Gas enters the home in two ways: through a gas pipeline and in cylinders. The first method is preferable in all respects, since, firstly, the arrangement and maintenance of the system is the responsibility of city utilities. Secondly, the cost of such a supply is much lower, and thirdly, the volume is much larger.

Selecting the diameter of the gas pipe

Self-installation is impossible: communications are laid only by special services and only after receiving permits.

Marking

You can determine high-quality pipes and find out their parameters from the markings, which are applied to the surface and are available in the technical documentation for the released batch.

The markings indicate:

- name of the manufacturer;

- grade of steel from which the products are made;

- outer diameter and thickness of the pipe wall;

- the nominal pressure that the pipe can withstand without any problems and in different climatic conditions;

- GOST or other technical conditions in accordance with which this pipe is manufactured.

Additionally, the following may be indicated:

- date of manufacture;

- lot number upon delivery;

- order number according to which the pipes were produced;

- total weight of the pipe;

- total weight of the entire lot.

Symbols of the main characteristics of the pipe

Supplying gas is a very responsible undertaking. If the master is not sure about the correct choice of steel gas pipes for constructing a network with certain operating parameters, then it is more advisable to obtain preliminary consultation from specialists.

How to choose a gas meter

So, if you only have a two-burner gas stove, then a G-1.6 meter will be sufficient. A gas stove consumes approximately 1 m3 per hour. If you also have a gas water heater, then it is better to use a meter marked G-2.5. If there are other gas appliances, then the passport of any gas equipment must indicate the gas consumption per hour. Thus, you can calculate what your planned total gas consumption is and then select a gas meter of the required marking.

But in addition to the estimated throughput of the gas meter, it is necessary to take into account such parameters as:

- Direction of gas flow in the meter

- Overall and connection dimensions

- Availability of temperature reading correction (thermal correction)

According to the direction of gas flow, the meters are left-handed (gas flows from the left) and right-handed (gas flows from the right). When choosing a meter, take into account the relative position of the gas pipe and the devices that you are going to connect.

If you are installing a new gas meter to replace the old one or you already have a gas pipeline installed, then you need to know the center distance (A) and thread diameter (F) of the connecting pipes. If the discrepancy in thread diameter can be easily compensated by selecting adapters, then if the interaxial distance does not match, you will have to move the gas pipe or, more likely, buy another meter.

You also need to take into account the distance (E) from the axis of the connecting pipe to the rear wall of the meter because the gas pipe runs at a certain distance from the wall and the meter may not fit in size.

Overall dimensions of the meter

Meters with automatic temperature correction (thermal correction) are initially more expensive than similar meters without thermal correction, but in the future they allow you to save on gas costs. The thing is that meters without thermal correction are designed for gas metering under normal conditions - with an ambient temperature of +20 ° C and a pressure of 760 mm Hg. Art. If the gas is colder, for example in winter, then its density increases, and in summer, on the contrary, it decreases. An increase in gas density leads to the fact that the consumer receives more gas and pays less according to the meter. Therefore, for those who have a gas meter located outside, the temperature coefficient is used in the calculation. In the middle zone for the summer months it is 0.96 - 0.98, and in winter it is about 1.15, and on average for the year it is about 1.1. The coefficient is applied monthly, without taking into account the actual temperature of the supplied gas. The volume of gas payable for a month is calculated as the product of the volume of gas on the meter for a given month and the corresponding temperature coefficient. To avoid disagreements when paying for gas, it is better to install a meter with a thermal corrector, which will automatically determine gas consumption in accordance with its actual temperature. This is especially true for those who consume increased volumes of gas, for example, for heating a cottage and heating water.

For those who have a meter in their apartment, the use of a thermal corrector is also relevant and allows you to save money. After all, in fact, the temperature in the kitchen is higher than +20°C, especially when the gas stove is on, so the density of the gas is lower than normal. Consequently, the thermal corrector will “slow down” the meter.

Metal-polymer pipes PEX-b/AL/PEX-b for gas supply

Scope of application of COMPIPETM metal-plastic pipes for gas supply:

- In-house gas supply in single-apartment residential buildings with no more than three storeys;

- Hot and cold water supply in residential, industrial and administrative buildings;

- Radiator and floor heating systems (“warm floors”);

- Water wall-mounted, radiator-free heating (“warm walls”);

- Technological pipelines and water treatment systems;

- Heating of open areas and staircases, stadiums, swimming pools, etc.;

- Heating the soil in greenhouses, greenhouses, winter gardens and greenhouses.

Advantages of the COMPIPETM metal-polymer pipe for gas supply:

— The service life of metal-plastic pipelines and connections is more than 50 years; — Ease of installation and low weight of pipes compared to steel pipelines; — High throughput due to the low roughness of the inner layer of the pipe; - Cost-effective. Minimum use of fittings, due to the ability of the pipe to retain its shape when bent; - Versatility. Crimping profiles for press fittings - TN; — a wide range of pipe sizes and fittings for connecting various gas equipment; - COMPIPETM pipelines do not require maintenance during their entire service life - COMPIPETM pipelines can be installed hidden, which allows: a) laying gas pipelines through residential premises; b) install gas equipment where necessary, for example in the center of the premises.

Technical characteristics of the CompipeTM metal-polymer pipe for gas supply are given in Tables 1, 2.

Table 1. Characteristics of metal-polymer pipes COMPIPETM PEXb-AL-PEXb for VDGO systems

| SPECIFICATIONS | ||||

| Nominal outer diameter | 16 | 20 | 26 | 32 |

| Inner diameter, mm | 12 | 16 | 20 | 26 |

| Wall thickness, mm | 2 | 2 | 3 | 3 |

| Weight of one meter, g | 112 | 148 | 262 | 328 |

| Coil length, m | 200/100 | 100 | 50 | 50 |

| Operating temperature, °C | -15/+40 | -15/+40 | -15/+40 | -15/+40 |

| Maximum working pressure, MPa | 0,01 | 0,01 | 0,01 | 0,01 |

| Roughness, mm | 0,003 | 0,003 | 0,003 | 0,003 |

| Oxygen diffusion, mg/l |

Table 2. Characteristics of COMPIPETM PEXb-AL-PEXb metal-polymer pipes for heating systems

| SPECIFICATIONS | ||||

| Outer diameter, mm | 16 | 20 | 26 | 32 |

| Inner diameter, mm | 12 | 16 | 20 | 26 |

| Wall thickness, mm | 2 | 2 | 3 | 3 |

| Coil length, m | 200/100 | 100 | 50 | 50 |

| Weight 1 l.m. pipes, g | 112 | 143 | 258 | 332 |

| Volume of liquid in 1 l.m. pipes, l | 0,113 | 0,201 | 0,314 | 0,531 |

| Min. bending radius with conductor, mm | 45 | 60 | 95 | 125 |

| Min. manual bending radius, mm | 80 | 110 | 115 | 160 |

| Operating temperature at pressure 1.0 MPa | (0÷95)ºС | |||

| Emergency temperature (no more than 1 hour) | 100ºС | |||

| Maximum operating pressure at a temperature of 95ºС | 1.0 MPa | |||

| Linear expansion coefficient | (0.26x10-4) K-1 | |||

| Change in pipe length after heating at a temperature of 120ºC for 60 minutes | 0,81% | |||

| Equivalent uniform-grain roughness coefficient | 0,007 | |||

| Oxygen diffusion | 0 mg/l | |||

| Coefficient of thermal conductivity | 0.43 W/mK | |||

| Bond strength | 70 N/10mm | |||

| Polyethylene cross-linking method | Silanol | |||

| Crosslinking degree | 65% | |||

| AL layer welding method | Argon-arc butt welding | |||

| Weld strength | 57 N/mm² | |||

| Resistance at constant internal pressure (without destruction) and temperature: | ||||

| 20ºС - for 1 hour, MPa (not less) | 4,5 | |||

| 95ºС - for 165 hours, MPa (not less) | 1,8 | |||

| 95ºС - for 1000 hours, MPa (not less) | 1,6 | |||

| Service life subject to installation and operation rules, years | 50 |

COMPIPETM is the first Russian metal-plastic system approved for use in intra-house gas pipelines;

Certificates and approvals are available upon request.

Gas consumption standards for home heating

Restrictions on the consumption of utilities may manifest themselves in minimum tariffs, permissible power and resource supply standards. The need for standards appears where there are no metering meters.

The norms for natural gas consumption by the population are determined in the following areas of its use:

- cooking for 1 person per month;

- heating water with autonomous gas and water supply in the absence or presence of a gas water heater;

- individual heating of residential premises and outbuildings;

- for the needs of keeping pets;

Gas standards for heating are calculated based on consumption in equal shares for the months of the entire year. Measured in cubic meters per 1 m 2 of heated area or per 1 m 3 of heated volume. If the building is multi-story, then the calculation is made for each floor separately. As a rule, heated rooms include attics, basements, and some basements.

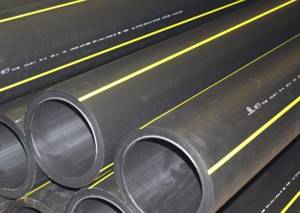

No. 5. Pipes for gas pipelines made of low pressure polyethylene (HDPE)

HDPE pipes have recently been in no less demand than steel pipes. It should be noted right away that the phrase “low pressure”, which appears in the name of the material, refers to the peculiarities of pipe production, and not to the operating conditions of the gas pipeline. There are polyethylene pipes that can withstand pressure up to 1.2 MPa. What makes us abandon the proven option with steel pipes and use polymer ones? The answer to this question lies in the advantages of the material.

The main advantages of polyethylene gas pipes:

- light weight;

- faster and simpler installation without the use of complex expensive equipment that requires special skills;

- strength, ductility and flexibility make it quite easy to bypass possible obstacles in the path of the gas pipeline. The maximum permissible bending radius is 25 pipe radii. Flexibility allows the pipeline to remain intact even with small soil movements;

- the ability to withstand pressure up to 1.2 MPa, so such pipes can be used in almost all sections of the gas pipeline;

- corrosion resistance, ability to withstand exposure to aggressive substances;

- high throughput, since the inner surface of the pipe is smooth. With the same diameter as a steel pipe, a polyethylene pipe will have a throughput capacity that is approximately 30% higher;

- HDPE pipes are produced in large lengths, which allows for fewer connections, thereby achieving structural integrity and reliability;

- polymer materials do not conduct stray current;

- low cost when compared with steel or copper analogues;

- durability is at least 50 years, and if all conditions are met, up to 80-90 years.

There are also disadvantages:

- polyethylene pipes cannot be used in areas where the temperature drops below -45C. Such a gas pipeline is located at a depth of at least 1 m; at winter temperatures of -40C, the depth increases to 1.4 m, and in some cases, laying HDPE pipes is completely impossible. At low temperatures, performance may deteriorate and durability may decrease;

- Pipes are also not suitable for seismically active areas;

- HDPE pipes will not withstand pressure of more than 1.2 MPa - only thick-walled steel will help here;

- sensitivity to ultraviolet rays does not allow above-ground installation - polyethylene pipes are only suitable for underground installation;

- Due to the increased level of flammability of polyethylene, such pipes are not recommended for indoor use. Already at +80C the material tends to deform and collapse;

- HDPE pipes are not suitable for laying gas pipelines in collectors and tunnels. In such places, a steel analogue is used;

- When a gas pipeline crosses roads and other communications, the pipes must be hidden in a metal case.

It is better not to use polyethylene pipes for installing a gas pipeline indoors, but they are being used more and more often for underground installation.

For the production of pipes, special pipe grades of polyethylene are used:

- PE 80 – black pipes with yellow inserts, withstand pressure up to 0.3-0.6 MPa;

- PE 100 - pipes with a blue stripe, withstand pressure up to 1.2 MPa. When installing them, more serious efforts are made, since the material has to be heated to higher temperatures, but the quality of the connection in this case is excellent.

The diameter of HDPE pipes can range from 20 to 630 mm or more; even pipes with a diameter of 1200 mm are used. When choosing, it is also worth taking into account such an indicator as SDR - this is the ratio of diameter to wall thickness. The lower this value, the thicker the walls and the more durable the product. SDR ranges from 9 to 26.

The connection of polyethylene pipes is carried out in one of the following ways:

- butt welding The edges of the individual elements are heated with a special soldering iron until a viscous consistency is achieved, which allows you to easily connect two pipes into one;

- Electrofusion welding involves installing the edges of the pipe into a special coupling, to which voltage is applied, due to which the two sections are heated and connected. This connection is stronger than the pipe itself and can withstand pressure of 16 MPa.

With an individual connection to the network, butt welding will be sufficient, but if, for example, gasification of an entire region is taking place, then it is better to use electrofusion welding - it is more reliable and airtight.

To connect a section of a steel and polyethylene gas pipeline, special elements are used, one side of which is welded to the steel, and the other to the polyethylene.

Gas pipe in the kitchen: norms, rules, requirements

All work on moving and replacing metal pipes, especially those requiring welding, is carried out by representatives of Gorgaz or another authorized organization.

Having received an application from residents, they are always interested in the reasons for the planned transformations. Most often, it is necessary to change the piping in the kitchen without changing the layout or moving equipment to other rooms.

The reasons may be different:

- replacing old equipment - purchasing a gas water heater, stove or boiler - which requires a little more space;

- major renovation in the kitchen;

- moving the gas stove from the window 0.5-2 m towards the sink;

- changing the installation location of the gas meter;

- moving a horizontal pipe from a great height under a table top, etc.

Often, the relocation of pipes is required in new buildings, where the original location of significant kitchen objects defies logic and explanation: suppose, if in a 15-meter kitchen the gas stove is located near the window, the sink is in the opposite corner, and the hood is on the other side, above the entrance to the kitchen.

We have to correct the design mistakes and move the stove closer to the sink so that food can be cooked in comfortable conditions.

It is strictly forbidden to carry out work to move the gas riser. The only change allowed is to disguise the pipes with easily dismantled structures, for example, wall-mounted kitchen cabinets

The most common reason is the purchase of a new kitchen set with built-in equipment (oven and hob). In this case, the pipes need to be either shortened or lengthened, depending on the planned installation location of the devices.

If you want to find out how best to move a gas pipe in an apartment with redevelopment, we recommend contacting a design organization to draw up a transfer plan.

The fact is that in typical city apartments it is prohibited to reinstall risers, pipes, as well as any gas equipment in living rooms, and even to combine a kitchen and a room, permission is also required.

Hello, dear readers. If there is a gas pipe in the kitchen, special standards apply to it. This includes distances from surfaces and from household appliances. Proper installation of gas pipes throughout the apartment is also important.

The gas pipeline is installed in the apartment according to a previously developed plan. But even before this, it is necessary to determine the operating conditions of the gas pipeline. So, if gas units operate in the kitchen, it will become a mandatory element for them. Its presence in the boiler room is the key to warmth throughout the house.

For the positions of the gas pipe in the kitchen and apartment, the standards are as follows:

- No installation in residential areas or ventilation shafts.

- Intersection with openings for windows and doors is unacceptable.

- Laying in hard-to-reach areas is prohibited. For example, behind designer decoration on the wall. Gas equipment must be provided with quick and easy access in case of malfunctions.

- The minimum distance of the gas pipe from the floor is 2 m.

- When using thin-walled pipes, the length of flexible communication components should not exceed 3 m. The density of connections of network elements is also of great importance.

- Installation is permitted only in those rooms where the minimum ceiling height is 220 cm. And these rooms must be well ventilated.

- The kitchen should not be provided with ventilation affecting the living areas.

- Wall and ceiling surfaces close to gas appliances must have a special coating of non-combustible plaster. If there is no such coating on the wall, it must be insulated from gas appliances using a metal sheet. Its suitable density is 3 mm.

To lay a gas pipe in the kitchen of a private house, you also need to know the standards. To begin with, gasification here begins with notification of the local gas organization and the planned work. It provides a technological condition that determines the algorithm for constructing a gas pipeline. The technical issue is being resolved. A personal development for gasification of a certain area is created. Also, a warrant for the installation of a gas pipeline is issued by the traffic police.

If neighboring houses are already provided with gas, you only need to connect the pipes in a specific area to the main network. The working pressure factor is also important here. Its parameter in the main pipes determines the choice of pipes to pass into the house.

The preferred gas source determines the gas supply technology: centralized or autonomous.

Gas pipelines can also run to private homes underground or above it.

And the standards for installing pipes to the kitchen in a private house are identical to the points in the housing issue.

Installation standards

The rules and regulations for installing a gas pipe in the kitchen are as follows:

- Before work, close the main valve.

- The gas pipeline is purged if the pipe is moved.

- The pipe is secured to the wall. These are special clamps and brackets.

The type of fastener is determined by the length and diameter of the pipes.

- If there are electrical cables near the pipes, then the minimum distance here should be 25 cm. And gas equipment is 50 cm away from the electrical panel.

- Location near cooling equipment is unacceptable. In this matter, owners often make mistakes. Is it possible to place a refrigerator near a gas pipe? It is forbidden. So the refrigerator radiator can quickly overheat, and the device itself will become faulty.

- The minimum distance from the gas pipe to the stove is formed as follows: the branch to it goes only along the line of the connecting fitting. The shut-off valve is placed 150 cm from the floor and 20 cm from the side of the stove. The slab is installed using a heat-resistant flexible hose.

- Work should be carried out in a room with stable ventilation and natural light.

- The minimum ceiling height is 220 cm.

- The slab and the opposite wall must be separated by at least 100 cm.

- The surfaces around the pipes and slabs are covered with fire-resistant material - plaster.

- The pipes are routed so that the slab is 7-8 cm from the walls.

- The stove is used only in a kitchen that has a fence from the corridor: a wall or partition and a door.

- The height of the gas pipe from the floor is at least 2 m.

Another important aspect is the maximum length of certified gas hoses. In Russia it has no restrictions. In Europe it is 2 m. We can have products from 2 to 10 m or more. It all depends on the owners’ tasks and working conditions.

Transfer Aspects

When a gas pipe is in the way in the kitchen, it can be moved or disguised. In the first case, you must strictly comply with the regulatory requirements for moving the gas pipe in the kitchen.

The maximum length of flexible elements is 3 m.

The norm for a gas pipe in the kitchen in height from the floor is 2 m (minimum).

The connection areas must be rigid.

The pipeline itself should be painted.

The areas where the system intersects with the walls are “packed” - a special case is used.

Read more: What is better for cesspools - live bacteria or chemicals?

When working on a gas transfer network, block the gas before working.

You need to decide on your tasks. It is better to designate them schematically and show them to specialists.

And the decision to cut or move a pipe in the kitchen is the prerogative of special services. The owner can only indicate his plan. And the masters can approve or prohibit it. They will tell you what the price of such an update is, where it is better to start and who to contact.

The algorithm of actions in solving these problems is as follows:

- Contacting the gas company at the registration area. Create a statement about the desired changes.

- Based on the application, specialists arrive. They inspect the conditions, carry out checks and make the necessary calculations so as not to violate the norms for the location of the gas pipe in the kitchen.

- Creating an estimate. When the finished plan is in the hands of the customer, other formalities are settled, the client pays for the service. If necessary, the plan is modified.

If the work according to the customer’s scenario is not safe, or the estimate does not suit him, he can disguise the pipe. For example, purchase a special elegant box

If there are no dilemmas with the estimate, then within 5 days of its approval, craftsmen arrive to the customer. Before their visit, the client can:

- Contact them and find out if they need any consumables and resolve this issue immediately,

- Clear the area for dismantling old products and installing new ones. Workers should not have problems accessing the network.

- Protect all valuables, kitchen appliances and surfaces. A tarpaulin or similar materials are used for protection. After all, the work ahead is very dusty.

- The valve is blocked. Gas should not flow to the pipes during this period. It is easier to connect components using a siphon connection.

The work itself goes like this:

- To remove residual gas and debris, the pipes are purged (after the gas is blocked).

- The unnecessary component of the system is removed.

- The resulting hole is plugged.

- A hole is made at the location where the new element is installed.

- The new structure and other elements are welded here, if they are included in the project.

- The crane is being installed. The connecting areas are sealed with tow.

- The stove is connected. The standard is observed at what distance from the gas pipe the stove can be placed. This aspect has already been discussed here (the tap is at the level of the connecting fitting, the minimum distance from the side of the slab is 20 cm). With the upper variation of the wiring, the shut-off valve is placed at the lower end of the gas appliance. Distance from the floor: 150-160 cm. The gas riser is at least 20 cm away from the tap.

- A work completion certificate is generated and signed.

The question of camouflage

Is it possible to hide a gas pipe when there is no way to move it? It is possible and necessary. Special boxes are available for sale.

You can come up with your own plan on how to hide the gas pipe, and at the same time the counter in the kitchen.

If you have absolutely no idea how to do this effectively and harmoniously, look at the photo “How to hide gas pipes in the kitchen?”

Conclusion

It is necessary to install gas pipes in the apartment and in particular in the kitchen in accordance with current regulations. This is both compliance with the law and a guarantee of your safety.

Most of the goodies on the tables appear with the help of a natural gift - gas. Naturally, the owners of the house want blue fuel to enter the kitchen unnoticed, without destroying the harmony, integrity of design and style, which has been thought out for months. Meanwhile, utility networks are not a toy, you cannot joke with them, because in the pursuit of beauty you can lose the main thing - life. So, how and where should a gas pipe be installed in the kitchen: norms and rules for handling the system.

Types of steel pipes for gas lines

Most often during installation, gas steel pipes are used GOST 20295-85, 3262-75 (for laying water supply lines, gas pipelines and heating) and some others. According to the requirements of these regulatory documents, all pipes for these purposes must be made of low-carbon steel with a minimum content of sulfur and phosphorus. It is this material that ensures the necessary performance characteristics of the product.

Based on the manufacturing method, the following types of pipes used in the installation of gas pipelines are distinguished:

- Seamless hot- and cold-formed pipes. They are produced by piercing a cylindrical blank. In this case, a hollow cylinder is obtained, the final shape of which is given by rolling through a rolling line. Seamless metal pipes (solid drawn) are distinguished by increased strength characteristics and can be used for the installation of pressure category 1 networks. The only disadvantage of such pipes is their higher cost, so it is not always advisable to use them for laying household lines.

- Hot-deformed pipes can have a wall thickness of up to 75 mm. The main area of application is particularly harsh operating conditions and high requirements for product strength.

Hot deformed pipe

- Cold-deformed pipes have more modest parameters, so the wall thickness usually does not exceed 24 mm, and the maximum diameter is 250 mm.

- Welded pipes are produced by giving a sheet blank a certain shape and welding the joint on automatic lines, ensuring high quality welds. The main requirement for the production of such pipes is the presence of an effective multi-level quality control system. In modern mills, every technological process carried out during the production process is controlled.

Experts distinguish two main types of welded pipes for gas pipelines:

- Long-seam steel pipes

make up the majority of our products. Its seam line is parallel to the pipe axis, which significantly simplifies the welding technology. Most often, TIG welding (tungsten electrode in shielding gases) is used, which allows obtaining a high-quality welded joint. But recently, HF technology (welding with high-frequency induction currents) has become increasingly used; this method can significantly reduce the cost of production, while the time required to weld one pipe is also reduced. - A spiral-seam pipe

is also made from strip; it is rolled up in such a way that the seam runs across the entire surface of the product in the form of a spiral (twisted seam). Such products have a lower cost; their production technology is practically no different from straight-seam strip welding. The disadvantages include the fact that the tensile strength characteristics of a spiral welded pipe are somewhat worse. Because of this, there is a limitation on the pressure of transported substances; it should not exceed 16 atmospheres.

Most often, such pipes are used when installing local distribution of gas lines and installing intra-house networks.

Consumables and necessary equipment

To connect a pipeline to equipment or to connect different sections of a network to each other, connecting elements . Products are produced for plastic, metal-plastic and steel pipes. There are also universal and transition connectors that allow you to join products made of different materials.

There are several main classes.

- Couplings and adapters – fittings used to connect straight sections and extend gas pipelines. Also used to connect pipelines to taps or other equipment. Placed on a steel gas pipeline dielectric coupling for gas – it prevents the passage of electric current and increases service life. Adapters, unlike couplings, have different diameters at opposite ends. The elements are used for joining pipes with different sections.

- Angles and bends – connectors that allow you to change the direction of the line. Required in cases where bending is not possible. Connections by soldering, welding, or threading are allowed.

- Water socket - a special, mostly decorative element designed to connect pipes located inside the wall. This is a kind of external line output. Water inlets are made of bronze and brass.

- Tees and crosses - parts that connect not 2, but 3 or even 4 pipes. Used when organizing wiring for several rooms.

- Sleeves - resemble a short section of metal pipeline. A sleeve is needed when a gas pipeline passes through a wall or ceiling of a private house or apartment. It protects the network when the wall shrinks.

- Stubs – this part closes the pipeline branch. This type of fitting should not be confused with a temporary plug, which is installed during repairs.

Pipe components are made from materials with properties similar to the pipeline material. For steel products, fittings are made of cast iron, steel or brass for welding or threading. For plastic pipes, connecting elements made of the same material are used; for metal-plastic pipes, fittings are made of cryoplastic and metal-plastic.

HDPE pipes for gas pipelines

Low-density polyethylene is used not only for the manufacture of gas pipeline elements. It is also used for the installation of other communications - water supply, sewerage, protective technical pipelines. Types of pipes differ in composition, characteristics, and markings.

Let us dwell on products for gas transportation, the production of which is subject to the requirements of GOST R 50838-2009 (outdated edition - GOST R 50838-95).

Types and sizes

Polymer pressure pipes for gas can consist only of polyethylene or are reinforced with additional layers.

Thus, there are three types:

- polyethylene, including those marked with yellow stripes;

- polyethylene with co-extrusion layers located inside or outside;

- polyethylene with a thermoplastic protective shell, which must be removed before installation.

All types of pipe material are designed for transporting various gases that comply with GOST 5542 standards and are used as raw materials or fuel for industrial and domestic needs. Restrictions for the use of pipelines are accepted: max. pressure – 1.2 MPa, max. work. temperature -/+40°С.

Pipes are sold in packages of various types: products with a diameter of 200 mm and above - only in straight sections, thinner ones - in coils or coils

Industrial products are supplied in sections of 5-24 m, multiples of 0.25 m, but more often than average length, convenient for transportation by special equipment - for example, 13 m. Winding a thin pipe in a coil requires different lengths, but more often you can find coils of 200, 500, 700 m. It is possible to produce products of other lengths, but only by agreement with customers.

Depending on the thickness of the walls and slave. pipe pressures are divided into two types:

- PE-80. Wall thickness – 2-3 mm, working. pressure – 3-6 MPa; suitable for gas and water pipelines;

- PE-100. Wall thickness – 3.5 mm, working. pressure – 8-12 MPa; This is an improved version of PE 80, characterized by heat resistance and increased density.

PE (options - PE, PE) in the name is polyethylene, the numbers 80 and 100 are grades of polyethylene.

From the point of view of economic feasibility, the PE 100 grade is used when installing a high-pressure gas pipeline or in special cases - for example, for the reconstruction of an old worn-out main line or the construction of experimental branches with a pressure of 0.6 MPa and above.

Technical characteristics and markings

Factory-manufactured polyethylene pipes are subject to the requirements listed in GOST R 50838-2009. These include recommendations for appearance and technical properties.

Externally, the pipes must have a smooth surface, without bubbles, cavities or cracks. Foreign inclusions visible to the naked eye are also excluded. Only minor waviness and longitudinal stripes are allowed

In terms of color, the possibility of variability:

- PE 80 – yellow;

- PE 100 – yellow, orange, black with yellow/orange stripes evenly distributed.

The document also specifies standards for such characteristics as resistance at constant internal pressure, elongation at break, resistance to crack propagation, thermal stability, and weldability.

Manufacturers apply markings in various ways: heat-stamping, color printing, heat-stamping with dyeing. The interval between signs is no more than 1 m

Marking should not affect the quality of the material, that is, provoke cracks, swelling, etc.

Letters and numbers must be easy to read, legible and understandable. Mandatory ones include:

- trademark or name of the manufacturer;

- symbol of the pipe;

- date of manufacture;

- nominal diameter/wall thickness;

- appointment;

- GOST

The remaining data - country name, batch number, etc. - is provided as desired.

For example, let's look at one of the samples:

Sfera LLC PE 80 SDR 11 - 150x10.5 GAS GOST R 50838-2009

- LLC "Sfera" - manufacturer

- PE-80 – type of polyethylene pipe

- SDR 11 – standard size ratio

- 150 – diameter

- 10.5 – wall thickness

- GAZ - purpose

- GOST R 50838-2009 – regulatory document

By marking it is easy to determine whether the pipes are suitable for domestic or industrial use, whether they correspond to their intended purpose and diameter.

Obtaining approval for gas pipeline replacement

Whether a transfer is possible or not can only be decided by authorized bodies, that is, the gas service of your city (district). Only a qualified specialist has the right to carry out any dismantling and installation work. Of course, pipes cannot be moved without approval.

Even such a simple step as cutting a pipe by 10 cm must be approved, since all work related to the gas pipeline falls into the risk category

The permit is issued in the following sequence:

- Find out the contact details of the gas service at the place of registration, contact specialists, explain the situation, and consult.

- You draw up an application (using a standard form) that will “launch” the approval process.

- Based on your application, a gas service representative will arrive at your home. The time will be confirmed in advance.

- The specialist performs an inspection, listens to wishes, and answers questions. Often at this stage it is necessary to change plans, since the desired transfer does not meet safety requirements (a preliminary study of the gas pipeline installation standards will eliminate this unpleasant moment).

- Approval of the final transfer scheme, drawing up an estimate. All documents are prepared by the organization providing the services. No work will be carried out without the consent of the property owner.

- If the transfer conditions are met, pay for the service using a receipt and agree on the start time of the work.

Read more: How to cover pipes in a toilet with plasterboard with your own hands video

The approval procedure usually takes several days; it can drag on for a long period for only one reason: if the property owners and representatives of the gas service have not found a compromise solution.

Any factors that violate the installation standards for gas stoves (boilers, meters, water heaters) may cause refusal to move pipes.

It is not recommended to change anything yourself, even flexible eyeliner. All the more so, cutting, extending or moving pipes should be carried out by a representative of the gas service. However, knowing the sequence and some nuances of actions when working with pipes will not hurt the homeowner.

Usually a team of workers (most often 2 people) arrives within the next week after approval. By this point, it is already known which sections will be dismantled or extended, and whether additional equipment will be installed, for example, a geyser. Let's look at what else is worth considering.

Taking this opportunity, you can install a gas meter or completely replace outdated equipment. If additional installation is planned, workers must be notified in advance

All equipment used in the kitchen belongs to the owner of the apartment and is purchased at his expense, therefore, it is better to immediately ask what else needs to be purchased for moving appliances and working with pipes.

If we are talking about connecting a stove or oven, you will have to buy a bellows hose of a certain length. Installers bring metal pipes with them, their cost is included in the total payment for services.

To avoid any hiccups and for the work to proceed quickly, you need to free up space from excess furniture or other items. Anything that cannot be removed must be covered with thick, non-flammable material.

Most likely, when moving the pipe, you will need to cut off a piece of the old one and build a new one, but in a different direction. To do this, the master, using a special tool, removes unnecessary sections of pipes.

The qualifications of the craftsman authorized to move pipes are of great importance. Mechanics and electric welders undergo special training and certification, after which they receive the appropriate certificate

When dismantling the branch leading from the riser to the consumer, it is necessary to leave a small area on which the gas valve is attached. This horizontal piece of pipe cannot be removed or changed. The only exception is if the pipeline is damaged and requires complete replacement.

Sometimes residents of the top floors require the removal of a large piece of pipe that rises 1.8 m from the floor to the ceiling and then bends down 180°. It is strictly prohibited to cut the pipe and install a tap on the remaining section. The only way out is to weld the pipe so that the tap can be installed under the countertop, at a height of 0.75 m.

The transfer of pipes always follows the same pattern: they are moved parallel to the ceiling or walls, since diagonal and any crooked placement is prohibited. Consequently, most often the branch from the riser is lowered down, under the tabletop (rarely raised), or the vertical fragment is moved to the right/left.

A popular option for masking gas equipment: a faucet, which is easily accessible, is installed on a pipe passing below the countertop. A bellows hose is stretched from the tap to the device

When changing the direction of pipes, remember the following rules:

- internal gas distribution is an open system, all covering elements are camouflage in nature and should not be firmly fixed;

- It is prohibited to lay pipelines through ventilation ducts, as well as doors and windows;

- metal structures are predominantly used; flexible connections are allowed in equipment connection areas, but their length should not exceed 3 m;

- a rigid method of connecting pipes and hoses to pipes is used;

- Pipe transitions through walls/partitions are equipped with special adapters - sleeves.

Any work related to the transfer of pipes must begin with shutting off the gas. The organization providing the services is responsible for this.

According to SNiP standards, any changes in the position of pipes must occur by welding. Detachable connections between two sections are prohibited.

Threaded connections are used only when installing gas meters, household equipment and shut-off valves.

During the welding process, the worker must use only serviceable tools and use protective equipment: work clothes made of thick material, goggles (mask), gloves

Places burned by welding have an unpresentable appearance and also require protection against corrosion. After finishing the work, they must be treated with waterproof metal paint, matched to the color of the walls.

Before extending or moving a gas pipe, it is necessary to consider the option of installing a flexible transition. This is done using a bellows hose.

When choosing a flexible eyeliner, pay attention to its type. It is indicated in the technical specifications and is designated “fitting-nut”, “nut-nut”, “fitting-fitting”

Previously, rubber and rubber-fabric products were used, but the bellows turned out to be stronger than outdated materials. At its core, it is a metal or composite corrugation, but it has unique qualities.

For a long period of time, it maintains tightness and elasticity even under active mechanical stress. The structure of the shell is preserved even under high pressure of the transported medium or under constant mechanical stress.

The installation of bellows connectors is also carried out by a gas service worker. He connects boilers, columns, stoves and ovens in accordance with all the rules of the PUE and, if necessary, uses adapters and seals, for example, FUM tape.

They try to hide gas pipes in the kitchen behind decorative panels or furniture. Options for masking a pipeline are described in this article.

Procedure for laying a gas pipeline

Despite the fact that pipe installation should be carried out exclusively by professionals with the necessary qualifications, every owner of a private house should familiarize himself in detail with the procedure for carrying out the work. This will avoid troubles and unplanned financial expenses.

Installation of the riser and preparation of the premises

If a private house is gasified for the purpose of organizing heating, then you need to take care of the arrangement of the premises. The room with all the equipment should be separate and have fairly good ventilation. After all, natural gas is not only explosive, but also toxic to the human body.

The boiler room must have a window. This will provide the opportunity to ventilate the room at any time, which will avoid poisoning by fuel vapors.

As for the dimensions, the ceiling height in the room should be at least 2.2 m. For a kitchen where a stove with two burners will be installed, an area of 8 m2 will be sufficient, and for a four-burner model - 15 m2.

If equipment with a power of more than 30 kW will be used to heat the house, then the boiler room must be moved outside the house and be a separate building.

Gas is supplied to the cottage through an input device, which is a hole above the foundation. It is equipped with a special case through which the pipe passes. One end of it is connected to the riser, and the other is part of the internal gas supply system.

The riser is installed exactly vertically and the structure must be removed from the wall at a distance of at least 15 cm. The reinforcement can be secured using special hooks.

Subtleties of internal system construction

When installing a pipeline in a wall, all its parts must be passed through sleeves. In this case, the entire structure must be coated with oil paint. The free space present between the pipe and the sleeve is filled with tarred tow and bitumen.

It is necessary to ensure that as few threaded and welded connections as possible are used during pipeline installation. This approach will make the entire structure as reliable as possible. Accordingly, for this you need to select pipes of maximum length

Each of the units is assembled at the bottom, and at the height only the fastening of the preparatory components is carried out. If the diameter of the pipes does not exceed 4 cm, then they can be secured using clamps or hooks. For all others, it is recommended to use brackets or hangers.

Welding, assembly and acceptance rules

The following article, which examines in detail the options for heating units, will introduce you to the specifics of organizing autonomous gas heating. Independent craftsmen will find the boiler piping diagrams given in the material we recommend useful.

All components of the pipeline are connected to each other by welding. In this case, the seam must be of high quality and reliable. To achieve this, you must first align the end of the pipe and strip about 1 cm from each side.

As for assembling threaded connections, you need to use a special technique for this. First, the joint is processed using whitewash. The next step is to wind long-fiber flax or special tape. Only after this can the threaded connection be tightened.

As soon as the craftsmen finish the work, a commission should come to the house. She carries out pressure testing of the gas pipeline and checks the quality of installation. Moreover, the owner is required to be instructed on the rules for using the gas pipeline. Employees will also tell you how to properly operate equipment that consumes blue fuel.

How to understand who is to blame for poor pressure?

The following reasons for insufficient pressure in the water supply system are possible:

- clogs inside faucets, as well as in water filters;

- failure of mixers;

- fouling of pipes from the inside with plaque;

- breakdown of the filter element inside the geyser, if it is used in an apartment.

In these cases, the tenant himself is responsible for poor pressure in the pipeline, since the decrease in pressure was caused by a breakdown or clogging of devices that are located within his own apartment.

This property will be considered personal. The resident will have to clean the filters and faucets themselves or replace them completely.

It is recommended to first check all faucets with filters in your home. If necessary, you can gently tap the pipes with a hammer to get rid of excess lime inside them. Also, if you have a geyser, it is recommended to check the filter element inside it.

If the cause is not faucets with filters, as well as the pipeline inside the apartment, then it is necessary to check the connections of the pipes in the entire water supply system.

It is recommended to check the condition of the riser and all equipment installed in the basement of the house. To do this, you will need to contact the Criminal Code. The pumping station may also need to be checked.

Why gasify your house?

The main reason is cheapness and convenience. The difficult economic situation in the country is forcing owners of private houses to look for the most affordable option for heating the building. Therefore, it is not at all surprising that over time, cottage owners come to the conclusion that the building needs to be gasified.

Yes, of course, you can heat your home with electricity. But such a solution is quite expensive, especially if you need to heat several hundred square meters. And the vagaries of nature in the form of strong winds or hurricanes can break the cables and you will have to sit for who knows how long without heating, food or hot water.

Modern gas pipelines are laid using durable and high-quality pipes and parts. Therefore, natural disasters are unlikely to harm such a structure

Another alternative to gas is the old and proven method - heating using a fireplace or brick oven. The main disadvantage of this solution is that storing firewood or coal will lead to dirt.

In addition, it will be necessary to allocate additional square meters for their storage. Therefore, blue fuel will occupy a leading position for many years to come, and the issue of designing a gas pipeline to connect the private sector will be relevant for a very long time.

What types of plastic pipes are there?

- Polyvinyl chloride, or PVC, pipes are the most well known. Their distribution on the market is largely due to their affordable price, because they are relatively cheap. However, during use, as a result of chemical decomposition, these products release toxic chlorethylene. For this reason they are not suitable for use in water supply systems. For sewer installations, these pipes are suitable as a cheap analogue to cast iron ones. Being light and cheap, they will replace their predecessors without problems.

- Polyethylene pipes are a more profitable option, especially for those who want to install a cold water supply system. The material of these pipes in isolated form is stable. The temperature of liquids or gas that these products can tolerate reaches -25 degrees. This is much less than other plastic analogues. Unfortunately, when uninsulated, polyethylene pipes lose strength and, therefore, their effectiveness. To summarize, it should be said that this type of pipe is only suitable when insulated and only for cold transmission conditions.

- Metal-polymer pipes are similar to the previous ones, but the polyethylene layer is completely insulated. The benefit of the purchase lies precisely in the versatility of this type.

- Polypropylene pipes are one of the most advanced options on the modern plastic pipe market. The fact is that polypropylene is chemically inactive. Therefore, it does not need isolation. That is, it is highly resistant to external influences, which means it can be used in various conditions.

The low thermal conductivity of polypropylene prevents condensation from forming, which means that transporting gases or liquids through such pipes does not damage the substance being transferred. Pipes can also be manufactured to any length and diameter, so they are suitable for operations of any size.

Advantages of using it in laying a gas pipeline

Connecting to a device

Plastic pipes have found their place in the construction of gas pipelines, having many advantages:

- Plastic pipes are ready to last much longer than metal ones.

- They do not interact with the soil and do not conduct current, which allows them to be cathodic exposed.

- In terms of weight, gas pipes consisting of polyethylene are several times lighter than metal ones, so the construction of gas pipelines proceeds faster.

- The prices for such pipes are lower, so the construction of gas pipes from polyethylene is much more profitable.

- Replacing plastic gas pipes is faster due to the availability and ease of installation of new ones. And this is another plus, since if cast iron pipes fail, tens and hundreds of people can be left without gas for weeks.

Gas polyethylene pipes have low pressure (hereinafter referred to as HDPE). They are capable of transporting water and gas over any distance. HDPE pipes transport natural gas from the main line to your apartment. They are also used for the construction of underground gas pipelines, through which flammable gases flow. This is, on the one hand, transportation of fuel, and on the other hand, raw materials.

Can be used in both household and industrial sectors. Nowadays, low-density polyethylene pipes occupy approximately 90 percent of all gas pipeline systems. It is worth noting that when gas is supplied through a pipe, the sound is isolated. Plastic pipes for gas pipelines have an aesthetic appearance.

Installation features

The installation of plastic pipes has its own secrets. Flexibility and high suitability for concealed installation make work easier. However, when installing, it is worth considering their low strength, thermal expansion and sensitivity to ultraviolet radiation.

The range of plastic pipes is wide

The fewer connections your system has, the stronger and cheaper your system will be. Gas pipes made of polyethylene must be installed in special conditions in which there are no external influences. To increase the maintenance-free life, you should plan a network of gas pipes of the same material. Otherwise, various cracks and gaps will form at the joints.

In order not to damage the material, the elements should be connected by welding. Pipes that are not resistant to sunlight should be installed in dark areas to ensure their longevity. However, it is possible to determine how long gas pipes will last at the installation stage, since if any material is made from low-quality raw materials or is already damaged, then problems will begin to arise when assembling the system.

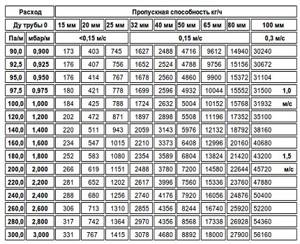

How to calculate the diameter of a gas pipeline?

When drawing up a project, special attention is paid to the diameter of the pipe. This will be done by the designer using complex formulas or a program

In order not to bother yourself with various formulas, a good choice would be to use one of the specialized programs. Fortunately, the Internet is full of such software. Using calculators is as easy as pie—you just need to fill in the fields with the appropriate information.

To determine the optimal diameter of the gas pipeline, you can use the table. To obtain the required value, you only need to select the required fuel consumption value

Standard prices for connecting a private household to main gas are given here. Owners of suburban areas should know “how much” gasification will cost.

Welding: little tricks

Special equipment was invented for this. There are three welding methods: electrofusion welding, butt welding and socket welding.

- Electrofusion welding uses a method of melting plastic as a result of the thermal effect of current and connection with a fitting. This welding is used on sections of gas pipeline connections. Socket welding is often used to connect polyethylene and polypropylene gas pipes.

- Socket welding is used for connections in sewer systems. It is also suitable for bathroom renovations of pipes with a diameter of 15 to 90 mm.

- Butt welding is used for almost any plastic gas pipes with a diameter range from 5 to 16 cm. Gas pipes eliminate the need for labor-intensive cutting work and in most cases eliminate welding work.

When choosing the nature of installation and the technology by which the system will be installed, it is necessary to study the characteristics of the polymer and the connection conditions favorable for it. For example, polyethylene pipes, regardless of the location of assembly, are connected to each other by connecting fittings. This method is the most durable only for this type of pipe.

You will need various accessories

For polypropylene pipes, an unusual welding method is used, in which the air is heated to approximately 270 degrees. With this method there is no usual solder. PVC pipes are held on with glue, because all other types of installation are unsuitable for this type of polymer. You should not treat such fasteners badly, since modern glue can ensure the operation of pipes for several decades.

Example of practical implementation

The gas line runs near a residential building, just 10 meters from the fence. When collecting documents, it turned out that the soil is ideal for laying the pipe and no additional measures are required to strengthen the pipeline

The house is located on a plot with a vegetable garden and trees, so when digging a trench we had to “loop” between pine and apple trees.

In total, the distance from the tie-in to the central highway to the basement input is 70 m. The depth of the trench is 1 m, width is 35-40 cm. This is enough to lay a pipe, and in case of repair, carry out replacement measures.

Next, the main line runs along the wall and is divided into two branches, one of which goes to the gas stove, the second to the household heating boiler.

There is an article on our website where we examined in detail the process of gasification of a private home. Recommended reading.

Installation

- How to install a gas pipeline in an apartment or private house?

In general, for any change in the configuration of gas equipment you need to contact Gorgaz. However, you and I are realists and we understand that it will take a long time to wait for a representative of this organization, and the price of the corresponding service will quite significantly hit the family budget.

Here are some simple tips that will help you avoid gas leaks and accidental damage to the gas pipe.

- Install the wiring under the ceiling. In this case, you will not touch the pipe when moving furniture;

The gas distribution is located under the ceiling of the room.

- As I recommended above, use maintenance-free connections whenever possible;

- Be sure to place a shut-off valve in front of the gas stove or boiler. I recommend using modern ball valves rather than obsolete plug valves. The purpose of the valve specifically for gas is indicated by the yellow marking on the body or handle;

Ball valve for gas.

- After installation, check each connection for gas leaks. The easiest way to do this is to apply soap suds to the fitting yourself. If there is a leak, it will begin to bubble.

Bubbling foam indicates a gas leak.

Categories of steel pipes and types of gas pipelines

To lay pipelines, different types of pipes for gas pipelines are used, which are divided into two categories:

- Seamless gas pipes can be hot or cold deformed.

- Welded pipes are distinguished by the type of seam; it can be straight or spiral.

In the production of both categories, the basis is carbon steel, the grades of which are specified in GOST 380-2005.

The chemical composition of the steel, as well as the type and size of the gas pipeline, are determined by the following factors:

- The amount of working pressure. This parameter can have a high, medium and low value.

- Pipeline location. It can be underground, above ground, underwater, or located indoors.

- Purpose of the system. The network can be backbone, distribution and backup.

The distribution system is designed to deliver gas to the direct consumer. Gas supply pipes may have a smaller diameter and thinner walls.

Sequence of replacing pipes in an apartment

It is strictly prohibited to independently carry out work with gas communications, because they belong to the category of increased danger. Seeking help from gas service specialists will not only significantly save time, but will also guarantee your protection.

An experienced gas technician will first of all carry out a preliminary inspection of the gas system and determine the degree of wear.

Replacement of gas pipes in an apartment is carried out in strict compliance with safety regulations.

First of all, it is necessary to ensure the presence of additional ventilation in the room, turn off the gas supply and be sure to blow out the pipes. Extreme attention is paid to the presence of open fire nearby, which is unacceptable and requires intervention.

After all preparatory measures have been completed, you can begin dismantling the required section of the gas pipeline. You don’t need any special tools for this; just having a regular hacksaw or grinder in the house is enough.

Insertion into a gas pipe is made using special fittings or overhead heating elements. Installation must be done in such a way that the structure is completely sealed and does not let gas into the room.

Currently, the buyer on the market has a rather small selection of pipes. On the one hand, these are steel pipes, which are very durable, but are afraid of aggressive environments, and on the other, plastic pipes, which are not afraid of corrosion, but they are much more fragile. But there are also metal-plastic pipes that combine the advantages of both materials. In this article we will talk about metal-plastic pipes for gas, their advantages and rules of use.

Main types of gas pipelines

There are three types of highways. The first is a low pressure gas pipeline. For such a system, the maximum permissible pressure is 5 kPa. Most often, this type is laid in small settlements. It is also used for gas supply to medical institutions, residential buildings, children's and public buildings.

For the second type - medium pressure line - the fuel flow can be supplied with a force of up to 0.3 MPa. The scope of application of this type is limited to the provision of gas to quarterly and regional regulatory stations.

As for the high-pressure line, it is intended for supplying fuel to large industrial enterprises. For owners of private houses, such a solution is irrelevant. After all, gas is supplied to the cottage using a pipe, the pressure in which does not exceed 5 kPa.

Details about pressure parameters and the classification of gas pipeline networks according to their value are written in the article, the contents of which we recommend that you familiarize yourself with.

Installation methods and their features

A gas pipeline can be laid using various methods. This is underground, onshore or underwater installation. In buildings, network installation can be done hidden or open.

Each variety has its own advantages and disadvantages. Therefore, before giving preference to any of the varieties, it is necessary to understand in detail all its features.

Advantages and disadvantages of the underground method

Until recently, the underground method was predominantly used when installing a gas pipeline. In this case, the pipes are laid in pre-dug trenches. Moreover, their depth must correspond exactly to the value specified in the project. Today this solution is used less and less.

The drop in demand is due to the high cost of this type of gasket. In addition, digging holes where the pipes will be laid will take quite a lot of time. Currently, engineers prefer the trenchless method. Its peculiarity lies in the use of equipment that can perform horizontal directional drilling.

Thanks to this, the cost of laying is reduced threefold, and the time required to organize the highway is reduced by at least two times.

The underground drilling method using HDD equipment eliminates the need to restore green spaces. Therefore, this kind of solution can be called as environmentally friendly as possible. Installation using this method involves drilling a pilot well, which is subsequently expanded to the required dimensions.

Next, the walls are strengthened using a special solution. To protect the pipeline from underground water flows and excessive mechanical loads, it is placed in a protective case. The final stage is pulling the pipes through the well.

External organization of the gas pipeline

The external method is used most often. In this case, the gas pipeline is usually stretched across the cottage yard. In this case, the structure must be protected from unauthorized persons. For this purpose, the pipes are located at a considerable height.