Water hammer in a water supply system occurs when there is no pipe capacity as a result of its blockage with an air bubble or a solid object, which reduces the fluid permeability in a certain area. A working injection pump helps the fluid pressure increase to critical levels. As a result, depressurization of the pipeline occurs as a result of pipe rupture or separation of connecting elements.

Pipeline damage due to water hammer can have serious consequences:

- the need to repair the defective area;

- long-term drying of the room;

- replacement of wooden furniture;

- replacement of wood cladding materials, plasterboard partitions.

Water hammer in the circulation communication system is a concomitant phenomenon when starting a pump pumping liquid. Vibration, both during manual and automatic start of the injection pump, is transmitted to the pipes, which also causes depressurization of the life support systems of the house.

Approximately the same overloads are experienced by the walls of the sewer system when water begins to drain from a washing machine or dishwasher, and by the autonomous heating system during the next cycle of supplying liquid to the radiators. The difference lies in the force of pressure on the pipe walls during startup and during a constant supply cycle.

Water hammer - a problem or an inevitability?

There are two types of water hammer in a water supply system, in the direction of increasing or decreasing pressure. This can be compared to a person's blood pressure. When there is negative hydraulic pressure of the liquid on the walls of the pipes, there is no threat; at this moment, a decrease in water pressure is observed.

Things are much more serious when there is a significant increase in pressure in the water supply, caused by a blockage in one or several areas. The reason for this may be:

- sharply open plug, shut-off valve;

- air accumulated during system downtime;

- depressurization resulting from improper preservation of the system before interruption in its operation.

This problem can be determined by ear; the pipes begin to make frightening sounds. The characteristics and volume of sounds differ depending on the material from which the pipes are made.

The nature of hydraulic shock in pipelines

Water hammer is a shock wave that propagates along the surface of the water supply system, as well as through the elements of the fittings. When the pressure rises it is positive, when it falls it is negative. It appears when an empty water pipe is filled or the tap is suddenly closed. The destructive effect of this phenomenon is associated, first of all, with the inability of the liquid to compress.

If water could, for example, be compressed several times like a gas, then the pipes would not burst from a sharp increase in pressure . Excessive pressure occurs when the movement of fluid suddenly stops, but other phenomena in the water supply system can also cause water hammer.

How to hear and prevent a threat

Metal-plastic and polypropylene pipes have a soundproofing layer. Excessive pressure inside the system - the struggle of water with an airlock, in auditory perception is more reminiscent of the loud rumbling of a well-fed cat or irritated intestines. Metal and copper pipes amplify the sound, broadcasting it throughout the system. The farther from its source, the stronger and longer the grinding.

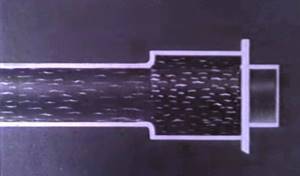

The best way to relieve stress from the inner surface of the walls of the pipeline can be considered an open tap if the cause of poor water permeability is an air lock formed during a sudden stop in the water supply. When the liquid comes out, it will be saturated with air bubbles.

Attention! The more shut-off valves in the system, the more reliable the protection. Blocking the passage of liquid to the damaged area, and not along the entire length of the pipeline, reduces the risk area for water hammer.

The nature of water hammer

First, let's figure out what water hammer is. It's simple: this is a sharp jump in water pressure in the pipes in one direction or another.

- When the pressure rises sharply when the pump is turned on or the tap is turned off, a positive hydraulic shock first occurs, since the water, by inertia, continues to flow at the same speed, but encounters a sudden obstacle in its path. In this case, in the area directly near the obstacle (for example, shut-off valves (see Valves for water supply: types, purpose, selection nuances)), excess pressure is formed on the walls of the pipe. The water has nowhere to go; it compresses poorly, so the walls of the pipe stretch.

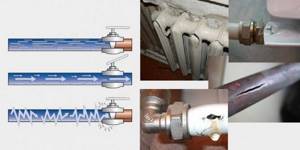

Pipe expansion due to water hammer

- When faced with an obstacle, the water stream is thrown back and collides with a wave that is still flowing towards it. Again, this puts pressure on the walls of the sealed pipeline.

- With a sharp outflow of water mass from the obstacle, an area of low pressure is formed next to it, in which the walls of the pipe are now compressed. This is negative water hammer.

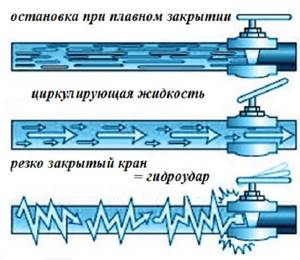

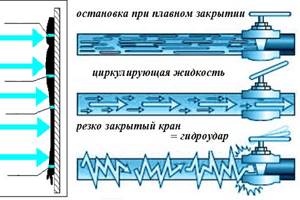

Flow movement under different conditions

The shock wave does not subside immediately; it rolls in and retreats several times with decreasing strength and amplitude. All this happens in a fraction of a second, during which the pipes alternately experience positive and negative loads.

There are other reasons that cause water hammer. These are air pockets in the pipeline, sharp turns or connections of pipes of different diameters, sudden pump starts. Any obstacle to the high-speed flow of liquid changes its volume and, as a result, pressure.

Vulnerability of pipes to water hammer

A faucet not opened in time or a pressure pump not turned off in an emergency is a prerequisite for water to find a hole and expand it. Each type of pipe has its own weak points.

- Seamless metal ones are more often damaged on bends; the steeper the angle, the greater the risk.

- Seams on rolled metal products are not designed to withstand pressures exceeding what is indicated on the markings.

- In metal-plastic water pipelines, risk zones are located at the joints with fittings - tees, shut-off valves and corner joints.

- Polypropylene ones are more stable due to their larger diameter and soldered corners, but the risk zones are the same as in metal-plastic water pipes.

Pipes with an internal diameter of less than 10 mm are most susceptible to damage due to water hammer.

The weak point of stainless steel welded systems is the edges of the joined elements that are exposed to plasma. The deterioration of the technical data of the metal is a more powerful argument for refusing to use stainless steel in the installation of an autonomous water supply system than the high cost of the material. Rainbow stains, classified by professionals as tarnished colors, do not always indicate overheating of the steel. Emitted oxides pose a great danger. In places where they are released, even stainless steel is subject to corrosion.

Basic preventive measures

In addition to strict compliance with all established operating rules, an accident can be prevented if a number of preventive actions are carried out promptly and regularly. The whole reason is that in the main heating or water supply system, absolutely all processes are closely interconnected. A water hammer unexpected by the user is just the final destructive stage, which may well lead to various negative consequences. All this happens against the background of the relatively poor technical condition of pipes that have been used for years.

Changes in pressure and resulting vibrations only contribute to the formation of various cracks in the thickness of the metal. Over time, more serious defects arise, which, after the onset of water hammer, immediately appear in areas of too high internal stress. These can be various bends, mechanical connections and even welds.

Preventive manipulations include the following steps:

- Timely check of the pressure behind the elastic membrane of the expansion vessel in use. If during this procedure the technician discovers unsatisfactory results, then it is prohibited to operate the system without quality adjustments.

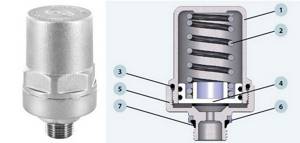

- Checking the functionality of the involved security groups. This applies to the air vent, safety valve, as well as the classic pressure gauge.

- Monitoring the position of the valves of the involved shut-off and control metal fittings.

- Periodically check the condition of all filters. These elements are responsible for retaining fine sand, classic scale, and rust fragments. If necessary, the technician will need to clean and then rinse the filters.

- Testing the system used for leaks. You also need to check the degree of wear of all elements.

Many experts recommend replacing the classic rigid pipe with a plastic product. It is more flexible in use and can expand quickly under pressure. But you need to be careful, as depressurization of the joints is possible.

A professional approach to prevention, which is aimed at overall maintaining the optimal condition of the heating and water heating system, necessarily includes basic types of work. It is not recommended to ignore this stage. This is due to the fact that heating repairs in a private house entail a large expenditure of finances and free time. All the described protective measures will be effective if you approach the work comprehensively. Only in such a situation can various undesirable consequences be neutralized and the life of the coordinated operation of the system extended.

Installing a high quality backwash filter

Possible reasons for the increase in hydraulic pressure and how to avoid it

Operation of an autonomous water supply system in non-stop mode is practically not carried out. The pump starts automatically when it is necessary to supply the next portion of water to the house. If there were no emergency situations before, then the overload will be short-term. Damage can only be caused by natural wear and tear of the pipeline.

If the previous shutdown of the pump was carried out in emergency mode, this may lead to the formation of a water barrier in the form of an air lock. The same thing happens when the shut-off valves are suddenly closed. When a master suggests installing a butterfly valve instead of a ball valve, there is a reason for this.

Old-style taps provide a real opportunity to smoothly turn off the water and also gradually open its access to the system when the pump is turned on again after maintenance or repair work. Perhaps this is the best protection for pipes from increased pressure on the walls.

If there is a long interruption in the operation of the water supply system, partly located outside the building, ice may appear in the pipes. This barrier is completely material and more dangerous than air. The melting of snow from the fields is not a criterion that the water located underground has completely melted.

When the air temperature drops significantly, it leads to freezing of water inside the pipes, even in existing autonomous water supply systems. Protection against water hammer in the water supply system, when starting up in severe frosts, lies in its maximum insulation. In areas with a temperate climate, the installation of insulated boxes that prevent freezing may be sufficient for protection. In areas where this measure may not be sufficient, an electric heating cable is used. It is laid along the entire length of the underground part of the water pipeline.

Causes

Most often, water hammer occurs when a shut-off valve is suddenly closed.

When water flows through the pipes and pours out of the tap, a constant pressure value is maintained in the water supply system, but at the moment of sudden shutoff of the fittings, this value can increase several times, as a result of which the pipe walls cannot withstand the pressure and burst. Water hammer can also be caused by:

- Abrupt switching on or off of a powerful pump.

- There are air pockets in the water supply or heating circuit.

Turning the pump on and off can be triggered by an unstable power supply to a facility where there are powerful pumping stations for pumping water. Air locks also play an important role in the occurrence of such a dangerous phenomenon, therefore, before operating closed systems with liquid, you should make sure that there is a complete absence of air in them.

Protecting the water supply from overloads inside the house

The main protection of a long section from damage inside the house was bellows-type expansion joints. This structural element, due to the stretching provided by the manufacturer, prevents deformation and rupture of pipes during water hammer. The peculiarity of expansion joints lies in the connecting function of the main parts of the pipeline and sealing the water supply system.

If it is possible to make a water supply system with fewer joints and tie-ins, then the craftsmen use a self-compensation method for the system. It consists of bending the pipe, which naturally dampens the pressure of the liquid pumped by the pump. The method of protection against water hammer in a water supply system, without the use of additional parts, works well on small pipeline sections. Where there are no large temperature differences, deformation from compression or tension of materials does not threaten the pipes.

For sections of pipes in contact with hot water, other hydraulic pressure compensators are used:

- U-shaped;

- lens;

- stuffing box

The selection of compensators and methods for damping water hammer is carried out at the design stage. But even during operation there is always the possibility of improving autonomous systems, water supply and heating. That most often this happens during the installation of additional plumbing points.

Methods of protection

Compliance with the rules for installing water supply and heating communications allows you to minimize the likelihood of such a dangerous phenomenon as water hammer, but it will not be possible to completely eliminate it only with properly designed systems.

To avoid such an unpleasant situation, an integrated approach and compliance with safety rules and technical instructions are required. You can significantly reduce the likelihood of water hammer if you follow the following rules when installing water pipelines and their operation.

- When putting the water supply or heating system into operation, the shut-off elements of the valves must open very slowly . Shutting off the liquid supply should also be done very smoothly. Smooth closing and opening of shut-off valves should be carried out not only at industrial facilities, but also when starting water supply and heating in a private home. Excessive pressure when water hammer occurs can easily damage home communications, so you should not neglect technical safety rules when water in a private home is supplied with significant pressure.

- If you install automatic devices for smooth opening and closing of shut-off valves in the plumbing or heating system, you can completely eliminate the human factor when a water hammer occurs. Of course, when using electronics, plumbing systems become dependent on electric current, but in order to completely eliminate the possibility of failure due to installed machines, it is necessary to equip such mechanisms with a backup source of electricity. Such insurance is absolutely necessary, both in a large enterprise and for the normal functioning of communications located in a private home. It is recommended to equip pumping stations with automatic adjustment. In this case, it is also possible to avoid water hammer from a sharp pressure drop as a result of turning on or off powerful pumping equipment.

- The use of hydraulic accumulators and damper devices also makes it possible to minimize the consequences of a sharp increase in pressure in the water supply network. Such devices usually consist of a metal housing with a membrane located inside. When a water hammer occurs, the membrane moves to accommodate excess liquid. When the threat of pipeline rupture passes and the pressure decreases, the membrane will be returned to its original position due to the air located on the reverse side.

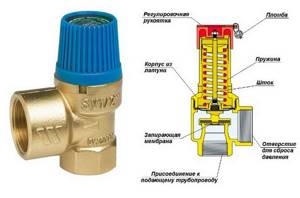

- To reduce pressure in water supply networks, a safety valve can be used, which opens when the liquid reaches a certain value. Such devices are also capable of protecting the pipeline from destruction, but to organize this type of protection, it will be necessary to make an additional branch from the valve to the sewer system

- To protect against water hammer in a private house or apartment, you can use a very simple method, in which excessive pressure is compensated by stretching the walls of the pipeline. It is not at all necessary to install heating or water supply using such materials, but a section of the pipeline made using heat-resistant rubber is capable of completely absorbing water hammer in a small system.

- Shunting the thermostat is an effective measure to combat low-power water hammer, therefore such an “improvement” of autonomous heating can only be done in a private heating system. As a rule, it is enough to make a hole with a diameter of 0.5 mm in the main valve, so that when high pressure occurs, excess liquid moves freely into the cold water circuit.

- A thermostat with protection installed in the heating system also avoids such a dangerous phenomenon as water hammer. The principle of operation of such a device is that in the main thermostat valve there is an additional small mechanism that opens regardless of the temperature of the liquid. Such an internal valve will begin to let liquid through when the coolant pressure approaches the maximum permissible value, thereby protecting the pipes from rupture.

One example of the occurrence of water hammer in an apartment water supply system

How to protect communications in an apartment from water hammer

Depressurization of the water supply in an apartment can lead to very serious consequences, especially if, as a result of a break, damage was caused to neighbors whose apartment is located on the floor below where the accident occurred.

Old metal pipes may be installed on the water supply section of the apartment, which rust over time and can be destroyed during operation, not to mention the deadly force of the water hammer.

IMPORTANT! To minimize the likelihood of a leak, it is recommended to install valve-type taps, which, due to their design features, are not able to instantly shut off the water. Lever ball valves, which are so convenient not only in the kitchen but also in the shower, can cause a serious accident.

Despite the fact that hydraulic accumulators are most often used in private houses, the water supply of which is carried out through a pump located in a deep well, such products will also help protect the water supply in the apartment from water hammer.

In addition, the accumulated liquid in such devices can be used in the event of a temporary shutdown of water supply. You can also protect your water supply from water hammer using special dampers that are installed in the cold or hot water supply pipe.

Unauthorized installation of any devices in the centralized heating system is strictly prohibited. To protect the living space from water hammer, you should allow a specialist from the management company to test run the heating.

If all air pockets are removed from radiators and pipelines in time, then there will be no fear of water hammer, due to the observance of all necessary measures to prevent such a phenomenon in the boiler room and along the path of coolant delivery to the apartment.

To reduce the risk of depressurization of hot water supply systems, it is also recommended to replace the taps with screw designs, and make the pipeline from modern materials that make it possible to cope with excess pressure in the pipeline as efficiently as possible.

A few words about the theory of water hammer

The occurrence of water hammer is possible only for the reason that the liquid is not compressed enough to compensate for the sharp increase in pressure. When pressure increases in one place, its force spreads to the entire section of the pipeline, and finding a “weak link” leads to deformation or destruction of the material.

This effect occurring in high-pressure pipelines was first discovered by the Russian scientist N. E. Zhukovsky at the end of the 19th century. Zhukovsky also derived a formula by which one can calculate the minimum time required to close the tap in order to avoid a dangerous increase in pressure in a closed water supply system.

Galileo. Experiment. Water hammer

This formula looks like this:

- Dp=p(u0-u1)

Where:

- Dp – pressure increase in N/m2;

- p – liquid density kg/m3.

- u0 and u1 are the average value of the liquid velocity in the pipeline before and after closing the tap.

The scientist proved that the speed of propagation of the shock wave depends primarily on the diameter and material of the pipe. This indicator also depends on the degree of compressibility of the liquid.

The calculation must be carried out only after the density of water has been experimentally established, which, depending on the amount of salts dissolved in it, can vary significantly. The speed of propagation of water hammer is always calculated using the following formula:

- c=2L/T.

Where:

- с – shock wave speed;

- L – pipeline length;

- T – time.

By substituting the values into this formula, you can accurately determine the speed of propagation of water hammer. Water hammer is a wave that oscillates at a certain frequency.

Calculating, if necessary, the number of oscillations per unit of time is also not difficult. It is enough to use the following formula:

- M = 2L/a

Where:

- M – duration of the oscillation cycle;

- L – pipeline length;

- a – wave speed (m/s).

To simplify the calculations, the shock wave velocity indicators during hydraulic shock for pipes made of the following materials will be given below:

- Steel – 900 – 1300 m/s;

- Cast iron – 1000 – 1200 m/s;

- Plastic – 300 – 500 m/s.

By substituting these values into the formula, you can accurately calculate the frequency of water hammer oscillations along a section of a water pipeline of a certain length.

This is the theory of water hammer in the briefest mathematical descriptions. When designing modern engineering systems, powerful computers are used to perform such calculations, so there is no need to resort to manual calculation of the speed and force of the water hammer.

The main protection is compliance with operating rules

It is not necessary to know what water hammer is in a water supply system, the main thing is to be able to prevent it:

- Before starting the water supply system for the first time, it is necessary to bleed the air.

- After the winter period, if the water supply well has not been used, it must be protected from rupture under the influence of ice. To do this, hot water is poured into the column to which the pump is connected.

- To avoid an air lock when connecting equipment after a long break, at a stable above-zero temperature, you can increase the level to operating condition with cold water.

- Before starting the pump, you need to check whether all shut-off valves are open.

- If the design of the electric motor allows you to regulate the supply mode, this should be taken advantage of by gradually increasing the pressure in the system.

Breakdowns in the water supply system are caused by water hammer, vibration, incorrect assembly of the pipeline, and incorrect calculations when selecting the diameter to the power of the equipment that ensures fluid circulation. Statistics show that 60% of damage is caused by systematic or one-time sudden surges in pressure in pipes.

Water hammer protection

Among other things, care should also be taken to install automatic protective devices. In particular, a circulation pump with smooth start-stop is suitable for a mansion. It will ensure a gradual build-up of pressure and a slow decrease. Parameters are adjusted by entering the required values into the electronic programmer.

If the pipes have been standing for a long time, then an important measure to prevent water hammer is to regularly carefully inspect them to identify leaks and damaged areas. It is recommended to replace metal communications with plastic ones with welded joints. Replacing faucets in your apartment will certainly help.

Almost all modern faucets have a ball lock mechanism. On the one hand, this is convenient because it allows you to turn off the water supply with one movement. On the other hand, as previously mentioned, they are not very good for the system as a whole, due to pressure surges that appear when using them

Replacing faucets in your apartment will certainly help. Almost all modern faucets have a ball lock mechanism. On the one hand, this is convenient because it allows you to turn off the water supply with one movement. On the other hand, as previously mentioned, they are not very good for the system as a whole, due to pressure surges that appear when they are used.

Valve designs (such as Soviet “carriages”) are completely free of this drawback. They are sold in almost every plumbing store and are often cheaper than ball ones.

In mansions, a compensator in the form of a special rubber jumper will save you from water hammer. When a shock is formed, it will simply stretch and absorb the destructive force. Thanks to the elasticity of the walls, the load surge itself does not cause any harm.

Bubbles on the pipe

A characteristic crackling sound in water pipes is a signal of a problem. The system has a prerequisite for depressurization. It is possible that the plastic had mechanical damage that was invisible until installation. The vibration created by the pump promotes its expansion. A slight increase in pressure in the pipeline is enough for the problem to become apparent.

The appearance of bubbles on multilayer cold water supply pipes directly indicates a weak link in the system. The area where the consequences of a pressure surge have appeared must be urgently replaced. The pocket created by water will certainly break through. It is much easier to replace a section of pipeline without waiting for a flood during which you will have to urgently close the valves in emergency mode, which can cause the next water hammer.

Bubbles on hot water pipes may not indicate damage at all if reinforced polymer pipes were used during installation. The structural features of the reinforced pipe are that the main part and the outer layer are separated by metal foil, fixed with two layers of needle glue.

When heated, materials exhibit different degrees of stretching. The outer layer is permeable to air, and when repeatedly cooled, its material undergoes deformation, creating pockets for condensation formed between it and the foil. In this case, there is no danger of rupture at standard pressure.

Causes and consequences

The water hammer that occurs in the heating system is manifested in sound - knocking, clicks and vibrations felt when touching the pipe. The fluid in the circuit has mass, inertia of motion and is incompressible.

Where can water hammer occur?

When an obstacle appears in the path of water, motion energy accumulates, which is expressed in a sharp increase in pressure in a closed system - an impact. The reaction causes the shock wave to move in the direction of lower pressure with increasing speed.

Upon reaching the weak point, the impact energy is released, rupturing the defective section of the pipe if the wave power is sufficient for this, or causing vibrations in the pipeline. Frequently repeated water hammers will lead to the need for repairs after some time.

The reasons for the pressure surge may be:

- air entering the system is due to improper installation of pipelines; air pockets are removed when filling the thermal circuit through special taps;

- quickly shutting off the liquid flow with a valve: a ball valve cannot be used for this purpose;

- changing the circulation mode: starting or stopping the network pump in the event of power supply failures at the facility;

- narrowing of the pipe flow area due to scale, build-up of other deposits in short sections;

- connection of pipelines of different diameters.

The magnitude of the pressure increase depends on the location of the obstacle on the line: at the beginning of the liquid path, the shock is weak, but as the plug moves away from the source, the power of the shock wave increases. Consequences of pulsed hydraulic action: damage to seals at joints, gaskets between flanges, shut-off valves, pump, heating boiler. Even the fin of the heating battery may rupture.

The destruction of individual elements of the system leads to damage to property when the room is flooded; if the water is hot with a temperature of ≥70ºC, then to injuries and burns to people. The second significant nuisance is the significant costs of bringing the heating system and apartment furnishings into good condition.

When this happens often enough and the system does not have the necessary safety margin, then it is quite possible that you will soon need heating repairs in your house. The specific cause of water hammer may be:

- breakdown or shutdown of the circulation pump;

- the appearance of air in the system;

- rapid closing of valves, stopping the flow of liquid.

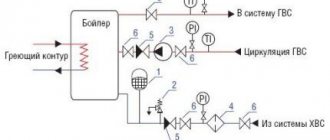

The figure below will help you understand the possible causes of its occurrence, with the last one being the most common. It is worth noting that the use of ball valves to shut off pipes is unacceptable.

Causes of water hammer

Why do you need a water pipeline project?

The length of the water supply system varies even in private houses. Each meter on a straight path adds a certain degree to the angle of inclination of the pipe. First of all, this is necessary to ensure that the water does not stagnate.

Straight and obtuse bending angles, with varying degrees of efficiency, dampen water hammer, which can cause damage to expensive equipment:

- power unit;

- water heater;

- A 2-circuit boiler that provides not only water supply to the washbasin, but also to the “warm floor” system.

Clear geometry is good for decorative finishing. When connecting plumbing points, straight pipe lines are not always relevant. Each bend and angle of inclination is repeatedly calculated and verified by designers.

The cost of a house project with communication interchanges is slightly more expensive than one in which amenities are not provided. In many private houses, the laying of the pipeline begins when laying the foundation. Phased assembly of all components in strict accordance with the construction plan is the best protection for the house from premature destruction, and the water supply from water hammer. It is not recommended to save on calculations, nor on hiring professional plumbers.

If a disaster has occurred and a heating pipe or heated floor has depressurized, then it is urgent to repair the damaged area. You can detect hidden leaks in the floor, wall or ground using a thermal imager. has been searching for leaks in heating systems and has been successfully helping people solve this problem for more than ten years.

Setting up the heating system

After installation and repairs are completed, the heating system is adjusted or, in other words, balanced. Errors made during the design and construction process must be eliminated before the thermal circuit is put into operation, so that an accident caused by a water hammer does not occur in the future.

Operations performed when setting up a heating system:

- measurements of the outer diameters and length of pipes at each section; in case of deviations from the design, errors are eliminated;

- identifying the presence of air jams in a closed loop and eliminating them;

- checking the liquid level when starting a heating pipeline with an expansion tank.

The setup helps make the system reliable with efficient heat consumption. A thermal circuit with natural circulation reacts especially sensitively to shortcomings. Sometimes cleaning the filter at the liquid inlet to the boiler normalizes the water circulation.

After debugging the equipment and fittings of the system, the thermal regime is balanced and the media heating is adjusted. If this is not done, the radiators closest to the heating boiler will be hot, and those further away will be cold. In this case, the heater operating mode will be uneconomical.

To balance the heating, a valve of a special design is installed at the input of each battery or the degree of heating is adjusted by installing washers of different diameters.

How to deal with water hammer

To protect water and heat supply systems from the effects of water hammer, a number of measures are used. Some of them are indicative of universal use, while some are used for pipelines for a specific purpose.

Smooth overlap

You need to get rid of the temptation to quickly cope with such a simple task as opening or closing a valve. This needs to be done slowly and smoothly. If the valve is tight, then it is allowed to move its handle with small jerks. This is customary at industrial enterprises, but it is indicative of implementation in everyday life.

To avoid water hammer, it is recommended to close the ball valve smoothly

Water hammer still occurs. But it breaks down into several smaller ones. The energy that affects the pipes once when the valve is suddenly closed is divided into portions that do not create strong pressure drops. And therefore - not dangerous.

Depreciation

By manually controlling the movement of fluid flows, they can be smoothly closed or opened. But thermostats, which automatically control the operation of the heating system, are not capable of this.

To soften the water hammer in the system, shock-absorbing devices are installed in it. Before installing the thermostat valve, part of the rigid pipeline is replaced with an elastic one. The materials used for this are either heat-resistant rubber or reinforced plastic.

Since these materials can stretch, at the moment of a water hammer they will absorb its force. By briefly increasing in diameter, the shock absorber will act as a damper and relieve pressure before the valve closes.

For most systems, installing a piece of elastic pipe of about 20–30 cm is sufficient. For long pipes, you can increase it by another 10 cm.

Bypass surgery

The method involves manual modification of thermal valves. To implement it, knowledge of their design is required, otherwise the device can only be damaged.

The shunt is a thin tube with a diameter of 0.2 - 0.4 mm. It is inserted into the valve in the direction of fluid flow. During operation, it does not in any way affect the performance of the system, but with a sharp increase in pressure it will help bleed it into the pipeline behind the valve.

Note: Such measures will only help in systems consisting of new pipelines, and preferably not made of metal. The presence of rust negates all efforts and tricks, as it will quickly clog the hole.

Instead of installing a tube, it is often enough to drill a hole of the appropriate diameter.

Protected thermostats

The industry produces thermostats equipped with a water hammer protection device. They have a spring mechanism installed between the valve and the thermal head. You can find out about the availability of this device when purchasing a thermostat from its technical documentation.

When the pressure is exceeded, the spring stretches and prevents the valve from closing completely. The same process occurs as with shunting - excess pressure is released into the pipeline behind the valve. When the water hammer stops, the spring will completely close the valve.

Important: Thermostats equipped with a water hammer protection system are installed into the system strictly in one direction, indicated by the arrow on the housing.

Compensators

One of the compensating devices used in heating systems (it is also suitable for water supply) to protect against water hammer is a hydraulic accumulator. It is a reservoir divided into two parts by a flexible membrane made of rubber or caoutchouc.

At the bottom of the tank, connected to the system, there is water. The top contains air under pressure. A product of a similar design is part of an automatic pumping station and is used there to turn off the pump when the nominal pressure in the system is reached.

As part of the heating system, the compensator is connected to places where water hammer may occur. At this moment, the increasing fluid pressure presses on the accumulator membrane. The air above it is compressed, the membrane moves towards it. Due to the increase in the volume occupied by the liquid, the pressure in it drops.

As soon as the impact of the water hammer ends, the membrane returns to its place. The use of hydraulic accumulators simultaneously allows you to remove excess fluid from the system.

To create a shock-absorbing effect in water supply systems, special dampers are used in addition to hydraulic accumulators.

Compensator device

Safety valves

Once upon a time, doctors performed bloodletting on patients with high blood pressure. Less fluid means less pressure. Safety valves work on the same principle.

They are placed in the most dangerous places subject to water hammer. They work either as independent devices, or from a command from a controller that controls the operation of the system and has information about the pressure in it at given points.

As soon as the pressure at the installation site of the safety valve exceeds the threshold level, it will open and throw excess liquid out. Naturally, this happens where they will not cause harm or discomfort to anyone.

As the pressure decreases, the valve will close, returning to its original state.

Relief safety valve

General information[edit | edit code]

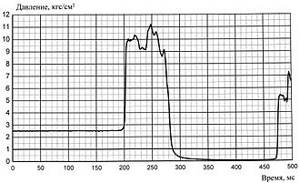

An example of the experimental dependence of pressure on time during a water hammer after the sudden closure of a valve in a pipeline. A decrease in pressure below atmospheric pressure is visible during the rarefaction phase.

The phenomenon of water hammer was quantitatively described in 1897-1899 by N. E. Zhukovsky. The increase in pressure during water hammer is determined in accordance with its theory using the formula:

D p = ρ ( v 0 − v 1 ) c {displaystyle D_{p}=rho (v_{0}-v_{1})c} ,

where D p {displaystyle D_{p}}

— pressure increase in N/m²,

ρ {displaystyle rho}

— liquid density in kg/m³,

v 0 {displaystyle v_{0}}

and

v 1 {displaystyle v_{1}}

— average velocities in the pipeline before and after closing the gate valve (stop valve) in m/s,

s

— propagation speed shock wave along the pipeline.

This formula can be obtained based on the law of conservation of momentum[1]: D p S t = ρ S ( v 0 − v 1 ) ct {displaystyle D_{p}St=rho S(v_{0}-v_{1}) ct} , where S {displaystyle S}

— cross-section of the pipeline.

Zhukovsky proved that the speed of propagation of a shock wave c

is directly proportional to the compressibility of the liquid, the amount of deformation of the pipeline walls, determined by the elastic modulus of the material

E

from which it is made, as well as the diameter of the pipeline.

Consequently, water hammer cannot occur in a pipeline containing gas, since gas is easily compressible.

Relationship between shock wave speed c

, its length and propagation time (

L

and

τ {displaystyle tau }

respectively) is expressed by the following formula:

c = 2 L / τ {displaystyle c=2L/tau }

Gradual shutdown of the system

This is one of the most important requirements when starting and subsequently shutting down a heating installation. All optimal parameters are described in detail in the basic accompanying documents. The whole reason is that the accumulated energy of the water hammer, due to the increased strength of the pipe walls, may not act with all its power.

This feature is achieved due to lightning-fast bending in the desired direction. With the same final impact force, the power of influence on a certain area of the system will be significantly reduced. Thanks to the smooth switching on, specialists are able to significantly extend the rate of pressure build-up, minimizing the likelihood of damage to the heating system of a cottage or apartment building.

Classic pipe burst

Water hammer compensators in Moscow

Water hammer compensators and other products can be purchased at Leroy Merlin in Moscow at low prices. Select the product you are interested in on the website and buy it in our online store. The range of products presented in the catalog is extremely wide. Among them there will certainly be a position suitable in all respects.

All products presented in the “Water Hammer Compensators” section are produced by well-known companies that have proven themselves to be of high quality for their products.

You can always place an order and pay for it online on the official website of Leroy Merlin in Russia. For residents of the Moscow region, we not only have low prices for products in the “Water hammer compensators” category, but also fast delivery to cities such as Moscow, Balashikha, Podolsk, Khimki, Korolev, Mytishchi, Lyubertsy, Krasnogorsk, Elektrostal, Kolomna, Odintsovo, Domodedovo , Serpukhov, Shchelkovo, Orekhovo-Zuevo, Ramenskoye, Dolgoprudny, Pushkino, Reutov, Sergiev Posad, Voskresensk, Lobnya, Ivanteevka, Dubna, Yegoryevsk, Chekhov, Dmitrov, Vidnoye, Stupino, Pavlovsky Posad, Naro-Fominsk, Fryazino, Lytkarino, Dzerzhinsky , Solnechnogorsk, Istra and Zhukovsky.