When repairing a heating device, it is often necessary to replace the gaskets for the heated towel rail: which is better to choose so as not to regret your decision later? It is better to buy the product not individually, but in a set. Selecting gaskets for heated towel rails

- Main types of plumbing gaskets

- Rubber and paronite seals

- PTFE and silicone gaskets

The cause of a heated towel rail leak is often a poor-quality or incorrectly installed gasket. At first glance, fixing such a problem is easy and simple. However, replacing the gaskets yourself is only possible if the heating device is equipped with ball valves to shut off the water supply system and a special jumper (bypass) that allows water to bypass the device. In most apartments, such a structure is not installed, so it will not be possible to disconnect the heated towel rail and replace the gaskets without the help of a specialist, since this requires shutting off the water in the entire riser for the period of repair. Disconnection of communications is carried out only with the permission of the organization supplying heating. The apartment resident needs to write an application and pay for the services of the master.

Diagram of sealing with a rubber gasket.

The process of replacing the heated towel rail gasket is simple. First, you should remove the paint from the union nuts, unscrew them, replace the damaged product, and then screw the nuts into place. The best tool to use is an adjustable wrench designed to work with parts of different sizes. In order to choose a suitable gasket, you need to find out what they are.

Types of plumbing gaskets

Plumbing gaskets differ primarily in the material they are made of.

- Rubber . Depending on the sulfur content, rubber can be hard (more than 50%), semi-hard (from 30% to 50%) and soft (from 0.5% to 3.5%) modifications. To understand, soft rubber is a car inner tube, hard rubber is the sole of a shoe.

- Silicone . Made from silicone rubber. They are conventionally divided into three types: technical silicone, food grade silicone and medical silicone.

- Paronitaceae . They are obtained by pressing asbestos, rubber, mineral fillers, and sulfur. Fillers influence the brand of paronite, and the brand, in turn, affects the area of application.

- Fluoroplastic. In its essence and characteristics, this is the same FUM tape, only made in the form of a ring.

- Fiber gaskets . This is pressed cardboard made from cellulose and wood pulp, impregnated with zinc chloride or sulfuric acid.

Classification of gaskets

Plumbing gaskets differ from each other by the material from which they are made. The most common are rubber sealing elements. There are also products from:

- fluoroplastic;

- paronitis;

- silicone.

Each group of gaskets is divided according to purpose (application):

- for heated towel rails;

- for heating radiators;

- for mixers;

- for ceramic crane axle boxes;

- for the diverter.

Before you go to the store to make a purchase, you need to decide on the material of the gasket.

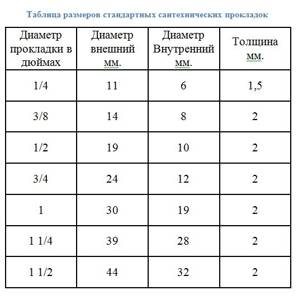

Plumbing Gasket Size (Plumbing Gasket Table)

To select a plumbing gasket, it is not enough to know only the outer diameter of the gasket. For example, the inner diameter of flexible hoses can vary greatly with the same outer diameter. Everything is even more complicated if there is a need to seal the external thread. Plus, you need to know the thickness of the gasket.

Below is a table with non-standard gaskets and seals.

Plumbing gasket or thread seal

To understand which threads a plumbing gasket is suitable for, and for which threads it is better to use another method of sealing the threads, just look at the thread from the end. If the threads have a sharp edge (photo left), the plumbing seal will be cut through during tightening or use. To use the gasket, the edge of the thread must be blunt (photo on the right).

Replacing the gasket

Once the cause and location of the leak have been established, work can begin to eliminate the problem.

Replacing the heated towel rail gasket begins with turning off the water. It is dangerous to loosen the nuts on the connections without shutting off the water supply to the apartment and relieving the pressure. You can get serious burns from boiling water.

Water supply shut-off valves are usually located next to water meters.

After the water supply is stopped, carefully loosen the nuts connecting the heated towel rail to the inlet. You need to wait until the water drains out of it.

After the water has stopped flowing, the nuts are completely unscrewed and the dryer is removed from the brackets.

Then the fitting is unscrewed from it, and after inspection, you can begin to replace damaged rubber gaskets and threaded seals.

To remove the liner from the “American”, a special hex key is used.

After replacing all the seals, the heated towel rail is placed on the brackets in the reverse order and connected to the water.

It is better to use flax in combination with an airtight paste as a winding on the thread of the liner.

Advice from experienced plumbers: for an easier connection with a water pipe, it is better to use fittings from the Italian company FAR.

During installation and assembly, you can do without “American ones”. This method is shown in the video.

Another method is a direct connection to the riser. In this case, only a straight fitting is required. But the layout and location of the liner do not always allow this.

This option is much simpler and faster. It looks like this.

Rubber gasket for plumbing

Rubber plumbing gaskets are in greatest demand due to their simplicity, low cost, and versatility.

Advantages of Rubber Plumbing Gasket

- Low price.

- Versatility of use.

- High wear resistance.

- Withstands pressure up to 25 bar.

- Withstands temperatures up to 100°C.

- Can be used for steel and plastic pipes.

Disadvantages of rubber plumbing gasket

- Service life is not high compared to other gaskets. In conditions of high temperature and pressure, up to two years.

- Single use.

Application of rubber gaskets

- Hot water.

- The best use for the rubber gasket is cold water.

- Drinking water supply.

- Gas supply.

- For installation of a sewer system (dishwasher, washing machine drain).

Heated towel rail "Sunerzha"

produces reliable heated towel rails made of high-quality stainless steel that can withstand pressure of 25 atmospheres and temperatures of up to 105 degrees.

You can choose the right design that will suit any bathroom layout. Simple fittings allow quick and easy gasket changes.

The Sunerzha heated towel rail is popular in the market due to its ease of connection and reliability.

Silicone sanitary seals

Silicone plumbing gaskets have a wider range of applications. When installing the connection on the silicone gasket, you should not use much force when tightening the fitting, because The seal can be easily damaged.

Advantages of Silicone Plumbing Gasket

- More elastic than other plumbing gaskets.

- They are odorless (compared to rubber analogues).

- Versatility of use.

- Withstands pressure up to 10 bar.

- Temperature range from -50°C to 280°C.

- Resistant to aggressive environments.

- Service life is about 20 years.

Disadvantages of silicone plumbing gasket

- High price (compared to rubber products).

- The tightening force of the connection should be monitored.

- Lots of fakes. If set on fire, the silicone gasket will not support combustion.

Application of silicone gaskets

- Hot water is the best use for a silicone gasket.

- Cold water.

- Heating.

- Food industry (food grade silicone).

- Medicine (medical silicone).

Paronite plumbing gaskets

Paronite is used for sealing plumbing and flange connections. It has higher technical characteristics compared to other materials. When choosing a paronite gasket, be sure to pay attention to the type of product. The area of application will depend on the type of gasket.

Types of paronite gaskets

- General purpose.

- Acid-resistant.

- Oil resistant.

- Reinforced.

- Unreinforced.

- Asbestos.

- Non-asbestos.

Advantages of paronite gasket

- Withstand pressure: Reinforced paronite - 64 bar (to improve technical characteristics, paronite is reinforced with a metal mesh) Non-reinforced paronite - 40 bar.

- Temperature range -60°C to 450°C.

- Does not corrode upon contact with other metals and alloys.

- Resistant to aggressive environments.

- Regardless of operating conditions, the properties of the paronite gasket do not change.

- Due to its rigidity, it is difficult to damage when tightened.

- The service life of a paronite gasket in domestic conditions is at least 5 years.

Disadvantages of paronite gasket

- There is one drawback. The maximum thickness of the paronite gasket is 6 mm.

Application of paronite gasket

- Hot water.

- Cold water.

- For gas supply systems it is the best gasket.

- Heating systems.

- Food industry.

- Automotive industry.

Rubber and paronite seals

Diagram of connection options for a heated towel rail.

Rubber gaskets come in various brands. For plumbing purposes, monolithic rubber of semi-hard and hard grades is used. It is able to maintain its performance at temperatures from -40 to +80°C, and some varieties do not lose their properties even at temperatures from -20 to +90°C. As gaskets for the heated towel rail I use technical rubber TMKShch (GOST 7338-90). This abbreviation means that the products are heat-, frost-, acid- and alkali-resistant. They are recommended to be installed in a system with a pressure of no more than 25 bar.

As practice shows, a significant disadvantage of rubber is that it is short-lived. Over time, the material loses its elasticity, so the layers between the parts of the device have to be changed. Quite often, if the necessary gasket is not at hand, home craftsmen cut it out from available materials - car or motorcycle tires, children's rubber toys.

Diagram of the correct connection of a heated towel rail.

Paronite gaskets can withstand higher pressure - up to 64 bar. They are made from leaf paronite. This material consists of a compressed mass of chrysotile asbestos, synthetic and natural rubber, and powder ingredients. Paronite layers differ from rubber ones in their high resistance to temperature and pressure changes in water supply systems. The maximum temperature of use reaches + 200°C.

According to the World Health Organization, chrysotile asbestos, like many other types of asbestos, is considered hazardous to health. Mainly because asbestos contains carcinogenic substances that cause malignant and benign tumors. Thus, in the European Union countries, the use of asbestos has been completely prohibited since 2005. Therefore, many craftsmen do not recommend using paronite gaskets for heated towel rails.

Fluoroplastic sanitary gaskets

PTFE gaskets are particularly resistant to aggressive environments. Quite soft material, but with a very high density. When tightening a threaded connection, the fluoroplastic gasket cannot be squeezed out, unlike a rubber or silicone gasket.

Advantages of fluoroplastic gasket

- Temperature range -250°С +250°С.

- Pressure up to 160 bar.

- Service life more than 10 years.

- Resistance to aggressive environments.

- Not subject to aging and corrosion.

- High wear resistance.

Disadvantages of fluoroplastic gasket

- The main disadvantage is the high price.

Application of fluoroplastic gasket

- It is absolutely harmless and can be used in the food and medical industries.

- Best used for heating systems.

- Hot water.

- Cold water.

- For gas supply systems.

Fluoroplastic

PTFE gaskets for plumbing fixtures are not so easy to find on sale. Their areas of application are the oil, food and chemical industries, due to the chemical neutrality of the material. Its quality cannot be surpassed by any other material!

In everyday life, the use of fluoroplastic sealing elements is only advisable for sealing aluminum radiators. For other purposes , their use is irrational from the point of view of financial costs .

The benefits include:

- low rate of aging;

- environmental cleanliness;

- elasticity;

- resistance to aggressive environments;

- the presence of antifriction properties;

- resistant to fire.

Elasticity and anti-friction features allow for strong fixation of plumbing elements to each other. Can be used in water supply systems with pressures up to 150 bar and temperatures not exceeding +150 degrees.

Fiber sanitary gasket

Fiber gaskets swell upon contact with liquid, which has a positive effect on the sealing of the threaded connection. Fiber differs in scope depending on the type of material. In everyday life, technical fiber (FT) is used; for contacts with oxygen, oxygen-resistant cushion fiber (FPK) is used; for contact with aggressive environments, castor-glycerin fiber (FCG) is used.

Advantages of fiber gaskets

- Maximum pressure up to 40 bar.

- Pressure in heating systems up to 10 bar.

- Temperature range from -40°C to 120°C.

- Resistant to aggressive environments.

Disadvantages of fiber gaskets

- The gasket is disposable.

Application of fiber gaskets

- For oxygen pipelines.

- Gas pipelines.

- Tolerates contact well with gasoline, kerosene, and machine oil.

- Hot water supply.

- Cold water supply.

- For heating systems.

Manufacturing of sanitary seals

There are times when you urgently need to fix a leak, but there is no suitable gasket at hand, or you need a gasket with non-standard dimensions, but there is none in stores. In this case, you can make the gasket yourself, you just need to know which material is right for you.

Rubber, paronite and silicone for making gaskets can be purchased at hardware stores.

Rubber for the manufacture of sanitary gaskets

For the manufacture of a gasket, a piece of monolithic (in no case porous), semi-solid rubber is best suited; in extreme cases, soft rubber can be used, but the service life and technical characteristics of such a gasket will be significantly lower. It is important that the thickness of the new and old gaskets be approximately the same.

Paronite for the manufacture of plumbing gaskets

To make a paronite gasket, you will need a paronite sheet of suitable thickness and dimensions. You can cut the gasket using scissors, then sand the edges with an abrasive material, although such a gasket is unlikely to be perfectly smooth. But if you need a large number of gaskets, and even perfectly even ones, it is better to get a special tool - a punch.

Silicone for making sanitary seals

To make a silicone gasket you need the following:

- Take a silicone tube with suitable characteristics.

- Decide on the thickness of the future gasket.

- Draw a template on a piece of paper or cut out a shape in paraffin.

- Fill the perimeter of the template evenly with silicone, or place the silicone tightly into the mold using a rubber spatula.

- Place several objects of suitable thickness, such as metal washers or coins, around the perimeter of the template, on the sides.

- Cover the top with another sheet of paper.

- Press down on top with a flat, heavy object for at least 24 hours. There is no need to press the silicone into the mold.

For critical work, it is of course better not to use such a gasket, but for sealing any non-standard connection, it is quite suitable.

Manufacturers of plumbing gaskets (plumbing gasket sets)

Russia

- Sibrtech . Produces sets of plumbing gaskets in a convenient case.

- Masterprof . Gaskets are sold in a case. For example, the “Universal” set has 200 gaskets for Russian and imported plumbing fixtures, as well as plumbing linen with thread sealing paste.

- PLUMBING KIT . The “Plumbing kit No. 5” includes 22 units of various gaskets in a blister pack, at a very low price.

Europe

- KROFT . Portuguese manufacturer of gaskets. The set includes 55 rubber spacers from 10 to 30 mm. The advantages of the kit are quality and price, but the disadvantages are that there is no description of the contents.

- Oras . The company from Finland, founded in 1945, produces sanitary ware, faucets and gaskets for its plumbing. Gaskets are sold in blister packs of several pieces.

- GROHE. A German set of gaskets for the actual plumbing fixtures, not cheap at all.