The simplest and cheapest way to organize hot water supply is a double-circuit boiler, which simultaneously provides room heating and water heating. Popular designs are products under the “Ariston” and “Baksi” brands.” These models attract buyers and are among the TOP sales. Despite the simplicity of the mechanism and a large number of advantages, such equipment often fails. The boiler does not heat water for many reasons. Sometimes a little maintenance is enough to restore the device to its functionality, and in some cases an expensive overhaul is required.

Malfunctions of heating boilers

A dirty heat exchanger is a common reason for the lack of hot water in the DHW circuit.

Common boiler breakdowns include:

- coolant leak;

- water hammer;

- after turning on the burner, the lock is activated;

- the burner does not turn on;

- fuel burns unevenly, in waves;

- soot is formed;

- decreased productivity;

- During operation of the burner, the ignition is switched on;

- soot forms on the walls of the chimney and combustion chamber.

To resolve a problem, you must first determine the cause of the problem.

Built-in pump malfunction

The reason for the lack of hot water may be a clogged built-in pump.

An important part in the heating system is the circulation pump. The quality of heating and the functioning of hot water supply depend on its uninterrupted operation. There are several signs and causes of breakdowns:

- The unit makes uncharacteristic sounds. This occurs due to oxidation of the shaft, the entry of a foreign object into the structure, problems with the power supply, air in the pipes, dry running of the mechanism, and the appearance of cavitation.

- After turning on the boiler, the pump does not start. Perhaps there is no power supply, the fuse has tripped.

- After a short period of time after switching on, the structure switches off: limescale deposits in the stator shell.

- Hot water does not turn on in a double-circuit boiler.

Also, the reasons for poor operation of the circulation pump are poor pressure in the system, wear of the bearing, which causes additional vibrations in the line, and low pressure.

To troubleshoot problems, you need to check the presence of electricity, clean the pipes and other elements, replace failed parts, and remove foreign objects from the system.

The heat exchanger is clogged

Heated gases are transported through channels, which are collectively called a heat exchanger. The design features are that the walls of the artery simultaneously serve as partitions of the water circuit, along which the coolant constantly moves, heating the metal surface. The combustion process is associated with the intense release of flue gases, partly consisting of soot and tar, which create a deposit inside the boiler, on the chimney. Therefore, the manufacturer recommends regularly cleaning the equipment at least once every 30 days and during the preparation of the device for the heating season.

When soot settles on surfaces, the performance of the mechanism decreases, fuel consumption increases, and the risk of costly breakdowns and internal fire in the contaminated area increases.

Possible solutions to the problem

When you know the reason why the boiler does not heat the water, you can try to eliminate it yourself. Manufacturers often make mechanical components available for self-service.

Important! When troubleshooting problems on your own, before starting work, you must disconnect the unit from the electrical power supply and free the internal components from the coolant.

Further on the situation:

- If the heat exchanger is clogged, you can clean it using special liquids, or using proven home remedies for descaling. In the future, it is better to use filter devices at the coolant inlet to the boiler.

- If the cause is a faulty pump, you should disassemble it and inspect the rotor. If foreign particles are found that block free movement, they must be removed. The filter should also be inspected for clogging.

- When the cause of the malfunction is the water flow sensor, it is necessary to remove from it the part containing the turbine inside. If, when rotating with your finger, it begins to click or slow down as it moves, this means that there are foreign particles in the body. You should try to flush the turbine and clean each of its blades using a cotton swab dipped in cleaning fluid.

- The three-way valve, if it caused a boiler malfunction, also needs to be cleaned, and at the same time check the gas hose and filter.

- If the pressure is low, you should check all fittings and valves on the device, the pressure with which water flows from the mixer. If there are no leaks and the pressure is weak or absent, then simply replenishing water in the expansion tank will help solve the problem.

One of the main tips is to follow the operating rules and follow the manufacturers' recommendations. It is important to remember that prevention is always more profitable and better than repair. Timely maintenance and checking of the main components of the system will extend the service life of the autonomous heating device.

Use a water heater

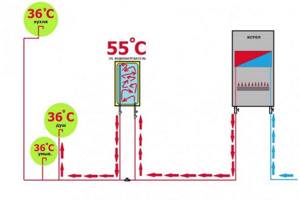

A water heater embedded in the hot water supply circuit acts as a buffer tank. Its purpose is to equalize the temperature of hot water and smooth out possible temperature surges. The storage water heater and the gas boiler heater are set to the same operating temperature.

Even if the hot water taps are turned on simultaneously at different points of its intake, all users will initially receive water from the storage tank. The time spent waiting for a comfortable water temperature is reduced. Unproductive water consumption is reduced.

Turning the hot water supply on and off at any point of intake causes a temperature difference in the water leaving the gas boiler. However, this water enters the lower part of the water heater, and when it leaves the upper part, the temperature jump is completely smoothed out.

Connecting the water heater through a ball valve allows you to switch to a conventional gas boiler operating system at any time, which can ensure uninterrupted hot water supply in the event of a water heater failure.

Using a bypass jumper with a tap in close proximity to the boiler allows you to exclude the boiler from the hot water supply system. If the boiler is under maintenance, using the existing water heater will ensure uninterrupted operation of the hot water supply system.

Use an expansion tank

In winter, when the boiler's heating circuit is activated, any activation of hot water results in the heating circuit being turned off so that the hot water supply circuit can turn on. In the summer, when the boiler's heating circuit is not activated, each turn on of the hot water leads to the gas boiler turning on.

Often the user opens the hot water tap to simply rinse his hands. The boiler turns on or switches, hot water flows through the pipes. But the user may simply not wait for it, washing his hands with cold water.

Meanwhile, frequent and useless turning on and switching of the boiler “eats up” its operating life. A possible solution is to install a small expansion tank. It is installed in front of the water heater. If there is such a tank, for the first time after turning on the tap, hot water enters the pipe exclusively from the water heater due to the increase in pressure in the tank. Thus, in case of short-term use of hot water, there is no need to turn on and switch the boiler.

It is recommended to use a tank designed for hot water supply. Using a tank intended for heating will cause an odor because its membrane is made of rubber.

Use a recirculation pump

The best option is that the water heater is located in close proximity to the hot water intake points. The closer it is, the faster the hot water enters the tap, the more efficiently it is used. If this option for installing a water heater is not possible, then it is recommended to install a recirculation pump.

The pump is installed in the section between the water heater and the hot water intake points, ensuring the slow movement of hot water through the pipes. In addition, if you install a heated towel rail in this section, it will perform its direct function at any time of the year, regardless of the operation of the heating circuit of the boiler.

Sources

- https://kotle.ru/gazovye-kotly/kotel-perestal-gret-vodu

- https://boilervdom.ru/kotly/problemy/gazovyj-kotel-ne-nagrevaet-vodu-prichiny-i-sposoby-ustraneniya-problemy.html

- https://StrojDvor.ru/otoplenie/prichiny-pochemu-kotly-ne-greyut-goryachuyu-vodu/

- https://utepleniedoma.com/otoplenie/kotel-rabotaet-a-batarei-xolodnye

- https://www.tproekt.com/pochemu-kotel-perestal-gret-vodu-prichiny-i-sposoby-resheniya/

- https://eurosantehnik.ru/reshaem-glavnuyu-problemu-gazovyx-kotlov-s-goryachej-vodoj.html

Three-way valve does not work

Depending on the model, the part plays the role of a flow separator, switch, or mixer. Loss of device performance often leads to overheating and incorrect coolant temperature.

Causes:

- violation of the integrity of the electric drive;

- wear of the flow distribution mechanism;

- malfunction of the electromagnetic coil;

- presence of condensation;

- power surge;

- stray currents;

- entry of a foreign body.

To diagnose and fix the problem, it is recommended to call gas specialists with appropriate qualifications. You can blow it yourself and release the resulting air plug. During the repair process, worn out seals, non-working elements or the entire valve are replaced.

Features of Navien gas boilers

The Navien double-circuit gas heater stands out among a huge number of competitors for its compactness and attractive design.

Even if low-quality gas is used, subject to the requirements and recommendations of the manufacturer, the Navien gas boiler will please the owner with reliable and long-term performance of complex and expensive repairs.

The Navien gas boiler is capable of maintaining functionality with voltage drops of up to 30%, a drop in gas and water pressure in the supply lines. Navien boilers, regardless of type, are equipped with systems that guarantee uninterrupted operation under various operating conditions. The antifreeze system will prevent water from freezing during the cold season.

The control system is intuitive and can be adjusted remotely. The design uses steel heat exchangers, guaranteeing high efficiency and long service life.

The air pressure sensor used in the circuit ensures complete combustion of the fuel, which leads to lower costs. The water heating mode is activated simultaneously with the opening of the hot water tap. The burner automatically starts up, and when the tap is closed, the system goes into standby mode. The boiler heats water only for the heating system. The winter-summer mode automatically switches the system to DHW or vice versa.

The Navien boiler has a closed combustion chamber. The coaxial smoke removal system prevents combustion products from entering living spaces.

A wide range of temperature settings, both room and hot water, makes the Navien boiler competitive even with representatives from high price categories.

Problems with the heating circuit

Often, the reasons for a malfunction in the functionality of the main line are malfunctions in the wiring:

- return filter clogged;

- incorrect installation of the heating circuit;

- insufficient pump power.

It is recommended to eliminate all of the above problems during preparation for the heating season, otherwise you will have to stop the operation of the unit and completely drain the coolant.

To eliminate clogging, the filter is cleaned, the circuit is washed, and the coolant is completely replaced with a new one.

A lack of power occurs due to the presence of branches located remotely from the pump or due to insufficient performance of the device. As a result, the equipment overheats, energy consumption increases, the batteries do not heat up to the required temperatures or remain cold. In this case, there is only one way out - replacing the pump with a more powerful analogue.

If there are errors during the installation process - an incorrectly selected line slope - it is recommended to redo the wiring, entrusting this matter to professionals.

Errors and their codes

Error codes that may occur during the operation of Baksi gas boilers can be divided into two groups:

- complete blocking of equipment operation;

- switching the device to standby mode.

If the installation is completely blocked, you will need to restart the boiler manually. The blocking is activated if serious problems occur in the boiler operation, which can pose a serious danger to human health. Failures that cause the boiler to block include overheating of the equipment, and in addition, lack of draft. Blocking also occurs if there is no gas supply. The error resolves itself in rare cases. If this happens, the device starts in automatic mode.

Error E01

This error is the most common. When the flame control sensor is triggered, this code is displayed. Several reasons can lead to its appearance:

- no gas supply;

- there is no correspondence between phase and zero; this reason is relevant for phase-dependent models;

- no contact with flame sensor;

- the sensor is dirty or faulty;

- there are malfunctions in the ignition system;

- the gas valve is faulty or the electronic board is faulty;

- air access is insufficient for normal combustion;

- The gas pressure in the system is insufficient.

If this code appears on the display, then the first thing to do is check whether the sensor is connected correctly. It is also worth checking the gas supply. If everything is normal, then in this case you can press R. It should be held for 3 seconds.

If accidentally triggered, the equipment will continue to operate normally. If the error continues to appear, then in this case you should contact a specialist . Note that the occurrence of this error is associated with problems in the electronics. If you try to solve the problem on your own, then everything can end disastrously for gas equipment.

Error E10

Another common mistake is E10. The main reason for its occurrence is sensors that monitor the operation of pumps and monitor water circulation. This error may appear on the unit display in the following cases:

- the coolant pressure in the system has decreased;

- there is no contact between the board and the pressure switch;

- pressure switch is faulty;

- the pump operation sensor has become faulty;

- there are malfunctions in the pump;

- heat exchanger clogged.

If this error occurs, you should not try to fix it yourself. Self-repair is acceptable if the pump needs to be replaced. Carrying out this event will not be difficult. You can also clean the filters without assistance. All other work related to the repair of the Baksi boiler should be performed by an experienced specialist.

Errors E96, E97, E98

Urgent repairs by a qualified specialist are required if the gas boiler display shows errors E96, E97, E98. If they occur, it is unacceptable for the owner of the equipment to interfere with the operation of the boiler. The prohibition on intervention in the event of these errors is due to the fact that these three codes appear when the electronic board has become faulty.

Causes of poor water heating

Gas boilers do not heat water for several reasons:

- clogged heat exchange pipes;

- pump malfunction: rotor jamming, air lock;

- problems with the flow sensor;

- three-way valve failure;

- insufficient pressure level.

To eliminate the malfunction, it is necessary to find the cause and carry out a number of works corresponding to the problem:

- flush the system using specialized compounds and install a filter at the coolant inlet to the boiler;

- remove all foreign particles that interfere with the functionality of the rotor or the water flow sensor;

- clean existing filter elements from dirt;

- Clean the three-way valve and check the gas hose.

If the Baxi boiler does not heat hot water due to low pressure, it is recommended to check the pressure level, fittings and valves. If there are no leaks or other technical problems, you need to add coolant to the expansion tank.

Why does the boiler not heat water for the heating system?

There can be many reasons why a gas boiler does not heat water for heating. We will consider the main ones and ways to eliminate these reasons below.

The boiler turns on, but the heating does not heat.

Possible causes and their elimination:

- First of all, you should check whether air has accumulated in the batteries; using taps, you need to remove air from the system. To avoid air venting, install an air vent.

Battery bleed valve