Sometimes, immediately after lighting the boiler, smoke comes into the room. This may be due to the weather and a long pause in the operation of the unit - the temperature in the room has become equal to that outside and the draft has disappeared. In this situation, you just need to wait until the chimney warms up and normal air circulation is restored. If combustion products return to the room frequently and regardless of the temperature difference, you should be wary. After all, this indicates serious problems in the system.

Why does a solid fuel heating boiler smoke?

Solid fuel boilers for the home help create fairly comfortable heating, and can help the heating system cope with increased demands.

They have enough advantages, but require maintenance from time to time, and always with care for fire safety purposes. p, blockquote 1,0,0,0,0 —>

- Reasons for smoking of a solid fuel boiler

- Troubleshooting

- Causes of reverse thrust

- What to do when a solid fuel boiler smokes: a real example

In this article we will look into this question that often arises among owners, why the heating boiler smokes and what to do in such cases. Often, the problem lies in the chimney pipe.

p, blockquote 2,0,0,0,0 —>

Smoke from the boiler into the room

Troubleshooting

All possible answers to the question “Why?” described above. And now the second question: “What to do?” if a solid fuel heating boiler smokes?

For kindling, you need to choose only dried logs, which should be stored under special covered sheds so that minimal moisture gets on the fuel. There is no need to use artificial materials as fuel.

Heating devices such as Buderus Logano SW, Stropuva S and Zhitomir D are heated only with dried wood. If you want to use different types of fuel, you should think about purchasing universal units, for example, KST or Dymok.

You can test the degree of gate opening in air-heated versions, such as Siberia. If smoke appears, the chimney opening should be made larger.

It is necessary to ensure the flow of air masses to the boiler. According to safety rules, the window must be open all the time while the boiler is operating during the heating season. A solid fuel boiler needs to be cleaned from time to time.

Shed for firewood made of profile pipe and polycarbonate

If smoke comes into the room from a gas boiler

A wall-mounted or floor-standing boiler and AOGV can smoke for two main reasons: a malfunction of the chimney or poor gas quality.

First of all, it is necessary to inspect the chimney and carry out the following work:

- The presence of traction is checked. This can be done either with a special measuring device, or by holding a lit match. The flame should deviate noticeably towards the boiler. If this does not happen, it means that the chimney for some reason does not pull smoke out.

- View the pipe using a mirror and a flashlight. If necessary, remove snow and foreign objects. If you cannot do this yourself, call a chimney sweep.

- If you heat with damp wood, you need to clean out the accumulated tar from time to time.

- Replace the chimney with a suitable type and diameter for this model. For example, the Lemax Premium device requires a chimney with a diameter of 200 mm. Increase the length of the pipe; in your house, its end should end above the ridge of the roof. Insulate the outside with glass wool.

- Inspect the chimney for cracks. Pay special attention to connecting seams. Remove right angles when turning and make transitions smooth.

In the room where the gas boiler is located, a window must be open to allow air to enter. This is especially true during the cold season in high-rise buildings, where a layer of cold air may prevent combustion products from escaping.

If you heat with a gas boiler and use cylinders rather than a centralized gas pipeline, it is important to purchase high-quality liquefied gas from trusted manufacturers. The Ross Lux model allows you to do this.

What to do if the boiler is smoking

Regardless of why the smoke began to appear, it is necessary to stop the kindling and conduct a visual inspection of the equipment for damage.

IMPORTANT! Particular attention should be paid to the traction stabilizer if it is built into the exhaust gas exhaust system. Sometimes it is enough to adjust the confuser or check the condition of the interrupt valve to get rid of problems for a long time.

Smoke immediately after installation of the equipment indicates errors made during installation. In this case, it is necessary to double-check all components and connections to ensure the integrity of the chimney and its correct installation.

At the beginning of the heating season, smoke in the boiler room indicates clogging or damage to the exhaust gas removal system. Usually, after eliminating the problems, traction is restored.

If a gas boiler smokes when starting up, and then everything gets better, then it makes sense to check the burner. When clogged, it not only produces soot, but also reduces the performance of the unit. In a solid fuel boiler, the cause of the “starting” smoke is often the low quality of the firewood.

The main reasons why AOGV gas boilers smoke

There are usually two reasons why AOGV gas boilers smoke:

- low gas quality;

- chimney problems.

You should check the presence of draft in the chimney using a lit match brought to the entrance to the channel: if the fire is deflected, then draft is present; If the flame burns evenly, then there is no draft. If there is no draft, check the chimney to see if it is clogged, if there are cracks in the pipe or ice crust on the tip.

Problems with a solid fuel boiler

Sometimes the heating device smokes due to the banal filling of the ash pan.

Before looking for another possible source of problems, you should empty the ashpit and check the condition of the grate. The second most common problem with a solid fuel boiler is a clogged chimney. The reason is poor quality fuel. When using damp firewood or wood with a high resin content, not only soot is formed, which easily crumbles after tapping on the chimney casing. Resinous soot with a high moisture content adheres firmly to the walls, after which it hardens and narrows the diameter of the pipe.

ATTENTION! If damp firewood is used and the smoker is not properly insulated, this leads to the formation of condensation. In combination with soot, it turns into a caustic substance that can damage the chimney. When the pipe is corroded, traction is disrupted.

Removing breakdowns of solid fuel models

Solid fuel boilers may have the same causes of smoke associated with the chimney as those described above for gas appliances. When using a combustion chamber, thoroughly dried raw materials must be used. It should be stored in well-designed places with low moisture levels. Do not use synthetic-based materials as fuel.

Wood-burning boilers, for example Buderus Logano SW, Stropuva S and Zhitomir D, should be heated only with dry wood. To be able to use different types of fuel, you need to purchase combined devices, such as KST or Dymok. You can conduct an experiment with the degree of gate opening in air-heating models from similar manufacturers as “Sibir”. If smoke appears, make the chimney opening larger.

Ensure air flow into the boiler installation. For safety reasons, the window must be opened regularly during the boiler's operating period during the heating season. The device operating on solid fuel must be constantly cleaned. This is especially important if it is coal or diesel, running on exhaust, since such fuel options clog the burner especially quickly.

Technical nuances

Overheating is equally dangerous for both metal and refractory brickwork, especially in the seams. Metal parts are prone to warping, bending, directional twisting, and burning. This is especially true for lightweight steel stove models. A few subtle but serious defects are already enough to cause a headache like why an iron stove smokes in a bathhouse. And if burnouts can, in most cases, be melted by inverter welding with repair heat-resistant electrodes or eliminated by applying patches, which is more correct, then warping and other linear deformations must be straightened, often painstakingly embroidering problem areas using an angle grinder cutting disc, and then restoring and strengthening the damaged geometry of various kinds of inserts, scarves, segments and other additional elements.

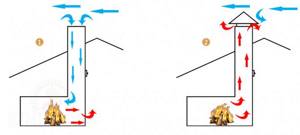

A few words should be said about why there is poor draft in the furnace, which is associated with the production culture determined by the construction of the furnace and the technical arrangement of smoke channels. Like any heating device whose operation involves burning fuel, the stove emits combustion products, both solid and gaseous. The dynamics of gases is associated, first of all, with the presence of certain obstacles in their path. It is not without reason that when constructing a chimney, responsible executors use such a technological technique as “scraping”, the essence of which is to eliminate various types of irregularities and obstacles in ducts, chimneys, distributors, and outlets. In metal single-wall pipes, a mandatory element is a condensate receiver glass, the purpose of which is to collect and remove condensate from the zone of movement of flue gases, preventing them from being moistened and cooled. The presence of these elements, as well as a sufficient number of service doors, will help to avoid an unpleasant situation when the stove in the bathhouse smokes, what to do, where to run.

Ventilation

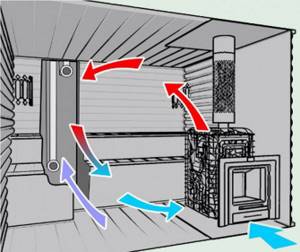

The chimney itself is a natural exhaust hood. In order to create upward movement of warm air, a full influx from the outside must be ensured.

However, often, when installing a forced ventilation system, owners only perform forced exhaust (in the kitchen and bathroom, for example). If some factors have influenced the reduction in draft in the chimney, powerful forced exhaust through a separate channel will become an additional obstacle to the normal movement of smoke from the stove.

The second floor may compete with the chimney. If there is a staircase nearby and an opening to the top, air sometimes rushes there more readily, especially if at those moments when a window on the second floor opens.

Possible reasons

Many people don’t understand why the stove smokes if it was working perfectly just a couple of days ago. It is worth remembering that smoke is in any case a deterioration or change in draft in the design of the furnace.

Note! Draft is a physical force that forces smoke gases to rise up the chimney.

With good draft, the fuel produced by the wood will burn completely, releasing maximum heat. If it’s bad, the stove will smoke, creating smoke in the room.

Therefore, at first it is important not to try to go on the Internet with queries: “the stove in the house is smoking, what should I do?”, but to find out the reason for the incorrect movement of flue gases in order to correct the problem correctly.

Weak traction

Over time, the stove, especially its chimney, becomes clogged with soot (a product of burning wood), which weakens the draft. As a result, the smoke that should go outside spreads throughout the room.

Important! The frequency of blockages is affected by the design of the chimney. The more turns, the more opportunities for soot from combustion products to settle.

Remelting

Those who heat the stove for 6 or even 10 hours without breaks are acting completely recklessly. Bricks and joints are destroyed under the influence of high temperatures. As a result, the structure is deformed and the thrust weakens.

Backdraft

Normally, when burning wood, the air moves “bottom-up” - from the room to the street. But then why does smoke from the stove come into the house? The fact is that if all the windows are closed or the ventilation is not working properly, then the air begins to move in the opposite direction, a phenomenon called “reverse draft” occurs.

This happens as follows:

- The combustion heating device draws in air from the room.

- A lack of oxygen gradually develops.

- Air begins to flow through the chimney.

- The stove goes out, filling the room with smoke.

Incorrect design

Mistakes by the stove maker during the construction of the structure lead to a weakening or change in draft. More often, masters make 3 types of miscalculations:

- Use of elements of different sections. As a result, air turbulence occurs in the oven.

- Underestimation of the location of the inlet to the well - smoke enters the room as soon as the door opens.

- Narrow chimney section. The diameter of the minimum chimney clearance for a house is 150 cm, for a bathhouse – 100 cm.

Soot and furnace wear

Why does the stove smoke in a private house? Other reasons

Even if the stove was perfect at the construction stage, over time the chimney clearance may narrow due to the build-up of soot. This is an inevitable process, so the oven is cleaned regularly. However, without wanting it, owners can significantly speed up the soot formation process.

What mistakes should you avoid:

- Do not use wet firewood, especially resinous wood.

- Do not over-burn large amounts of synthetic waste in the oven (cellophane, plastic, rags, rubber...).

- During the construction stage, do everything possible to ensure that the inner surface of the stove does not have protrusions, is smooth and uniform.

- Do not try to convert a regular oven into a pyrolysis oven.

Thrifty owners often strive to do the latter in order to save money. They limit the air supply, without opening the vent, but leaving only a small gap. The result is not combustion, but smoldering and decay. But a Dutch oven or a Swedish oven will never become pyrolyzed; by their nature, they should “hum” during combustion, and the vent can only be closed when there are coals left.

Particular attention should be paid to cleaning the stove for those stoves that are regularly fired with coal. This fuel quickly leads to the pipe becoming overgrown with soot (coal, like firewood, needs to be given a sufficient amount of oxygen to allow it to flare up properly).

By the way, the fact that it’s time to clean the stove can be indicated not only by the smoke in the house, but also by the sparks flying out of the chimney into the street. This happens when combustion does not occur in a furnace, but the soot itself burns in wells.

If after cleaning, the problem with traction remains or worsens, it is possible that soot fell on some area during cleaning, and the area remained uncleaned. With an aged stove, such a nuisance may occur as part of the brick falling off, which is not noticeable from the outside.

To be sure that the wells are clean along their entire length, you can make additional holes for cleaning. This is done using a hammer drill or a drill with a Pobedit drill bit.

Prevention

The best method to get rid of problems with the stove is prevention:

- Timely cleaning of chimneys will protect you from blockages. It is recommended to do this at least once a year. When you use a lot of fuel, or if the fuel itself burns, producing too much soot, it is a good idea to have your chimneys cleaned twice a year.

- Monitor the condition of the chimney pipe. It is enough to do a visual inspection of its condition once a year. Secure the brick pipe parts using clay or cement mortar with sand. Use clay for work inside, cement for outside. Repair cracks. Monitor the condition of the insulation and insulation of the metal pipe. Strengthen it in a timely manner if you notice damage.

- Remember to maintain your oven when it is not in use. Try to paint all its metal elements with heat-resistant paint. This will extend the service life. Protects against corrosion. Examine the internal condition of the firebox of a brick kiln. If necessary, replace damaged bricks and grates with new ones. Check the condition of the welds on the metal stove and repair them if you see cracks.

With these simple tips, you can troubleshoot your stove and also keep it in working order so that it warms you with its warmth on cold winter evenings.

The video below shows the reasons why the stove smokes and how to fix it: