What is important to know?

The wiring diagram and methods of connecting a device such as a circulation pump to electricity can have different designs. The choice of a specific option is determined by the characteristics of the heated object, as well as the location where the device is located. There are two ways to connect it:

- direct connection to a 220 V power supply;

- connection to an uninterruptible power supply, which in turn is connected to a 220 V or 220/380 V network (in the case of a three-phase UPS).

By choosing the first method, the consumer risks being left without heating in the event of a prolonged power outage. This option can be considered justified only if there is a high degree of reliability of power supply, reducing the likelihood of a long power outage to a minimum, and also if there is a backup source of electrical energy at the site. The second method is preferable, although it requires additional costs.

Basic problems and methods for resolving them

In cases where vibration appears during operation of the device, extraneous noise occurs, or the pressure in the system changes, you should determine the cause and, if possible, troubleshoot the problem yourself.

When turned on, the pump hums, but the shaft does not rotate:

- The shaft jammed due to prolonged downtime. Remove the protective cap on the motor housing and rotate the shaft using a flat-head screwdriver;

- if foreign objects get in, disassemble the pump and clean the impeller, after which replacing the cleaning filter, which is installed in front of the device;

- problems with power supply (insufficient voltage in the network).

When turned on, the device does not work:

- there is no voltage in the network. Electrical wiring and protective automation are checked;

- The fuse has blown. Replaced with a new one.

Automatic shutdown of the device after a short period of operation:

Rules for installing and connecting the circulation pump

- accumulation of limescale in the stator cup. The glass and rotor of the electric motor are cleaned.

The pump makes a lot of noise when running:

- dry operation with air in the system. Release the air and make sure the pump shell is filled with liquid;

- cavitation. The pressure in the fluid supply line must be increased.

Excessive pump vibration:

- critical condition of support bearings due to severe wear. The bearings should be replaced.

Reduced head and flow compared to manufacturer's specifications:

- power supply failure or phase change, which leads to a drop in power or reverse rotation of the impeller. Checking the phases (three-phase motors) and replacing the capacitor (for single-phase power supply);

- the pipeline has great resistance to fluid movement (hydraulic resistance). Clean (replace) the filters, check the shut-off valves, and increase the diameter of the pipes if necessary.

Connection methods

Connection to the electrical network using a plug and socket . This method involves installing an electrical outlet in close proximity to the place where the circulation pump is mounted. Sometimes they can be supplied with a connected cable and plug included, as in the photo:

In this case, you can simply plug the device into the mains using an outlet located within reach of the cable. You just need to make sure there is a third, grounding contact in the outlet.

If there is no cord with a plug, they need to be purchased or removed from an unused electrical appliance. You should pay attention to the cross-section of the cord conductors. It should be in the range from 1.5 mm 2 to 2.5 mm 2. The wires must be stranded copper, ensuring resistance to repeated bending. The cord with a plug for connecting electrical appliances to the network is shown in the photo below:

Before connecting the circulation pump, you need to find out which of the three wires of the cord is connected to the ground pin of the plug. This can be done using an ohmmeter, while at the same time checking the integrity of the remaining wires.

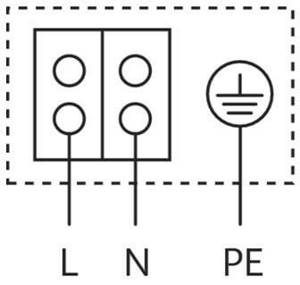

Open the terminal box cover. Inside the box there are three terminals designed to connect the device to the network, marked as in the picture:

We unscrew the clamp of the cable coupling (in the first photo it is a plastic nut into which the cable is inserted), put it on our cord, and insert the cord into the coupling. If there is a cable tie inside the box, thread the cord through it. We connect the ends of the cord wires, previously stripped of insulation, to the terminals.

The wires connected to the plugs of the plug should be connected to the L and N terminals (don’t be afraid to mix them up, this is not critical), the wire of the grounding contact of the plug should be connected to the PE terminal (but you can’t make a mistake here). The instructions supplied with the product prohibit its operation without protective grounding. Next, tighten the clamp (if any), tighten the cable sleeve clamp tightly, and close the terminal box cover. The pump is ready to be plugged into the mains.

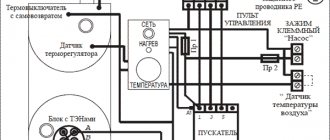

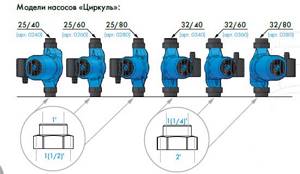

Fixed connection. The connection diagram for the circulation pump to the electrical network with grounding is provided below:

The requirements for the wire cross-section here are the same as in the previous version. The cable for this installation can be used either flexible or inflexible, copper, VVG brand, or aluminum, AVVG. If the cable is inflexible, the installation should ensure that it does not move. To do this, the cable along the entire route is secured with clamps.

In this option, a residual current device (differential circuit breaker) is used. Instead, you can use a regular single-pole circuit breaker, passing only the phase wire through it. If the machine is installed in a panel where there is a PE bus, then the cable from the pump to the machine must be three-core. If there is no such bus, the PE terminal should be connected to a grounding device. This connection can be made with a separate wire.

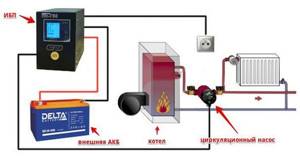

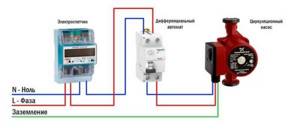

Separately, I would like to consider such an installation option as connecting the pump to the UPS. It is the most preferable and ensures the independence of the heating system from power outages. The connection diagram of the circulation pump to the uninterruptible power supply is provided below:

The power of the UPS should be selected based on the power of the pump motor. The capacity of the battery is determined by the estimated time of autonomous power supply of the circulation pump, that is, the time when the power supply is turned off. We talked about how to choose a UPS for a boiler in a separate article. Requirements for cable cross-section, as well as the presence of protective grounding, apply to all connection options.

Finally, we recommend watching video instructions for connecting various pump models to the electrical network:

So we looked at how to properly connect the circulation pump to the electrical network. The diagram and video examples helped to consolidate the material and clearly see the nuances of installation!

It will be useful to read:

Circulation pumps are installed in heating systems with forced or natural circulation. It is needed to increase heat transfer and to be able to regulate the temperature in the room. Installing a circulation pump is not the most difficult task; if you have a minimum of skills, you can do it yourself, with your own hands.

Installation diagrams in various types of systems

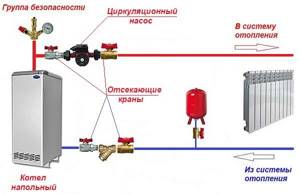

To begin with, let’s clarify the place where to install the flow pump, which circulates water through the boiler and forcibly directs it to the radiators of the heating system. According to our expert Vladimir Sukhorukov. whose experience is trustworthy, the installation location must be chosen in such a way that the unit is convenient to maintain. On the supply side, it should be located after the safety group and boiler shut-off valves, as shown in the installation diagram:

In order for the equipment to be removed and serviced, it is necessary to install shut-off valves

On the return line, the pump must be placed directly in front of the heat generator, and in tandem with a filter - a mud trap, so that you do not have to buy and install extra taps. The wiring diagram for the pumping unit looks like this:

When installing on the return, 1 less tap is used

Recommendation. A circulation pump can be installed in this way in both a closed and an open heating system, there is not much difference. The statement also applies to the collector system, where the coolant moves to the radiators through separate connections connected to the distribution comb.

A separate issue is an open heating system with a circulation pump, capable of operating in 2 modes - forced and gravity. The latter is useful for homes where power outages often occur, and the owners’ income does not allow them to buy an uninterruptible power supply unit or a generator. Then the device with shut-off valves must be installed on the bypass, and a tap must be inserted into a straight line, as shown in the diagram:

This scheme can operate in forced and gravity mode

Important point. On sale there are ready-made bypass units with a pump, where instead of a tap on the flow there is a check valve. Such a solution cannot be called correct, since a spring-type check valve creates a resistance of the order of 0.08-0.1 Bar, which is too much for a gravity heating system. Instead, you can use a petal valve, but it must be installed only in a horizontal position.

Finally, we will explain how to install and connect a circulation pump to a boiler that burns solid fuel. As mentioned above, it is better to place the unit on the line coming from the heating system to the heat generator, as shown in the diagram:

As you can see, the piping uses a pump connection to the boiler circulation circuit with a bypass and a three-way mixing valve. The important role of these strapping elements is described in detail here.

What is a circulation pump and why is it needed?

A circulation pump is a device that changes the speed of movement of a liquid medium without changing pressure. In heating systems it is installed for more efficient heating. In systems with forced circulation it is a mandatory element, in gravity systems it can be installed if it is necessary to increase the thermal power. Installing a circulation pump with several speeds makes it possible to change the amount of heat transferred depending on the outside temperature, thus maintaining a stable temperature in the room.

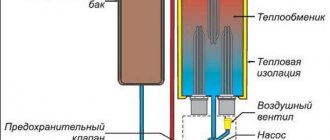

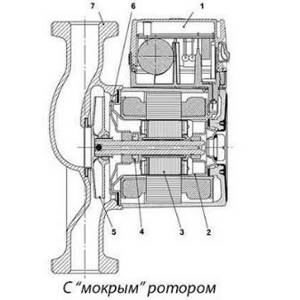

Cross-section of a circulation pump with a wet rotor

There are two types of such units - with a dry and wet rotor. Devices with a dry rotor have a high efficiency (about 80%), but are very noisy and require regular maintenance. Units with a wet rotor operate almost silently; with normal coolant quality, they can pump water without failure for more than 10 years. They have a lower efficiency (about 50%), but their characteristics are more than sufficient for heating any private home.

Application and purpose

Gilex Compasses are circulators designed for heating and cooling, air conditioning and ventilation systems. The purpose of the units is to circulate the working fluid in closed systems. When operating the devices, pipes of a smaller diameter are used than with natural circulation. Ensure uniform temperature distribution in systems. The series of units is distinguished by a wet rotor and a three-speed motor. The engine houses a unit for manually adjusting the speed of the working fluid in a closed system.

Gilex Compass ensures heating of the heated room and uniform distribution throughout all parts of the working fluid circuit.

Standard equipment for the Gilex Compass pump

The presence of a wet rotor allows you to regulate the system. It features high performance, energy efficiency and low noise during operation.

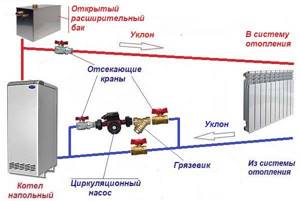

The lineup

The Gilex Compass series consists of six models with different characteristics.

Description of Compass models:

- 25 40. Circulation pumps Gilex Compass 25 40 operate with a temperature range from ten to one hundred and ten degrees Celsius. Creates a head of four meters. Throughput capacity is three cubic meters per hour. Has three speeds. Operates at room temperatures up to fifty degrees. Weighs three kilograms;

- 25 60. The difference between the model and the previous one is the created pressure of six meters and a throughput capacity of 3.8 cubic meters per hour. Creates a noise level of 65 dB;

- 25 80. The model creates a maximum head of eight meters. Capacity eight cubic meters per hour. Gilex Compass 25 80 pumps produce a noise of 45 dB;

- 32 40. Model of circulation pumps Gilex Compass 32 40 is made of cast iron. Works with liquid temperatures up to one hundred and ten degrees Celsius. Circulation pumps Compass 32 40 have a rated power of 32 W, a head of four meters, a weight of 3600 grams, a hole diameter of 1.25 inches;

- 32 60. The power of the model is 55 W, creates a pressure of six meters, and a throughput of 3.8 cubic meters per hour. Produces noise of 45 dB;

- 32 80. Pump model 32 80 The compass weighs six kilograms. The rated power of the device is 135 W. Circulation pumps Gilex Compass 32 80 operate at three speeds. The maximum pressure and throughput are eight meters.

Features of design and application

Compass devices have a number of features that distinguish them from other models and manufacturers.

Model range of pumps Gilex Compass

Features of the devices:

- The devices are highly efficient;

- used for domestic hot water supply and heating systems;

- Do not use in drinking water systems;

- wet rotor for all models;

- three-speed manual control motor;

- works with water and liquids with ethylene glycol;

- cast iron body, not subject to corrosion;

- mounted horizontally and vertically;

- Reducing the rotation speed reduces energy consumption and device volume;

- The package includes nuts for installation;

- low vibration level.

Harness

There are two types of heating systems - forced and natural circulation. Systems with forced circulation cannot work without a pump; systems with natural circulation work, but in this mode they have lower heat transfer. However, less heat is still much better than no heat at all, so in areas where electricity is often cut off, the system is designed as hydraulic (with natural circulation), and then a pump is installed into it. This gives high heating efficiency and reliability. It is clear that the installation of a circulation pump in these systems is different.

All heating systems with heated floors are forced - without a pump, the coolant will not pass through such large circuits

Forced circulation

Since a forced circulation heating system without a pump is inoperative, it is installed directly into the gap in the supply or return pipe (of your choice).

Most problems with the circulation pump arise due to the presence of mechanical impurities (sand, other abrasive particles) in the coolant. They can jam the impeller and stop the motor. Therefore, a mesh dirt filter must be placed in front of the unit.

Installing a circulation pump in a forced circulation system

It is also advisable to install ball valves on both sides. They will make it possible to replace or repair the device without draining the coolant from the system. Turn off the taps and remove the unit. Only that part of the water that was directly in this piece of the system is drained.

Natural circulation

The piping of the circulation pump in gravity systems has one significant difference - a bypass is required. This is a jumper that makes the system operational when the pump is not working. One ball shut-off valve is installed on the bypass, which is closed the entire time the pumping is running. In this mode, the system operates as forced.

Installation diagram of a circulation pump in a system with natural circulation

When the electricity goes out or the unit fails, the valve on the jumper is opened, the valve leading to the pump is closed, and the system operates as a gravity system.

Installation features

There is one important point, without which the installation of the circulation pump will require rework: it is necessary to rotate the rotor so that it is directed horizontally. The second point is the direction of flow. There is an arrow on the body indicating which direction the coolant should flow. This is how you turn the unit so that the direction of movement of the coolant is “in the direction of the arrow”.

The pump itself can be installed both horizontally and vertically, just when selecting a model, make sure that it can work in both positions. And one more thing: with a vertical arrangement, the power (pressure created) drops by about 30%. This must be taken into account when choosing a model.

How to choose a Wilo pump for a heating system

Wilo electric circulation pumps for heating systems of private houses are suitable for any type of water circuit, regardless of the diameter of the pipeline and the performance of the boiler. When choosing a suitable model, several important points are taken into account:

- Type of connections - models have a flanged and threaded connection of the pump to pipes. Flanged ones are designed for apartment buildings and large heated premises. Threaded ones are often installed in apartments and private houses up to 200 m².

Power connection

The circulation pumps operate from a 220 V network. The connection is standard; a separate power supply line with a circuit breaker is desirable. The connection requires three wires - phase, neutral and ground.

Circulation pump electrical connection diagram

The connection to the network itself can be organized using a three-pin socket and plug. This connection method is used if the pump comes with a connected power wire. It can also be connected via a terminal block or directly with a cable to the terminals.

The terminals are located under a plastic cover. We remove it by unscrewing several bolts and find three connectors. They are usually labeled (the pictograms are N - neutral wire, L - phase, and “ground” has an international designation), so it’s hard to make a mistake.

Where to connect the power cable

Since the entire system depends on the performance of the circulation pump, it makes sense to make a backup power supply - install a stabilizer with connected batteries. With such a power supply system, everything will work for several days, since the pump itself and the boiler automation “pulls” electricity to a maximum of 250-300 W. But when organizing, you need to calculate everything and select the battery capacity. The disadvantage of such a system is the need to ensure that the batteries do not discharge.

How to connect a circulator to electricity through a stabilizer

The performance of the heating system in many multi-story buildings cannot be called satisfactory. This is due to the small diameter of the pipes used through which the water flows and the pressure being too low. If you solve the second problem, then you won’t have to think too much about problem number one, since with the help of a good circulation pump it will be possible to ensure normal movement of the media along the wiring, thus increasing the performance of the entire system.

Electrical repair

The electrical part of the pump includes the following components:

- inductor;

- starting capacitor;

- connecting wires;

- control terminal.

If the stator winding breaks down, the pump becomes unrepairable; all other components can be repaired or replaced. To analyze the condition of electrical parts, you will need an ohmmeter.

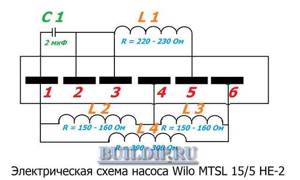

Photo of the circulation pump Wilo MTSL 15/5 HE – 2.

Main symptoms of malfunction

If the boiler display shows an error code corresponding to a water circulation problem, and it is not reset, the problem may be hidden in the electronic part of the device.

Circulation pump with cover removed.

To identify the problem you must:

- Turn off the heating mode in the boiler, and after stopping all components, turn off the power (soft stop).

- Open the front panel of the case.

- If the pump is covered with a large layer of dust, clean its surface.

- Using the information in the diagram, remove the control terminals and remove the terminal with the capacitor.

- Visually examine the condition of the pump contacts and terminals; they should be free of oxides, burnouts and mechanical damage.

- Using a tester in diode testing mode, determine the integrity of the connecting wires that go from the control board to the pump.

- Use an ohmmeter to determine the resistance of the inductors. On a working device, the instrument readings on the contacts will correspond to the following values:

- No. 1, 4 – 150 – 160 Ohm;

- No. 1, 6 – 290 – 300 Ohm;

- No. 2, 3 – 0 (contacts connected together);

- No. 3, 5 – 220 -230 Ohm;

- No. 4, 6 – 150 – 160 Ohm.

- The device will be considered faulty if the ohmmeter reading on any of the above pair of marks is 1 (winding wire break) or 0 (short circuit, except for contacts 2,3).

- Check the condition of the starting capacitor. To do this, switch the tester regulator to the 20 microfarad capacity test mode. Connect the probes of the device to the terminals of the capacitor and determine its capacitance. It should match the nominal ± 10%. Loss of capacity leads to a decrease in pump performance; it will emit an uncharacteristic hum.

Electrical diagram of the pump Wilo MTSL 15/5 HE – 2.

Measuring the resistance of the circulation pump windings.

Peculiarities

Not all manufacturers can offer a good productive liquid transfer station. As a rare exception, we can name the German concern Wilo, whose pumps can be presented in various variations. All proposed models are distinguished by high-quality ergonomics and modern controls.

Wilo pumps can be used to provide hot water supply to any heating systems and various air conditioning systems; they are considered the most versatile type of equipment, which is intended for small areas of the residential sector, supplying multi-storey buildings and industrial applications.

Advantages of pumps from Wilo:

- versatility and wide scope of application;

- significant savings;

- compact dimensions of components;

- corrosion protection;

- reliability and durability of the device;

- overheat protection;

- reliable cleaning system;

- reasonable prices.

The technical characteristics of Wilo heating circulation devices include several parameters.

- Convenient control in the form of a mechanical or electronic switch. You can adjust the power and speed of the coolant.

- Models with electronic control have a built-in thermostat.

- The electric motor and rotor will be protected from electrical surges.

- Operating characteristics of the device: water column pressure from 1 to 7.5 m, heated area - from 100 to 2200 m2, throughput - from 1 to 12 m3 per hour. Operating temperature parameters from -10C to + 110C.

The manufacturer offers the consumer an assortment whose technical characteristics are almost identical, the main difference being only in the flange parameters.

Wilo Star Series

The Star-RS unit is a low-power device that is perfect for home use. The body is made of high-quality cast iron, the impeller is made of plastic, and the shaft is made of stainless steel. Used for pumping clean water that does not contain abrasive substances or various impurities.

The RS series includes 12 samples, which are named from 15-4 to 30-8. These circulating heating products have a capacity of 6,000 liters per hour at a normal pressure of 10 atmospheres.

- Star-RS 25/4 is a surface-type pump for clean water, capacity - 3 m3 per hour, water pressure - 4 m, power 68 W.

- The Wilo 25/6 pump is purchased for supplying water to small heating systems and closed systems.

They can be chosen for apartment buildings and private houses.

- The circulation device Wilo Star-RS 25/7 for heating systems is a three-speed equipment with a threaded connection type.

- Product Wilo Star RS 25/2 with threaded connection and wet rotor. Designed for installation in air conditioning, heating and cold water supply systems, as well as in industrial systems.

- Wilo Star series Z Nova is a device with a wet rotor and a synchronous electric motor, resistant to blocking currents, used in industry for equipment of various types of structures.

- Wilo-Star-RS 30/8 units are used to work in different temperature parameters: with ventilation units, with various radiators, underfloor heating systems. And they are also used in air conditioning systems.

- Star-RSD is a dual mechanism that increases operational reliability: when the first mechanism breaks down, the second one starts working automatically. With another option, the devices operate simultaneously, but water will be supplied through different lines: separately for heating and hot water.

You can choose one of two models: 30-4 and 30-6.

Wilo Stratos-Eco

This is the most advanced electronic version, which was released for the operation of boiler rooms with low power. The device regulator will control the operation of any heating system, which guarantees savings in resource use and its operation at the lowest temperatures. The Wilo product is presented in seven markings: from 25/1-8 to 65/1-2, which are equipped with a wet rotor and are suitable for hot water supply with a large volume of oxygen.

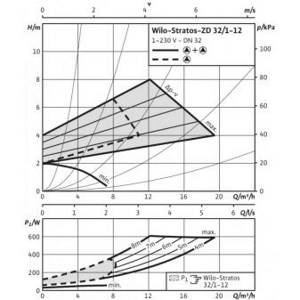

The Wilo Stratos-Zd has a pre-speed for continuous automatic day-night operation. Available in 2 types: 32/1-12 and 40/1-8.

Wilo Top and DHW

This series is used for heating systems of premises that have an area of more than 1,500 m2. Circulation devices of the Wilo Top brand have a water pressure of up to 10 m of water column with a working pressure of 10 bar. Among Wilo Top you can find flanged pumps.

- Top-Rl and Top-S are two-phase equipment that provides high-quality work in continuous mode. The pumps operate at temperatures from -20 to +130 C and can be used for a separate circuit in closed-type water supply and hot water supply systems.

- Top-S 40/10 – maintenance-free, has a threaded or flanged connection; If desired, you can select speed stages for precise power control.

- The Top-S 50/15 pump can be used for various water heating systems, air conditioning, refrigeration and industrial circulation systems.

- The Top-Z series unit is needed for pumping water for drinking. Silent operation is ensured by the wet rotor design. Full protection of such a motor is guaranteed by an electronic shutdown system.

Pumping equipment is placed even in the most unsuitable places.

Heating equipment Wilo

The company released these devices, which also work for domestic hot water supply, not so long ago. This equipment is adapted to water with a relative degree of hardness with a low content of magnesium and calcium. In models of this series, the impeller is made of stainless steel.

The modification was developed specifically for large heating systems. Such equipment can be connected to boilers with a capacity of 25 kW or more.

The characteristic features of the operation of the Wilo Stratos device with an electronic control unit can be considered:

- Wilo 2 product power – 48 W;

- there is a night mode when electricity use is reduced;

- automatic adjustment of operating parameters - the controller is connected to a thermostat, which will allow you to select the optimal speed and performance depending on your needs.

Wilo Yonos

It has an electronic control unit, protection against airing of the system and the function of removing solid particles from the environment of a specific coolant.

The lineup

The concern is famous for its fairly wide range of products. The Wilo CAD catalog contains 142 series, among which the most common are:

- Wilo-Economy-CO – multi-pump and single-pump pressure boosting stations. They are assembled on the basis of vertical pumps MVI, Helix V, MVIS, MHI. 2-4 units are installed in parallel in the station, which increases operational reliability and productivity. Supplied with storage tank and solids separation system and control panel. The pressure varies from 60 to 160 m. The flow rate, depending on the pump, can be 14, 75, 80, 135 cubic meters per hour.

- The Wilo-Multivert MVI family are outdoor centrifugal devices for vertical placement. They provide water for irrigation installations and are components of boiler houses and fire extinguishing installations. The design and dimensions of MVI allow you to save space during installation. The MVI 2 series consumes 5 cubic meters per hour, head - 220 m, the fourth series - 8 cubic meters per hour, pressure - 210 m, the eighth - 14 cubic meters per hour at a pressure of 225 m.

- Star – a line of models with a wet rotor and a threaded connection type. There are 3 speed modes available. The devices are used for cold water supply and heating systems. Pressure – up to 8 m. Consumption reaches 6 cubic meters/hour.

- TOP - compact circulation pumps, with the ability to connect it to a pipe. They operate quietly, are ideal for pumping liquid through pipelines in private homes, and are thermally insulated. Pressure – 9 m, flow – 65 cubic meters/hour.

- The Wilo Helix pump family is a multi-stage equipment belonging to the subtype of non-self-priming pumps with a flow rate of up to 93 m3/h and max. pressure up to 240 m. The units are equipped with a dry rotor, each unit has a frequency converter and air cooling.

- Stratos are highly energy efficient circulation devices. Applicable in heating systems, cooling circuits, air conditioning. The company also creates various control devices. For example, Wilo SK 702 is a device for controlling, protecting and monitoring pumps against overcurrent and dry running.

- The Wilo Comfort Vario pump line includes 3 series, differing in design features. The controller can connect up to 4 products in parallel.

Wilo Comfort Vario pumps

Popular models, their technical characteristics

The most popular models are:

- WJ 203 EM is a self-priming water supply station with a 50-liter tank and a power of 0.75 kW. Max. pressure – 41 m, flow rate – 5 cubic meters/h;

- Star-RS 25/4 is a circulation model of a balanced design, used in heating and hot water supply systems. Pressure – 4 m. Connected to the power supply, the unit operates in one of three stages of rotation. VIT has a 2-way cable drive, stamps;

- installation with a cutting mechanism for sewage disposal Wilo Hisewlift 3-35 with a power consumption of 0.4 kW and a direct start type. Rated rotation speed – 2900 rpm. Tank volume – 17 l;

- Wilo JET HWJ 204 is a portable self-priming jet device for horizontal installation, single-stage. Pumps water in supply/suction modes. Delivers water at a depth of up to 8 m thanks to the hydraulic power of the system. Power consumption – 1.3 kW;

- HWJ 202 EM Wilo device for water supply, irrigation, pumping rainfall, used mainly in garden plots; a 20-liter membrane tank helps reduce the frequency of switching on. Suction height is 8 m, pressure is 37 m. Max. water supply is 4.5 cubic meters/hour.

- Wilo Hisewlift 3-15 - automatic installations that remove waste water from the sink and waste water from the toilet. The tank volume is 17 liters. Power – 0.4 kW. Liquid temperature – from +5 to +35 degrees;

- Wilo RS 30/6 occupies a special place in the Star RS circulation model range. This is a standard pump with a wet rotor, the connection is threaded. Has 3 speed levels, manual control. Head 6 m, flow rate – 4 cubic meters/hour.

Device

The company produces pumps of two subtypes:

- with dry rotor;

- with a wet rotor.

Dry rotor pumps

This type of pump means that the rotor of the electric motor does not have contact with water. The connection of the motor itself with the working part is made using special sealing rings, which will not allow the liquid used to end up in the electric drive.

This unit consists of two parts: the 1st part is the electric motor itself, the 2nd part is a housing with two pipes - one discharge pipe, the other suction. In addition, it has an impeller that performs pumping.

This type of pump is used in systems with a fairly long length of pipelines and a large diameter. Most often they can be found in industrial and heating boiler houses.

Main indicators of the device:

- high level of efficiency - more than 80%;

- It is necessary to install filters to prevent foreign objects and particles from entering the product.

The room where this equipment will be installed must be free of dust, otherwise the O-rings will quickly become unusable. Replacing the rings will be quite difficult; only a specialist can do this. The connection type is usually flanged.

Wet rotor units

This product is often used for household needs. The design of such pumps will differ significantly from other models. The electric motor and impeller are located in the housing itself, which has both an inlet and an outlet. The coolant is transferred as if by the rotor itself, which is equipped with an impeller.

The bearings are cooled and lubricated by the pumped liquid itself. This product is used in heating systems with short lengths and small diameters of pipelines. They are connected with a threaded connection.

Key equipment indicators:

- almost silent operation;

- has the most compact design;

- if necessary, you can change the operating parameters, which will help seriously save on electricity consumption;

- long service life;

- requires almost no constant maintenance.

Models of units with a wet rotor for various heating systems are equipped with three-mode units for adjusting the speed of the impeller. These blocks are controlled manually. The temperature parameters in which such units can operate range from -20 to +130 degrees.

To correctly connect the selected pump, be sure to read the electrical connection diagram, and best of all, contact an experienced specialist.

Pumping station and its types

A pumping station is a complex system of pumping equipment that is used for pumping liquid and consists of a main pump and an additional pump, a tank or container for water, a hose, a pressure gauge for pressure control, a pressure switch and a fitting. Simple and common pumping stations in this design: a membrane tank, a self-priming pump and a pressure control relay.

Modern equipment has reached a high level and a dozen types of pumping stations have appeared. Stations that are capable of pumping liquid are divided into two types:

- household;

- industrial.

Domestic pumping units are necessary for water supply to private houses and cottages, cottages, farms and agricultural holdings, automatic and manual watering of gardens, personal plots and greenhouses. Such Wilo pumping equipment is widely used in water supply and sewerage sewer lines, where they collect and discharge wastewater to special treatment facilities.

Industrial pumping stations:

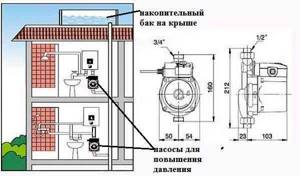

- Boost station. Such a station is used to increase pressure or to maintain it at a given level in a hydraulic line.

- Fire station. High pressure and pressure stations are used in fire extinguishing.

- Hydraulic. With the help of such stations, hydraulic tools are supplied with working fluid and tools under constant pressure.

- Modular. Used for collecting and draining wastewater. Most often, modular equipment is supplied ready-made and assembled. This increases reliability, quality and saves time during further assembly.

- Pumping and filtering. Such installations are necessary when it is necessary to provide drinking water to cities and villages. Modern filtration systems cope with the elimination of impurities and bacteria in water. Filtration occurs using ultraviolet purification technology without the use of chemicals.

Wilo pumps

Among pumping equipment, Wilo products have proven themselves. Vilo pumping equipment is of high quality and reliability.

About Wilo

Wilo SE is a world-famous manufacturer of pumping equipment in various fields: air conditioning systems, ventilated systems, plumbing, heating and fire extinguishing, founded in 1872. The company's main office is located in Dortmund, Germany, and has 60 representative offices around the world. Wilo was founded in 2002. The company uses innovative and highly efficient technologies for production.

Advantages of Vilo products

- low consumption of electrical energy by equipment;

- high level of build quality, mechanisms and components are carefully selected;

- pumping equipment from this manufacturer is easy to use and repair;

- low noise level of equipment during operation, which is appreciated by owners of houses and estates;

- availability of specialized Wilo service centers in major cities. This allows for quick service and repair of equipment.

Use of Vilo pumps and stations:

- Vilo pumps for houses with a small number of apartments and low buildings;

- Vilo pumps for houses, dachas, cottages;

- Vilo pumps for business buildings;

- Vilo pumps for industrial use;

- Vilo pumps for use by utilities and businesses.

Pump increasing pressure in water supply system

Installation

The installation of a Wilo unit in a heating system must be carried out in full compliance with the existing operating instructions provided by the manufacturer. There are several important rules to follow during installation.

- Only vertical installation of units from this company is allowed. Horizontal placement of Wilo pumps into the system is strictly prohibited. The only exceptions will be those models that are specifically designed for horizontal connection. The installation position of a specific pump can be found in the detailed instructions.

- Connecting a heated floor system - the device is installed in a special unit. The correct placement of the Wilo heating product will be indicated by arrows located on the body of the unit itself and on the hydraulic wiring.

- Connection to a radiator-type heating system - installation is carried out in the heating return, directly in front of the boiler. In order to prevent a complete stop of coolant circulation, a bypass is also installed here.

The rules for installing Wilo devices allow you to select equipment for heating systems with both natural circulation and forced circulation.

- Installation and maintenance - the pump is mounted vertically in compliance with the direction of the coolant, which will be indicated by arrows on the body and assembly. Installation should only be performed by qualified technicians.

- Methods for installing the device will depend on the selected model; as a rule, they are described in some detail in the instructions. If connected correctly, the Wilo pump will not require any special maintenance.

- You need to place a coarse filter on the bypass frame immediately in front of the pump. Only an experienced specialist can take into account all the specifics of installing a Wilo heating pump, disassemble and reassemble it, and carry out repairs. Installation of the device is completed in just 2-3 hours.

If you also install a bypass, it will take 4-6 hours.

Connection steps:

- the pump is assembled, the connection location on the circuit is selected;

- the water is turned off, a connection to the heating system occurs;

- the device is mounted, the main thing is to install it in the correct position;

- connections are tightened and sealed;

- the product is connected to electricity;

- the liquid is supplied to the circuit and the device starts;

- tested in operating mode.

An extraneous hum when the device is operating will indicate a number of possible malfunctions. The air vent may become clogged, resulting in air not being removed from the system. Another common malfunction will be an incorrectly selected operating mode.

Reducing the speed of the device with your own hands usually leads to the disappearance of the hum. If this does not happen, the pump needs to be serviced.

The most popular models of Wilo drainage pumps

- Pump Wilo-DrainTMT 32H102/7.5Ci. Submersible unit for vertical installation. Can be used for pumping hot water and aggressive liquid media.

- Drainage pump Wilo-Drain TMW 32/11. Used for pumping wastewater. Prevents the accumulation of settling substances and destroys them along with the pumped out liquid. Temperature environment no more than 35 degrees.

- DrinVC model. The vertical placement device can cope with contaminated media containing particles with a diameter of 5 mm. Type VC30/10 pumps water at a speed of 7 m³ per hour with a head of ten meters.

- The EMU KS unit is used for pumping wastewater from flooded basements or pits; grains with a diameter of 5-45 millimeters are allowed to enter.

Wilo produces universal equipment that can be used in different areas of life. Each drainage pump of this brand will delight you with its excellent quality and optimal technical characteristics.

Tips for use

We can offer several key recommendations that will ensure long-term operation of this type of equipment.

- You can leave the device in constant operation mode without fear.

- Experts advise sometimes turning on the equipment for 10-20 minutes after the heating season has ended.

- You can turn on the equipment only if the heating system is filled with media.

- Models that have a wet rotor in their structure use a coolant for lubrication. When turned on, if there is no lubricant, the bearings can burn out very quickly.

You can learn how to connect a circulation pump to a heating system from the following video.