. Temperature changes are not scary for it - the operating temperature range is huge (-170 / +170 degrees Celsius), it can be called extreme.

Clinker thermal panel - front view

It would seem that this is almost an ideal material for finishing and insulating a house, but buyers are reluctant to purchase it, and there is a simple explanation for this.

Pros and cons of thermal panels

So, we have become familiar with the characteristics of the material, these are definitely its advantages, but in most cases these are just numbers that mean little to the average user. Let's now look at the real advantages and disadvantages noted by home owners who have chosen thermal panels for their decoration.

The embroidered thermal panel is externally indistinguishable from brickwork

Let's start with the positive points:

1. First of all, people note the ease of installation. The products are light in weight and have a large area, so the work goes quickly. The material is easy to lift and cut. The panels have locking joints, due to which they are easily joined and held securely.

2. The panels really do a good job of insulating facades. Their use allows you to protect walls from freezing and move the dew point outside. How effective such insulation is can be determined by comparing the type of insulating material used.

3. The products are resistant to moisture, they are waterproof, but water can still penetrate under the finish if the installation is poor.

Products are resistant to moisture

4. The light weight of thermal panels is also important because the load-bearing walls of the building will not experience strong additional loads.

5. The decorative side of the material also does not react to water, practically without absorbing it, and does not collapse under the influence of ultraviolet radiation, which allows the panels to maintain their original appearance for many years.

6. Caring for the panels is exactly the same as for ordinary clinker bricks, that is, you can immediately forget about the need for periodic processing and cleaning - a worthy plus.

7. The panels are presented in a good assortment. To suit your taste, you can choose options that imitate brick, stone, log or block masonry.

The facade of the house is completely ennobled with thermal panels

So why are thermal panels used so rarely; are their shortcomings really so significant? Actually, yes! There are few of them, but two of them are very serious:

- The main reason is the high cost of the panels. Compared to competitors, the price difference can be two or even three times. What's the point of saving on building materials for your home when you'll immediately spend money on expensive panels? That's right, it makes little sense, so it's easier to make the walls thick with real high-quality cladding.

- The second point is the already mentioned service life of the panels. The promised 50 years are quite realistic, but on the condition that no one touches the panels. Here we mean rodents who will happily make themselves a warm home in polystyrene foam. No matter how hard you try, they will find a loophole, and then the thermal protection of the house can be seriously damaged. In general, the point is controversial. It is worth considering that the promised deadlines are forecasts of technologists, and, as it seems to us, even marketers. The panels appeared on the market about 10 years ago, so nothing has been tested in practice yet.

- Installation requires smooth walls or a level frame. Not to say that this is a complete drawback, but it’s worth keeping in mind.

Installing thermal panels using a dry method is a quick and uncomplicated process

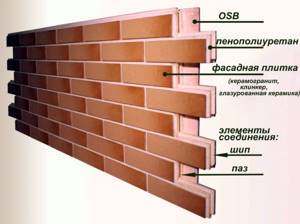

Details about the composition of thermal panels

What are thermal panels usually made of? There are two varieties - two-layer and three-layer. Let's look at them in order.

Double-layer panels

Double-layer panels are an affordable type of such material. It is based on extruded polystyrene foam, on top of which decorative elements are glued. It is the insulating part that gives rigidity to the entire structure.

Double-layer thermal panel based on polystyrene foam

This material has the following properties. Service life is 10-15 years (again, provided there is no external influence). The material is not resistant to aggressive environments, which can cause it to deform.

Flammable - when ignited, the flame spreads very quickly and produces a lot of acrid smoke.

Such panels should only be used for installation on a flat base, since their rigidity is not enough for installation on a frame.

Three-layer panels

We actually described three-layer thermal panels when we talked about the advantages of this material. At the base they have an OSB panel, which significantly increases the strength of the material as a whole. In the middle there is a layer of polyurethane foam - this material is also quite strong and dense, along the entire perimeter of the panel there are locks formed on it, which were not there in the previous version - this structure allows you to avoid the appearance of cold bridges. The insulating properties of such panels are higher than those of their analogues.

Structure of three-layer thermal panel

Finishing layer

Both panels have a finishing layer. Usually this is clinker, which, by the way, can be glazed, or polymer elements made mainly of acrylic. Both options have a long service life, easily withstand weather conditions and look beautiful, however, clinker still looks more natural and richer, which is why it costs much more.

Also, artificial stone, ceramics, porcelain stoneware, plastic, metal, and sometimes wood are used as materials for the front side of the panel. The latter panels are very rare and difficult to find for sale. Models for decorative plaster, the role of which is played by glued marble chips, look interesting.

We recommend: What is perlite and where is it used in construction and renovation

Variety of appearance of facade thermal panels

Interesting to know! To seal the seams between the panels under plaster, a special paste is used, the same color as the panels themselves. If you don’t look closely, you get a completely monolithic surface.

Stone effect panels - for facade and with insulation

Today you can easily decorate your home with different panels imitating stones - just choose which stone is preferable to you:

- bottle;

- quartz;

- marble;

- travertine;

- sandstone;

- granite;

- limestone;

- dolomite, etc.

Looks very natural

To do this, simply choose slabs that reproduce these types of stones as much as possible. All of them must meet the following criteria:

- low thermal conductivity;

- resistance to external factors;

- tightness;

- without toxic compounds and any level of danger to human health;

- non-flammability;

- long term;

- ease of installation.

All criteria are fully met by stone-look panels produced with decor from different materials:

- Metal.

- Vinyl is preferable for interior work.

- Acrylic.

- Fiber cement.

- Clinker.

These types of finishes are indistinguishable from cobblestone, flat, rocky, burnt stone. Modern technologies for manufacturing such panels help to reproduce natural stones with maximum accuracy. But the price is very different from the cost of natural representatives, although in terms of performance, insulating panels are also at their best and are not inferior to natural materials. Even special stone base slabs have been developed, with a high level of strength, a dark and larger-scale pattern. More often they are made of metal, which allows them to protect the lower part of the walls from influences of any nature, including moisture and temperature, wind, and ultraviolet radiation. In addition, such insulating slabs imitating stone give the overall facade an original, expensive look.

Advice from professionals

Experts in laying clinker thermal panels recommend following certain actions when working with products. For example, before starting the cladding process, it is advisable to treat the base with an antibacterial primer to prevent mold and mildew. The entire house can be finished with panels, and not just its lower part, while the base, as a rule, is highlighted with slabs of a different color to give a more interesting look.

A wide range allows you to play interestingly with the color and texture of clinker to give the house originality and add a little zest to the external facade. Certain types of thermal panels have special requirements for the installation process. To avoid mistakes, you should carefully read the instructions and follow them.

Main differences from other types of finishes

Facade panels differ from other types of finishing in that they do not have their own appearance, as is the case with facade paint, plaster or natural materials. Facade panels only imitate a certain type of material - brickwork, a stone wall made of one or another type of stone.

In this regard, facade panels are closest to siding, which they essentially are. At the same time, they fully protect walls from external influences, atmospheric or mechanical, far superior to some other materials in this regard.

Another difference lies in the possibility, or more precisely, in the purpose of forming a ventilated façade. Many materials are suitable for this purpose, but only facade panels were originally created for this task; all components or additional elements were made to create a ventilation facade.

How to choose?

The market is rich in a variety of facade panels. How to choose those that will last a long time and will not require overpayments. To do this, you must follow the usual rules:

- Purchase from the manufacturer or its full-fledged representative.

- When purchasing, check the licenses and certificates on the panel.

- Read the instructions carefully.

- Ensures guarantees in case of breakdowns or defects.

- Read forums and reviews on a particular panel.

- Take into account the climatic conditions of your region.

- Consult with specialists.

Prices for facade thermal panels

Thermal panels for facades

Video - Clinker thermal panels

If you do everything correctly, then the façade panels with insulation will reciprocate your feelings and will last for many years without breakage or deformation. And your house will always look like it was just built and have its own style and uniqueness.

If you are in doubt about the choice, read our article on the topic - Cladding the facade of a house. Which material is better?

Indeed, in your work on the design of the facade, you can be guided by a mixture of styles, simultaneously using, for example, plaster and panels, or natural stones at the bottom - panels at the top and so on. There is scope for imagination and the embodiment of the most unusual desires for the appearance of the house. But it is important that in addition to appearance, using this type of facade panels you simultaneously insulate it and also reduce the level of noise penetration into the house. All these factors will help maintain home comfort and a comfortable stay within your own walls.

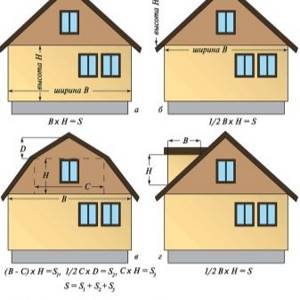

Calculations

To understand what the need for a building material is, it is necessary to find the total surface area. From the resulting value, the sum of the area of doors and windows is subtracted and 10% is added, which is taken away by cuts and overlaps during the work. The resulting figure is divided by 4.55, which is exactly how many square meters. m is in one package of plates.

The amount of required starting strip for insulating panels is calculated based on the perimeter of the building. The width of the doors is subtracted from the resulting value and divided by 3. To avoid mistakes, add 5% of the resulting number.

External angles are determined by the sum of the heights divided by 0.45 m. To be correct, it is worth adding 5% of the obtained value.

When making calculations, it is worth taking into account not only the area of the walls to be covered, but also heat loss, according to which in the future the material of the required thickness will be selected

- The U-value is a measure of how much heat is lost through a given thickness of a particular material, but includes the three main ways in which heat loss occurs - conduction, convection and radiation. This is a measure that always applies in the Building Regulations. The lower the U-value, the better the material is as a thermal insulator. The U-value provides insight into the consequences that thermal performance has when aimed at meeting current building codes.

- The R-value is a measure of the resistance to heat flow through a given thickness of material. Thus, the higher the R-value, the higher the heat resistance of the material and, therefore, the better its insulating properties. Heat moves in and out of a building in several different ways, and the R value only takes into account conduction and does not include either convection or radiation.

Design nuances

A weather- and mechanically resistant material that provides thermal insulation and protects the walls of the house from wear and tear is not all that is usually needed to enjoy looking at the house. Otherwise, everyone would live in houses covered with simple sandwich panels. Aesthetics are important.

Brick finish

It is affected by the location of the panels:

- Vertical. It will make the house visually taller, which is useful for small, squat houses.

- Horizontal. Will make the house appear lower and wider, which is useful for tall houses that look too narrow.

- Brick. It is used for base planks - they are not laid exactly on top of each other, but with an indentation, just like bricks are laid. It looks good and does not bring any special visual changes to the shape.

Vertical products will make the house visually taller

It is influenced by colors:

Bright white looks good, but it needs to be washed constantly, otherwise it will fade and turn gray very quickly. Bright black is usually not used for houses unless it is a Gothic style house.

The exception is a black background with a bright pattern or accessories that attract attention. But still, it is generally considered that the effect is too dark. Shades of yellow

The sunny color will attract attention to the house, making it visually cozier and more pleasant. A common color that looks good in a garden setting. Shades of green. They are rarely used for summer cottages, since a green house surrounded by greenery will look a little strange. But for a country cottage surrounded by other buildings, a garage and a neat garden, soft shades of mint or light green are well suited.

Bright white looks good but needs constant washing

- Shades of red. They are usually considered too bright and therefore undesirable, but muted options, such as brick, fully correspond to the classic ideas of a country house.

- Shades of brown. They look good and remind you of village houses. But it is not recommended to take cold or too dark ones.

- Delicate shades. Beige, pink, peach. They will make the house a little larger and more comfortable in appearance. Well suited for small houses where coziness is the main idea of the design.

- Cool shades. They will also make the house look larger, but at the same time more austere and darker. Pairs well with glass or metal inserts.