How does an air lock form in the cooling system?

What are the reasons for the formation of an air lock and where exactly can it occur? There are several reasons, as well as “secret” places of its formation. For example, an air lock in a radiator is obvious, and its diagnosis and “treatment” are elementary. It’s more difficult when air appears in the cooling system, and at the same time, somewhere “deep inside”. Everything is much more complicated here...

1. The main reason is poor sealing. In the cooling systems of modern cars, antifreezes are used not only with a low freezing point, but also with fairly high boiling points - up to 115-120 degrees. Accordingly, the pressure in the system rises to 1.2-1.4 atm.

Coolant leakage occurs due to wear and tear of the pipes themselves, their connections to each other and to the metal pipes of the radiator, block and cylinder head, heaters, etc.

Sometimes this leak can be detected visually, but often it occurs “somewhere in the depths” of body parts or decorative interior panels. Such a leak is difficult to detect. And when the system cools down (and the pressure drops), the reverse process occurs - air is sucked into the system, and the “weak spot” can be in the most unexpected place - even for master mechanics.

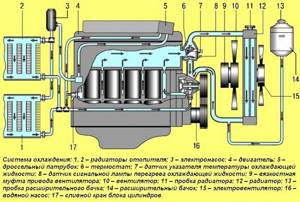

This is what the “principal diagram” of the cooling system of a modern internal combustion engine looks like

2. Air also enters the system, for example, when adding or replacing antifreeze . An inexperienced motorist or lazy mechanic pours coolant into the filler neck directly from the canister - in a wide, powerful stream. While the manufacturers' technological maps instruct their service technicians to fill the system from a small container and, most importantly, in a slow, thin stream. Then air will definitely not get into the system.

3. A vapor lock in the system can also occur for the following reasons:

- due to a faulty pump (water pump), it begins to make noise and later begins to leak;

- due to a failed air valve in the expansion tank plug;

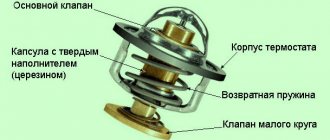

- due to a faulty thermostat;

- due to problems in the stove/heater (or heaters, if there are several of them);

- due to a breakdown of the cylinder head gasket, as well as at the junctions of the cooling, lubrication and gas distribution systems.

In the latter case, the development of events occurs according to the following scenarios.

If there is a breakdown of the gasket between the cylinder block and the head, then the exhaust gases find two outlets:

- or into the cooling system, then the coolant begins to bubble in the expansion tank or upper radiator reservoir; or - white steam begins to escape from the exhaust pipe;

- or into the lubrication system, then an emulsion appears in the engine oil, and this situation is fraught with a major overhaul of the engine; or black/blue thick smoke comes out of the exhaust tract - this is engine oil or antifreeze burning.

If a breakdown occurs between the cooling and lubrication systems, then either the so-called “paraffin” appears in the coolant, or the same water emulsion appears in the lubrication system.

This is what a more complex cooling system looks like with several heaters, an electric pump, a viscous fan coupling and an additional electric fan.

The main reasons for airing the system

The presence of air is a common cause of failure of many components of the cooling system. The thing is that the plug stops circulation in the system channels, thereby disrupting the stability of the cooling devices. Surely every driver has encountered boiling antifreeze or antifreeze while operating a car - this is also a sure sign of the presence of air. Common causes of traffic jams:

Often an air lock appears due to a failure of the cylinder head gasket. At the same time, antifreeze enters the engine cylinders, which is important to prevent in time. In this case, a characteristic rise in temperature is observed in the expansion tank due to the penetration of exhaust gases.

Some car owners prefer to purchase antifreeze filters instead of high-quality antifreeze. Such a solution will be beneficial - there will be no traffic jams in the system. However, the filters themselves lose their service life after 5 thousand kilometers, which is unprofitable from an economic point of view. It is much wiser to purchase a good coolant that can effectively cope with its tasks throughout the stated service life.

Air in the engine cooling system - how to determine?

There are several signs of “airing” the system:

- the coolant temperature indicator on the dashboard rises or the red indicator light comes on if the indicator is not provided by the manufacturer - in other words, “the engine is heating up”;

- when the engine is “boiling”, cold air comes from the heaters;

- when there is a noticeable difference in the temperatures of the upper and lower radiator pipes or, conversely, when their temperature is equally high - however, for this you must have at least a little driving experience.

Air in the engine cooling system is not just a “slightly unpleasant” moment, it is a harbinger of disaster!

An inexperienced driver may simply miss the moment when the system begins to overheat, and he has to stop his car in an extremely inconvenient, or even dangerous, place, when steam is already escaping from under the hood.

Unfortunately, some manufacturers (in particular, General Motors) have abandoned dial temperature indicators, limiting themselves to a “red LED”. But arrow indicators (on cars such as BMW or Mercedes-Benz) do not always protect their owners from such problems.

You need to be careful!

From personal experience

If you just suspect a problem, you should take action immediately. After all, at first the temperature gauge needle only rises slightly above its nominal value. Later, it begins to approach the red zone and only then enters this red zone. The last “line of driver inattention” is steam from under the hood and a stalled engine.

The biggest mistake that novice drivers make is that they stop, immediately open the hood and immediately try to open the radiator or expansion tank cap. This should absolutely not be done under any circumstances!

Neither in the case of beginning heating, nor in the case of beginning boiling, nor, especially, in the case of the already completed boiling of the motor. Strong steam pressure in the system, firstly, will splash out the remaining coolant into the engine compartment and onto the roadway, and secondly (which happens quite often) will scald the driver’s hand.

A typical mistake is to turn off the engine. This also cannot be done ! You need to stop, open the hood and let the engine idle for a few minutes. The temperature will drop significantly within a minute or two or three.

Common questions and opinions

Some car enthusiasts advise lifting your face up, some don’t. Some argue that this is only relevant for cars with a radiator, which also serves as an expansion tank. Then, indeed, in an inclined position, the top of the radiator will be the highest point and the air will freely leave the system.

Owners of systems with an individual expansion tank do not see any benefit in this solution. Sometimes this recommendation is interpreted in the following way: jack up the side of the car on which the expander is installed. There is some sense in this, but it is not necessary to perform this action.

It makes much more sense to compress the pipes going to the radiator. This really allows you to quickly flush the air out of the system. It is only important that the tank is open. What is also useful is the autonomous purging of the furnace radiator. In order for the stove to heat for sure, it is necessary to pump antifreeze through it by disconnecting the outlet pipe. To do this, the system should be warmed up a little by increasing the pressure in it. Next, the motor stops and the pipe is disconnected.

Source

What is the risk of engine overheating?

Due to high temperatures (and the steam temperature can reach 500 ° C and higher), as well as due to high pressure, “for starters” a breakdown of gaskets and partitions between engine systems - cooling, gas distribution, lubrication system, etc. can occur.

With significant overheating, the cylinder head becomes bent - this is the most common “malfunction” of an internal combustion engine during overheating; mechanics say so: the head has become a propeller. As a result, a breakdown of the head gasket occurs, oil and/or coolant enters the cylinders, which entails scuffing, water hammer and similar “joys”. And this is definitely a major overhaul with unpredictable costs for the owner.

How to prevent an air lock from occurring? You need to be careful and systematically look at the instrument readings.

Some recommendations

Every driver must remember that an effective remedy is timely technical inspection and proper car care. As a rule, fluid leakage is a common cause of traffic jams; to prevent them, you need to look under the hood or underneath as often as possible in search of spots.

Poor quality refrigerant can also be the cause, since it is not able to cope with the cooling task at 100% and contributes to clogging of the channels in the cooling jacket.

Some experts recommend installing additional filters for antifreeze or antifreeze for the purpose of double filtration. Complete replacement of the element is recommended every 4,000–5,000 km. mileage

. But, you must agree that the cheapest and most practical thing is to buy high-quality refrigerant, and not diluted powder with water, which costs a penny on the car market. With this approach the car will not go far.

This concludes our discussion of the topic of how to remove an air lock from the cooling system. Let's hope that our recommendations will help many drivers gain experience in quickly troubleshooting problems in the cooling system. Of course, the above methods are not a panacea; you can recommend your own, share situations and experiences. Ready for review and discussion. Good luck to you.

How to remove air from the cooling system?

In fact, there is no universal recipe or guaranteed methods for removing air from the cooling system. If only for the simple reason that the designs of the systems are different. Some are simpler, others have a lot of additional elements and “assisting” mechanisms. It all depends on the class and purpose of the car.

The Internet is full of all sorts of recipes on how to remove an air lock “on your own in a garage,” but, I repeat, each engine and each system has its own specifics, and no one can do it better than a specialist. And the most common “home-grown” techniques are considered to be two.

Method one

Remove attachments and all protective elements from the engine in the area of the expansion tank. Disconnect one of the pipes, which is responsible, for example, for heating the throttle valve (if you understand and know what we are talking about). Blow inside the expansion tank, and excess pressure in the system will force excess air through the removed pipe.

As soon as water (antifreeze) comes out of the removed pipe, immediately put it back in place.

Method two

How to remove an air lock from a “simple” motor? Place the vehicle on an elevated position so that the front end and therefore the radiator cap are higher than the rest of the cooling system. Run the engine for 10-15 minutes to allow the thermostat to operate and open the large cooling circuit. Remove (carefully!) the cap from the expansion tank or radiator, whichever is higher at the moment.

This method, I repeat, is suitable for cars of older designs without “all sorts of electronic and other problems.” However, even on such cars, the mechanic sometimes leans deep into the engine compartment and, like a pear, pumps and presses alternately the upper and/or lower radiator hose in order to expel and remove air from the cooling system.

Correct filling of the system with coolant

In order not to be faced with solving the problem of how to bleed air in the heating system, it is important to correctly fill the circuit with coolant; to do this, follow the following rules:

- Any system is filled from the lowest point; for this, a ball valve is placed in the pipeline at the installation stage.

- The coolant should be supplied at a low speed, this is especially important when filling extended circuits of heated floors.

- When filling a closed system, a pressure of 1 - 1.5 bar is maintained, which is controlled by a portable or built-in pressure gauge.

- After filling the system (in the gravitational degree it is determined by the amount of water in the expansion tank, in the forced degree - by pressure), they begin to bleed air from the batteries. Before this, it is advisable to turn on the boiler and heat the water to a temperature of about 60 °C.

- After de-airing, add coolant and again check the uniform heating of the radiators - if the result is positive, the work is stopped. If uneven heating of the batteries is detected again, the de-airing procedure is repeated, after which coolant is added to the circuit.

Rice. 9 How to bleed air from the heating system using a Mayevsky tap. Examples of their use in radiators

The problem of how to properly bleed air from a heating system is solved using special devices - manual or automatic air vents. Mayevsky taps are used to bleed air from radiators; the de-airing procedure does not present any particular difficulties for any user and does not require the use of expensive special tools.

General recommendations and tips for preventing system airing and engine overheating

- Always ( ALWAYS, and this is very important) monitor the coolant level in the radiator neck or expansion tank and, if necessary, add distilled water if you have a modern car with antifreeze class 11G and higher. By the way, monitoring the coolant level (as well as the oil level in the engine crankcase, as well as the pressure in the wheels) is prescribed by the recommendations for the so-called EO - daily car maintenance, prescribed in your Instructions.

- Systematically, and especially before the autumn-winter period of operation, check the density of antifreeze in your system.

- Always be careful and monitor instrument readings.

This is the result of that same water hammer. Need comments?

Even at the slightest suspicion of an increase in temperature, it is better to stop immediately and try to find out the reason. If the indicator arrow systematically or periodically attempts to leave its usual nominal values, immediately contact a car service center.

If you need specialized specialists, then use the recommendations and tools of the Autobooking website and independently find the service station you need in your city or region.

If you need to replace antifreeze, use the form below to find a service station:

Sergey Zhebalenko, automotive engineer, journalist, manager of the automotive program “Motor-TB”

Useful tips

To avoid problems with the engine cooling system during operation, as well as to extend the life of the components (pump, thermostat), you cannot use ordinary water instead of antifreeze or antifreeze. It is also not recommended to use distilled water instead of antifreeze. This water should only be used to dilute antifreeze or antifreeze concentrate in the required proportion.

In this case, frequent addition of only distilled water to maintain the level leads to the fact that the density of the solution decreases. This can lead to freezing of coolant in the system in winter. To prevent this from happening, you need to check the density with a hydrometer. If necessary, the density is adjusted by pouring undiluted concentrate.

Stopper removal methods

Before removing the plug, the cause of air getting into the cooling system is eliminated. If the cause is not eliminated, the removed air will reappear in a fairly short period. After eliminating the problem, you can begin to remove the plug.

The first step is to eliminate the cause of the airlock.

The vehicle is placed on a slope so that the radiator neck is at the top. This position will facilitate the release of air from the system. But simply lifting the radiator neck is not always effective, since the closed cycle of the cooling system does not allow the air lock to move on its own. To facilitate the release of air, the following methods are taken:

It is important! The main element of the cooling system is the thermostat. Its serviceability should be given special attention. If the device is broken, then simply getting rid of the air will not help.

After using any method of removing an air lock, it is important to check the operation of the stove and compliance with the correct temperature conditions of the engine.

How to determine whether there is an air lock or not

As mentioned above, the plug disrupts the circulation of fluid through the channels of the cooling system. Normal heat exchange between the engine and antifreeze does not occur, resulting in overheating of the power plant. Or, on the contrary, the engine does not warm up enough. Such malfunctions in the operation of the power unit, in theory, can result in serious repair costs. It is important to identify even the slightest air in time and take actions aimed at removing excess air. You can understand that a blockage has formed in the system by the following signs:

Removing air from the cooling system is a trivial task and can be done even by a novice driver. The main thing is to detect the appearance of airiness in time, so as not to spend money on serious repairs to the main unit of the machine in the future.