Cats don't sleep on cold radiators.

The efficiency of the entire heating system directly depends on the performance of the boiler. Malfunctions of the main heating equipment negatively affect the efficiency of the home heating circuit and lead to excessive energy consumption. That is why any breakdowns, even the most insignificant ones, are given special attention. People’s experiences are understandable if the boiler is working and the radiators are cold. After all, this not only reduces the level of comfort in the house, but also entails expensive repairs. To properly solve a problem, you need to understand its essence. Only a specialist can correctly determine the reasons why the boiler does not heat the batteries. Also read: “Why do radiators heat poorly?“.

Reasons for frequent switching on and off of a gas boiler

It happens that a new installed device, after configuration and commissioning, begins to turn on and off too often. Although such a device should automatically regulate its operation, such a process clearly indicates a failure in the system. This can have a detrimental effect on the life of the device, because the working elements begin to wear out quickly, and the device itself will fail.

There are reasons why a heated boiler fires quite often. In any case, it is better to contact a specialist if you lack professional experience, because you need to be careful when manipulating blue fuel. The main reasons for turning heating equipment on and off at frequent intervals:

- incorrect device selection. The power is provided for a large room, and the unit was installed in a small room;

- incorrect installation of the circulation pump;

- the temperature range is incorrectly set;

- There is no thermostat in the room, for this reason the operating state of the device is adjusted according to the temperature readings of the coolant.

Important! This problem is quite simple, but there are times when the device has to be replaced with another model.

Incorrectly installed thermostat

In practice, two types of thermostats are used: built-in and remote type. The first option does not involve transfer. Remote models require proper installation. The installation should be carried out in the fastest cooling room, which allows the heating system to operate normally. Installation prohibited:

- in basements;

- near window and door openings;

- next to household appliances;

- very close to the surface of the ceiling, floor;

- under direct exposure to sunlight.

- Installation in kitchens is not recommended

Particular attention is paid to proper connection in accordance with the circuits recommended by the manufacturers, in accordance with the technical characteristics of the device.

Problems of open-type atmospheric boilers

There are a number of reasons that affect the working process of the device, which worked properly for some time, and then suddenly begins to go out.

Traction problems

To check the device for this problem, bring a lit match to the main window. If there is draft, then the fire will deviate to one side; if there is no draft, the flame will burn evenly.

The main factors influencing traction disorders:

- Lack of proper ventilation. The air intake is carried out from the room; a window is required for ventilation. Natural ventilation is required to maintain the flame. You must open the window to resume operation of the device.

- Weather. Adverse weather conditions negatively affect the working process of the chimney. If a foreign object gets into the shaft, backdraft may occur, leading to carbon monoxide poisoning.

- Ice formation. The accumulation of condensate on the shaft walls leads to icing of the part, and consequently a barrier is formed for normal draft and smoke removal. This reason must be eliminated in the following way - knock off the frozen layer, insulate the walls of the mine.

- Sooty accumulation. Simultaneously connecting a gas appliance and a solid fuel model leads to a similar problem. In this situation, it is better to resort to the help of utility services.

- Pipe burnout. The part must be completely replaced.

Healthy! A high-rise building located next door may block the house, for this reason the chimney is located in a leeward area, which negatively affects its operation. The recommended height of the shaft above the roof of the structure is more than two meters.

Reduced gas pressure in the line

If there is draft in the chimney, then you need to move on to the next step of checking the unit for fuel supply. A sign of reduced gas pressure at the inlet is the unreasonable extinguishing of the burner when the flame burns on the igniter.

The main factors influencing the reduction in fuel supply to the mains:

- clogging, breakdown of the meter - extraneous noise may occur. A working meter changes readings properly; if it fails, you will need to contact a specialist. Solving the problem yourself is strictly prohibited;

- triggering of protective sensors - modern models are equipped with gas control and temperature sensors. If there is a fuel leak, the operation of the equipment is blocked. You can identify an unfavorable area in a simple way: apply a soap solution to the connections; if bubbles appear, turn off the gas supply, open the windows to ventilate the room and immediately call the gas service;

- clogging of the fuel filter - you need to clean the mesh part, and after cleaning is completed, the wick and the main boiler burner are ignited.

Important! Before performing any manipulation with the gas pipeline, it is imperative to shut off the fuel supply with a shut-off valve.

Freezing of the head

The head is the outer element of the boiler; if ice forms on its surface due to low atmospheric temperatures, it is completely impossible to knock it down. To eliminate this factor, you will need to remove the part and defrost it.

It is quite possible to start the unit in this state, but before starting it you should warm it up: tighten the gas supply valve, then gradually unscrew it and light the burner. The supply should be increased little by little until the entire structure is heated to the point of thawing.

Lack and excess of air

Normal operation requires supply air through the ventilation duct or from other rooms. You should also not allow drafts, which could extinguish a low-power burner.

Causes of poor heating and methods for eliminating them

Let's consider what are the reasons why a gas boiler does not gain temperature.

The coolant temperature is incorrectly set

First you need to set the temperature on the unit correctly. This indicator may differ for different boiler models. Usually the maximum and minimum values are indicated in the instructions. Most boilers have a maximum temperature of 80ºC or 85ºC, but experts recommend setting it to no more than 60ºC. Since at high rates the water gets very hot, and scale begins to appear. Deposits cover the walls of the circuit, and its heat transfer deteriorates. This leads to the heat exchanger overheating, and the liquid does not have time to heat up enough. As a result, the heating system does not provide the optimal temperature. This problem can be solved by cleaning the heat exchanger from scale.

In modern models, the heating level of the coolant can be set not only by a person, but also by an outside temperature sensor. Depending on weather conditions, it automatically regulates the heating of the liquid in the circuit. If you have this device, adjust the temperature on it.

The power of the unit is incorrectly selected

When choosing a gas boiler, attention should be paid to determining the required power. If it is less or more than needed, this will lead to poor heating quality. If there is insufficient power, the unit will operate at maximum, but there will still not be enough heat.

If a gas boiler has too high a capacity, then a problem such as the unit’s clocking often arises: the gas boiler quickly gains temperature and turns off, and then turns on again after a few minutes. The room warms up poorly in this mode of operation.

This problem can be solved in several ways:

- inclusion of additional radiators in the system;

- unit settings change;

- replace the boiler with a less powerful option.

Burner not adjusted correctly

The reason that the gas boiler does not reach temperature may be improper regulation of the burner flame. In this case, the temperature usually does not exceed 50-60ºC. In this case, it is necessary to increase the flame strength using the burner regulator. To do this you will have to remove the boiler body.

Note! When adjusting the flame, you should monitor the main settings indications. You may need to increase or decrease the flame further.

Low coolant velocity

The reason for the lack of heat may be a decrease in the speed of movement of the coolant through the system. This may happen if:

- Leaks in radiators or pipes. You should first check all connections and joints. If a leak is found, it must be sealed. After this, coolant should be added to the system.

- Incorrect pump adjustment. Circulation pumps usually have a speed controller. To speed up the movement of the coolant, switch the pump to higher speed.

- Closed shut-off valves. You need to make sure that all radiators have a good supply of water.

- Airing the system. Trapped air delays the circulation of coolant in the system. To eliminate it, Mayevsky taps are used, they are opened and excess air is released from the batteries.

Automation malfunctions

Faulty temperature sensors can lead to insufficient heating of the boiler. One of them may send a false signal about the set temperature indicator, as a result of which the boiler will turn off.

To correct this situation, it is necessary to check the correct operation of the temperature sensors.

Weak output of combustion products

Poor draft restricts the flow of air to the burner and impairs the removal of combustion products. As a result, the burner device cannot maintain a stable flame. And due to difficulties in removing smoke, the unit overheats.

In this case, you should check the quality of the draft and, if it is weak, you need to clean the chimney.

Read about coaxial chimneys for boilers here

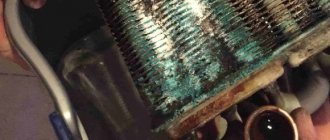

Heat exchanger clogged

If filters are not installed on the water supply pipes, sooner or later this will lead to the heat exchanger becoming overgrown with limescale from the inside. This layer of deposits will greatly impede the heat exchange between the circuit and the coolant. As a result, the heat exchanger will overheat greatly, and the liquid will remain slightly warm.

This problem can be solved by cleaning the circuits from scale. To do this, you should dismantle the unit, pour reagents into it and pump all the bends of the coil with a pump. To prevent this from happening again, it is recommended to install water filters.

Unstable gas pressure

If the cause of insufficient temperature rise is problems with fuel pressure, then you need to check the fuel valve. It needs to be unscrewed completely - it happens that excess lubricant interferes with the normal flow of fuel. Then you should remove any excess from the part.

Problems with closed-type turbocharged equipment

Sometimes when installing a new chimneyless apparatus, the flame periodically goes out. In this case, you need to check the components and parts. The problem is detected by the following factors:

- ignition of the igniter is accompanied by periodic attenuation - this indicates a failure of the thermocouple, which affects the operation of the valve. It is produced in the form of a copper tube with a bimetallic piece at the end. When different metals come into contact, the voltage increases to 20-45 W. This problem keeps the gas valve open. The thermocouple must be replaced with a new one; it cannot be repaired;

- breakdown or clogging of the traction sensor - the flat part is combined with the fuel valve. When the leading contacts are closed and the burner is ignited, a fire occurs - this indicates the need to replace the sensor. Oxidized areas of contacts can be cleaned with sandpaper with fine abrasives;

- if the circulation pump malfunctions, it is necessary to carry out a complete diagnosis of the unit and replace it;

- A yellow flame is due to the fact that the jet is clogged. You can clean it if you have experience working with gas appliances.

Most of the reasons can be eliminated with your own hands, however, this will require some knowledge and a lot of time.

Why can a gas boiler leak?

A leak from a gas boiler can be associated with both simple malfunctions and serious breakdowns. Minor costs will arise if the connections of water supply pipes , oil seals wear out, and seals wear out.

In a situation where the heat exchange chamber , the owner in most cases expects serious material costs, since this unit has extremely low maintainability , and its cost can be up to 50% of the total cost of the boiler .

The leak can also be caused by the built-in circulation pump .

Severe leaks sometimes occur as a result of a failed relief valve . This block is designed to discharge water when the pressure in the system is exceeded. If it malfunctions, a direct flow of water from the make-up system (plumbing) into the room occurs.

Malfunctions of electrical and gas equipment

Electric gas models need to be checked for voltage; to do this, just turn the plug over when inserting it into the socket to change the phase. In such devices, the main signs of failure are:

- There is no indicator light warning.

- No ignition when LEDs and operating display are on.

- The burner goes out after ignition.

The first step is to inspect the safety block. If the element burns out, a new fuse is installed. If this procedure does not help, you need to proceed to further study of the system:

- Cleaning the filter is carried out after completely turning off the device and closing the valves. The filter part is washed under running water and installed in place;

- If an air lock or excess fluid is detected in the pump, the main central screw is unscrewed, the air is released and the rotor of the device is turned with a screwdriver. After complete drying, the parts are installed back;

- low pressure in the system is eliminated by pumping the air mass into the area of the expansion tank located inside the structure. The pressure should be 0.2 bar lower than in the system itself.

These recommendations allow you to eliminate minor causes of breakdowns yourself without the help of professionals.

Self-diagnosis of Navien boilers

Automatic self-diagnosis systems, combined with protection systems, make it possible to prevent serious breakdowns at a very early stage. If any errors are detected, the electronics shuts down the equipment, displaying a code on the indicators or LCD screens. In the absence of self-diagnosis, troubleshooting becomes a little more difficult, but in general the algorithm for checking internal components remains approximately similar.

Self-diagnosis makes it easier to troubleshoot gas equipment in Navien boilers equipped with electronics. It interrogates numerous sensors and nodes, analyzing the results and storing them in internal memory. Critical errors are immediately displayed on the indicators. Self-diagnosis systems were originally created for specialists. But having at least a little experience in boiler repair and straight hands, nothing prevents you from repairing Navien equipment yourself.

Before attempting to repair Navien boilers yourself, make sure the warranty period has expired. If the device is still under warranty, call the service center - repairs will be free.

Repair of wall-mounted and turbocharged units

Modern products have a complex design, they are equipped with electronics and a security system. Even in such instances, you can eliminate minor problems yourself.

To detect malfunctions, you need to study the instructions for using the device. The technical documentation specifies the error codes that appear on the unit display. The heat generator does not work due to the following symptoms:

- The indicator lights do not light up, the heater does not turn on;

- Automatic ignition does not occur when the device is turned on, in which the display and network notifier are lit;

- Extinguishing occurs after the main burner starts.

In such situations, the voltage supply is immediately checked; if it is supplied to the device, it is necessary to proceed to subsequent repair points. Initially, the front panel of the device is unscrewed and the front cover is removed. The remaining manipulations are performed step by step:

- the fuse box is checked, if a faulty element is present, it is replaced with a new part;

- when the equipment starts, the work process begins;

- if the product turns on and stops working again, then you need to seek help from a technician, since this problem cannot be fixed without professional knowledge.

It is possible to eliminate other signs of device failure by describing the error code. You can deal with such breakdowns yourself:

- A clogged sump can be easily cleaned after disconnecting the generator from the electrical network and turning off the taps;

- Jamming of the rotor or the appearance of airiness affects the operation of the circulation pump. These causes are eliminated by unscrewing the large screw to bleed air and turning the rotor with a screwdriver. When completely dry, the parts are mounted in place;

- Low pressure on the pressure gauge without leaks in the system itself is eliminated by pumping air into the expansion tank;

- If the pressure is low due to a leak, the faulty area should be repaired and water added to the heating system.

Narrowing of pipe diameters

As a rule, blockages cause narrowing of the lumen in the pipeline system. When the riser is clogged, there is an increase in the resistance of sections of the heating system and a reduction in the flow rate of the circulating coolant. After identifying the blockage, hydraulic, pneumatic flushing or cleaning is used to narrow the diameter of the pipes.

Before performing this procedure, leaks are checked, disassembled and cleaned. Hydraulic flushing involves creating a high flow rate of water through the pipeline system. The used liquid with contaminants is discharged into the drain. In order to increase speed, pumping equipment of network, circulation or other types is used.

Pipeline cleaning is carried out in cases where it is impossible to remove the blockage using standard flushing. For this purpose, the clogged narrowed section of the pipeline is turned off, after which the coolant is drained. To clean disconnected pipes, a thick and fairly elastic wire with a fixed brush is used. At the final stage of getting rid of pipes from narrowings, the heating system is assembled in the reverse order.

Possible reasons

There are times when you purchased a new boiler, installed it and started using it. But it starts turning on and off randomly. Of course, it must regulate its operation itself, but there should not be frequent shutdowns. In this case, it is necessary to understand the reason. After all, this indicates the presence of some problems. If the device is often turned off and on, its service life is significantly reduced due to wear of the working parts. And, consequently, the boiler will fail.

There are several reasons for frequent shutdowns of the heating boiler. But if you do not understand gas boilers, it is better to contact a specialist.

Let's look at the possible reasons:

- The boiler power is designed for a larger area than there is in the room.

- The circulation pump is not installed correctly.

- The boiler is not selected correctly.

- There is no thermostat in the room. The boiler is regulated according to the temperature of the coolant.

- The temperature range is incorrect.

The problem is not complicated, but sometimes it requires replacing the gas boiler.

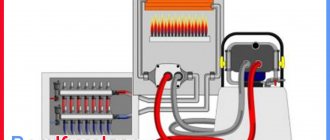

Problems with the heating circuit

The pump must be selected according to the requirements of the heating circuit.

Malfunctions in the operating mode of the heating circuit are not always associated with a malfunction of the main heating element. If the boiler works, but does not heat the batteries, the reason must be sought in the wiring itself.

List of main heating circuit malfunctions:

- the filter on the return line or the needle tap (Maevsky tap) is clogged;

- insufficient power of the circulation pump;

- the rules for installing a heating circuit with natural circulation have not been followed.

Excess power

Under no circumstances should you install a boiler of greater power than required for a particular room. It is necessary to accurately calculate the required power. After all, a lack or excess of power can negatively affect the operation of the equipment. Therefore, if you were unable to independently calculate the required power, then you can turn to specialists who will correctly carry out all the calculations.

But in order to determine the power, it is not enough to know the area of the heated room. The following factors influence the power value:

- House wall material;

- Material of windows and doors;

- Room area;

- Climatic conditions of your area.

But there are many resources on the Internet where you can find online power calculations. You can use them for an approximate calculation.

But if you bought a heating boiler and noticed that the power is much more than required, then you need to solve this problem. First you need to find out how often the boiler can turn on during normal operation. In order to ensure normal operation for a boiler with increased power, it is necessary to install a four-way mixing valve in the hydraulic system. This option will show excellent results. But you will also have to spend a considerable part of your funds.

If your appliance has a multi-stage burner, then you can try the method of lowering the burner.

Another way is to connect the boiler to the boiler. In this option, in addition to reducing the power of the gas heating boiler, it will be possible to provide the house with hot water supply. In order to determine the power of a single-circuit and double-circuit heating boiler, it is necessary to use different schemes. It is better to choose boilers with the minimum power required to heat your home.

In order to correct the problem of frequent boiler switching on, as well as reduce fuel consumption, you can use a thermo-hydraulic distributor instead of a mixing valve. It costs a lot more, of course, but the result is much more effective.

Navien boiler error 10

This error is related to the smoke removal system of the gas boiler. Combustion products must be removed; for this purpose, the boilers are equipped with a fan. To control the operation of the fan and determine the presence of permissible draft for boiler operation, a differential relay is used, which is connected to the turbine by two plastic tubes. When the fan is running, a vacuum is created, the relay closes, and the boiler functions normally.

Reasons for error 10

may be a clogged chimney, the presence of reverse draft, or incorrect connection of the air pressure control sensor to the fan. For the latter case, you need to check that the yellow tube is connected to the bottom of the fan, and the transparent one is connected to the top, and the tubes themselves are not damaged, deformed or condensation inside.

Increased resistance in the chimney can occur due to direct gusts of wind or blockage of the chimney (bird nest or cobwebs, freezing in winter). That's right, the location of the chimney should be taken into account the direction of the winds of a particular region at the design stage and the chimney should not be installed on the leeward side of the house.

We focused on the most common malfunctions of Navien boilers, but in fact there are significantly more error codes. Methods for checking and troubleshooting are the topic of a separate article. For convenience, here is a summary table of codes with a brief description:

I once wrote here about this boiler. Following the problem with the high temperature of the batteries, which has not yet been resolved, the following one appeared. During DHW operation, the boiler turns off spontaneously and immediately turns on. In 10 minutes of work it can glitch about 5 times. I called a technician - they washed the heat exchanger, swapped the temperature sensors of the circuits - to no avail. The master shrugged his shoulders and assumed there was a problem with the board. I also noticed that if you set the temperature higher, it turns off much less often, or does not turn off at all. What's the matter?

Thermostat device

Another common reason for the heating boiler turning off and on frequently is the lack of a thermostat. This means that the device is regulated only by the temperature of the coolant. When the water is heated to the desired temperature, the boiler turns off. And after the water begins to cool, the boiler turns on again. But the problem is that the air in the room takes longer to cool than the coolant. With this method of controlling the device, fuel consumption increases significantly. And the air temperature in the room will be elevated, and it will be uncomfortable to be in it. Therefore, it is necessary to install a thermostat. With its help, the heating gas boiler will be automatically controlled. After installing a room thermostat, fuel consumption will decrease and heating will become more comfortable and efficient.

Why are the radiators cold when the boiler is running?

Low efficiency of the heating system can be the result of malfunctions of both the circuit itself and the main heating element. In the case of a heating device, it is necessary to pay attention to the three-way valve, the functionality of the pump and the technical condition of the heat exchanger. Typical problems for heating wiring are a clogged filter, insufficient power of the circulation pump and lack of slope of the pipes of the circuit with natural water circulation.

Group: New Posts: 17 Registration: 11/4/2012 User No.: 169081

Group: Forum Participants Messages: 1365 Registration: 4.4.2010 From: CIS. User No: 50549

But an unknown problem appeared! The problem is this: I set the set temperature for the heating system and the following happens - the boiler heats the water five degrees more than the set one, the burner turns off, the pump continues to work, but at the same time there is a very sharp drop in temperature (in 1 minute T drops by 10 degrees) then the burner turns on again and everything happens according to the above cycle. This has never happened before. And the temperature outside today is not exactly low - 5 degrees. Last winter the boiler worked as it should. The temperature in the system rises, the burner turns off, and the pump circulates hot water for a long time, the temperature slowly decreases (30 minutes when it’s 40 outside), then turns on as usual. the burner gradually heats up, etc. The boiler does not give any errors, everything seems to be fine, everything seems to be working.

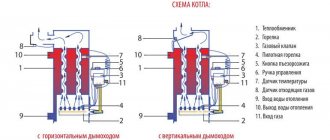

Types of wall-mounted boilers

There are three types of wall-mounted heating devices of this class on the domestic market:

- Navien atmospheric (open) boiler;

- turbocharged wall models;

- condensing devices.

Each of these positions requires separate consideration.

Atmospheric gas boilers

Units of this type have an open combustion chamber. Represented by the Navien Atmo model. It is intended for operation in conditions of uneven gas pressure (its differences can reach 8-17 mbar) and the coolant itself - from 0.6 to 8 bar. The power of the offered units varies from 13 to 24 kW. At an operating temperature of 80°C, the coolant heats hot water to 60°C with a production volume of 10 liters per minute. To remove combustion products, they are equipped with standard chimneys.

The heating circuit in atmospheric boilers is made of copper, and the heat exchanger body is made of stainless steel.

Only double-circuit units in wall-mounted and floor-mounted versions are supplied to the markets of Russia and the countries of the former USSR. A portable remote control is used to control the gas boiler. All samples of Navien Atmo products provide protection against freezing of the coolant; their efficiency is about 86%.

Turbocharged units

The group of units of the second type (with an isolated combustion chamber) includes models of the following series:

- Prime, represented by boilers with a capacity of about 13-35 kW;

- Deluxe, whose declared power ranges from 13 to 40 kW;

- modern Smart TOK models with an indicator of 13-35 kW.

Portions of air are forced into the isolated combustion chamber - they are pumped through a special fan installed in a coaxial pipe. Thanks to this, units with a Coaxial design have a higher efficiency, sometimes reaching a record figure of 93%. Gas boilers from the Navien Deluxe series are able to withstand significant changes in supply voltage, as they are equipped with a built-in stabilizing device. In addition, they have the option of automatically maintaining the temperature of the media at a level not lower than the “cooling point” (6-9 degrees).

Condensing boilers

The third type of Navien gas boilers is represented by samples of equipment from the NCN and NCB series. Due to additional heating of the carrier with the heat of the condensate, their efficiency was increased to 99%. The functionality of these units is even higher than that of turbocharged boilers - the controller built into them allows you to set temperature parameters for a week in advance.

The Navien NCN product series includes four varieties with power from 22 to 40 kW, and NCB has the same number of products with ratings of 24-40 kW. The water in them is heated to 65°C, and the coolant circulating through the pipes is heated to 90°C. These units are able to withstand media pressure up to 10 Bar.

The air supply in equipment of this class is organized through a coaxial or conventional chimney.

Conclusion and useful video on the topic

The video explains what clocking is, how such a negative phenomenon occurs, and also outlines ways to combat it:

The following video describes the situation with boiler attenuation in strong winds:

Frequent repetition of off/on cycles of any modern gas boiler directly indicates its unstable operation. And therefore, there is a malfunction or incorrect setting, which causes accelerated wear of the equipment. Therefore, having identified a problem, you should immediately begin to eliminate it.

Have you ever encountered interruptions in the operation of your gas boiler? What exactly was the problem you faced and how did you manage to overcome your situation? Please share your experience with our readers in the comments section.