Control board errors

The control board should be considered as the cause of hot water problems when all other checks have failed.

The cause may be a malfunction in the flame modulation circuit. The boiler control unit constantly adjusts the burner power depending on the conditions, and if there is a fault on the board, the boiler can spontaneously reboot or turn off when it reaches maximum power, which in most cases is required precisely in the hot water preparation mode. It is also possible that boards may be configured incorrectly as errors. But this only applies to those cases where problems appeared after its replacement. BAXI boards are universal and require customization for a specific boiler.

Good evening everyone! After 4 months of operating the Baxi double-circuit gas boiler, it stopped heating hot water. Why? What is the reason? I assume that the boiler runs on untreated water and is possibly “overgrown” with scale or rust. What do you advise Lord?

NURLAN_DRAGON 2015.06.21 06:21

User Answers:

None. I don’t communicate closely with them))))) Oh, I remembered - when Dolph Lungren, Van Damme, ... If other problems in connection with the move do not bother you, go calmly! ... Happy holiday, Irina! Beautiful photo. How I love mimosas! I didn’t have to choose, my hand reached out to

The most common cause of boiler breakdowns is scale. Most likely, your boiler heat exchanger is clogged with scale and that’s why it’s not heating. Solution - install special. filters. For example, magnetic or electromagnetic. They are placed in front of boilers and work for many years without requiring maintenance. See manufacturers Kema (Moscow) or Aquashield (Ufa). Good luck!

Yes, most likely your double-circuit boiler is covered with scale. That's why it stopped heating hot water! Why? Hard water! What to do? Install a filter. For example, ion exchange or electromagnetic.

OBAPATEH 2015.06.21 12:26

User Answers:

Chakapuli, chashushuli…. and many more dishes of Georgian cuisine... also fried potatoes with wild mushrooms.... I’m listening to biology now... I can’t even imagine this. It would be boring for me alone, to get involved with all sorts of dubious companies

Vaillant and Baxi boilers are particularly reliable and safe. Breakdowns of such complex equipment must be repaired by a specialist. But, minor faults can be removed yourself if you have a basic level of knowledge about the design of heating and heating gas double-circuit boilers Baxi, Aristan or Naien. Most faults are indicated on the display of the Baxi double-circuit gas boiler. Having deciphered the errors, you can figure out the reason for the boiler’s failure to heat water. Where to start the search if the heating of water in a double-circuit gas boiler Baksi or Vaillant does not work, and the indicator does not show an error or it can be interpreted differently? The gas boiler does not heat hot water. Why? Cause? Double-circuit boiler Baxi (baxi). If the Vailant, Baksi, Aristan or Navien double-circuit gas boiler does not heat hot water, you should check the secondary heat exchanger. It also tends to get clogged quickly. But, fortunately, it can be easily removed, cleaned and reinstalled. What is the reason? Why is this happening?

Water heaters are used as the main or additional source of hot water supply in apartments and country houses. A complex device can fail for various reasons; breakdowns cause a lot of everyday inconvenience and require urgent repair. Let's take a closer look at why cold water does not flow into the water heater, why the pressure may decrease, and why difficulties arise with heating.

Water heater

Repairing the electronic control unit - do it yourself

In this topic, I don’t just want to point out the reason - the relay is stuck. You will learn why the boiler reacts this way to a malfunction, which relay on the board is responsible for the fan, how to replace it and where to get it.

In subsequent articles from this section, I talk about other faults related to the ECU and more.

First, we look at the block board and get acquainted with the location of the Ariston Clas 24 FF boiler relay

RL01 - Fan control relay.

RL02 - Three-way valve control.

RL03- Pump speed control.

RL04 - Pump control (Supplies power supply to the pump)

RL05\RL06 - Supply power to the ignition unit and gas valve.

Relay serial numbers are indicated as they are indicated on the board.

The malfunction we are talking about now is caused by a malfunction of relay RL01. Relay type JZC-43F (coil power supply - 24 volts)

It is this relay that is responsible for controlling the fan.

Since I was running out of time for repairs, and did not have the required relay, I installed a relay with a lower coil supply voltage, using a stabilizer chip - this design works reliably.

I removed the detailed description of this alteration from the article, but if anyone needs it, write, ask, I will explain.

Modulation errors on the burner

To heat running water, in most cases a boiler power close to maximum is required. In modern boilers, the burner power is regulated over a wide range. The adjustment occurs by changing the amount of gas supplied by the gas valve. The amount of adjustment is determined by the control board depending on the operating logic and settings. The process can be observed visually by the height of the flames on the burner.

If the boiler settings are set to 100% boiler power in DHW mode, but visually the flames on the burner are weak, or obvious interruptions are visible, then you should check:

setting the gas valve (static and dynamic gas pressure)

control board

Such checks should only be performed by a qualified person.

Error codes for gas wall-mounted boilers Ariston BS II

On the BSII boiler panel, in the event of an Emergency Lockout or Emergency Shutdown, the corresponding combination of indicators lights up.

Error - the red LED for blocking the operation of the column and the temperature LED are not blinking 90

Blockage due to overheating.

Error - yellow LED flashes for anomalies in the smoke removal system and temperature LEDs for 40 and 50

Alert for insufficient water pressure.

Error - the red LED for blocking the operation of the column and the temperature LED for 40 and 50 do not blink

Blockage due to insufficient water pressure.

Error - the yellow LED for anomalies in the smoke removal system and the temperature LED are flashing at 60 and 70

Short circuit or open circuit of the temperature sensor in the heating circuit flow line.

Error - the yellow LED for anomalies in the smoke removal system and the temperature LED are flashing at 70 and 80

Short circuit or open circuit of the temperature sensor in the return line of the heating circuit.

Error - the yellow LED for anomalies in the smoke removal system and the temperature LED are flashing 70

Communication failure between the column circuit and the user interface circuit.

Error - the yellow LED for anomalies in the smoke removal system and the temperature LED are flashing 80

EEPROM failure.

Error - the red LED for blocking the operation of the column and the temperature LED are not blinking 80

Electronic circuit malfunction.

Error - the red LED for blocking the operation of the column does not blink

Blockage due to lack of automatic ignition of the burner.

Error - yellow LED flashes for anomalies in the smoke removal system and temperature LED 50, 60, 70

Flame detected with gas valve closed.

Error - the yellow LED for anomalies in the smoke removal system and the temperature LED are flashing 60, 70, 80

Flame separation.

General recommendations

There are many ways to fix a radiator leak available to the owner, and he can choose the most suitable option based on the equipment available. However, the above recommendations make it possible to urgently solve problems in the winter season, when it is not possible to turn off the heating system for a long time and carry out major repairs of heating devices.

It is quite natural that homeowners have a question: the heating battery is leaking, what to do in the summer? Having survived the winter with a hastily patched radiator, in the summer you should remove the battery from its mounts, inspect for damage and carry out a number of measures:

- remove old patches;

- clean leaks with a wire brush;

- treat cracks and holes with a grinder and a cleaning wheel;

- eliminate the defect by soldering or welding.

Next, you should paint the battery (you can read about paint for radiators here) and install it in place

In this case, it is important to follow the installation rules - use tow, FUM tape, high-quality shut-off valves and pay special attention to the joints

Having installed the battery in the circuit, it is worth filling the system with water and checking the tightness of the heating device

It is important to carry out this step while the boiler is running, since the circulation of coolant under pressure can reveal leaks and weak points in connections. If no leak is detected during intensive use of the heating system during the day, then the problem can be considered solved

Descriptions of the Ariston double-circuit boiler

One of the most important components in all gas boilers is the burner, in this case it can be modulating or conventional. The first option is more popular than the second. When using it, the entire system will be adjusted automatically, without human intervention. In this case, the power of the installed heating equipment depends on temperature indicators.

The burner is also divided into 2 types:

open;

The safest is since it does not involve combustion products entering the room in case of emergency. Also in this case, the owner does not have to worry about building a chimney. A special coaxial pipe must be connected to the closed burner; it can always be brought outside in any accessible place.

An open-type Ariston boiler, in any case, requires a chimney to remove combustion products to the street. Also, do not forget about natural cravings. Air will enter the system from the living space, so it will have to be constantly ventilated.

The coaxial pipe used in a closed combustion system has the advantage of being made of 2 layers. One is necessary to remove combustion products, and the other will ensure fresh air enters the boiler. Thus, the owner of the equipment does not have to constantly ventilate the room and worry about natural draft. The room will always have a sufficient amount of oxygen.

Why the gas boiler does not ignite and displays error 607

The gas wall-mounted boiler has several degrees of protection, for your safety and to protect the boiler from more serious damage.

One of the elements of the safety group is a pressure switch or, as it is called in the boiler manual, “air pressure switch”

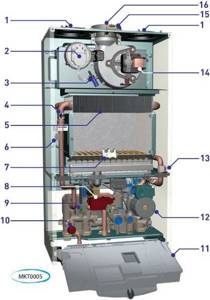

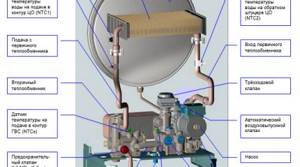

Boiler design diagram

In the above drawing, the air pressure switch (pressostat) is located at No. 2,

No. 14 Fan motor for exhaust gases (combustion products)

No. 3 Air pressure tap with condensate drain.

By the way, in my boiler this unit No. 3 was made differently. I had a so-called Venturi tube, which also has a certain protection function and, in the event of a malfunction, displays its own errors.

Let's return to our malfunction: As it should be!

The main problems are why the boiler does not heat water

More often, boiler problems are detected during the heating season, when both circuits of the device are operating. There are two main problems that owners of wall-mounted gas boilers such as Ariston face:

- all boiler systems are working, the device turns on, but heats the water poorly or does not heat at all;

- the boiler does not start and, as a result, no hot water is supplied.

Before finding out the reasons for the malfunction of the unit, you should look at the operating manual, read the instructions and check that the settings and connections of the device are correct.

Note! Modern gas boilers are equipped with a diagnostic system that detects faults and displays an error code on the display. The instructions for the unit will help you decipher the codes.

If all requirements and conditions are met, the most common causes of malfunctions should be considered:

- Blockage. Experts say that using unfiltered working fluid increases the risk of clogging the heat exchanger pipes. The resulting scale reduces its thermal conductivity, which causes the unit to operate with excessive energy consumption. In this case, the optimal temperature regime is not achieved even with continuous operation of the device. Due to limescale deposited inside the heat exchanger pipes, the metal is subject to corrosive changes, which can lead to its rupture.

- Faulty pump. The circulation of the coolant may be stopped due to the accumulation of air, the so-called air lock in the pump. The second cause of a pump malfunction may be a rotor that is jammed. A circulation pump that stops functioning can lead to overheating of the gas boiler.

- The flow sensor is stuck. Inside the boiler there is a sensor in the form of a turbine, resembling a small fan. When the turbine rotates inside the sensor, an electrical pulse is generated due to the fluid flow, which is supplied to the control unit. This way the electrical system understands that it needs to warm up the coolant.

- The three-way valve is stuck. Such a malfunction will not allow you to switch the water supply from heating to DHW. Valve stoppage can occur due to blockage, either in the part itself or in the gas hose or filter.

- Insufficient pressure. If the volume of liquid in the system does not create the required pressure, the water supply valve does not open, which leads to burner ignition failure.

When you know the reason why the boiler does not heat the water, you can try to eliminate it yourself. Manufacturers often make mechanical components available for self-service.

Important! When troubleshooting problems on your own, before starting work, you must disconnect the unit from the electrical power supply and free the internal components from the coolant.

Further on the situation:

- If the heat exchanger is clogged, you can clean it using special liquids, or using proven home remedies for descaling. In the future, it is better to use filter devices at the coolant inlet to the boiler.

- If the cause is a faulty pump, you should disassemble it and inspect the rotor. If foreign particles are found that block free movement, they must be removed. The filter should also be inspected for clogging.

- When the cause of the malfunction is the water flow sensor, it is necessary to remove from it the part containing the turbine inside. If, when rotating with your finger, it begins to click or slow down as it moves, this means that there are foreign particles in the body. You should try to flush the turbine and clean each of its blades using a cotton swab dipped in cleaning fluid.

- The three-way valve, if it caused a boiler malfunction, also needs to be cleaned, and at the same time check the gas hose and filter.

- If the pressure is low, you should check all fittings and valves on the device, the pressure with which water flows from the mixer. If there are no leaks and the pressure is weak or absent, then simply replenishing water in the expansion tank will help solve the problem.

One of the main tips is to follow the operating rules and follow the manufacturers' recommendations.

It is important to remember that prevention is always more profitable and better than repair. Timely maintenance and checking of the main components of the system will extend the service life of the autonomous heating device

Error codes for geysers Ariston Marco Polo

This list contains fault codes specifically for Ariston Marco Polo gas water heaters.

Error code E1 - Ignition error

Ignition did not occur.

Error Code E2 - Flame Error

Flame failure/chimney blockage.

Error code E3 - Coolant error

Overheating of water / heating without water.

Error code E4 - Temperature sensor error

Failure of the temperature sensor.

Error code E5 - Shutdown soon

Shutdown after 30 min.

Error Code E6 - Flame Error

There is no flame.

Error Code E7 - Fan Error

Fan failure, rotation speed outside the permissible range.

Error Code E8 - Communication Error

Communication failure.

Error Code E9 - Main Board Error

The main board is faulty.

Damage to the heat exchanger and pipes

If the heat exchanger of a gas boiler is leaking, the wall may have burned out, a crack or a fistula has formed. Based on the material used, heat exchangers are divided into copper, steel, and cast iron.

Cracks in metal are formed under the influence of thermal stress and hydraulic pressure. Corrosive processes lead to the formation of fistulas. Repairs are carried out by soldering.

Main stages of the process:

- dismantling the heat exchanger;

- cleaning and degreasing the area around the leak;

- soldering using flux and solder;

- trial;

- installation.

If there is a leak in an easily accessible place, complete dismantling of the heat exchanger for repair is not necessary. It is enough to remove the casing, turn off the gas and water, disconnect the electrical wires, and drain the remaining water.

For soldering, select a solder that corresponds to the material of manufacture, for example, copper-phosphorus solder containing silver is suitable for copper heat exchangers; the temperature regime at the soldering site must be observed

The soldering area is cleaned and degreased with a solvent. Soldering is performed using a soldering iron or gas torch. The heat exchanger is installed in place and communications are connected to it.

Tests are carried out by crimping. The circuit is filled with water, the pressure is increased to the test value and monitored using two pressure gauges for at least 5 minutes. If no pressure drop is detected and no leaks are noticed during a visual inspection, the repair can be considered complete.

In case of severe damage, repairing the heat exchanger is impractical. It is simply replaced with a new one. It is also impossible to solder many Chinese-made heat exchangers, since they are made of thin-sheet alloys that cannot withstand soldering.

Vaillant boiler does not heat hot water due to blockages

This is one of the most common problems. Most often, the reason is poor water quality - scale appears, units, filters and pipes become clogged.

If the flame does not light up in the boiler, start checking with the flow sensor. Finding this cylindrical device is quite simple. The flow sensor is located near the pump; the wires go to it. There are two sensors installed near the pump:

- Pressure sensor in the heating system.

- Flow sensor.

The flow sensor looks like a small fan; it begins to rotate as water moves through the pipes. If the flow sensor detects the movement of water, the automation receives a signal to turn on the gas and heat the water. If the flow sensor is clogged, water will flow but the fan will not move. Accordingly, the signal to turn on the heating is not received. There are two ways to solve the problem:

- Don’t rush to disassemble the boiler and try to “blow out” the system first. Turn off the main water supply valve to the house. Open the hot water tap and drain the system. Now the percentage of air in the pipes has increased. Start sharply opening and closing the water tap immediately in front of the boiler. These simple manipulations will help create pressure and clear the flow sensor fan of debris.

- If “blowing” does not solve the problem, you need to open the boiler, unscrew the flow sensor and clean it manually.

If the Vaillant boiler does not heat hot water

, the secondary heat exchanger should be checked. It also tends to get clogged quickly. But, fortunately, it can be easily removed, cleaned and reinstalled.

A clogged three-way valve can also cause the boiler to fail to heat water. And you can remove this unit yourself, clean it and install it back.

Having purchased a Vailant boiler, be sure to check with the seller

information about the places where filters are installed. You can clean and change these components yourself.

Faulty pump

Heating of water in a Vailant boiler largely depends on the operation of the pump. To repair or replace this unit, you must call a specialist. But, you can check for yourself whether this is the reason for the boiler’s failure to work.

Set the water temperature on the boiler to 0 °C and turn on the water heating mode. During this time, monitor the operation of the pump. If after 20 minutes of operation it does not heat up, then the problem is with the pump.

The reason for the boiler’s failure to heat water may also be due to a simple loosening of the bolts at the connection areas. Carefully examine the boiler diagram and check that all connections fit tightly. Perhaps simply tightening the bolts will solve your problem.

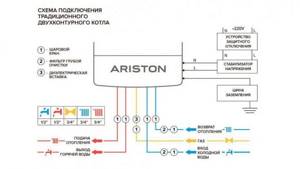

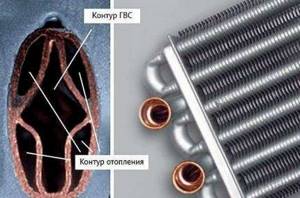

When problems arise with preparing hot water in a double-circuit boiler, you must first determine how the boiler operates in DHW mode. There are two options: bithermic heat exchanger and secondary heat exchanger.

In the first case, the heating circuit and the hot water circuit are combined in one heat exchanger - the primary one. When it is necessary to prepare water, the heating circulation pump stops working and all the boiler power is transferred to the flowing tap water.

In another case, the boiler is equipped with an additional (second) plate heat exchanger and a switch (three-way valve). When it becomes necessary to prepare water, the coolant from the heating circuit is directed to a second heat exchanger, through which the heat is transferred to the flowing tap water. At the same time, the pump continues to work - pumping the coolant in a small circle.

Therefore, hot water problems must be diagnosed differently for different circuits.

Most frequently encountered problems:

Baxi boiler does not heat hot water well

Baxi boiler does not heat water (hot water does not turn on)

Other breakdowns

In addition to those described above, the following codes may appear:

The reason lies in the NTSc sensor, there is no hot water at the outlet, the safety valve is leaking. If there is no hot water, but the heating system is working, most likely the water flow sensor is faulty or clogged with debris. Another reason may be that the turbine blades have worked too hard, stuck to the housing, this can interfere with rotation, replace the blades or the turbine itself.

The second reason in this situation may be the NTC sensor; to check its functionality, measure the resistance at its contacts with a multimeter; if it is unstable, replace the sensor with a new one. If the safety valve is leaking, the gaskets may be worn out, replace them.

NTC sensor

How to determine the error code if the device does not have a display or does not have a dial, such as on the Ariston BS II 24FF model? This device is equipped with indicator lights, thanks to which you can determine the breakdown. So, for example, if the 90 indicator and the crossed out water drop icon are on, this means that the boiler has overheated and is blocked. To eliminate this, you need to check the pressure switch and its connection to the board.

The principle of operation of a double-circuit gas boiler

To understand why a gas boiler began to heat water poorly or there is no hot water supply at all, you need to understand how a double-circuit unit works. Almost any gas equipment of this type is equipped with several units.

The main unit ensures ignition of the gas mixture and its combustion. An additional water unit ensures the level of hot water supply and monitors the pressure in the line. The smoke removal unit is responsible for removing combustion products outside the home.

When the equipment starts, the pump is activated, pumping water into the system. The liquid begins to circulate through the heat exchanger tubes, where it is evenly heated due to the action of the burner.

The boiler has two circuits, one of which is responsible for heating, and the second for DHW operation. Simultaneous operation of two circuits is impossible

The heating process is controlled by sensors or a simple mechanical system or automatic gas boiler, depending on the model and complexity of the device. When the set temperature is reached, the gas supply stops. When the temperature drops to a critical value, the burner starts and the cycle repeats.

Distinctive operating patterns of double-circuit boilers

If problems arise with hot water supply, in order to find out the reasons, it is necessary to understand the operating diagram of the gas unit in DHW mode. There are two options with bithermic and secondary heat exchanger.

Boiler with bithermic heat exchanger

The operating principle of a unit with a bithermic heat exchanger is related to the configuration - essentially, it is one complex-shaped tube located inside another. The coolant flows through the outer section of the tube, and hot water water moves through the inner section.

When operating in heating mode, the burner ensures heating of the coolant to the set temperature and turns off. When the hot water tap is opened, the liquid begins to move along the internal circuit of the heat exchanger, and at the same time the blocking valve of the external circuit is closed.

In double-circuit boilers with a bithermic heat exchanger, one heat exchanger simultaneously contains internal and external circuits responsible for the operation of heating and domestic hot water.

The burner operates continuously at maximum power, providing heating of running water. After closing the tap, the coolant supply valve opens and the boiler begins to operate normally.

Boiler with secondary heat exchanger

In another type of boiler with a secondary heat exchanger, the operating principle is slightly different. It is not just the second circuit that is responsible for heating the water, but a separate plate heat exchanger equipped with a three-way valve.

The secondary heat exchanger looks preferable to the bithermic one - it is easier to remove for washing and cleaning

When you open a hot water tap, the coolant is redirected from one heat exchanger to another, where heat is transferred to the flowing water. At the same time, the pump continues to operate, pumping coolant through a small circuit.

System with natural and forced circulation

The reasons why gas boilers stop heating water may also depend on the method of circulation of the coolant. But this has less to do with heating the water, and more to do with the operation of the device itself. The reason for poor operation of a boiler included in a natural circulation circuit is either non-compliance with slopes or the presence of air pockets.

In heating circuits with forced circulation there is no such problem, since the coolant moves through the system under the action of a circulation pump. Further, we will not dwell on the operation of the gas boiler itself, but will consider exclusively the problems of hot water supply, assuming that the boiler functions normally in heating mode.