The temperature during a fire in a building is the most important indicator. On the basis of it, fire-fighting actions, preventive measures and tactical actions of fire departments, as well as voluntary squads, are determined. The temperature of the fire indoors is especially important. This parameter depends on:

- the speed of movement of hot gas flows from zone to zone inside the building;

- the intensity of heat transfer from the source of fire to adjacent rooms, rooms and the environment;

- the likelihood of conditions arising under which an explosion is possible.

All three positions pose extreme hazards that can affect people during the firefighting process.

It must be noted that the temperature inside a burning building is not uniform. It is clear that the closer to the source of fire, the hotter it is. The same applies to areas located under the ceiling. Simple laws of physics play a role here, where heated air rises to the upper supporting structures. But to accurately determine the combustion temperature during a fire, take the average value. At the same time, the temperature indicator of heating of the building structures and the materials from which it is constructed is also taken into account. Eg:

- temperature of the surfaces of boundary structures (walls, floors, ceilings and others) located in the fire zone;

- the same thing, only on surfaces located on the opposite side of the fire.

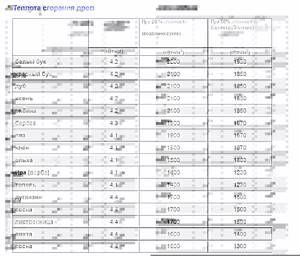

Temperature threshold for combustion of wood of various species

Depending on the structure and density of wood, as well as the amount and characteristics of resins, the combustion temperature of firewood, its calorific value, and the properties of the flame depend.

If the wood is porous, it will burn very brightly and intensely, but it will not produce high combustion temperatures - the maximum value is 500 ℃. But denser wood, such as hornbeam, ash or beech, burns at a temperature of about 1000 ℃. The combustion temperature of birch (about 800 ℃), as well as oak and larch (900 ℃) is slightly lower. If we are talking about species such as spruce and pine, then they light up at approximately 620-630 ℃.

Burning aspen wood.

Aspen loves moisture. It grows on river banks, near swamps. Aspen begins to rot very early. You will not find a tree that is not rotten and is more than 15 years old. Mature trees rot from the inside. There appears emptiness and rot in the trees, where birds and insects like to move in. If you choose this tree to harvest for the winter, be careful, you may be stung by a wasp or bee.

Aspen is a very delicate tree. Knots are fragile and break easily. This wood is only good for crucifixion; it is of little use for a main fire. This wood produces little heat and breaks into burning coals, which creates an unpleasant atmosphere. May burn clothes, tents, etc.

Use of wood based on its heat capacity

When choosing a type of firewood, it is worth considering the ratio of cost and heat capacity of a particular wood. As practice shows, the best option can be considered birch firewood, which has the best balance of these indicators. If you purchase more expensive firewood, the costs will be less effective.

To heat a house with a solid fuel boiler, it is not recommended to use types of wood such as spruce, pine or fir. The fact is that in this case, the combustion temperature of the wood in the boiler will not be high enough, and a lot of soot will accumulate on the chimneys.

Firewood made from alder, aspen, linden and poplar also has low thermal efficiency due to its porous structure. In addition, sometimes during the burning process alder and some other types of firewood shoot out coals. In the case of an open furnace, such micro-explosions can lead to fires.

It is worth noting that no matter what the wood is, if it is damp, it burns worse than dry wood and does not burn completely, leaving a lot of ash.

Burning aspen wood.

Aspen loves moisture.

It grows on river banks, near swamps. Aspen begins to rot very early. You will not find a tree that is not rotten and is more than 15 years old. Mature trees rot from the inside. There appears emptiness and rot in the trees, where birds and insects like to move in. If you choose this tree to harvest for the winter, be careful, you may be stung by a wasp or bee. We suggest you read: How to build a bathhouse with a place to relax

Aspen is a very delicate tree. Knots are fragile and break easily. This wood is only good for crucifixion; it is of little use for a main fire. This wood produces little heat and breaks into burning coals, which creates an unpleasant atmosphere. May burn clothes, tents, etc.

Heat transfer when burning wood in a stove

There is a direct relationship between the combustion temperature of wood in a stove and heat transfer - the hotter the flame, the more heat it releases into the room. The amount of thermal energy generated is influenced by various characteristics of the tree. Calculated values can be found in reference literature.

It is worth noting that all standard indicators were calculated under ideal conditions:

- the wood is well dried;

- the furnace firebox is closed;

- oxygen is supplied in clearly dosed portions to support the combustion process.

Naturally, it is impossible to create such conditions in a home oven, so less heat will be released than calculations show. Therefore, the standards will be useful only for determining the general dynamics and comparing characteristics.

Briefly about the main thing

To summarize, in order to achieve maximum heat transfer from burned wood, you need to:

- Select wood with the highest density.

- Prepare firewood in advance by sawing trunks and cutting logs.

- Reduce the moisture content of wood by storing it in piles under cover for at least one year.

- When burning in a furnace, provide the required amount of oxygen to the fire, trying not to exceed the required threshold.

Compliance with all specified conditions will guarantee that the combustion temperature of the wood will reach its maximum value, but will not disappear in the chimney. With a reasonable approach, all heat transfer will remain in the living space and optimally heat it.

Read later

What is the combustion process

An isothermal reaction in which a certain amount of thermal energy is released is called combustion. This reaction goes through several successive stages.

In the first stage, the wood is heated by an external fire source to the ignition point. As it heats up to 120-150 ℃, the wood turns into coal, which is capable of self-ignition. Once the temperature reaches 250-350 ℃, flammable gases begin to be released - this process is called pyrolysis. At the same time, smoldering of the top layer of wood occurs, which is accompanied by white or brown smoke - these are mixed pyrolysis gases with water vapor.

At the second stage, as a result of heating, the pyrolysis gases ignite with a light yellow flame. It gradually spreads over the entire area of the wood, continuing to heat the wood.

The next stage is characterized by ignition of the wood. As a rule, for this it should warm up to 450-620 ℃. For wood to ignite, you need an external heat source that is intense enough to rapidly heat the wood and speed up the reaction.

In addition, the rate of firewood ignition is influenced by factors such as:

- craving;

- wood moisture;

- cross-section and shape of firewood, as well as their quantity in one stack;

- wood structure - loose firewood ignites faster than dense wood;

- placement of the tree relative to the air flow - horizontally or vertically.

Let's clarify some points. Since wet wood, when burning, first evaporates excess liquid, it ignites and burns much worse than dry wood. Shape also matters—ribbed and jagged logs ignite more easily and quickly than smooth, round ones.

The draft in the chimney must be sufficient to ensure the flow of oxygen and dissipate thermal energy inside the firebox to all objects located in it, but not to blow out the fire.

The fourth stage of the thermochemical reaction is a stable combustion process, which, after the outbreak of pyrolysis gases, covers all the fuel in the furnace. Combustion goes through two phases - smoldering and burning with flame.

During the smoldering process, the coal formed as a result of pyrolysis burns, while gases are released rather slowly and cannot ignite due to their low concentration. The condensation of gases as they cool produces white smoke. As wood smolders, fresh oxygen gradually penetrates, causing the reaction to further spread to the rest of the fuel. The flame occurs as a result of the combustion of pyrolysis gases, which move vertically towards the outlet.

As long as the required temperature is maintained inside the furnace, oxygen is supplied and there is unburnt fuel, the combustion process continues.

If such conditions are not maintained, then the thermochemical reaction enters the final stage - decay.

Combustion formulas

Ignition temperatures of different types of fuel (click to enlarge)

When fuel (wood, coal) ignites, a chemical reaction occurs and heat is released.

Carbon dioxide reacts with the carbon in the fuel in the upper layers to form carbon monoxide.

The combustion process does not end there, because rising up in the combustion space, carbon monoxide reacts with oxygen from the air, the influx of which occurs through the vent or the open firebox door.

Its combustion is accompanied by a blue flame and the release of heat. The resulting carbon monoxide (carbon dioxide) enters the chimney and escapes through the pipe.

Good to know: when the blue flames disappear above the fuel, then you can close the chimney damper so that the heat does not escape through the pipe to the street.

Smoldering with minimal oxygen will produce non-poisonous carbon monoxide, producing even heat.

How to determine the combustion temperature in a wood-burning stove

Measuring the combustion temperature of wood in a fireplace can only be done with a pyrometer - no other measuring instruments are suitable for this.

If you do not have such a device, you can visually determine approximate indicators based on the color of the flame. Thus, a low temperature flame has a dark red color. A yellow light indicates that the temperature obtained by increasing the draft is too high, but in this case more heat is immediately evaporated through the chimney. For a stove or fireplace, the most suitable combustion temperature will be one at which the color of the flame will be yellow, such as, for example, dry birch firewood.

Modern stoves and solid fuel boilers, as well as closed fireplaces, are equipped with an air supply control system to adjust heat transfer and combustion intensity.

Open option

When choosing which type of firewood is best for burning a fireplace, you should consider wood from both deciduous and coniferous trees, since each variety has its own strengths and weaknesses. Taking into account the characteristics of wood, you can choose suitable options for both open and closed fireplaces and stoves.

In particular, for fireplaces with an open firebox, you should select wood with a long burning time, a pleasant smell and a smooth fire without sparks or flares. You should not choose pine, spruce, larch or other coniferous firewood for a fireplace of this type, since when this type of wood burns, a lot of smoke, sparks, and crackling appear, and the fire quickly burns the wood placed in the firebox. Despite all its shortcomings, pine needles have a wonderful smell that fits perfectly into the atmosphere of the bathhouse.

Beautifully designed home fireplace

Strong and harsh oak. The optimal solution for an open fireplace is oak wood. This type of wood, when burned, releases a large amount of heat, which will allow you to heat the room well. The duration of combustion of logs in the firebox is long, which allows you to take your time adding new firewood and save raw materials. At the same time, a pleasant and healing aroma floats in the air, appearing during the combustion of essential oils contained in oak firewood.

The main disadvantage of oak wood is its cost and scarcity. Finding such firewood is often quite problematic, and their cost is high. But when answering the question, what is the best way to burn an open fireplace, oak wood is always first on the list.

Royal alder. In addition to oak wood, you can use alder to burn a fireplace. Alder has long been considered firewood for the nobility; it was used to light the stoves in royal baths. The distinctive features of alder are: a small amount of smoke during combustion, a pleasant aroma and a sufficient level of heat transfer. You can also use alder firewood in an open fireplace in your home because it looks quite colorful, because... The wood of this tree has an orange tint. By the way, in the woodshed they can be easily distinguished from other types of wood by this color.

Harvesting firewood from alder

Native birch. The most popular domestic firewood is birch, which can also be used in a fireplace with an open firebox. Birch firewood smells amazing when burned. It is believed that the smoke of burning birch wood has healing properties; it has a beneficial effect on the respiratory system and cures colds.

Since the good combustion of birch is due to the presence of resin in its composition, when fireplaces and stoves are constantly lit with such wood, soot will inevitably accumulate in the chimney. Therefore, if you regularly use birch firewood, do not be lazy to clean the chimney of soot in order to achieve a normal burning temperature of the wood in the firebox or stove.

Popular bundled birch firewood

When harvesting birch, separate and dry a certain amount of its bark, which will then be useful to you for lighting stoves and fireplaces.

Cleansing aspen. A good option, recommended by many experts, is aspen firewood. Aspen logs cannot be used as a heating option, since there is little heat from this wood. At the same time, they are capable of creating living, beautiful fire. But their main advantage is considered to be the release of steam during combustion, which allows the chimney to be cleared of soot.

By burning aspen in the firebox from time to time, you will greatly simplify the process of cleaning the chimney. Listen to your fireplace or stove when aspen is burning in the firebox, and you will hear soot falling from the chimney. Aspen is useful for a fireplace or stove, but you shouldn’t get hung up on it; it’s enough to light it a couple of times a month.

Such firewood is an excellent solution for open fireplaces, stoves in bathhouses, and barbecues. Note that to create a characteristic aroma, you can even use dried branches left after pruning trees.

Heat output of wood

In addition to the value of calorific value, that is, the amount of thermal energy released during fuel combustion, there is also the concept of heat output. This is the maximum temperature in a wood-burning stove that the flame can reach when the wood is burning intensely. This indicator also completely depends on the characteristics of the wood.

In particular, if the wood has a loose and porous structure, it burns at fairly low temperatures, producing a light, high flame, and produces fairly little heat. But dense wood, although it flares up much worse, even with a weak and low flame gives a high temperature and a large amount of thermal energy.

What kind of wood is best to heat the stove?

The choice of the optimal method for warming a room, cooking or lighting a fire is based on the properties of each type of wood. To achieve a better result, you can combine several types at the same time, while maintaining the sequence of actions and adding other types of wood.

For home heating

If the calculation is for a small room that requires constant heating, then the best choice would be to use fruit wood. If you don't have one, you can use pine needles. However, only for closed type boilers.

To clean the chimney from combustion products, you can burn alder or aspen. It is convenient to use them by throwing them into the oven at the end. In this case, it can be combined with birch or acacia logs, or dust.

Larch

For the bath

For bathing in baths and saunas, you need to choose firewood with stable heat, aroma and non-smoking. Conifers are not suitable for this. The best choice is linden or alder. Both varieties have a pleasant and, most importantly, healing scent, provide a sufficient amount of heat and burn for a long time. To further increase the burning time, you can add birch or aspen.

Alder has a pleasant aroma and burns well. You don’t need to set fire for a long time, so you can go to the bathhouse quickly.

It is convenient to use aspen. However, without combining with other types it will not be possible to properly warm up the room. In combination with birch, which gives a stable temperature, does not smoke, and emits an aroma when burning, you can get air with antiseptic properties and a clean chimney.

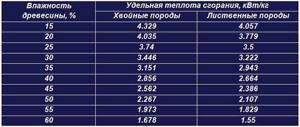

Humidity and combustion intensity

If the wood was recently cut down, it contains from 45 to 65% moisture, depending on the time of year and the species. Such damp wood will have a low combustion temperature in the fireplace, since a large amount of energy will be spent on evaporation of water. Consequently, heat transfer from damp wood will be quite low.

There are several ways to achieve optimal temperature in the fireplace and release enough heat energy to warm up:

- Burn twice as much fuel at a time to heat your home or cook food. This approach is fraught with significant material costs and increased accumulation of soot and condensate on the walls of the chimney and in the passages.

- Raw logs are sawn, split into small logs and placed under a shed to dry. As a rule, in 1-1.5 years, firewood loses up to 20% of moisture.

- Firewood can be purchased already well dried. Although they are somewhat more expensive, their heat transfer is much greater.

It is worth noting that the wood of raw felled poplar and some other species is completely unsuitable for use as fuel. It is loose, contains a lot of water, so when burning it produces very little heat.

At the same time, raw birch firewood has a fairly high calorific value. In addition, raw logs made from hornbeam, ash and other dense wood species are suitable for use.

Cons of wet firewood

Now let's try to figure out why wet firewood is bad.

The main disadvantage has already been mentioned above - they burn worse. Since part of the heat is spent on moisture evaporation, noticeably less energy is released. For example, consider birch wood - one of the most popular and widespread types of solid fuel in private homes.

Freshly cut wood has a moisture content of 50%. When one cubic meter is burned, 2371 kW of energy is released. If you dry the wood a little, reducing the humidity to 30%, you can significantly increase the amount of heat generated - up to 2579 kW from the same amount of firewood. Finally, fuel whose moisture content does not exceed 20% is considered well-dried. By burning a cubic meter of such birch wood, you can get 2716 kW of energy. That is, after good drying, the amount of energy received increases by 345 kW or about 15% - quite a good saving.

An additional disadvantage of wet firewood is the difficulty of ignition. Well-dried wood is very easy to set on fire - just put a piece of birch bark or paper under it and set it on fire. In a matter of seconds, the flame will spread across the surface of the firewood, which will soon begin to crackle merrily, warming the entire house or bathhouse.

Finally, high humidity leads to the formation of large amounts of soot. It clogs the chimney and gradually worsens the draft. Because of this, the fuel burns worse, and the risk of burning increases due to the accumulation of carbon monoxide in residential areas - it has no odor, so it is very dangerous.

How does draft in a stove affect combustion?

If an insufficient amount of oxygen enters the furnace firebox, the intensity and temperature of wood combustion decreases, and at the same time its heat transfer decreases. Some people prefer to cover the ash in the stove to extend the burning time of one bookmark, but as a result, the fuel burns with lower efficiency.

If wood is burned in an open fireplace, then oxygen freely enters the firebox. In this case, the draft depends mainly on the characteristics of the chimney.

Under ideal conditions, the formula for a thermochemical reaction looks something like this:

C+2H2+2O2=CO2+2H2O+Q (thermal energy).

This means that when oxygen is available, hydrogen and carbon are burned, resulting in thermal energy, water vapor and carbon dioxide.

For the maximum combustion temperature of dry fuel, about 130% of the oxygen required for combustion must enter the furnace. When the inlet dampers are closed, an excess of carbon monoxide is produced due to a lack of oxygen. Such unburnt carbon evaporates into the chimney, however, the combustion temperature inside the firebox drops and the heat transfer of the fuel is reduced.

Modern solid fuel boilers are often equipped with special heat accumulators. These devices accumulate an excessive amount of thermal energy released during fuel combustion under conditions of good traction and high efficiency. This way you can save fuel.

In the case of wood-burning stoves, there are not many opportunities to save wood, since they immediately release heat into the air. The stove itself is capable of retaining only a small amount of heat, but an iron stove is not capable of this at all - excess heat from it immediately goes into the chimney.

Thus, by increasing the draft in the furnace, it is possible to achieve an increase in the intensity of fuel combustion and its heat transfer. However, in this case, heat loss increases significantly. If you ensure slow combustion of wood in the stove, then its heat transfer will be less, and the amount of carbon monoxide will be greater.

Please note that the efficiency of the heat generator directly affects the efficiency of wood burning. Thus, a solid fuel boiler boasts 80% efficiency, and a stove – only 40%, and its design and material matter.

Fire in the house

Private houses burn frequently. The temperature regime of their combustion depends on the materials from which these buildings were erected. But the temperature during a house fire must be approached from the perspective of the type of fire. That is, the fire has an open or closed form of combustion.

In the first case, this is the most dangerous option. Fresh air supports combustion, so the combustion intensity of building materials is at the highest level. In such fires, metal melts as if it were wax. In closed fires, the access of oxygen to the fire zone is limited, which means the intensity of combustion is reduced. This makes it possible to study the fire situation more thoroughly.

But there is one negative aspect in closed fires. The heat generated indoors causes sudden convective flows of hot gases. This happens in cases where firefighters go inside a burning building, or one of the fire barriers has lost its tightness. A change in gas exchange occurs. This is the worst thing that can happen.

In this case, indoor humidity is taken into account. For example, in an area with dry filling (here we mean gases, smoke, etc.), a person can hold out for 10-15 minutes. This is at a temperature of +50-60C. If the humidity is increased, then one minute will be enough to lead to irreparable consequences.

A private house is on fire

How to choose the right one

It is immediately necessary to say that, although beech or ash is characterized by a high combustion temperature of firewood, using them for the combustion chamber of a stove or bathhouse is very costly and unprofitable.

This article will help you make a sauna stove yourself: https://teplo.guru/pechi/bannye/stroim-pech-dlya-bani.html

Because of this, birch firewood is used, which burns at 800-820 degrees. Also, oak and larch, flaming at 840-900 degrees, are suitable for these purposes.

The coniferous tree species - pine - is most suitable for a fire. However, no one prohibits its use for heating a stove. At a combustion temperature of 610-630 degrees, half as much firewood will be used as oak or birch.

- low combustion temperature;

- smoke and soot formation.

Because they contain a decent amount of resins. The latter settle on the walls of the chimney, clog it for some time and require cleaning. Due to this, the use of coniferous wood for these purposes is not best and is recommended only in extreme cases.

In addition, it is necessary to look at the moisture content of the firewood, because its percentage has a direct impact on the combustion process. Based on this, wet material will burn poorly and create a decent amount of smoke.

This article will help you find out which is better for heating wood or briquettes: https://teplo.guru/kotly/toplivnyie-briketyi-ili-drova.html

Consequences of heating wood

A process where an area of rock is exposed to an external heat source and fire appears. It could be paper set on fire with a match, or something else.

At a temperature of 120-150°C, the wood begins to char. Self-igniting coal is formed.

When the degrees reach 250-350°C, the material will begin to thermally decompose into its components. The surface of the tree will begin to smolder, but the flame cannot be seen. Brown smoke will appear. The breed has already warmed up and is ready to move into a new stage.

Ignition

The initial stage of the combustion process in which thermochemical reactions are accelerated. Activates at temperatures of 460 degrees and above.

Additional energy is required to evaporate water. Also, thermal conductivity slows down. A massive round tree burns worse. Rectangular with a small cross-section - good. An unplaned wood surface is more likely to ignite than a smooth one.

It is also important that there is enough oxygen supplied. Otherwise you will have to wait a long time for fire

Self-ignition

The process is possible without the influence of external sources. For example, a certain area of the rock is overheated. It starts to char. Charcoal reacts with oxygen. A flammable mixture appears above the surface.

High temperature ignites the formation. Smoldering charcoal appears on the fibers of the boards. To avoid spontaneous combustion, especially if the rock is located near fire sources, you need to remove uneven areas. Then the emergency will not happen.

Combustion products

In the process, gaseous particles and solid particles turn into smoke. Their composition depends on the type of wood. These are compounds of chemical elements with oxygen.

Combustion products are:

- carbon dioxide;

- water vapor;

- nitrogen;

- carbon monoxide;

- sulphur dioxide.

The listed products cannot burn in the future. Except for one exception. It is carbon monoxide. Particulate matter in smoke is soot. The composition of the products depends on the combustion conditions. It may or may not be complete.

If there is not enough air, acrid smoke appears. It is very dangerous for humans. Often inhaling it in large quantities is fatal.

How not to burn your kebab?

To reduce too high a temperature, distribute the coals evenly over the entire area. Additionally, you can also close the air holes. With a limited supply of oxygen, the intensity of the combustion process will decrease, and the temperature will decrease accordingly.

To increase the temperature, do exactly the opposite. Move the coals as tightly as possible and open the air holes. The temperature in the grill should be selected according to the type of meat. The highest temperature range is required for beef, slightly lower for pork. Chicken and fish are cooked at lower heat.

To maintain even heat during the cooking process, do not add a new batch of coal. Because it will not be possible to mix the coals evenly when the kebab is laid out. As a result, zones of uneven burning are formed, that is, in one place the meat will begin to char, and in another it remains raw.

Source of the article: https://villadacha.ru/barbecue/temperatura-v-mangale.html