Mortar

The clay mixture is not suitable for the construction of a chimney and stove foundation. Condensation collects in the part of the chimney that is located above the roof. Because of it, the clay can crack. When building a foundation, clay mortar is not strong enough. It is best to use lime paste as a base for such purposes.

This dough is made by mixing water and quicklime in a 3:1 ratio. It is not recommended to make it yourself, as this can lead to injury to the skin and respiratory tract. It is better to purchase ready-made lime dough at any hardware store.

To prepare the solution, you need to sift the sand and rub the dough through a sieve. Then you need to mix one part of the dough with three parts of sand. Add water to obtain the required consistency.

To increase the strength of brickwork, you can use lime-cement mortar. To prepare it, we take one part of cement, two parts of lime paste, and ten parts of sand. First, mix sand and cement. Dilute the dough with water until it becomes viscous. Then add a mixture of sand and cement to the milk of lime and mix. If necessary, add water again in small portions.

Self-preparation of refractory mortar

To prepare a refractory mixture for a stove, you need to dig up or purchase raw clay. It is this type of material that has the necessary qualities to prevent shrinkage of assembly seams. To prevent clay from crumbling, it is reinforced with cement and sand (2 parts clay, 0.3 parts cement and one part sand).

It is also important to check the saturation of the clay. To do this, it must be kneaded in water to a plastic state, forming a ball with a diameter of about 5 cm from the resulting mass. It is placed between two boards, which are gradually shifted by pressing on the ball. A normal concentration of material will crack when the lump shrinks 1/3. An earlier appearance of cracks will indicate a lack of fat content in the clay, and a later appearance will indicate an excess of it. Clay with low fat content is usually rejected. Excessively fatty material is additionally diluted with sand.

How long does clay mixture take to harden?

The time for complete drying of fireclay paste in air is 72 hours, inside the brickwork this time increases, it depends on the thickness of the masonry, temperature and humidity of the surrounding air. Petrification of fireclay mortar occurs at 800 degrees Celsius.

Important! Fireclay masonry does not like sudden changes in temperature. The stove is heated for the first time three days after completion of construction.

Use thin, quickly burning logs. The dampers and vents are fully opened during the first fire. Then the stove is dried for a week, burning small portions of wood daily

The furnace is heated for the first time three days after construction is completed. Use thin, quickly burning logs. The dampers and vents are fully opened during the first fire. Then the stove is dried for a week, burning small portions of wood daily.

Fireclay masonry dries faster than masonry made from ordinary clay-sand mortar and ceramic bricks, but only the firebox is usually made of fireclay. Therefore, the timing of the start of operation of a furnace with fireclay masonry will be the same as the timing of use of a furnace built on clay and lime mortar. In summer, a new stove is heated to maximum after 10-14 days, in winter - after a month.

Application

To lay out the body of the furnace you need red brick, and fireclay for the firebox. Therefore, you should use a clay mixture and mortar accordingly. They will fill the seams well and make the masonry airtight. Clay solutions are not suitable for constructing the foundation of a stove and chimney. For such work it is better to use lime, lime-cement or concrete mass. To build a stove in a bathhouse, you also need a solution containing lime milk. Regardless of the type of building mixture, the seams are made 2-4 mm thick, since in high-quality masonry they should be thin.

A brick-lined stove should be heated no earlier than three days after the completion of the masonry. This period of time is needed for the solution to completely harden so that complete, strong seams are formed. It is recommended to begin finishing work no earlier than a month after full operation. For laying facing bricks not in a kiln, gypsum can be added to the clay mixture.

Scope of application

Fireclay can be used alone or mixed into plaster solutions. Fireclay is not only thermally resistant, but has deep brown and brown shades and an impressive texture. Aesthetic qualities significantly expand the scope of application of the material:

- production of construction refractories;

- interior design using fireclay plaster;

- casting and sculpting of souvenirs, dishes, figurines;

- preparation of solutions for the construction of stoves and fireplaces;

- for the formation of heat-insulating screens.

For designers, sculptors, craftsmen, and decorators, refractory clay opens up endless possibilities. You can add various fillers and dyes to it. The plastic material can take on the most intricate shapes. The spectacular texture brings an element of uniqueness. In construction and renovation, fireclay is characterized by local use.

Decorating the walls of premises with fireclay plaster

How to prepare a solution from fireclay clay

Depending on the application, clay mixtures have different proportions. Let us consider in detail how to properly mix a chamotte-based mortar for laying bricks and for plastering work.

Mix for laying bricks

In most cases, fireclay mixtures are used for the construction and repair of stoves, fireplaces and other objects operating at high temperatures. For the construction of stoves and fireplaces, heat-resistant silicate or fireclay bricks are usually used.

To ensure strength, reliability and maximum service life, it is necessary that the mortar and brick have the same coefficients of thermal expansion.

Masonry mortar based on fireclay clay

- In a prepared container, quartz sand and crushed fireclay clay are mixed. The proportion is as follows: 2 parts quartz sand to 1 part clay.

- Water is added to the resulting dry mixture. The composition is thoroughly mixed, after which it settles for 2-3 days until the liquid is completely absorbed.

- For final mixing, you can use a concrete mixer or a construction mixer. The solution is kneaded until the consistency of a thick viscous mixture.

If the mixture turns out to be too liquid, you can add quartz sand to the composition. Thick mixtures are diluted with water to the required consistency.

There are also more complex compositions. High-strength heat-resistant solution that can withstand temperatures up to 1840C.

The solution is prepared by mixing 1 part blue clay, 1 part fireclay clay and 4 parts white kaolin sand. After thorough mixing, water is added to the dry mixture. The solution is mixed in a concrete mixer until a homogeneous viscous mass is obtained.

You can improve the performance characteristics of the solution by adding the following ingredients to it:

- PVA glue;

- liquid glass;

- table salt.

The addition of these components significantly increases the plasticity of the solution.

Plaster mortar

Plaster mortars based on fireclay clay are characterized by high strength, heat resistance and long service life.

The method of plastering with fireclay is no different from plastering with lime or sand-cement mortar. The only difference is in the composition of the solution.

Plaster mixture based on fireclay clay

To prepare the solution you will need:

- Portland cement – 1 part;

- fireclay clay - 2 parts;

- quarry sand - 7 parts.

Before mixing, the sand must be thoroughly sifted. The solution is prepared in the following sequence:

- Clay and sand are poured into the container in appropriate proportions and mixed thoroughly.

- The dry mixture is diluted with water and remains in this state for 2-3 days.

- Portland cement is added to the mixture thus obtained. The solution is mixed in a concrete mixer or using a construction mixer until a uniform consistency is achieved.

Important! The finished plaster mixture must be worked out 2-3 hours before hardening begins.

A plaster mixture based on fireclay clay should be applied to a surface treated with a heat-resistant primer. This will ensure maximum adhesion to the base.

Composition for the manufacture of decorative elements and souvenirs

To make decorative interior items, the mixture is prepared in a certain sequence:

- In a suitable container, mix 6 parts of ordinary clay and 4 parts of fireclay powder.

- The resulting dry mixture dissolves in water and settles for 2-3 days.

- The prepared composition is intensively mixed until a homogeneous mixture with the consistency of liquid sour cream is obtained.

- The pre-prepared mold is filled with the resulting mixture and is not removed from the mold until it hardens completely.

The casting can dry more quickly if 1 part of PVA glue is poured into the finished composition. When the product is completely dry, it is subjected to high-temperature firing. In this case, the temperature in the oven should be approximately 1300C.

Factory-made masonry mixtures for laying stoves

We are talking about fireproof dry powders, which, after dissolving in water, turn into a homogeneous mass. The cooking recipe is usually indicated in the accompanying instructions. Along with the usual components (sand and cement), the solution contains special heat-resistant additives.

The refractory mixture for laying furnaces produced at the enterprise has a number of advantages:

- Well-calibrated composition. Under production conditions, careful dosage of each component is carried out, according to time-tested recipes and proportions.

- Specific additives. The components that give refractory mixtures their “proprietary” characteristics are often not commercially available (and sometimes even kept secret).

- Versatility. As a rule, industrial solutions are multifunctional: they can be used to lay stoves and then plaster finished walls.

- External aesthetics. Although a finishing finish is still applied over masonry or plaster, it is much more pleasant to work with an attractive-looking mortar.

Our stove makers especially liked the products of such manufacturers of masonry mixtures for stoves and fireplaces: “PLITONIT”, “TERRACOT”, “Makarov Stove House”, “Pechnik”, “Scanex”, “SPO”. As for the disadvantages of this type of material, it is usually called their high cost. In cases where it is necessary to save money, they try to use self-prepared heat-resistant solutions.

Working with mixture and fireclay bricks

Mixtures for laying fireproof stoves must be made with high quality

But it is equally important to do their proper installation.

Particular attention must be paid when filling the seams with mortar. If the filling is poor, water may get into the seams, and if it freezes, the masonry will crumble much earlier than planned.

The choice of brick laying category depends directly on the future temperature condition. The higher the temperature, the smaller the seam should be:

- 1 mm – first category;

- 2 mm – second category;

- 3 mm – third category;

- more than 3 mm – fourth category.

To determine the quality of the seam, I use a special probe with a width of 15 mm, and the thickness must be equal to the seam.

- The probe must penetrate 20 mm into the seam. To ensure that the bricks are positioned correctly, they are tapped with the handle of a trowel. To ensure that the seams are of a certain horizontalness, ordering slats are used and a cord is attached to them. After the first layer, the laying is determined only by this cord.

- The characteristics and reliability of masonry largely depend on the uniform application of the mortar to the surface.

Note: The brick sucks moisture out of the mixture, preventing it from drying out. Therefore, the brick is periodically wetted during the laying process, or even pre-soaked beforehand.

The fireproof mixture will help you make a quality structure, but you should never rush. You should look at photos and videos to understand the entire cooking process. After all, construction requires high-quality materials.

This is interesting: How to choose a set of drills: we explain the question

Clay-sand mortar

Sold in construction stores or prepared with your own hands. When it is possible to obtain clay, the mixture is practically free. A solution of clay and sand is the main one, since it is used for laying almost the entire furnace. An exception is a chimney pipe with a foundation, since the moisture resistance of the resulting mixture is quite low.

A kiln mortar based on sand and clay interacts well with fired clay bricks. It has average strength, is resistant to fire, and, most importantly, does not allow gases to penetrate the substance. Another advantage is the possibility of secondary use. The solution has no shelf life limitation. It can be diluted with water and used again.

Clay

The basis of the oven solution, which, when independently “extracted”, requires the correct determination of fat content. Regular moistening with water and kneading in the hand is not enough. A more thorough check needs to be carried out. It can be made in different ways, but among the simplest and most accessible is kneading 2-3 liters of clay using a kneading spoon with plain water.

When the resulting mass almost completely sticks to the jig, it means that the clay has a high fat content and needs to be artificially depleted by adding sand. If the clay remains in small clumps on the tool, it is ideal for mortar and does not require any “rework.” This stage can be continued by directly mixing the masonry mixture, but the clay must first be cleaned. This also applies to sand, which must be washed.

Clay preparation

Properly selected clay should be pre-cleaned, which will significantly improve the quality of the material. It is enough to sift the dry material through a sieve with 2-3 mm mesh. Next, it is soaked, laid in layers of 15-20 cm, poured on top with water, and then a day later mixed with the addition of a small amount of liquid. When another 24 hours have passed, the completely swollen mixture is thoroughly stirred again. It is this clay that is used for the further preparation of the stove solution.

Sand cleaning

Purchased bulk material is usually sold washed, but it most often requires additional preparation. The presence of any foreign inclusions reduces the quality of the masonry mortar, and, therefore, affects the quality of the seams, which should not be allowed. It is enough to sift sand purchased in a store through a fine sieve with cells from 1 to 1.5 mm, while sand mined independently will require additional washing under high water pressure. On an industrial scale, sand is cleaned of organic components by heating to high temperatures, at which the bulk material is perfectly fine dries. You can do this at home, but only when you make a special installation yourself, which is impractical for laying out one structure.

Options and technology for preparing the solution

For laying stoves, the proportions of clay and sand are selected based on the characteristics of the available materials. If the clay is oily, increase the proportion of sand; if it is thin, less quartz. As a result, a good composition for the furnace is obtained experimentally.

The clay is pre-soaked in water for 2 - 3 days.

The masonry composition is prepared according to several “recipes”. Technology of the most accessible method:

- The clay is soaked for 2–3 days in a wooden box or in a tin trough. After 3 days, add sand and, putting on boots, trample the mixture until all the lumps are broken.

- Then the solution is mixed with a tamper and hands to crush all small lumps.

- Normal mortar, suitable for building a furnace, slides off the shovel, but does not drain. If you lay a layer of 3-4 mm between 2 bricks, after 5 minutes the stones will no longer come off each other.

- If the mixture is too fatty, add sand - no more than 15% of the volume, and repeat all the manipulations.

The following method is recommended if using normal clay.

- First, they build a wooden flooring with sides - a striker.

- Clay is placed on the striker in layers and moistened with water. When the material softens, it is turned over, raked into piles and beds, leveled and cut into pieces with a shovel. All these operations are repeated until the solution becomes completely homogeneous.

High homogeneity is achieved more quickly when method 3 is used. It is effective, but also labor-intensive. The clay for soaking is placed in barrels, then the mixture is filtered through a sieve with 3*3 mm cells. Sifted sand is also added to the composition. If the consistency is too thick, dilute with water.

For oily clay the proportions of sand are increased, for lean clay they are reduced.

The volume and ratio of ingredients vary widely. The optimal combination is the proportion of sand to clay 1:2 or 1:1. The volume of water is approximately ¼ of the amount of mineral.

In fact, the proportions are determined by the fat content of the mineral. With high fat content, 2 parts of clay may contain 4 parts of sand. If the material is thin, the proportion of sand is halved.

Lime based

To prepare the mortar and build the base for the chimney, it is advisable to use a composition with lime and cement. It is important to properly mix quicklime and water in proportions of 3:1. The result is a finished dough, to which sifted sand is added, passing through a fine-mesh sieve, in the proportion of 3 parts sand to 1 part dough. After which the mass is diluted with clean water to obtain a thick consistency.

As a result, it is possible to obtain something strong and flexible enough so that it can be laid normally and serve for at least 10 years. The percentage of fat content can be changed by adding sand. If the mass is too greasy, add 5 parts of sand, and for a normal mass, add 3 or less parts.

Cement will help increase the strength of the solution. For production you need to mix 1 volume of dough with 5 volumes of sand and 0.5 cement. The methods for manufacturing the fastening composition have a similar sequence: the components are mixed in a special container.

The resulting dough must be mixed with an uncontaminated liquid until a dense consistency is obtained.

Cement mortar

What solution is needed for arranging the stove foundation and laying the outer part of the chimney? The answer is simple - a composition based on cement, sand and water. In terms of strength, it is equal to its lime counterpart, but it takes much longer to harden.

The optimal composition of the finished mass is obtained in the following proportions - 3:1 (for 3 volumes of sand 1 volume of cement grade M 300 or 400). Before mixing, all components are sifted through a fine-mesh sieve. Sifted sand is poured into a deep container, cement is added and mixed until smooth. At the end water is added.

The finished mixture must be brought to a thick and viscous consistency. Determining the appropriate density is quite simple - the composition should remain mobile, but not flow off the shovel when it is rotated up to 45 degrees.

To build a monolithic stove, it is recommended to use refractory concrete mixture in the following proportions (parts):

- Cement (M 400) – 1;

- Crushed stone or gravel – 2;

- Fine sand – 2;

- Fireclay sand – 0.4.

In order for the stove-maker to have a solid foundation, it is recommended to prepare a masonry mortar consisting of coarse gravel, sand, and cement (proportions 3:3:1).

To increase strength, you can use quartz chips. The refractory concrete mixture is coarse-grained, has increased density and is waterproof.

Use Cases

Kaolin can be used for furnace masonry. It is also used as plaster and for making decorative items.

In addition to being used for decorative purposes, chamotte clay is actively used when laying stoves and fireplaces

When building stoves, they look at the markings applied to the surface of the products. Usually the letter "Ш" is indicated. The material most often used is for masonry of the firebox, since its cost is high, so it is impractical to use it for the rest of the work. They lay it on special clay. Its characteristics are the same as those of brick.

Fireclay fireclay has a unique texture and composition

That is why designers paid attention to it and began to use it to produce unique blanks. These can be ceramic dishes, original figurines

To ensure greater plasticity, various impurities are added.

Description and characteristics of the material

Chamotte is kaolin clay that is subjected to heat treatment during the production process. It is fired in a kiln at a temperature of about 1500 degrees, eliminating water and plasticity. Thus, the material resembles stone. It can be observed in the form of a powder, which is mixed into mortars, or in the form of bricks. Depending on the manufacturing process, kaolin can be gray-brown or white with creamy shades.

Compound

The basis of chamotte is clay, which contains highly dispersed hydroaluminosilicates. Briquettes or some other shapes are made from this clay and sent to the oven. The firing temperature and time are different. Next, the fireclay clay is crushed into small or large grains.

The composition of the material includes: quartz, oxides of calcium, sodium, iron, magnesium and potassium.

Specifications

When buying fireclay clay, make sure that the expiration date has not expired and that the material was in appropriate conditions. Long-term storage, humid air and water can worsen the properties of fireclay clay. The shelf life of fireclay is up to 3 years if it was in the original packaging and in a dry place.

According to GOST, the material has the following parameters:

- grain size – about 2 millimeters;

- moisture absorption - up to 25% for low-burnt fireclay, 2-10% for high-burnt fireclay;

- humidity – up to 5%;

- fireproof characteristics - 1550-1850 degrees.

Advantages and disadvantages

Why use fireclay fireclay? Among the advantages of the material, the following factors can be noted:

- fire resistance;

- high adhesion characteristics;

- vapor permeability;

- reliability and long service life;

- environmental friendliness.

The disadvantages of fireclay include its higher cost when compared with traditional types of clay.

Consumption

20 kilograms of fireclay (standard package) is enough to lay about 25 bricks. For 1 cubic meter of masonry you need about a hundredweight of burnt kaolin.

What solutions are used when laying individual brick oven elements?

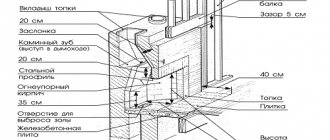

The choice of solution for work must be carried out depending on which part of the stove it will be used for laying. Using the diagram below, we will consider each of them in detail.

General structural diagram of a standard furnace masonry

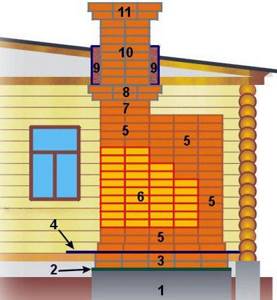

- The reinforced concrete base of the furnace foundation, which is also called the pillow or root. It is manufactured using standard technology, however, in order to avoid unpleasant consequences, it must be physically separated from the foundation of the house itself. The need to comply with this condition is explained by differences in the degree of shrinkage of the building and the furnace in it.

- Waterproofing layer. To create it, roofing material is perfect, which needs to be laid on top of the foundation in several layers.

- Actually, the stove foundation itself. Since it is not exposed to powerful thermal effects, it does not require the use of particularly heat-resistant mixtures when laying. At the same time, the reliability of the entire structure depends on the quality of assembly of this furnace element. There are cases when, due to errors in laying the foundation, it was necessary to completely disassemble the stove and redo it in a new way. Complex, three- or more-component cement-lime mixtures are used for work. Well, red solid brick is best suited here as the main building material.

For the manufacture of compact stoves or stoves with a large base area (for example, a Russian stove), you can also use a regular lime mixture.

- A layer of thermal insulation with a fire protection area. It is made from a mineral cardboard or asbestos sheet, on which a sheet of iron is placed on top, covering the entire structure with a finishing layer of felt cloth soaked in so-called clay milk (this is a solution of very thinly diluted clay; we will describe how to prepare it below).

- A heat exchanger that accumulates the energy released during the combustion of wood. It is one of the main parts of the so-called furnace body. During kindling, it rarely heats up above six hundred degrees, but is subject to very active influence from the smoke and other gaseous substances released during combustion. It is not uncommon for destructive acid condensate to settle on the inner surface of heat-storing masonry. The brick used here is special: stove type, M150 grade, solid red ceramic. The bricks are fastened together with a simple one-component clay solution. It should be noted that the term “simple” refers only to the composition of the building mixture. Its preparation is a rather labor-intensive process, the features of which we will consider below.

- The hot part of the stove body is also called the combustion chamber. It is subject to moderate chemical influence from gases, but heats up to very high temperatures, up to 1200 degrees. For masonry, so-called fireclay bricks and fireproof clay-fireclay mortar are used.

- The source of the chimney. It is made from the same brick and fastened with the same mortar specified in point No. 5, since this element of the furnace is subject to similar temperature and chemical influences as the heat-accumulating part of its body.

- "Fluffing" of the stove chimney. Its task is to create a flexible mechanical connection connecting the ceiling and the chimney itself. Allows you to avoid a situation where ceiling subsidence is possible. The fluff can be repaired separately; it does not require complete disassembly of the entire structure. The bricks used for masonry are standard stove bricks, and lime-type mortar is ideal for laying this part of the stove.

- A fireproof cutting is a special metal box filled with a non-flammable heat-insulating substance.

- Chimney pipe. This element is susceptible to wind and precipitation. It heats up weakly, so the pipe is laid from standard red brick. However, for greater reliability and heat resistance, they use lime mortar.

- Fluffing the chimney pipe (11). It is made from the same materials that are used when laying the main part of the pipe.

Step-by-step process for plastering a stove

- Heat the stove. The walls of the furnace must warm up well before starting work. This step is mandatory even in the hot summer season.

- Surface preparation.

- Applying the first layer. You need to moisten the surface to be plastered with water (with a brush or a spray bottle), and then apply a thin layer of liquid clay (for this you use a wash brush). Before the next stage, this plastered layer should dry out a little.

- Reinforcement.

The specifics of this step depend on the material chosen: Burlap. The material must be cut and soaked in a solution of liquid clay. After this, it needs to be distributed throughout the oven: the laying process is carried out in the direction from top to bottom, the overlap should be about 50 mm. If such material is used for reinforcement, the stove must be protected from overheating during operation; - Plastering. The solution is applied from top to bottom, each layer must be even - its thickness should not be more than 5 mm. After the solution has set, it should be rubbed in using a grater in a circular motion. If the plaster has hardened too much, it can be moistened with water. Some home craftsmen recommend, after applying the plaster solution, to smooth it with a rag (it must first be moistened in the same solution).

After finishing applying the plaster, it needs to be allowed to dry. If cracks appear, they can be widened using a regular knife, then moistened with water and covered with a solution (if a clay-based solution was used, for these purposes you can use the remains of the plaster, which can be stored in an airtight container).

At this stage, the surfaces are completely cleaned of old mortar, dirt and dust. The seams between bricks or stone are cleared with a trowel and hammer to a depth of 150 mm. This will ensure reliable adhesion of the surface to the plaster composition.

Important! Plastering of a new stove is carried out 3 weeks after completion of masonry work and complete drying of the stove mortar. Failure to comply with the established deadlines may result in the decorative layer beginning to crack and deform. After dismantling the old cladding, the surfaces are cleaned with a wire brush and a clean dry rag to avoid dirty stains that may appear through the fresh plaster layer.

After dismantling the old cladding, the surfaces are cleaned with a wire brush and a clean dry rag to avoid dirty stains that may appear through the fresh plaster layer.

The prepared surfaces are treated with an antifungal primer. 10 cm nails are driven into the cleaned seams at an angle with the heads raised above the surface up to 0.5 cm. The horizontal step between nails should be 15 cm, the vertical step - every 2 rows. A wire is fixed to the nails, and a metal mesh is placed on top. The reinforced base will ensure good adhesion of the plaster to the surface being treated.

You can plaster the stove with ready-made store-bought or homemade solutions.

If a ready-made dry composition is used for work, then the kneading is carried out according to the instructions:

- Water is poured into the container. Next, dry mass is added in the proportions indicated on the package.

- Kneading is carried out with a construction mixer until a viscous homogeneous mass is obtained.

- The finished mixture is kept for a quarter of an hour, mixed again, and then used for surface treatment.

To independently mix a solution for plastering surfaces, traditional components are used, which are mixed in the required proportions. Recipes for homemade compositions are given above.

The finished solution should be plastic and viscous, without air bubbles, lumps and dry inclusions.

Depending on the condition of the surfaces, the stove structure can be plastered in one of two ways.

Furnace design and masonry mortar

Brick sauna stoves are large structures, their parts function in different conditions. The humidity level and temperature conditions at the base of the stove, next to the firebox and in the chimney duct are different. Temperature delta can reach from 0 to 1000 degrees or more. Smoke passes through the firebox and chimney. In addition, the pipe is exposed to rain, wind and cold. A universal mortar that would fit all these parameters and withstand them with honor has not yet been invented.

Cement or lime, either together or separately, cannot withstand such a temperature range.

In addition, it should be borne in mind that fire-resistant solutions are expensive. It is advisable to use them where the maximum temperature develops. But for the foundation and main structural parts of the furnace, you can prepare cheaper mixtures. Clay is considered a relatively inexpensive building material. If you wish, you can obtain it yourself, and then the solution will be practically free. All that remains is to determine its quality and suitability for masonry and prepare it in a special way.

Clay sand mortar for furnaces is also sold and manufactured in factories. There is already a calculated ratio of components. The big disadvantage is their high price; the oven will turn out golden, because you need quite a lot of solution. For comparison: for 100 bricks you need about 2-3 buckets of the mixture. The exact quantity depends on the thickness of the seams and the density of the rows. Each master has his own style of masonry and, accordingly, the consumption of mortar.

If you recalculate factory mixtures to the actual scale of construction, then thrifty owners will not be pleased with the price. Therefore, you can take a closer look at budget masonry mortars that you can make yourself. It is also possible to prepare clay for ovens with your own hands; the composition of the solution will not be affected.

Types of masonry stove mixtures

Mixtures for laying stoves are divided into the following types:

Heat-resistant solution. This kiln masonry mixture has good resistance to high temperatures. Once cooled, it retains its chemical properties and structure. In this case, irreversible deformation does not occur. The described mixture does not lose its load-bearing capacity even when heated.

Heat-resistant solution. When exposed to high temperatures, this mixture does not expand and does not change its properties. When heated, the mixture retains all its characteristic mechanical properties. The solution is more resistant to thermal deformation compared to a heat-resistant mixture. Excellent resistance to both static and dynamic loads.

Fireproof solution. It can be heat-resistant or heat-resistant. The fire-resistant furnace mixture can withstand not only high temperatures, but also the influence of chemically aggressive substances found in the exhaust gases.

When constructing any furnaces, even those that heat up to no more than 400°C, only fire-resistant and heat-resistant masonry mortars should be used. In this case, using conventional building mixtures is impossible and extremely dangerous, since destruction under the influence of high temperatures of a stove or chimney often leads to fires.

Technical parameters and properties

The characteristics of fireclay clay from each manufacturer must comply with the standards of GOST 6137-8, which determines the main parameters of the product:

- the color of the dry fireclay mixture is gray, the structure of the product is free-flowing, without lumps or large conglomerates;

- grain diameter fraction – approximately 2 mm;

- highly burnt fireclay has a moisture absorption coefficient of 2 to 10%;

- low-burnt fireclay has a moisture content coefficient within 25%;

- the total moisture content of the product should not exceed 5%;

- The melting temperature ranges from 1550 to 1850°C.

The shelf life of dry fireclay composition does not exceed 3 years when stored in dry and tightly closed packaging. Fireclay clay mixtures are used for laying stoves, fireplaces, and chimneys.

Burnt kaolin has the following beneficial properties:

- a high degree of resistance to high temperatures makes it possible to use the product for arranging fireplaces, stoves, and chimneys;

- clay is able to pass moisture through itself, thereby maintaining a comfortable microclimate in the room;

- when laying, clay is used in the form of a solution, which has high adhesive properties;

- the natural composition of clay is an absolutely safe product for human health and the environment;

- The service life of the clay is long, and during operation the material does not crack or crumble.

The main physical properties of fireclay clay are its fire resistance, good plasticity, ability to sinter and fire shrinkage.

Plasticity - this term for a moistened fireclay composition means the ability, with the application of little effort, to modify a given shape, while the mixture remains in its plastic form and does not crack. Clay exhibits plastic properties only upon contact with water, and in small quantities. Plasticity properties depend on the composition of the minerals included in the clay structure, as well as on the particle size. When heated to 150°C, the plasticity of the mixture is reversible. However, if after the end of the dehydration process the fireclay is heated to 500-600°C, then the reversibility of plasticity will be lost. If it is necessary to reduce plasticity, then so-called thinning agents in the form of quartz and fireclay sand are added to the clay. In addition, excessive plasticity can be reduced by adding low-plasticity clays of a different composition.

To obtain a product according to the specified dimensional and volumetric parameters, during molding it is necessary to take into account the percentage of shrinkage and increase the parameters of the workpiece. The shrinkage process of fireclay clay begins to occur already at a temperature of 600°C, and it continues for quite a long time. This uniform process occurs until the temperature rises to 1000°C. After this point, shrinkage occurs most intensively and continues until a temperature of 1300-1400°C; after reaching this mark, shrinkage stops.

- Sintering temperature is an indicator of the temperature regime under which the clay mixture loses its ability to absorb moisture, that is, it sinteres. The refractory fireclay composition and all products made from it are sintered without melting or deformation, without losing their fire resistance.

- Fire resistance - this term refers to the property of a clay mixture not to melt under the influence of temperature conditions within 1580°C. Such fire resistance of clay is achieved due to the small percentage of foreign impurities it contains. This type of clay is used in the manufacture of heat-resistant products, including earthenware or porcelain.

Due to its fire-resistant qualities, clay is most often in demand for laying stoves. In addition, refractory bricks are made from this material, which is necessary for laying out the inside of the furnace, that is, for forming the firebox. The same clay is also used as masonry mortar, as it has good adhesive ability to surfaces. In addition to using fireclay clay in furnace making, it is also used for coatings in the form of refractory masses and mortars. For these purposes, PHB or PGA brands are used.

How to save on masonry materials?

The answer to this question would seem to be quite obvious: it is necessary to make maximum use of available materials, which can be obtained for free right at the site of construction of the furnace. In our case, we can independently obtain the following components: clay, sand and water. But, as practice shows, in reality everything is far from so simple. You can’t just take any water, mix it with the first available sand and clay, and as a result get a good quality mixture for masonry. A number of serious requirements are put forward for each component for creating a stove mortar. Let's learn more about each of them and learn how to select all the necessary components.

How to distinguish high-quality clay suitable for laying a furnace from other minerals?

Quite often, broken clay can be purchased cheaply from local stove makers, but we do not recommend that you take the easy route. Such material is usually heavily contaminated with organic impurities. Subsequently, they will rot and decompose, worsening the consistency of the mixture and the quality of the finished joints. It is much more profitable to find good clay in the surrounding area and dig it yourself. The difficulty lies only in learning to distinguish high-quality deposits from contaminated ones.

Clay is essentially a mixture of aluminum oxide Al2O3 and silicon oxide SiO2 (in simple terms, sand). The main determining parameter for clay is its fat content. In turn, the strength of its structure, plasticity, adhesiveness (ability to stick to other surfaces), hygroscopicity and even gas tightness will directly depend on it. Typically, the fat content of clay containing 62 percent aluminum oxide and 38 percent sand is taken to be 100%, and the fat content of pure sand without impurities is taken as the zero reference point - 0%. To mix the mortar for laying the stove, we will need clay with average fat content, because seams made from material with too high a fat content will crack during drying. “Low-fat”, or as it is also called, “skinny” clay is also not durable.

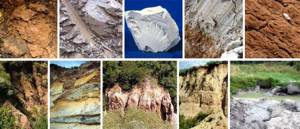

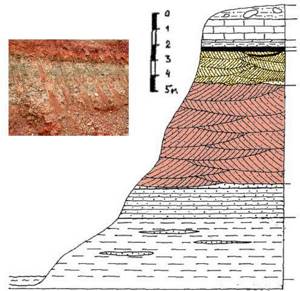

Clay deposits of various types

Clay has several fossil twins that are often confused with it. However, furnace work with other mineral materials is impossible, so it is important to be able to distinguish them from what we need.

Shale and marl. The material is a brittle rocky rock. It lies in horizontally arranged layers that are visible to the eye and have rounded edges. In addition, if you take a sample of shale and break it, the shale structure will be clearly visible on the resulting section.

Appearance of shale

The greatest difficulty in identification is caused by bentonite, also known as bentonite clay ( bentoclay ). This is a valuable mineral resource, but it is completely unsuitable for use in the furnace business. Sometimes bentonite is found in bright colors, virtually identical in appearance to the clay we need.

Bentonite clay, consisting of sodium-calcium compounds, montmorillonite and other impurities, has found its use in pharmacology, medicine, perfume production, winemaking and even in mining. The uniqueness of this mineral compound lies in its ability to absorb moisture. Bentonite saturated with water can increase in volume by one and a half dozen times without consequences, turning into a gel-like state. But, unfortunately, it does not have the properties of ordinary clay, such as fire resistance, gas tightness and heat resistance. It is quite simple to distinguish benthoclay from the building material we need. It is enough to take a small test sample and place it in a glass filled with water. After a short period of time, bentonite will absorb moisture and noticeably increase in size. After waiting a sufficient period, you will be able to witness the transformation of the sample into a bentonite gel, which looks like a jelly, somewhat similar to jellied meat. Clay in water will not turn into anything like that.

Appearance of bentonite clay

In the figure below you can see a schematic cross-section of the soil structure characteristic of our country. Clay located in the upper layers of the earth is highly contaminated with organic impurities. On top, the main layer of clay deposits is covered with so-called loam - a layer of soil with a significant admixture of alumina and sand. In the diagram, loam is indicated in yellow. Actually, the main layer of clay has uneven fat content: at the top it is minimal and grows as it goes deeper into the soil.

Layout of clay layers

We will determine the fat content of clay using a special test. Raw materials for analysis must be collected after passing through a layer of loam. In this situation - starting from five meters from the surface of the earth.

The clay test itself is very simple: we pick up a lump of material the size of half a fist. We wet our hands with water and begin to knead it like plasticine, gradually giving the sample the shape of a ball.

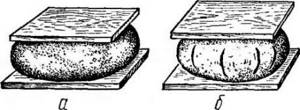

Test ball rolled from clay

After the ball is ready, we begin to slowly press it with two flat boards on both sides exactly until the first cracks form. If you managed to compress the ball by at least a third of its diameter, then such clay is quite suitable for our tasks. We take about five more kilograms of material in a bucket and take it home for further tests, which we will talk about later.

Testing a clay sample using boards

How to find high-quality water used in mortars for masonry stoves

It is necessary first of all to check the quality indicators of the water that we plan to use to create the stove solution. Only so-called “soft” water, or at least water with medium hardness, is suitable for work. Hardness is measured in units called German degrees. One such degree means that each liter of water being tested contains 20 milligrams of calcium and magnesium salts. Kneading the stove solution can only be done if the water hardness is below ten degrees.

| An experiment that allows you to determine water parameters will require purchasing about 0.2 liters of distilled water from a pharmacy. We also take a piece of laundry soap and crumble it into small pieces. It will be our indicator, since soap neutralizes salts dissolved in water. One gram of standard 72% soap neutralizes about 7.2 milligrams of hardness salts. Until the process of completely softening the water is complete, the soap solution will not foam. This is what will show us how “hard” the water is. | |

| Heat the water and add soap crumbs to it | Heat distilled water to about 75 degrees and carefully dissolve the soap in it. This operation should be performed carefully, avoiding foaming of the mixture. The proportions in which our “indicator” must be added will be as follows:

|

| Draw a soap solution into the syringe | As a result, after everything has cooled, we will get the so-called “titration mixture”. We take about 500 milligrams of the test water using a beaker, and 20 milliliters of the resulting soap solution with a syringe (without a needle). |

| Water with soap dissolved in it | Add the solution drop by drop to the water being tested, stirring it carefully as you do so. First, the soap, interacting with calcium and magnesium salts, will begin to precipitate in the form of characteristic gray flakes. We continue the process until foam with rainbow-colored soap bubbles begins to form. When bubbles appear, we stop adding soap dissolved in the distillate and see how much solution we needed to completely neutralize all the salts. Next, we perform simple calculations and find out the hardness of the water. |

| Example of calculations. | |

| Let's say we used pure 100% soap, 10 milliliters of which contains one gram of soap. This amount of soap in 500 milliliters of tested water should have precipitated 10 milligrams of Mg and Ca salts. This means that one liter of water contains 20 mg of hardness salts, which corresponds to one German degree. And if we spent 80 milliliters of soap titration solution, then the water hardness is 8 degrees and it is also suitable for stove masonry. The main thing is not to cross the hardness limit of 10-11 units. | |

What sand is suitable for laying a stove? Sand preparation

As for sand, there is no need to take samples. Near clay deposits you can always find layers of white quartz sand and yellow sand containing feldspar. The first is suitable for creating any stove structures, and the second can be used in the laying of all elements except the hottest part - the firebox. Remember that preparing sand for use will require a significant amount of water. That is why you should take care in advance to resolve issues regarding uninterrupted water supply.

Sand dug up on your own must first be passed through a sieve with a mesh size of 1-1.5 millimeters. This allows you to get rid of various large debris and obtain the necessary set of fractions. The biggest problem for self-dug sand is organic impurities and various living microorganisms living in it. The sand must be cleaned from them, otherwise the masonry seams may deteriorate over time.

Sifting sand with a sieve

There are many industrial methods for cleaning sand, but they all involve significant energy costs. In order to save money, we will use a simple and accessible washing method for everyone.

To make a cleaning apparatus, we need a piece of pipe 15-20 centimeters in diameter. Its height should be approximately three times its thickness. We fill a third of the volume with sand and supply water from below under high pressure. The power of the water jet must be selected in such a way that the washed sand swirls, but does not flow into the drain located on top. After clean water flows into the drain, wait about ten minutes more and finish the procedure. The first batch of purified sand is ready. All that remains is to dry it.

Scheme of a sand washing apparatus

The method of filtering sand by washing also allows us to remove from it various inclusions of alumina that we do not need.

Proportions of mortar for laying a stove, how much sand, water and clay should there be?

An important step in preparing a construction kiln mortar is to determine the optimal proportion between sand and clay. After we bring home the clay sample selected according to the algorithm outlined above, it is necessary to divide it in two. We set aside the first half, and divide the second again into five identical pieces. We place each of them inside a separate bowl and add water (hardness up to 11 German degrees), about a quarter of the volume of the clay itself.

Next, we leave the clay to liquefy in the water. Typically, this process takes approximately 24 hours. After a day, stir it thoroughly and pass it through a sieve with a mesh size of three millimeters to sift out large lumps.

Clay dissolving in water

Place the container with the strained solution back to settle. When a cloudy slurry (the so-called “sludge”) appears on the surface of the solution after settling, remove it by pouring it onto the ground.

That's it, now you can start adding sand to each container with prepared clay. This must be done in the following proportions:

- First container - do not add sand;

- The second is one part sand to four parts clay;

- Third - two parts sand to four parts clay;

- Fourth – 3 parts sand and four parts clay;

- Fifth - sand and clay are added in equal quantities.

Adding sand to each container must be done gradually, in small portions, in several approaches (optimally - no less than three and no more than seven). Everything needs to be mixed very thoroughly. Do not rush to add the next portion of sand before the previous one has completely and evenly dissolved in the mixture. A well-mixed clay-sand solution is quite easy to identify: just try rubbing it between your fingers. If the roughness of individual grains of sand is not felt, then everything is done correctly.

Add sand to the clay

The next step in preparing the clay-sand mortar will be the production of prototypes. We take clay in each of the five containers and alternately do:

- Two bundles of approximately 35 centimeters in length and a centimeter and a half in diameter;

- We fashion a ball with a diameter of five centimeters;

- A round clay cake with a thickness of 12-15 millimeters and a radius of 7.5-8.5 centimeters.

As a result, we will have exactly 20 samples on hand that need to be marked and left to dry inside the building. For normal drying, samples should not be exposed to drafts or direct sunlight. Usually the ropes dry out in a couple of days, but cakes and balls can take up to two dozen days. If the ball does not wrinkle and the cake no longer bends in half, it means the material has completely dried.

Clay ball and cake

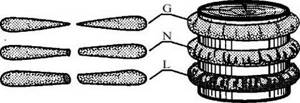

When the samples are ready for testing, we proceed to the next classic experiment, which allows us to determine the fat content of the clay solution. To do this, wrap a clay rope around the handle of the shovel, then tear it apart and observe the results:

- The greasy clay, indicated in Figure G (from the German “greesy” - greasy) will practically not crack, and when the rope is torn in half, the break point will have teardrop-shaped ends.

- Clay of normal fat content (marked as N) will have a cracked top dried layer and, after breaking the rope, its thickness at the point of separation will be approximately a fifth of its original thickness. These are the samples we need to select.

- Dry (lean) clay, designated as L (from the German “Lean” - lean), will be marked by the maximum number of deep cracks and, when broken, will have the largest area where the pieces of the rope separate.

As a rule, after selection, several (usually 2 or 3) seemingly suitable samples remain.

Determination of clay fat content

Dried balls and cakes will help us carry out the final “clay casting”. We drop samples from a height of a meter above the bare floor. The most durable of them will indicate the required consistency of sand and clay. If, after falling from a meter, all samples remain intact, we begin to gradually increase the height until we can determine the strongest of them.

Checking a clay-sand mortar using a flat cake as an example

Checking the quality of a clay-sand mortar using a ball as an example

The next step in preparing the mortar for laying the stove will be to calculate the required ratio of water to the proportion of sand in the mixture. The physical limits within which a clay mixture will have normal fat content are quite wide. Our main task, since we are building the stove for ourselves, is to make the strongest possible structure, with excellent gas tightness of the connecting seam material.

First of all, we sift the clay remaining during the test sampling. Press the clay through a fine mesh sieve so that it mixes evenly with the sand. Add the required amount of prepared washed sand. We learned the proportions of sand and clay earlier thanks to experiments. We start adding water and gradually mix the solution. Remember that the water must meet the hardness parameters that we talked about earlier.

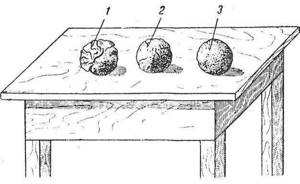

Next, we take a trowel in our hands and make a depression on the surface of the mixed solution.

The mark from the trowel (trowel) will help determine the readiness of the solution

- A tearing hollow indicates that there is not enough water (Fig. 1)

- If the hollow immediately behind the trowel begins to float, it means you have overdone it with water (Fig. 2). Let the solution settle and remove the sludge into a separate bowl. The difference in volume between the filled water and the squeezed out sludge will show us the required optimal proportion.

- If you immediately guessed the required amount of water, the trowel will leave a clear, clearly visible, even trace with highlighted edges on the surface of the mixed solution (Fig. 3).

Proportions and proper preparation of clay mortar, testing for strength

The so-called cross test will allow you to find out whether our clay solution will be sufficiently strong and have the required degree of adhesiveness. This final test will show how accurate the results of all our preparatory checks on the material were and how well we cleaned the constituent components of the oven mixture.

To test, we need a couple of bricks, one of which we place flat on the ground and cover its largest plane (the so-called “bed”) with a thin layer of prepared test clay mortar. Place a second brick on top and, tapping it with a trowel, let the mixture dry for about ten minutes . After this, we grab the brick located on top with our fingers and pull it up. Having raised it to a certain height, we shake the structure by weight: if the bottom brick does not come off, it means that all the preparatory work was carried out carefully and we correctly calculated all the proportions of the clay mortar.

If you still do not understand the individual details of preparing mortar for laying a stove, we recommend that you watch this video:

Proper preparation of mortar for laying a stove: video tutorial

How to make fireclay?

You can often hear that fireclay is cracked, plaster is crumbling, and so on. The reason may be material that was stored in unsuitable conditions, the expiration date has expired, or (the most common option) an incorrectly mixed composition. So how to properly make a mortar for laying brick and plaster?

Fireclay mortar for bricklaying

In this case, the first material you come across will not work. The fact is that the quality of fireclay powder depends on its fraction and production method. Like cement, fireclay clay has its own brands. If you see the letter “U” on the bag, this means that defective kaolin brick was used in production. It is cheaper, but it is not worth using it for important work.

Most often, the following types of solution are used:

- A solution of 1 part kaolin and 2 parts fireclay sand (fraction up to 0.5 mm).

- A solution of 1 part kaolin and blue clay, 4 parts fireclay sand.

Higher strength of the solution can be achieved by adding Portland cement to the composition. It should be understood that this will reduce the fireproof qualities of fireclay.

To dilute clay for laying a stove, you need:

- Select a container of the required size (the solution should be mixed without splashing out).

- Pour out the required composition (choose from those described above) and fill with water.

- Mix the solution so that there are no lumps in it. It should be thick.

- Leave it for three days.

- Add water; the consistency should resemble sour cream. If the solution turns out to be too liquid, add powder.

If the mass is thick, without lumps, it can be used. Don't rush to add water a second time; if you don't let the solution sit long enough, the clay will crack.

There are compositions for instant mixing that do not need to be kept for three days, but they are much more expensive. In addition, PVA glue is added to the solution and reinforced with fiberglass.

A special refractory brick is placed on such a solution; it is not used for laying ordinary red bricks due to the difference in the coefficients of thermal expansion.

Chamotte mortar for putty

In this case, the mixture is prepared with the following composition:

- Portland cement – 1 part;

- fireclay clay - 2 parts;

- quarry sand - 7 parts.

You need to mix the solution in the same way as for masonry.

To strengthen chamotte plaster, a special metal mesh is used.

Plaster on metal mesh

Supplements

To enhance any properties of the solution, the following components are added to the composition:

- PVA glue;

- table salt;

- liquid glass.

Table salt is added in an amount of about 100 grams per bucket of solution, and glass - up to 3% of the total mass of the mixture. Additives are an excellent way to improve the characteristics of fireclay.

Fireclay clay is a safe material, but you should not allow it to come into contact with your face or eyes. Also, if you are mixing the solution indoors, ensure proper ventilation.

Heat-resistant mixture for masonry stoves

To give greater strength, concrete is also added to the material. In terms of its performance properties, such a solution will not be inferior to lime. Hardening of the concrete mass begins after 45 minutes. Before mixing the components, they are passed through a sieve. Then sand is poured into the prepared container, and cement is poured on top of it. This mass is mixed until a homogeneous composition is obtained. Then water is added. When mixing, it is necessary to achieve a viscous consistency. The solution should not be too thin or thick. To construct a monolithic firebox, components are used in the following ratio:

- 1 part Portland cement (M400);

- sand – 2 parts;

- brick crushed stone - 2 parts;

- fireclay sand - 0.3 parts.

Composition of fireclay refractory

In stores, fireclay is sold as a dry mixture in bags. It is produced from raw materials with a high content of highly dispersed hydroaluminosilicates. In addition to these components, refractory clay contains:

- Na sodium;

- Ca calcium oxides;

- K potassium;

- Fe iron;

- Mg magnesium;

- aluminum oxides and other components depending on the type of raw material.

When purchasing, you need to pay attention not only to the composition, but also to the expiration date. Kaolin, which is part of the building material, loses its properties over time.

Expired goods cannot be used.

The composition and instructions for use are printed on the packaging

When choosing a material for a specific job, you need to pay attention to its technical characteristics:

- grain sizes;

- firing temperature: at lower rates, fireclay absorbs up to 25% of moisture, at higher rates – up to 10%;

- humidity indicators, high-quality refractory should not contain more than 5%;

- temperature limit of the building material, the maximum limit is 1850 degrees C.

Fireplace made of fireclay bricks and fireproof clay mortar

The basis is clay with highly dispersed aluminum hydrosilicates. This material can be given any shape, for example, to make briquettes. The firing time and temperature can be different. After this, crushing is carried out and a granular structure is given. The main components of fireclay clay are:

- calcium oxide;

- quartz;

- compounds of potassium and magnesium.

It also includes sodium and iron in the form of oxides.

Sometimes you can hear that the plaster has begun to crumble and is covered with cracks. Most often, this phenomenon occurs if the material was kept in the wrong place or its expiration date has expired. Another possible scenario is improper preparation of the composition. The first material you come across is not suitable for this.

It is important to store the dry fireclay clay mixture in a dry place

To make a solution of fireclay clay for laying out a stove with your own hands, you need to follow certain instructions and use the main components in certain proportions.

Fireclay powder has the properties that it acquired depending on the production method. The fraction of the material also matters. Fireclay clay has its own special marking. If the letter “U” is indicated on the packaging, this indicates the use of defective kaolin in production. It is cheaper, but you should not use it in important work. Options for diluting fireclay clay:

- 2 parts of fireclay sand with a fraction of no more than 0.5 mm to 1 part of kaolin;

- 4 parts fireclay sand to 1 part kaolin and the same amount of blue clay.

For the durability of the treated surface, the solution with clay must be mixed correctly

To dilute the composition for laying the furnace, you need to take a container of suitable volume so that the solution does not splash out. It is also permissible to use any solution option from the above. It must be stirred so that there are no solid inclusions left in it. The mixture should be thick. Leave it for 3 days, add water so that the resulting solution looks like sour cream. If it becomes too liquid, add powder. If, on the contrary, the mass is thick, there are no lumps in it, it can be considered ideal.

It is important to keep the solution and not rush to add water to it. Patience is key here, otherwise the clay will crack.

There are special compositions for quick mixing. They are convenient because you don’t have to wait for several days. True, they cost more. PVA glue is added to this mixture. Fiberglass is used for reinforcement.

Related Posts

- Mortar for laying a stove: varieties, composition, mixing methods

- How to plaster a stove to prevent it from cracking: types of putty for stoves and execution technology

- Types and sizes of Russian stoves: types, sizes, 5 construction recommendations

- Clay mortar for stoves: preparing a mixture for masonry and plaster

- Homemade Russian stove on the street under a canopy

- Secrets of stove makers: brick stove for a bath

- Bricklaying in winter

- 9 types of heat-resistant tiles for fireplaces and stoves: choosing the best

- Fast and correct furnace repair

- How to operate a plastering machine correctly

- Instructions for using fireclay clay

- How to dilute alabaster

- How to cover an iron stove in a bathhouse with bricks with your own hands?

- Volumetric weights of materials

- Adding liquid glass to concrete. 2021 instructions

- Step-by-step technology for pouring self-leveling floors

- Wood-burning stoves and their variety of designs

- Brick laying mortar

- How to make a long-burning stove yourself

- Types of stoves for the home: classification and review of equipment from the best manufacturers

- How to fold a Swedish oven with a stove

- Adhesive foam for aerated concrete blocks

- The best way to glue plaster figures, means and rules for do-it-yourself restoration

- Not afraid of temperature or moisture, holds tightly

- Types of Kuznetsov furnaces and their order

Read with this

- Mortar for laying a stove: varieties, composition, mixing methods

- How to plaster a stove to prevent it from cracking: types of putty for stoves and execution technology

- Types and sizes of Russian stoves: types, sizes, 5 construction recommendations

- Clay mortar for stoves: preparing a mixture for masonry and plaster

- Homemade Russian stove on the street under a canopy

- Secrets of stove makers: brick stove for a bath

- Bricklaying in winter

- 9 types of heat-resistant tiles for fireplaces and stoves: choosing the best

- Fast and correct furnace repair

- How to operate a plastering machine correctly

Features and composition

For the construction of stove and fireplace structures, only refractory bricks or natural stone are used. The solidity of the structure can be ensured by the use of a special mixture for laying furnaces, which has heat resistance and increased strength. In addition, such mixtures are characterized by medium plasticity, the absence of toxins and unpleasant odors when heated. Their peculiarity is that they fill all the space between the elements without forming voids. This ensures the tightness of the stove - air that disturbs the draft does not enter it, and carbon dioxide and toxins released during the combustion process do not escape.

Such compositions can be purchased ready-made or mixed yourself. In the first case, we are talking about dry mixtures consisting of the necessary ingredients in the required volume. Before use, just fill them with water and mix with a mixer or a special attachment on a drill until a homogeneous consistency. Self-preparation of the solution involves purchasing the necessary ingredients and mixing them in the prescribed proportions. Homemade mixtures are often inferior in quality to ready-made ones, since it is not always possible to correctly calculate the required ratio of products or find the right ingredient.

When it comes to baking mixtures, professionals use terms such as fireproof, heat-resistant and heat-resistant. Despite the similarity, these concepts have different semantics, which should be understood before mixing the mixture.

Heat-resistant is a composition that can withstand high-temperature heating and at the same time maintain its load-bearing capacity. When cooled, such a mixture retains its chemical and structural characteristics and does not deform. The heat-resistant version differs in mechanical and physical characteristics. But in short, it can withstand higher temperatures and can also be used as part of mechanisms.

Fireproof is a heat-resistant or heat-resistant composition that can withstand, in addition to high temperatures, the effects of aggressive components contained in flue gases without loss of strength.

Clay acts as a binder in mortar. Its main property is plasticity, determined by such an indicator as the plasticity number or fat content. This is a changeable parameter. The composition of the mixture depends on what material is used.

- The fat content of a clay mixture can be assessed without special measuring instruments. A handful of the composition is moistened and kneaded. If the material acquires the consistency and elasticity of plasticine, the clay is fatty. If the lump crumbles, it’s skinny.

- A more accurate method is this: add 100–150 ml of water to 500 ml of clay, stir until smooth so that the material does not stick to the skin. Roll the mixture into 2 balls 50 mm in size and one is flattened into a flat cake. The samples are left to air dry for 2–3 days.

If cracks appear on the test lumps after drying, the clay is oily, it is mixed with a large amount of sand. If a ball thrown from a height of 1 m breaks into pieces, it is too skinny. It is mixed with fattier varieties.

The type that is optimal for oven work is the one the lump of which does not break when falling on the floor.

The proportions of the oven mixture are determined by the plasticity number: for 1 part of clay take from 2 to 5 parts of sand. Depending on the fat content of the material, the masonry solution is prepared as follows: add 2 to 5 parts of clean river sand to 1 part of clay.

A different composition is made for the combustion chamber. To 1 part of refractory clay add 1 part of ordinary red clay and 4 parts of fireclay sand. Fireclay is not a natural material. It is obtained by crushing fireclay bricks. It can be replaced with ordinary river sand, but this option is less reliable and can withstand smaller temperature changes. Find out about lime mortar for bricklaying here.