Homemade designs

The simplest smokeless furnace for burning waste is made from a metal barrel (the desired wall thickness is from 2 mm). A 200 liter container is suitable, not too rusty to ensure a long service life of the product. An alternative option is a piece of pipe with a diameter of 500 mm. They have thick walls (from 8 mm), which increases the weight of the structure and makes it more difficult to make holes. Although the system turns out to be stronger and more durable. To work with any workpiece you will need:

- drill or screwdriver;

- grinder - for removing the bottom or cutting out large holes in it;

- metal rods or finished grate;

- welding machine (optional);

- bricks or other material for the frame.

It will be enough to dig a hole (according to the diameter of the structure and a depth of 20-30 cm) above which, on legs made of bricks or other objects, the firebox will be placed. For better traction, holes with a diameter of 25 mm are made at the bottom of the body and above the stiffeners.

The garden stove can also be made in the form of a rectangular box. The combustion chamber is located at the bottom (side loading). To make this design you will need:

- blueprints;

- sheet steel, thickness from 2 mm (replaced with a rectangular tank if available);

- metal corners;

- welding machine;

- cutting tools.

A ready-made container is the optimal solution. But even in this case, you will need welding equipment to attach the lid hinges, chimney and other components. Making a hearth from scratch will take longer than turning a tank into a stove. First, steel parts of specified sizes are cut out, depending on the planned volumes of waste to be burned and the area of the selected area - some sellers offer to perform this procedure for the client. Places of future connections are cleared. For additional strength, the corners are fixed from the inside. They can reinforce all seams, but 4 elements at the joints of the sides are sufficient.

For the chimney, if provided, it is convenient to take a metal pipe of round, square or rectangular cross-section. The size is calculated based on the parameters of the firebox, but for a small stove a channel with a passage diameter of 80-100 mm is suitable. You can cover the chimney with thermal insulation and equip it with a filter with a spark catching function.

The energy generated is suitable for cooking or heating food. You should not barbecue over garbage coals. But its heat from an iron barrel is suitable for heating water; warm liquid is a necessary condition for dissolving a number of fertilizers and poisons. A large pan fits well into the hole without blocking the draft due to the perforation of the hearth body. The upper plane of the rectangular heat exchanger will turn into a full-fledged cooking surface.

A brick kiln is also used for recycling solid waste. Both the sauna hearth, which has received a second life, and a new design created specifically for the task are used. The bricks are placed without mortar, remaining in place due to their weight and rough surface. They line a barrel or create independent structures. Be sure to use fireproof blocks. Suitable for oven:

- Fireclay stone can withstand temperatures up to 1500°C, but only if the manufacturing conditions are met. Blocks overexposed in the oven lose their fire-resistant properties.

- Red brick - designed for heat up to 1000°C. Solid blocks are used for masonry.

- Graphite - intended for finishing the inner surface of the firebox. Depending on the composition, it can withstand up to 1600-1700°C.

Products made from red clay are the most affordable. Brick, due to the lower outside temperature, provides greater safety compared to bare metal. It opens up additional design possibilities, allowing you to make a two-chamber waste incineration furnace without welding and cutting tools - you just need to correctly design the arrangement of the blocks and then complete the drawing.

Manufacturers

The number of companies and industries that specialize in creating furnaces for burning garbage and other items in large

scale is very large, so choosing the appropriate option is not a problem.

It is not recommended to choose products from foreign manufacturers if the volume of waste burned is limited, since the cost of such products is extremely inflated.

There are a large number of domestic analogues, the quality of which is not inferior to foreign ones. Among the leading Russian leaders, Intech, as well as Gorbylya stand out.

The range of these products is very large, so potential buyers often have a number of questions. Depending on the functionality, size and manufacturer, the price can vary widely.

The most budget products for summer cottages and private use are sold from 10-15 thousand rubles, but the cost of an industrial furnace for burning solid waste starts from 100 thousand rubles.

If you are interested in foreign-made waste incineration furnaces, then the best solutions on the market are presented by Burn Mizer (USA), VOLKAN UK. As practice shows, finding a stove that would fully satisfy your needs and wishes is quite simple - the choice is truly huge.

It is much more important to determine the maximum budget, required functionality and level of “environmental friendliness” at the early stages of purchasing planning. If you have these parameters, you will be able to make a purchase in the shortest possible time.

Alternative disposal options

You can pay for the removal of solid waste to companies or utilities that specialize in this.

The second option is to use plant waste to create compost. Such fertilizer will have a beneficial effect on the condition of the soil. To turn dead plants and wood into compost, you need a special compost bin, which is easy to make yourself.

Construction waste (broken bricks, slate, blocks) can be used as rubble when pouring the foundation for a house, gazebo or bathhouse. Broken stone and brick can be useful when laying decorative paths for a summer house.

You can also put containers and separate waste collection for subsequent recycling. This option is more suitable for environmentally conscious people who care about the environment and are willing to spend time cleaning and sorting waste items.

Barrel used for burning garbage

A stove made from a barrel for burning garbage with your own hands, which can be made especially quickly, is very simple, but in order for it to become a decoration of the site and impeccably fulfill its purpose, you will have to work hard. A used barrel that isn't used can make a great stove option. This container is ideal for flammable waste products. There are several options for transforming a barrel into a combustion container:

- bottomless design. It's not difficult to do. To do this, you need to use a grinder to cut off the bottom and make holes in the lower part to create traction. Such a product is installed in a pre-dug groove, ensuring free flow of air through the holes. Before using the container, you need to light a fire using branches and paper, and only then can you start burning the garbage, which is supplied in small batches;

- installation on solid building material, for example, brick. For such installation, it is necessary to make holes in the bottom and lower part of the container for traction, mount a strong and reliable base, and install the barrel on it. This barrel stove is suitable for burning large amounts of waste.

This incinerator is not durable, but it fulfills its purpose flawlessly. The service life can be extended if the barrel is covered with steel sheets. This way, the stove in your dacha for garbage will become more resistant to burning out. Barrels for burning waste should not be installed in the foreground of the site, as they can ruin the appearance of the dacha.

Old heater

To make an incinerator, you can take an old heater from a bathhouse . It makes an excellent recycler, of course, if you properly modernize and assemble the structure. First you need to remove all unnecessary parts, leaving only the body and grille.

After everything unnecessary has been removed from the heater, it is necessary to strengthen it. It is best to strengthen the structure with metal sheets; to do this, you need to weld the metal to the base, this is done using a welding machine.

Next, light a fire in the heater, wait until it burns well and add garbage. Moreover, recycling products are placed on top. In addition, during combustion it is necessary to cover the hole with a metal lid or other available material, this will speed up the combustion process.

But such a stove must be constantly monitored so that burning coals do not fall onto the ground. In addition, this stove will not be able to process a large amount of garbage, as well as large elements. It is suitable for the disposal of small waste and thin branches.

Oven Alternatives

Experts continue to raise the question of whether to burn or bury when discussing waste disposal. Opinions vary, although most believe it is not environmentally efficient to burn trash in your backyard. Composting is a smart alternative to fire. Garden shredders allow you to ferment branches and tough stems into a pit, turning them into mulch suitable for covering the soil to protect against pests and erosion. But the price of such equipment exceeds the cost of a simple backyard fireplace.

Landfills and compost pits are alternatives to the incinerator, but do not replace it. Fire speeds up the disposal of waste, provides useful heat and ash - natural fertilizer.

Removal, processing and disposal of waste from hazard classes 1 to 5

We work with all regions of Russia. Valid license. A complete set of closing documents. Individual approach to the client and flexible pricing policy.

Using this form, you can submit a request for services, request a commercial offer, or receive a free consultation from our specialists.

Today, waste disposal is a big problem for owners of summer cottages. Household waste, fallen leaves, and gardening waste simply have nowhere to go. The ideal solution in this situation is to use a waste disposal oven. This design can be made with your own hands or purchased ready-made incinerators in the store.

Typical waste incinerators

They are made of 2mm thick steel, coated with fire-resistant enamel. Small dimensions, which makes it easy to transport the stove in a passenger car. The combustion process takes place on the grate, which traps large debris and household waste, and also does not interfere with the flow of air from the bottom of the stove.

The ash itself falls through the bars of the grate. Combustion is adjusted by opening/closing the ash door, through which oxygen enters. From there, ash is raked out, which gardeners love to use as fertilizer for their plots. There is a lid on top that not only protects the flame from rain, but also serves as a flame limiter.

What does a wood waste disposal stove consist of?

The equipment has a fairly simple design and operating principle. To operate the unit, there is no need to undergo lengthy additional training, and the recycling process itself takes place with absolute safety for the company’s employees.

So, a furnace for burning wood waste has the following design:

- loading chamber made of fireproof reliable steel;

- productive grates that provide optimal temperature and uniform heat distribution;

- an afterburner chamber, where combustion products undergo additional purification, which ensures complete safety of the equipment for the environment;

- secondary air heater and heat exchanger;

- fan and chimney.

By purchasing a stove for burning sawdust and other wood waste, you will also save significantly in the future. Maintenance and maintenance of cremators and incinerators does not require large financial and resource costs. This purchase will pay for itself in the near future, and you will have in your production a highly efficient and productive unit for recycling unusable material, which also generates heat.

Useful tips

- Make the seams 10 mm high.

- Prepare the solution from 2 parts PCS and 1 part cement.

- Install the grate and steel plate on the masonry without mortar.

- Attach the firebox door frame to the structure using wire, which is then embedded in the masonry seams.

- For the ash pit door, use a brick with through holes, after attaching a wire handle to it.

- To make a chamfer, pour 10×20 mm fraction gravel with liquid cement solution (sour cream consistency).

- Cover the inner surfaces of the barrel and the tall steel reinforcement with the same liquid cement mortar.

- Make fireproof amplifiers (high and low) from steel strips according to the dimensions indicated above. Do not bend them first, but roll them into a cylinder smaller than the inner diameter of the barrel, place them on the bottom, release them and level them to achieve a complete fit to the mating surface. Do not use percussion instruments!

- Dry the masonry under a waterproof film for 28 days.

- Do not cover the entire outer part of the barrel with cement mortar - this will reduce the heat transfer from the heated barrel and will contribute to its rapid burning.

- Do not make an external chamfer between the barrel and the brickwork from mortar - this will worsen the heat transfer from the heated surface of the barrel.

Methods for burning garden waste

Today, several ways of burning such waste are known.

Burning garden waste on an open fire

The first and predominant method of our summer residents is burning garden waste on an open fire. This is especially noticeable in early spring and autumn. On gardeners' plots you can regularly find blazing fires and columns of smoke rising high above the ground.

LIGHTING AN OPEN FIRE IS VERY DANGEROUS, and is also harmful to the soil, since under the influence of high temperatures from a fire, the earth loses its fertility, and all soil microorganisms located in the combustion area die.

And if you do not have the opportunity to make a fire in another place, then still build it on a thick metal pallet, which is best raised above the ground with the help of some kind of pads: stones, bricks and other available materials.

Safety Tips

- Do not light a large fire right away, as there is a high chance of losing control over it.

- It’s better to throw it in small portions, but more often, and the combustion will be more efficient this way.

- In windy weather, it is better to avoid this event.

Burning garden waste in an old barrel

The second method does not have the disadvantages of the first and consists in the fact that a wide variety of containers are used for combustion, which have already served their purpose and can no longer be used for their intended purpose.

- The most suitable option for burning waste is an old metal barrel.

- This container will take up little space.

- It can be installed in a permanent place, away from trees and various buildings.

In order to use a barrel, it must first be prepared. It’s simple, remove the bottom with a chisel, and then bend all the uneven and torn edges with a hammer.

Principle of operation

Despite the fact that the operating principle of industrial furnaces is practically no different from conventional devices of an alternative type, some citizens do not fully understand the principles of their operation.

The structure of the furnace is a housing in which the combustion process takes place. Under the influence of high temperatures, the molecular bonds of the substances from which objects are made are destroyed, which makes it possible to neutralize their dangerous properties.

Actually, immediately before lighting the flame and placing the waste in the oven, it is mixed with sand until a homogeneous mixture is obtained. This process helps prevent excessive temperature rise and incomplete combustion of waste. An important condition is the homogeneity of the waste, since for each type of material a strictly defined temperature is set.

As the mixture is heated by a mechanized burner, hydrocarbon molecules are burned, which pose a danger to nature. Some models have two or more circuits for additional combustion of carbon in gases that are formed from the primary combustion.

For the first time, an industrial furnace for burning wood waste was created, and subsequently, based on such a device, the model range was significantly expanded. Thanks to the development of modern engineering, a large number of additional models have appeared.

The main advantages that the biowaste incinerator and many others boast are:

- Compact dimensions;

- High environmental performance;

- Simplicity and low cost of operation;

- The ability to use combustion energy to heat air, water, etc.

For some organizations and firms, the use of furnaces brings additional benefits. In recent years, the document incinerator has become quite popular, since with its help you can guarantee confidentiality in the enterprise. In order to purchase a suitable option, you need to not only know about the availability of such devices, but also about their characteristics in order to buy the best!

Some tips

You should follow these tips:

- Do not set fire to residues in open areas without using containers.

- Stoves should be placed in separate places.

- You need to be careful when disposing of polyethylene and plastic materials, as they emit toxic gases when burned.

Safety regulations

When working with open fire, you must always follow the safety rules:

- When operating any stoves, you must be nearby and monitor the combustion.

- Just in case, you should place a reservoir of water or sand near the stove.

- When preparing a place to place the stove, it is necessary to thoroughly clear it of any remaining hay, dry grass, branches, paper, and other flammable materials.

- It is necessary to limit the access of children and animals to the firebox.

Each summer resident decides for himself whether to buy a ready-made stove or create one from scrap materials. The second option will be more profitable, but you will need to tinker for some time. But the finished version will have a box for collecting ash and meet all safety requirements.

Rules for installing a stove in a summer cottage

Any source of fire, even if it is fenced with a metal container, must be located on the site:

- freed from flammable objects;

- away from trees at a distance of at least 30 m, and from any buildings - at a distance of at least 50 m;

- remote from gas pipelines, communication lines and power lines.

Failure to comply with mandatory requirements creates a potentially unsafe environment and threatens the owner with a significant fine.

Children and animals should not be allowed near the fire, which must be constantly supervised. The entire fuel supply is stored out of reach of the flame, and nearby are extinguishing agents: water, sand.

How to make a waste incinerator

From a metal tank you can make a stove of several variations, which differ in design.

Safe Barrel

You can assemble a garbage disposal even with a minimal set of tools.

For this you will need:

- metal barrel;

- 8 mm bolts and nuts;

- iron pipe 100 mm;

- metal sheet 4-5 mm.

Step-by-step instruction:

1. We make a piston for compacting waste by cutting a circle from a sheet of metal with a diameter slightly smaller than the inner diameter of the barrel. You can also use a pair of lids from the same container fastened together.

2. Cut the pipe a little longer than the height of the tank and make a hole in the metal circle.

3. Using welding or bolting, we connect the pipe to the iron circle.

4. We make a hole in the upper part of the barrel on the side according to the diameter of the pipe. We weld a pipe about half a meter long. Then we make a corner connection as in the photo.

5. Cut a hole in the barrel lid for the piston pipe.

After constructing the disposal, all that remains is to fill in the garbage, compact it well with a piston and ignite it.

Barrel without bottom

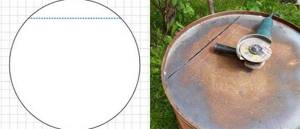

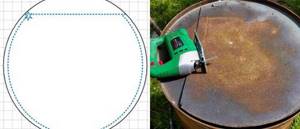

The construction and operation of a barrel consists of the following steps:

1. Using a grinder, cut off the bottom. If the container is old, then the procedure is greatly simplified: the bottom can simply be broken off.

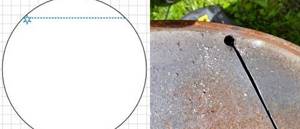

2. To ensure traction, we drill holes in the bottom of the tank.

3. To ensure safety, dig a hole under the container about 40 cm deep, about a meter long and wide.

4. At the bottom of the pit, light a small fire and place a container.

5. Gradually add trash.

6. Good draft will ensure quick burning of branches and other waste.

Barrel with bottom

This option is constructed as follows:

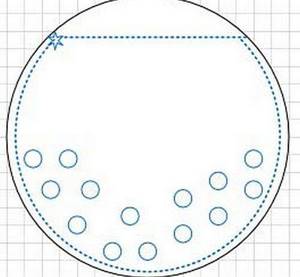

1. We drill many holes in the bottom of the tank to create traction.

2. We lay out a brick base on which the container will stand.

3. Place the barrel on a brick, add garbage and light a fire.

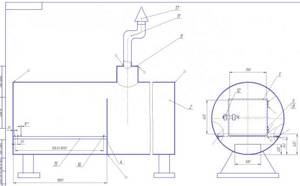

Horizontal barrel with chimney pipe

The most successful option is a design with a chimney pipe, since the smoke will be vented to the side. However, such a design will require the construction of special supports, securing the lid and pipe.

Materials:

- barrel;

- metal corner;

- fittings;

- pipe 100-150 mm.

Tools you need to prepare:

- grinder with cutting wheels;

- drill with drills;

- jigsaw;

- bolts with nuts, self-tapping screws.

- loops.

You can take one of the drawings as a basis:

Step-by-step assembly instructions:

1. Using any suitable tool, remove paint and loose rust from the barrel.

2. We cut off the metal from one of the ends, leaving about 10-15 cm of material. We make several holes in the remaining metal for air flow.

3. We fix the part cut off in step 2 using loops and fasten the handle.

4. On the opposite side, in the upper part of the barrel, we make a hole for the chimney. We fix the pipe by welding. If you do not have a welding machine, the pipe can be secured with self-tapping screws and rivets. To do this, use a grinder to cut through the container as in the photo, bend the petals inward, insert the pipe and fix it with any fasteners.

5. We make a grate from metal mesh or reinforcement. Its length should be slightly less than the height of the barrel. To support the grate bars, we attach a corner to the walls of the barrel.

When the frame and barrel are ready, they are coated with heat-resistant paint, giving the product a more attractive appearance.

Mobile barrel

This option is very convenient because it uses a trolley for moving.

To work you will need:

- barrel;

- small metal wheels;

- M20 bolts and nuts;

- reinforcement grid;

- steel strip 40*40 mm;

- profile pipe 20*20 mm;

- corner 50*50 mm;

- suitable metal lid.

Manufacturing procedure:

1. Use a grinder to cut off the top cover. We cut out the bottom in the same way, but with some indentation from the edge.

2. We weld the platform under the barrel from thick reinforcement and corners in size, slightly larger than the diameter of the container.

3. Select a bolt based on the diameter of the inner race of the wheel bearing.

4. We weld a frame from a metal corner and fix the bolts for the wheels to it.

5. We weld elements for installing the pallet, as well as the front stop, from a corner or profile pipe.

6. To make it easier to move a barrel made of 20*20 mm corrugated pipe, we weld the handle and attach it to the cart.

7. To keep the barrel securely on the cart, we make a fastening from a metal strip.

8. We cut out a piece from the same strip and form a handle for the pallet, securing it with self-tapping screws or bolts.

9. To prevent the garbage in the barrel from caking, we weld a pyramid of rebar in the middle of the rebar grid.

Industrial technology

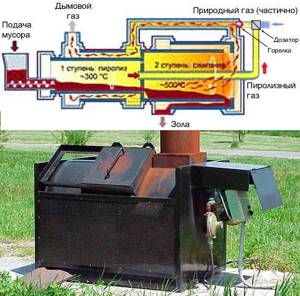

Most of the old waste incineration plants are currently unprofitable and rely on subsidies. A modern horizontal thermal destruction incinerator (garbage boiler) is a complex, expensive, but payable 3-stage device on a large scale (above in the figure below). In the pyrolysis chamber, at a strictly fixed, relatively low temperature, light flammable gases are released. It is impossible to run effective high-temperature pyrolysis - the garbage is full of harmful rubbish, which should not get into the pyrolysis gases. For the same reason, combustion in the combustion chamber is also carried out at a lower temperature that is not optimal from an efficiency point of view.

The design of a modern industrial boiler for burning waste and the appearance of its household analogue

Pyrolysis gases enter the burner, which heats the afterburner; It is this that ensures proper operation of the boiler. Since garbage is a highly unstable source of combustible gases, the burner is fueled by natural fuel gas. In the afterburner, the temperature rises as much as possible, to 900-1000 degrees or more. Having heated the pyrolysis chamber as long as necessary, the flue gases, consisting only of CO2 and H2O, escape into the atmosphere, possibly passing through an economizer or hot water heat exchanger.

The ash goes for further processing - the content of elements such as palladium, iridium, and rare earth metals in it is higher than in natural deposits that are considered industrial. Recently, they have been trying to extract gold from garbage ash - it comes there with microchips flying into the trash. Next, the ash is purified from toxins and radionuclides (both are also valuable raw materials), and the harmless granular residue is used in construction, road work, etc.

Doesn't take out equipment...

Industrial-type horizontal incinerators are commercially available; Amateurs are also trying to build them “homemade” (below in the figure). But:

- Purchase prices - Mom, give birth to me back! 220,000 – 250,000 rub. for an economy class installation it is still cheap; however, with delivery within the region, installation (the foundation is the owner’s according to the manufacturer’s specifications), commissioning and start-up in operating mode. The main reason is complex, expensive (and energy-consuming) electromechanics, because in order for garbage to move from chamber to chamber, and ash to the ash pan, pallets with material must be shaken in a certain way all the time.

- Mechanical resource is limited: approx. Once every 3-5 years, a major overhaul of the boiler is required. The cost is about a third of a new unit.

- Fuel gas is needed to feed the burner. There is a monthly fee or the cost of receiving a one-time batch. In private household plots, gas - please, according to the house meter. There are no discounts or subsidies, because self-disposal of waste is not legalized.

- Ash from the boiler is not suitable for fertilizer, because contains a lot of harmful and dangerous substances. Again, it needs to be taken in for recycling. They do not pay for the accepted material - the deliverer needs to pay in order to take it, because, unlike mass household and industrial waste, the profitability of processing garbage ash from one farm is in no way guaranteed.

Note : most often, home craftsmen build horizontal incinerators based on the model of the Vesta Plus furnace, patented by engineer Mikhienko (Kazakhstan), see video:

Video: Vesta Plus waste incinerator

Types of Incinerators

In summer cottages, various homemade stoves for garbage are often observed.

There are such varieties:

- Stationary structures that are characterized by good capacity and convenience. They usually have significant dimensions, weight, and are located in one place. Allows you to dispose of large volumes of waste.

- Mobile design, it is also called portable or mobile. Suitable for occasional use and for handling small amounts of waste. These varieties are distinguished by their compactness and save space. It can even be transported in the trunk of a car; they are light in weight.

Buying a ready-made waste incinerator for your summer cottage

To burn waste directly at your summer cottage without breaking the law, you can buy an incinerator stove with a chimney. Manufacturers produce these products not only aesthetically, but also functionally, presenting various types of designs. Taking into account the fact that they are made of high-quality steel and coated with fire-resistant enamel, they are characterized by a longer service life.

The finished products include an ash pit, a chimney and a grate. Some ovens have containers for heating water and even a stove for cooking food.

Factory ovens are small in size and light in weight. They can easily be placed in the cargo compartment of a car or rearranged in the garden. The top cover protects the fire from precipitation.

Equipment

Many manufacturers try to supplement and modernize the configurations of their industrial devices as much as possible, but most often the configuration is standard. Thus, furnaces for burning tires and other industrial waste have:

- The actual stove with a flame source;

- Dust removal mechanism;

- Set of secondary cameras;

- Auger, vibrating sieve and hopper for transporting and storing waste;

- Unloading mechanism;

- Process control system.

Modern furnaces have a large number of mechanisms with the help of which the process of monitoring work is automated as much as possible. If you are thinking about creating such a device for personal needs from scrap materials, then this idea is very real, but you will need specialized circuits and components that can be found on the Internet!

The performance characteristics of industrial models are orders of magnitude higher than those of “handicraft” installations. It is for this reason that if the expected volume of waste to be burned is very large, it is worth buying a waste incinerator from trusted manufacturers.

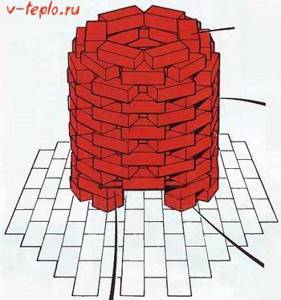

Method four. Brick stove for waste disposal

Let’s immediately say that a permanent brick structure will last an order of magnitude longer than the metal waste disposal devices described above. And its aesthetic indicators are at a fairly high level, because such a stove will be a wonderful decoration for any suburban area. With average volumes of waste, a smaller structure will be required (only 115 units of brick will be needed), although if necessary we can increase its dimensions. The procedure in this case is given below.

Step one. First, we clear an area measuring 1x0.7 meters, after which we fill it with sand (the layer thickness should be at least 5 centimeters).

Step two. We lay the first layer of bricks along the perimeter of the future structure. We don’t use the solution for this, but put it “dry”

It is important that there is a slight gap between the bricks (at least 1.5 centimeters) to ensure good traction. In total, the first layer will require eight bricks: one each on the right and left, three each in the upper and lower parts

Step three. After this, we lay down a metal grid (you can use reinforcing rods instead), which we welded in advance from thick wire. If we talk about our specific design with its dimensions, then it requires a lattice of 3 transverse rods and 14 longitudinal ones. At the same stage, you need to take care of the ash pan. There are several options here:

- lay out a brick ash pit;

- pour it out of concrete;

- made of sheet steel.

Which option will be chosen does not play a special role, so we will not dwell on this issue.

Step four. We continue to build a garbage stove for our dacha with our own hands. For the next row we will also need eight bricks, but here we are already observing the dressing, so we are already laying two units on each side. We lay all subsequent rows in the same way, and, as in the beginning, we do not use the solution. The last, twelfth row is made continuous. We install an iron cover on top of it.

Note! Instead of a square “garbage” oven, it is quite possible to build a cylindrical structure. If we do this, we will definitely leave air gaps between the bricks necessary to ensure traction, and install a grate

To make such a grating, we can use both strong iron mesh and steel reinforcing rods.

Video - We burn garbage correctly

Method to use a damaged barrel

Installation of a holey barrel can be done on bricks. It is advisable to choose for these purposes an area where it would be best to rake the ash. The result is a kind of blower. The holes at the bottom of the container act as a grate. As a result, you get a design ready for use.

If your summer cottage is a small area or there is a fire hazard near it, then it is advisable to cover the barrel with a flame with a sheet of iron. Then the calves will not fly to the sides. When the bottom has burned out, instead of grates you can use twigs that are inserted through the container.

Prices for outdoor LED pole lights can be found here.

It is necessary to cross a couple of rods. They will act as grates on which compressible waste is laid out. From below there will be air draft, which is required for waste disposal.

Adjusting this flame is very easy. If necessary, it can be quickly extinguished. And the barrel can be located in any convenient place. In addition, large branches can be used when burning garbage.

The presented work on waste disposal at the dacha is considered the simplest. When disposing of waste in large quantities, you need to watch for sparks. To carry out such work, it is better to choose wet and cloudy weather. Then it will be more difficult for the flame to spread, and all conditions for burning waste will be created in the container.

You will find all the information about heated barrels for country showers here.

It is very important to take care of your personal safety. Therefore, be sure to wear glasses to prevent sparks from damaging your eyes. Wear gloves on your hands to avoid thermal injury. You will also make yourself a poker stick, which you will use to move the branches. Such activities will contribute to their final combustion. It is advisable to always have a fire extinguisher on hand. If such a situation occurs that the flame spreads to dry grass and bushes, then you will be able to localize the fire in time.

What should not be burned

Recyclers are designed for organic waste. Do not place plastic, glass, metals, electronics or synthetic fabrics in the oven. It is prohibited to dispose of used aerosol cans by fire - they belong to metal waste and pose an additional hazard, creating a risk of explosion. The following cannot be burned:

- painted boards; a possible exception is products with a water-based coating;

- posters and other papers with a lot of ink (advertising brochures, flyers and similar materials);

- particle boards whose components or coating are capable of releasing toxic substances when burned.

By-products of gardening activities (branches, dry grass, weeds, wooden remains of equipment), worn-out rags and organic compounds that are not suitable for composting are suitable for disposal in incinerators.

The presence of unwanted scraps from the above list occurs in small concentrations - it is rare that a homeowner will look for a painted board or an old poster in a pile intended for burning.

These requirements apply to homes. Industrial equipment, such as Japanese smokeless stoves, one of which went into operation in the summer of 2018 in the medical sector of Yakutsk, is designed for many types of combustible waste. Similar installations are used in Australia, the European Union and other regions, allowing to reduce the concentration of solid waste in landfills. But for individuals it is better to limit themselves to pure or minimally processed organic matter.

What does the law say about the use of waste incineration barrels?

Russian legislation is gradually approaching the laws of developed countries of the world. The use of a barrel as a waste disposal agent is prohibited by Article 20.4 of the Code of Administrative Offenses of the Russian Federation and the Federal Law “On the Protection of Atmospheric Air”.

By burning waste, especially of plant origin, you harm the environment. If your neighbors report you, you will have to pay a fine of 2,000.00 - 3,000.00 rubles. In the event of a fire, the amount of the fine will increase depending on the damage caused.

It is more expedient to make compost from accumulated plant debris. And entrust the disposal of other types of waste to special services.

Homemade options

To make an outdoor stove with your own hands, you need to prepare separate materials. Most likely, an old metal barrel, a pipe with a diameter of 50 cm, and a container will come in handy.

Barrel stove

It is necessary to build a grate inside the structure and provide for the location of the ash pan. You need to make a hole in the upper half of the barrel and weld a chimney.

This garden waste stove usually has a pyramidal or rectangular shape. The elements of the device must be attached to the bottom, maintaining a distance of 3-5 cm. The latter will ensure sufficient air supply during combustion. It is necessary to lay a grid made of reinforcement at the bottom. This stove will last a long time.

Its main drawback is its massiveness, which creates difficulties in case of movement.

A sauna stove, even if it is damaged, can be converted into a garbage disposal.

First, you need to remove everything from the heater, leaving the grate and body. Then sheet steel is welded from the inside to the base, which will strengthen the entire structure well.

The waste can then be thrown from above. But on the eve of loading large parts, you need to light the flame. When disposing of waste, it is advisable to cover the stove with an iron sheet, placing pieces of brick to ensure unimpeded escape of smoke.

Brick oven

Such a waste incinerator will have a long service life and an attractive appearance. The stove will require approximately 115 bricks.

Main stages:

- Apply a layer of sand on an area of 1 m by 0.7 m.

- Lay out the 1st row without mortar. Leave 1.5 cm gaps between the bricks (8 pieces) around the entire perimeter for traction.

- Place the grate.

- Form an ash pan from a steel sheet and brick, fill it with mortar (cement-sand).

- Gaps are maintained in subsequent rows.

- The final row is continuous.

- Install the iron cover.

It is much safer to burn waste in a special oven. Such a simple device for a summer cottage can be purchased or made independently using a drawing.

We achieve complete destruction

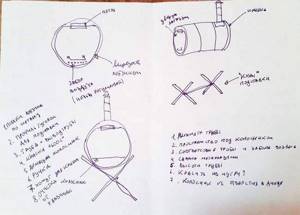

Of course, not something useful, but garden and household waste. Let's try to come up with an incinerator for it, suitable for the destruction of solid waste, pesticide packaging, and so that the ash from the stove is suitable for fertilizer without restrictions. This requires excess carbon from plastics and metals (including aluminum bag gaskets) to be released into the pipe in the form of harmless, stable compounds. We also set the condition that the furnace can be reloaded on the move without any significant smoking.

In short, is it possible to make a waste incinerator at the dacha that is not inferior to industrial waste destructors? Yes, if you focus (“sharpen”) its design specifically on waste in private household plots, without industrial and mass urban household waste. To do this, it is necessary to maintain a stable temperature of at least 800-900 degrees in the combustion chamber, separate from the furnace shell, with continuous access of air to the most critical zones. And for this, in turn, you will have to, in addition to the described technical solutions - a perforated self-adjusting burner, a gas deflector, operational adjustment of the air supply - resort to the experience of... metallurgists.

Why metallurgists? Because a mixture of charcoal and raw ore (which has not undergone purification, enrichment and agglomeration) in terms of its properties as a combustible material is very, very similar to household garbage “straight from the bucket”. Without continuous blasting, a blast furnace will not smelt metal, and even then, for centuries, labor and material costs per unit of its mass were enormous, and the quality left much to be desired. It is this circumstance that has held back technical progress for a long time. According to theoretical and related technological factors (for example, the technology of coking coal), the first scientific and technological revolution could have begun somewhere at the beginning of the 17th century, but was “late” by 200 years due to the lack of a large amount of cheap high-quality metal. Until E. Cowper thought of heating the air blown into the blast furnace, using the residual chemical energy of the exhaust unburned gases. The result is natural: the speed and course of chemical reactions strongly depend on the temperature of the reagents. But the most difficult thing is to see the obvious...

The difference between recycling and the blast furnace process is the temperature of complete destruction: we don’t need 2000 degrees, 800 is enough, stable in terms of loading volume. Therefore, there is no need to fence off regenerators-coopers and an air preparation shop on the site. The entire incinerator can fit into the same 200 liter barrel. True, its volume for loading waste will be used by almost half. But taking into account the possibility of additional loading on the go, this is enough for the needs of an average private household plot.

A diagram of a household furnace for complete destruction of waste is shown in Fig. below. Dimensions are given as standard for barrel D600x850; their deviation up to 10-15% will not significantly affect the device parameters.

Construction of a household furnace for complete destruction of waste by combustion

The main heating of the air occurs above the burner arch: here the afterburner pipe, heated to 600-700 degrees, intensely radiates heat in all directions. IR is very well absorbed by water vapor, i.e. The more humid the outside air, the more it will heat up.

Next, the hot air passes through a fairly narrow gap between the casing (shell) of the furnace and the burner body. This enhances the self-tuning of the combustion process “under air”, see above. In fact, a correctly placed load (see below) accelerates very quickly in highly economical surface combustion, and just as quickly passes into a less economical, but developing high temperature, volumetric combustion. At the same time, pyrolysis occurs in the mass of solid waste under wood waste at temperatures average for this process. Its products pass through a zone with a temperature of approx. 1000 degrees, which guarantees complete disintegration of hazardous substances.

Recharging the furnace on the move is possible due to the fact that the pressure in the burner is below atmospheric, and the cross-sectional area of the neck of the loading hatch is no more than 1/5-1/6 of that of the burner. Assuming efficiency: remove the lid, quickly pour it out, and close it. If you hesitate, the stove will start smoking, but if you close the hatch again, it will quickly return to normal. There is no need to chop large branches, just break them into pieces so that they do not interfere with closing the lid - they will burn perfectly, as happens in a rocket oven.

How to use

First, solid waste and toxic chemical containers (if any) are loaded into the oven to a level not higher than the maximum starting level (see figure). Then - drier wood waste, and so on in layers of 10-15 cm to the level of the maximum working load of flammable materials; the topmost layer must be made of flammable materials. As loading progresses, the size of wood waste may decrease and the humidity may increase until it becomes half-damp.

Light the oven from above through the loading hatch with paper or rags soaked in liquid oil or flammable liquid. The air throttle must be fully open. The hatch is closed, making sure that the loaded material has caught fire. When smoke comes out from under the gas deflector. Then the air supply is adjusted until the smoking stops. The same thing happens if the stove starts smoking while running, because... There is no garbage with stable properties.

Cleaning this stove from ash and carbon deposits is its weak point, but it can be overcome. Ash is removed from the extinguished furnace by lifting it. “Just lifting it up” cannot be written, because Two or three of us will have to work hard.

If the stove does not come into operation (it smokes, it takes a long time to burn out), then it is time to clean the burner from carbon deposits. In order for complete (major) cleaning to be possible, the afterburner chimney and the hatch neck do not need to be welded to the casing. The gaps between them must be covered with oven glue or simply clay, and the lower fastenings of the combustion chamber must be attached to it with threads or other detachable connections.

For routine cleaning of the combustion chamber, the stove is removed from the bottom and placed on its side. Then, with a sharpened rod, they poke into the perforation holes of the burner hearth, knocking off the carbon deposits. Next, the stove is placed back on the pallet and poked through the hatch with the same rod until the crushed carbon deposits fall onto the pallet, from where it is removed. After cleaning, check the coating of the seams, because their leakage can lead to the stove smoking and the inability to put it into operation. If major cleaning, repair and/or replacement of the combustion chamber is necessary, its lower fastenings are released, and the chamber is removed from the furnace laid on its side.

Pros and cons of burning waste in a barrel stove

Each design has both its pros and cons. Of the general advantages and disadvantages, the following positive and negative points can be highlighted.

Pros:

- barrel-stoves are mobile and easy to move around the garden;

- allow you to avoid open fire;

- the strength of the fire can be controlled.

Minuses:

- constant exposure of the barrel to elevated temperatures leads to wear and tear of the structure;

- the use of barrel stoves even in your own garden plot is prohibited by law; constant use of them will most likely lead to the payment of fines;

- This method of disposal of garbage is not environmentally friendly, and also does not provide absolute fire safety.

Safety regulations

- The process of burning waste is accompanied by a number of dangerous and harmful factors that can lead to fires, burns, and poisoning by combustion products. Such devices should be installed as far as possible from residential premises, on the border of the garden plot.

- When using them, it is necessary to take into account the direction of the wind; it should blow in the opposite direction from the buildings. During strong winds or hot dry weather, the operation of such stoves is extremely undesirable, as this can lead to a fire.

- When burning garbage, you should constantly monitor the process occurring inside the container. However, it is extremely undesirable for a person servicing such a device to be in the area where the smoke escapes. Children and pets should be protected from inhaling such smoke.

Garbage incinerator

This version of the stove for destroying garbage in the countryside is made from an ordinary metal barrel. It is noteworthy that there is absolutely no need to have any special knowledge or skills for this. Anyone can make such a stove. And first of all, it is necessary to prepare materials and tools for work.

What you will need in the process:

- grinder and two discs for it (for metal and emery);

- bolts and nuts (six pieces each);

- twenty self-tapping screws;

- spark arrester (with fasteners diameter 11.5 cm);

- paint with fire-resistant properties;

- paint brushes (can be replaced with a spray gun);

- meter of metal grating;

- degreaser;

- a pair of door hinges;

- one and a half meters of tin pipe (11.5 cm in diameter);

- wire (approximately 200 g);

- five-meter steel profile;

- five-meter steel rod;

- handle with wooden attachment;

- metal drill (diameter 1.2 cm);

- electric drill;

- jigsaw and metal saws.

Having completed the preparation, you can begin the main workflow. A garden waste oven is made in several specific steps.

Barrel processing

You need to mark a straight line on the bottom - it is to this that the door will be attached in the future. Then make a cut according to the marks using a grinder, being careful not to touch the sides.

Make a hole at one of the edges of the resulting cut.

It is extremely important that it is located as close as possible to the side of the barrel, as well as directly on the cut strip

From the intended point you will need to move further with a jigsaw. Insert the saw into the hole and carefully cut out the bottom. Do not touch the upper part (the one above the cut). You need to move as close to the walls as possible.

It is necessary to make several holes in the resulting door - it is through them that air will flow. You can do them at will.

If necessary, clean the barrel from old paint or rust using a grinder with an emery attachment.

Place the door, securing it with hinges, and install the handles. For reliability, you can use self-tapping screws and a screwdriver.

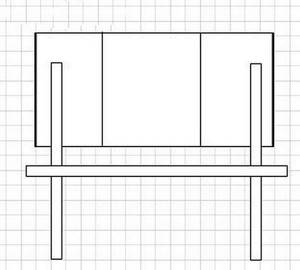

Goats

To make a trestle you will need five sheets of metal profile. The goats will be made up of a pair of crosses, fastened together by a rod.

The profile must be connected at a right angle. To do this, you need to make two holes in each and tighten them with bolts.

The next step is degreasing and painting the barrel. We must not forget about goats.

It is advisable to handle goats disassembled. You need to apply the paint in several layers, each time waiting for it to dry.

A day after dyeing, you can collect the goats. Don't forget to put washers under the nuts. Tightly tighten all parts of the structure. The resulting strength should be sufficient for a metal barrel with an additional load in the form of debris.

Smoke exhaust

To make a hole for the smoke to escape, you need to draw a circle with a diameter of 11.5 cm at the top of the barrel. Cut the circle into slices, like a cake. There should be about ten elements in total. Bend the slices vertically upward.

Place the chimney pipe so that all the pieces fall inside. Then secure the pipe at several points with self-tapping screws for reliability.

Install the grate. Do everything as in the picture.

Place the cover - you can secure it with clamps or bolts.

The DIY waste incinerator is ready and you can start using it now.

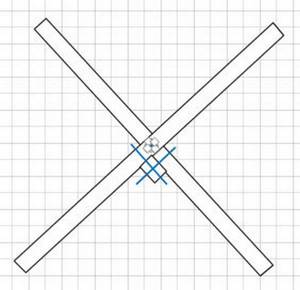

Horizontal stove made from a barrel with a pipe

The design of horizontal barrel stoves consists of a container turned on its side, standing on supports or legs. Such bases can be made in the form of trestles, vertical or inclined metal profiles, connected from below to a container in which waste is burned.

They are equipped with a door, a chimney and, sometimes, an ash removal system (an ash container and a grate). During one working cycle, such a device can burn up to 150 - 170 liters of waste.

A typical stove for burning garbage from a horizontal barrel is shown in the diagram:

Materials and tools

To create such a furnace, you will need the following consumables, tools and accessories:

- Empty barrel with a volume of 200 liters.

- Steel profile (5 meters).

- Metal rod (5 meters).

- Hinges for the door.

- Welded mesh (1 square meter).

- Wire (200 grams).

- Spark arrester.

- Tin pipe for the chimney (1.5 meters).

- Metal handle with wooden nozzle.

- Bolts, nuts - 6 pieces each.

- A jigsaw, several metal files.

- Self-tapping screws with large flat heads (20 - 25 pieces).

- Set of drills for metal.

- Angle grinder (grinder) with cutting and grinding wheels.

- Fireproof paint.

- Acetone or white spirit.

- Several brushes or a paint sprayer.

- Electric drill.

- Personal protective equipment for working with an angle grinder (goggles or mask, gloves).

- Measuring and marking tools (core or sharpening, tape measure, building level, square).

Step-by-step instruction

After preparing all the materials and tools, you can begin the actual production of components and assembly of the structure. How to make a stove for burning garbage from a horizontal barrel:

- First the door is cut out. To do this, using a marking tool, draw a straight line parallel to the diameter of the barrel and 10 centimeters from the edge. Using a grinder, a slot is made along the resulting chord. When performing this operation, you need to ensure that the cutting disc of the angle grinder does not cut through the side of the container. Next, using a drill with a diameter of 12 millimeters, a hole is made for the jigsaw file and the door itself is cut out. You cannot use a grinder for these purposes, as the disc will cut through the side surfaces of the barrel.

- Several holes are drilled in the lower part of the resulting door to allow air to enter, which is necessary during the combustion process.

- Using an emery disc and an angle grinder, the surface of the barrel is cleaned from rust and burrs. This is needed for the upcoming painting of the incinerator.

- A support post made in the form of goats is constructed from a metal profile. Profile sections 1 meter long are joined into two X-shaped crosses at an angle of 90 degrees using bolts and nuts. Next, they are connected using the fifth piece of the profile into a single whole.

- All structural elements are degreased using a solvent and, if desired, primed. Next, a layer of fireproof paint is applied. It is better to do this in 2-3 layers, waiting for it to dry after each painting.

- All elements that have dried after painting are assembled. The goats are tightened using bolts, nuts and washers. The barrel itself is secured to the trestles using the same self-tapping screws.

- Hinges and a handle are installed on the door using self-tapping screws and an electric drill (or screwdriver).

- A chimney hole is made in the body using a grinder, and not just a circle is cut out, but cuts are made in the form of petals. Then they bend back and the chimney itself will be fixed to them.

- Using self-tapping screws, the chimney is installed on the surface of the barrel and petals.

- At the bottom of the barrel, the grate is assembled and mounted.

- The back cover is installed using clamps and bolts.

- The oven is completely ready for use.