5726 0 0

Vadim August 25, 2016

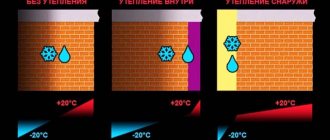

There are now quite a few different types of insulation materials competing on the modern market. But for more than half a century, expanded clay has been considered one of the most popular materials. In this article I will tell you how to insulate floors, ceilings and walls with expanded clay in different conditions with your own hands and in what cases it is worth doing.

This is what expanded clay looks like.

Expanded clay advantages and disadvantages

Like any material, expanded clay has its pros and cons.

To make an informed choice, you need to get acquainted with the properties of insulation. Among the products of this type offered on the market, expanded clay is not a new product: it has been used for several decades and has managed to prove itself to be of the best quality. Bulk thermal insulation consists of granules of 3 different fractions. Any type of expanded clay is suitable for roof insulation; materials of different sizes can also be combined

It is important to know that effective insulation of the ceiling from the cold can only be achieved by backfilling a layer 30-40 cm thick

Expanded clay granules are made from fired slate clay. During the firing process, the surface of the lump is sintered, and the inner layer acquires pronounced porosity, noticeable at the fracture. It is the cavities of the bubbles that give expanded clay its insulating properties, since air has relatively low thermal conductivity. Materials such as penoizol, EPS, polystyrene foam, etc. are constructed using the same principle. But, compared to them, expanded clay has its advantages.

Among the advantages of granular thermal insulation made of clay:

absolute fire safety, since expanded clay does not burn, does not melt and does not release harmful substances when heated; lightness, which is important when insulating the ceiling; resistance to mold, rot or damage by rodents, since ceramics are biologically stable and quite hard; ease of use of the material; long service life - expanded clay can withstand more than 25 cycles of thawing and freezing and does not decompose.

The price of 1 m³ is low and comparable to the cost of other heat insulators (mineral wool, expanded polystyrene).

Among the disadvantages, the most obvious drawback is the presence of dust generated during the firing and transportation of granules. Like other insulating materials, expanded clay is capable of absorbing moisture, which reduces its insulating properties. All insulation materials have an increased tendency to absorb moisture. It can be considered a disadvantage, but the easiest way is to take appropriate measures and protect the insulating material from water.

Bulk material is inconvenient for insulating suspended ceilings. Despite their lightness, the granules have weight and create additional stress on the coating.

How to lift expanded clay into the attic

The difficulty of insulation is associated with the supply of thermal insulation to the attic. You need a lot of bulk material. Special machines are used in production. At home, they come up with various devices.

Special machines in production help to quickly feed expanded clay to heights in large quantities

To ensure effective insulation, it is optimal to use expanded clay of three fractions. The granules are mixed before being placed into the attic. They do it on the ground. The presence of granules of different sizes will make it possible to obtain a dense and even layer of insulation.

Various devices are used to supply bulk materials to the attic in private construction. Most often, a block is hung on a beam. A rope with a hook is used to hook the buckets. You will need at least two assistants: one loads on the ground, and the other scatters the insulation over the ceiling. To speed up the process, you can use a block to lift not buckets, but a larger capacity container, for example, a trough.

If expanded clay is purchased packaged in bags, lifting it into the attic is simplified. There is no need to load it on the ground. You just need to pick up the bags and lift them with a block. Another device is a soft container. It is made from a piece of durable tarpaulin. Loops are made at the four corners and ropes are attached. The four free ends are tied with a knot. It looks like a hammock. At one time, a durable tarpaulin can lift up to 100 kg of pellets.

If the attic is large, it is difficult to lift huge amounts of building material by hand. Here it is optimal to use the service of a crane. However, several sheets of roofing will have to be removed, since the supply will be carried out through the roof.

Useful tips

When the ceiling opens onto a residential attic, you need to pour expanded clay so that there is a gap between it and the attic floor covering. If this is not done, the grains will constantly creak under the feet of those who walk above. But when backfilling is done correctly, expanded clay will also serve as a soundproofing material.

Sometimes it is necessary to insulate sloping attic ceilings. For this purpose, it is better to choose other types of insulation. Bulk material cannot be laid on an inclined surface: round granules will roll down. Expanded clay backfill is used only on a horizontal plane.

Self-leveling mixtures should not be used to fill expanded clay screed. The liquid mass will flow between the granules until it saturates the entire insulation, and when the thickness of the layer is large, the repair will cost a lot of money. If you need to make poured floors in the attic, you first need to lay a concrete screed, and then apply a thin layer of leveling mixture.

By pouring expanded clay to a thickness of only 10 cm, you can already save up to 70% of the heat that escapes into the atmosphere through the ceilings. The popularity of expanded clay for insulating ceilings in private wooden houses is due to its low thermal conductivity and low price

The fire safety of granules is also important.

Ceiling insulation with expanded clay has been carried out since the production of this material at the beginning of the last century. The popularity of using expanded clay has not faded to this day. Floor insulation with expanded clay performs three protection functions: thermal insulation, sound insulation and moisture insulation.

Lightweight expanded clay used for floor insulation consists of porous, ceramic granules formed by the expansion of special clays at high temperatures.

Directions for using light expanded clay:

- Insulation base.

- Filler for concrete blocks and panels.

- Hydroponics.

- Drainage of areas.

The insulation installation is carried out in three ways: dry filling, combined filling, wet screed using factory-made dry building mixtures.

The technology for insulating the ceiling using the dry backfill method is performed using expanded clay of different fractions. If you backfill only with granules of one fraction, the density of the layer will be non-uniform, which will negatively affect its thermal conductivity. If you mix up granules of the middle fraction of 5-10 mm and granules up to 5 mm, then the filling will be dense and non-shrinking: small granules will fill the spaces between the middle ones, resulting in a homogeneous layer.

Advice from professionals

- If there is a residential attic floor above the ceiling to be insulated, it will be necessary to provide an air gap for ventilation located between the expanded clay layer and the floor covering. It will protect you from creaking noises that will be made when walking

- A properly laid layer of expanded clay granules will not only maintain a comfortable microclimate inside the home, but will also take care of insulation from external noise.

- If a screed is installed on top of expanded clay insulation, you should give preference to a concrete screed. Popular mixtures with a self-leveling effect cannot be used. Their texture is too liquid, and therefore the mass will penetrate between the expanded clay granules and saturate them through and through, significantly increasing the consumption of material. If there is a need to create floors based on pouring, the self-leveling mixture is applied in a thin layer and only on top of the concrete coating.

What is expanded clay

Expanded clay is a small-sized granule, due to its small pores it has little weight. These granules are obtained by firing clay. We can safely assure you that expanded clay is also an environmentally friendly natural material, moreover, it is characterized by relatively good technical indicators, such as:

- Noise and sound insulation - muffles impacts;

- Thermal insulating properties – retains heat well;

- Frost resistance - does not collapse even at low temperatures;

- Fire resistance - the material is not exposed to fire;

- Strength - its structure does not change under the influence of water (hot and cold);

- Durability - the properties of expanded clay do not change even when exposed to high or low temperatures; it lasts much longer than other insulation materials.

Why expanded clay is better than other insulation materials

Expanded clay insulation is a lightweight porous material in the form of round granules. It contains only baked clay, so this material is environmentally friendly.

There are several types of expanded clay:

- expanded clay gravel – grains 5-40 mm in size. It is used in insulation of ceilings, walls, floors. Also used in concrete production;

- expanded clay sand – grains 0.14-5 mm in size. Filler for concrete and mortars. It is used for thermal insulation fills with insulation thickness up to 50 mm.

How to choose the right insulation? Compared to other materials, expanded clay has a number of advantages:

- most insulation materials are made from materials that decompose over time, releasing substances that are toxic to the human body - this does not apply to expanded clay;

- rodents cannot live in expanded clay;

- expanded clay is a fire-resistant, water-resistant material with a good degree of sound insulation;

- Expanded clay is one of the most affordable materials.

Technology of ceiling insulation with expanded clay granules

Before insulating the ceiling, be sure to lay a layer of membrane (polyethylene, for example) that is impervious to dust and vapors.

In cases where thermal insulation is installed in a bathhouse, this becomes especially important due to the large amount of water vapor in the air. No other preparatory actions are required: the loose insulation will perfectly fill all the unevenness and easily penetrate into niches and gaps between structural elements. To work on ceiling insulation you will need the following materials and tools:

- thick polyethylene film or isolon, foil, etc.;

- scotch;

- expanded clay of any fraction;

- bucket and shovel;

- a tool for leveling the backfill (even a rake will do);

- cement and sand for screed, sheet materials for covering - if necessary.

Screed or flooring is done if it is planned to use the attic space as a residential or utility room. Their installation is optional and remains at the discretion of the owner.

How to insulate a concrete floor?

For concrete floors, expanded clay, as a ceiling insulation, is an ideal material.

Concrete, impermeable to dust and vapors, does not require even minimal preparation. Therefore, backfilling can be done in just a few hours. To make the expanded clay layer even, you need to install beacons made of thin bars or boards at a height equal to the thickness of the layer. These elements are leveled horizontally using a building level.

When purchasing expanded clay, you need to take into account the shrinkage coefficient of the granules. It is approximately equal to 1.2, so it is better to buy a little more. Laying consists of pouring the contents of the bags between the beacons and leveling the layer using the rule. If desired, you can do without beacons, taking level measurements directly along the backfill.

If you do not plan to walk in the attic, then it is enough to lay a layer of polyethylene on top, connecting the panels with tape. The film protects the backfill from moisture from the atmosphere. But you can protect expanded clay in another way:

- Pour the granules with cement laitance (a liquid solution of cement in water) and dry the backfill for at least 7 days.

- Lay the reinforcing mesh on top and make a screed of cement-sand mortar.

A screed on top of expanded clay will protect the bulk material from moisture and make it possible to move around the heat insulator without the risk of destroying its layer. The ability to retain heat with this method does not suffer at all.

Ceiling insulation in a wooden house

The technology for insulating the ceiling in a wooden house involves the use of a moisture barrier.

To do this, you can take any material from those that are used for a similar purpose. The most affordable is plastic film. It is advisable to lay a waterproofing layer across the ceiling joists to securely cover them too. The width of the film is usually no more than 3 m, so individual strips will have to be joined together. This is also done using a certain technology:

- roll out a strip of polyethylene over the surface, covering the beams protruding above it;

- lay the next panel with an overlap of at least 5 cm on the previous one;

- Tape the joint with wide stationery tape.

When the polyethylene is laid, a protective material should be applied to it. For this you need ordinary clay. It needs to be crushed (a fraction of about 1 cm) and covered between the joists with a layer of 5 cm.

What layer of expanded clay is needed to insulate the ceiling in this case? According to building codes, expanded clay insulation begins to effectively perform its function at a thickness of 10 cm. This layer is sufficient for thermal insulation of a bathhouse or garage that does not require constant heating.

In a private house in central Russia, the entire space between the joists will have to be filled with insulation until a thickness of about 20 cm is achieved. Only in this case will it be possible to properly insulate the home. Calculating the volume of granules in cubic meters is simple: you need to calculate the area of the ceiling and multiply it by the thickness of the layer, expressing the value in meters. Add about 20% to the resulting figure for shrinkage.

It is best to buy expanded clay of different sizes: by mixing a large fraction with a smaller one, you can achieve a dense layer that practically does not lose height. Backfilling is done in the same way as in the previous case. When using a rake to level the granules, you should turn them over with their teeth facing up so as not to tear the polyethylene. After the heat insulator is laid, polyethylene is again spread over it and the log, joining the strips with an overlap and securing them with tape.

Flaws

Despite the fact that expanded clay insulation is simple and profitable, the material has a number of disadvantages that the contractor should take into account:

- due to the large amount of dust contained in expanded clay granules, they are not laid directly on the ceiling - the first layer must be an insulating material;

- Expanded clay's resistance to moisture is accompanied by the fact that it easily absorbs liquid and requires waterproofing.

For these reasons, it is necessary to use both vapor and waterproofing to insulate the attic floor. The vapor barrier layer is usually a special film, covered with foil on one side. Waterproofing can also be film, but if the insulated surface is intended to be used as an attic floor, it is worth using a sand-cement screed.

How is expanded clay produced?

Expanded clay is produced in several stages:

Low-melting clay, which is the starting material, is loaded into a thermal chamber, in which it is softened to the state of dough.

Then the material is quickly heated under the influence of a temperature of 1000-1300 degrees Celsius - this leads to the fact that the raw material “boils”. “Boiling” promotes the formation of voids in the material, upon cooling of which porous granules are formed - expanded clay fractions.

Under the influence of high temperatures, the surface of the material will melt - thus, a good sealed shell appears, which has high qualities of strength and wear resistance, and resistance even to mechanical stress and damage.

The quality of the future product directly depends on how accurately all the rules of technology were followed. Since information on the production of expanded clay also contains information about its environmental friendliness, the question of whether expanded clay is harmful automatically disappears.

How to insulate a ceiling with expanded clay using Knauf technology

Dry backfill

For floor screed using the Knauf technology, dry backfill with granules no larger than 5 mm without impurities of dirt and dust is used. Expanded clay dry backfill KeraFloor is certified, which guarantees the quality of the screed.

- Bulk density 500-600 kg/m3;

- Humidity less than 0.5%;

- Thermal conductivity coefficient is 0.12 W/mK.

The technology is used for rooms where floors are not subject to strong vibrations , when repairing floors of residential and commercial buildings to improve thermal and sound insulation characteristics. Cannot be used on floors subject to heavy weight and vibration loads.

How is screed volume calculated? Up to 100 mm the screed is a single layer; above 100 mm it is recommended to divide the layer in half and perform the screed in two stages. A reinforcing platform is placed between the screeds using cement mortar in a 1:1 ratio (cement + water) or additional sheets of plasterboard are used: regular gypsum board 12.5 mm thick, and instead of the expensive KeraFloor, the first layer is made with dry expanded clay backfill AKZ with a low shrinkage coefficient and is cheaper 50-60 rubles per bag of the same volume - 40 liters.

Translated, it means 0.04 m3 - the volume of one bag. If the screed is 100 mm high, then 1 m2 of screed will require 1 m2 x 0.1 m = 0.1 m3 of expanded clay, which in terms of the number of bags will be 0.1/0.04 = 2.5 bags.

Buy installation-related products and get to work:

- Clean the floor from dirt and debris.

- Seal cracks, potholes in the slab, and seal the gaps between the slabs with foam sealant.

- Apply liquid waterproofing to the slabs in two layers.

- Place the reinforced waterproofing film on the base of the slab, covering the seams by 10-15 cm with adhesive tape. Apply a damper tape around the perimeter of the wall to compensate for the thermal expansion of the floor.

- Install beacons.

- Fill in expanded clay and level with the “rule”.

Ceiling insulation with expanded clay: pros and cons

The positive aspects stand out:

- Environmentally friendly, for use in residential premises;

- Availability of material, can be purchased in any region with delivery;

- Cheapness of the product;

- Low thermal conductivity coefficient, effective insulation;

- Non-flammable material;

- Absorbs noise;

- Shrinkage of the floor when exposed to high loads leads to cracking of the granules, compaction and increased thermal conductivity;

- The thickness of the backfill layer significantly reduces the height of the room;

- High labor costs when performing wet expanded clay concrete screed.

Nevertheless, this material is still used today. The production of expanded clay concrete slabs and blocks is in demand in low-rise construction. Lightweight floor slabs reduce the load on load-bearing walls, which can now be made from lightweight aerated concrete. Insulation of floors using expanded clay is a multidisciplinary stage of work.

A little about expanded clay

Expanded clay is a material consisting of granules. They themselves are made from natural slates or natural clay. Expanded clay granules undergo high-temperature treatment, as a result of which they significantly increase their size and obtain a porous structure. The surface of the particles acquires a brown or reddish color, compacted and smooth texture.

The finished material has the following set of qualities:

- the density indicator ranges from 250 to 600 kg/cubic meter. m;

- the thermal conductivity coefficient is about 0.091–1 W/m °C;

- water absorption of the material is at a level of 8 to 20%;

- Standard frost resistance is at least 25 cycles.

Advantages and disadvantages of using expanded clay for thermal insulation

Insulating the ceiling using expanded clay has a number of advantages:

- Increased service life of the thermal insulator;

- A high level of fire safety, since the material does not support combustion, and when heated there is no release of toxic substances that could pose a danger to human and animal health, as well as the environment.

- The porous structure of the insulator makes it possible to achieve a low weight of the material, which analogues cannot boast of.

- The insulating material does not provide a habitat for harmful insects, rats and mice to live and breed, and also prevents the development of fungi and mold.

- The low cost of expanded clay makes it widely available for use in construction.

- The material will provide high-quality insulation against heat loss and the penetration of extraneous sounds, which will have a beneficial effect on the atmosphere of your home.

- The heat insulator can effectively absorb moisture without increasing its mass or losing its basic qualities.

- Expanded clay chips or crushed stone from it do not cause allergic reactions, since the material is made from natural raw materials.

- The insulated surface is covered with a mound of material, its use is as simple as possible.

- The structure of expanded clay is an obstacle to air penetration. This significantly increases the level of heat insulation and promotes natural convection.

In addition to its positive qualities, the material also has objective disadvantages:

- The degree of energy efficiency of expanded clay is directly dependent on the thickness of the insulation layer. A backfill thickness of 20-40 centimeters does not make sense.

- The material must be carefully protected from rain and snow.

- It is best to apply a layer of insulating material to reinforced concrete floors. This is due to the fact that monolith beams will be able to withstand significant loads, and will also prevent granules from spilling onto the lower floor.

- When planning to install an insulated ceiling in a house built of wood, take care to protect the expanded clay with a film with a vapor barrier function. It must be placed under the heat insulator and on top of it. This will help create a protective layer that will protect the insulation from moisture.

It is prohibited to lay expanded clay insulation on suspended ceiling structures that are lined underneath with lath or clapboard. If we take into account the total weight of the insulating structure, the amount of material and its structure, it is very likely that the suspended ceiling will be damaged and its integrity will be compromised. Moreover, a collapse will occur inside a residential area, which could result in damage to people or valuable property.

Laying features

Beginners are often lost in the question of what layer of expanded clay gravel is required to reliably insulate walls and ceilings, and what additional elements are needed to create a heat-insulating “cushion.”

It is recommended to pour a thick layer of large expanded clay for complete insulation, but taking into account the total load on the ceiling. In cold regions, the height of the buried gravel reaches half a meter, and, despite the insignificant mass of the granules, the insulation makes the structure heavier.

Gravel sand is poured under the main layer, and in addition, two types of insulation are laid under the bulk material and on top of it: steam and hydro. To reduce the cost of the project, polyethylene or roofing felt is used, but the vapor barrier is broken, since the film creates a greenhouse effect, and condensation accumulates if the room is poorly ventilated.

When planning to pour only one fraction, spread the membrane fabric, choose which optimal layer is needed, and scatter the expanded clay to the height required for insulation, evenly distributing it over the surface of the ceiling.

To enhance the insulation and sound insulation of a wooden or concrete ceiling, the material is compacted by mixing sand with expanded clay.

The same effect is achieved by combining gravel with smaller granules. You can increase the heat saving rate by filling the granular insulation with concrete. In this case, there is no need to place a vapor barrier under the screed.

Professionals do not recommend insulating the top floor if it is the ceiling of a flat roof without an attic. This applies to both bathhouses and residential buildings. Expanded clay is highly hygroscopic, which negatively affects the thermal insulation properties of granules.

Whatever fraction of clay expanded clay you take, during work and use as insulation the material emits dust, and therefore for a plank ceiling an additional layer to contain dust is required.

The optimal thickness is 10 cm, a thinner layer of expanded clay is ineffective for insulation, and in regions with low temperatures, the height of the embankment starts from 20-40 cm, subject to the appropriate ceiling height or the possibility of its reconstruction.

The different size fraction and lightness of expanded clay allows you to create an effective heat-saving “cushion”. All insulation work is simple and it is possible to install the ceiling yourself, without special construction experience. Consumers are also attracted by the low cost of the material, the lack of special equipment for installation, and the effectiveness.

Why is expanded clay suitable for insulation?

Each expanded clay granule is a piece of clay expanded at high temperatures. Heat treatment technology results in the crumbly material acquiring a dense outer crust and a porous structure inside. Due to the large amount of air in the cavities, these clay balls do not allow heat to pass through well, and due to the sintered crust, they do not allow moisture to pass inside.

The use of expanded clay for insulation is due to the additional properties of the material. Firstly, it is 100% fireproof - clay, as you know, does not burn under any conditions, and does not emit harmful substances when heated strongly. Which, by the way, cannot be said about polymer insulation like expanded polystyrene.

An important argument in favor of expanded clay is its ease of installation. Those who have ever worked with glass wool or mineral wool are familiar with how much unpleasant itching comes from getting small crumbs of the material on the skin. Due to the same dusty crumbs, personal protective equipment must be used during installation. In addition, contact of wool with moisture leads to loss of insulating properties.

To summarize, we list the advantages of expanded clay:

- It is convenient to transport and pour without special protection and irritation.

- This is a 100% natural and environmentally friendly product, safe for people and animals even in case of fire.

- It can swell with prolonged contact with moisture, but is reliably protected from it by a vapor barrier membrane.

- It does not breed putrefactive bacteria, mold fungi, parasitic insects and rodents.

The last argument is the price of expanded clay. One cubic meter of loose material with a fraction of 10-20 mm will cost only 1,200 rubles. This is enough to fill a room with an area of 18 m with a layer of 7 centimeters. It is this fraction that is selected for the thermal insulation backfill of attics. The average weight of one cube is 250-450 kg.

Preparing for insulation

When calculating the amount of expanded clay for insulating a cold attic, you need to correlate the area of the room with the insulation layer. As a rule, it is necessary to pour at least 16-20 centimeters; accordingly, the area of the room should be multiplied by 0.16-0.2. So, for example, with an area of 20 m2 you will need to buy expanded clay for 3.2-4 m3

When poured in a layer of 200 mm, even the floors of wooden buildings can easily withstand the created load. The exception is buildings with a false ceiling without ceilings (baths and outbuildings are made like this). In this case, it is better not to use expanded clay.

To insulate the attic you need:

- isospan or other vapor barrier membranes;

- dry clay (pre-dried);

- multi-fraction expanded clay;

- in the used attic - materials for flooring;

- garden rake.

It is better to use isospan and analogues as a vapor barrier, but you can get by with roofing material or polyethylene with a thickness of 200 microns. The membrane is securely fixed to the base with a hardware gun. When purchasing isospan, you must also purchase a special tape to hold its flaps together.

Laying technology

Insulation work begins with lining a vapor barrier. It is necessary to purchase and calculate its installation so that the walls and beams have a free edge no shorter than the height of the expanded clay mound. The membrane pieces should lie on top of each other with a margin of 10 cm. You need to connect them together like this:

- Izospan and similar vapor barrier materials. Glue the overlapped edges with tape. It is desirable that it be released by the same manufacturer.

- Polyethylene. Connect with wide packing tape.

- Ruberoid. Fill the seams with bitumen resin or glue them with mastic.

Vapor barrier tapes are laid across the attic beams so that the latter are covered both on top and on the sides. The vertical surfaces of walls and beams with which the edges of the membrane come into contact must be wrapped with them to a height no less than the planned layer of expanded clay. Construction staples are used for fixation.

After installation and fastening are completed, the vapor barrier should be covered with dried clay with lumps no larger than 1-1.5 cm and leveled. Recommended layer – 20-50 mm. To avoid damage to the insulating film, leveling is best done with a mop or building code.

Backfill

For backfilling for thermal insulation purposes, it is recommended to buy expanded clay of different fractions and mix it. This way the balls are stacked more tightly and minimal air cavities are formed between each other. This ensures stability and even laying of the material.

The prepared expanded clay mixture is poured into the spaces between the attic beams and leveled. If the room will not be used, you can level it “by eye” with a rake. The next step will be laying roofing felt, plastic film or membrane.

If the attic space is equipped for use, it is necessary to scatter expanded clay on a flat horizontal surface, on which chipboard, plywood, gypsum fiber board, etc. will then be laid. In this case, it is important not to create an excessively thick layer of expanded clay, because it will be less stable, and the floor will begin to “play” when walking. Moreover, if the attic is heated, there is no need for insulation between warm rooms.

The topmost layer of the floor is not laid on the expanded clay itself, but on an intermediate sheet material: plywood, gypsum fiber sheet, chipboard.

Rules for working with expanded clay

Firstly, expanded clay should be poured only onto the substrate. It is better to use a vapor barrier substrate. The side covered with a layer of foil should be laid towards the room to be insulated. This especially needs to be done when expanded clay is used as ceiling insulation in a bathhouse.

Thirdly, the thickness of expanded clay for insulation should be from ten to twenty centimeters.

There are several types of expanded clay. They all differ in purpose. Three types of expanded clay are usually sold:

- Expanded clay crushed stone. It measures from 0.2 to 0.4 cm and has an angular shape. Only the foundations of buildings and structures are insulated with this expanded clay.

- Expanded clay gravel is used to insulate the ceilings of buildings. This expanded clay has a small fraction of approximately 0.1 to 0.2 cm and a round shape.

- The finest of expanded clay is the so-called expanded clay sand. This sand is not used for insulation.

Calculation of the required thickness of the expanded clay layer when insulating the ceiling

You need to decide on the right amount of insulating material before purchasing it. The thermal insulation effect becomes pronounced only if the minimum level of expanded clay filling is 40 centimeters and above for a wooden house and over 30 centimeters for concrete buildings.

The process of insulating a ceiling with expanded clay in a private house consists of the following steps:

- Complete dismantling of the previous insulating coating, if present, and cleaning the surface of dirt and debris.

- Laying a vapor barrier layer. The film for waterproofing should be laid with an overlap on the edges of adjacent fragments of material. The overlap width is from 15 to 20 centimeters. The junction points must be secured with construction tape.

- Backfilling of the material itself for thermal insulation. First, lay a layer consisting of granules of small diameter. After this, a larger fraction is placed on top. The finishing layer should again be made of fine expanded clay.

- Pouring the final floor screed.

When calculating the required backfill thickness for thermal insulation, it is necessary to take into account the level of loads to which the ceiling will be subjected. Accurate calculations will allow for maximum reduction of heat loss and reduce pressure on the load-bearing parts of the building structure. Once the parameter has been calculated, you can begin to determine the volume of material that will be spent.

The correct calculation is made in this way: the 1-centimeter thickness of the expanded clay layer is distributed evenly over 1 square meter. Insulator consumption in liters is calculated differently - 1 centimeter of heat insulator = 10l/1m2. To obtain the result, the area of the entire ceiling surface is multiplied by the standard insulation consumption per 1 square meter.

Advantages and disadvantages of ceiling insulation with expanded clay

Expanded clay has more than enough advantages, so let’s focus on the most important of them:

- The insulator is highly durable among many other materials.

Expanded clay is fireproof because it does not burn and does not emit substances hazardous to human health into the atmosphere.

Thanks to its special porous structure, this insulator weighs much less than other similar materials.

It is not edible and is not attractive to various bugs, rodents, bacteria, mold and fungi.

The low price of the material explains the fact why it has been successfully used for ceiling insulation for decades.

High thermal insulation qualities are complemented by excellent sound insulation properties, since it quickly absorbs acoustic vibrations.

The material easily absorbs moisture without increasing its own weight or losing its basic qualities.

Expanded clay chips or crushed stone do not cause allergic reactions in households or animals due to their natural origin.

Like other bulk-type thermal insulation, expanded clay is very easy to use.

Thanks to the fractional release form, the air between the individual pebbles further improves thermal insulation and produces natural convection.

Let's consider the possible negative aspects that may be associated with the use of expanded clay as a heat insulator:

- Its effectiveness is directly related to the thickness of the insulating layer. In other words, there is no point in making the thickness of the bedding less than 20, or even 40 centimeters.

This material must be reliably protected from atmospheric moisture or precipitation.

It is optimal to use it for thermal insulation over reinforced concrete floors. Firstly, they are quite monolithic in themselves and are able to withstand the weight of expanded clay. Secondly, they reliably keep crumbs and dust from spilling down.

When insulating houses made of wood, expanded clay must be protected by a vapor barrier on both the top and bottom sides.

It is not recommended to pour this insulator onto a ceiling that is attached to the beams below. Considering the weight and volume of expanded clay, it is possible that it will be able to break through the entire structure, which will collapse inside the room.

Negative aspects of expanded clay as insulation

*

Of course, expanded clay is a very good insulation material, but it also has its minor disadvantages.

- You should not use expanded clay to insulate a house if the layer thickness does not reach at least 30 cm.

- If moisture gets in, you will have to completely change the insulation

- Best used on top of reinforced concrete structures. Because the filler crumbles a lot and can seep through the coating.

- To insulate a wood ceiling, it is worth protecting the material from steam.

- Expanded clay, consisting of small fractions, cannot be poured onto a surface that is reinforced with beams from below. Since due to the heavy weight the material can break the ceiling.

Brief characteristics of expanded clay

Clay rocks are used to make the material. Granules are obtained by firing raw materials in special ovens. Since the surface of the expanded clay is melted, it becomes smooth. The porous structure is formed due to the action of gases released under the influence of high temperature.

The size of the material fragments varies: from 5 mm to 4 cm. Only natural raw materials are used to make the material, so it is completely safe for health.

An example of insulation of a reinforced concrete floor

For greater clarity, we will consider the process and sequence of stages of insulating a ceiling or attic using expanded clay using the example of reinforced concrete floors.

What needs to be done?

- Pour expanded clay directly onto the floor slabs. We level it using a rake, a piece of reinforcement, a bar, etc. The thickness of the layer can be controlled with any straight iron rod with a mark applied to it.

- Cover with a layer of expanded clay. You can use roofing felt or ordinary dense polyethylene. The main thing is to carefully glue the joints. The entire result we expect depends on this.

- That's it - insulation is done!

In the case of wooden floors, it’s worth starting with high-quality installation of a vapor barrier. Further, the same as in the case of reinforced concrete floors. However, it is worth considering that the level of expanded clay filling must necessarily be slightly lower than the level of the floor beams!

Ceiling insulation in a private house

You can carry out the insulation process yourself if you follow the installation technology.

In the bath

Ceiling insulation with expanded clay for wooden floors has some features. The seasonality of the heating of the building is taken into account. An equally important parameter is the often increased level of humidity in the room. Since expanded clay absorbs moisture, it must be protected with foil film. The metallized layer is placed inside the room.

The vapor barrier is laid not along, but across the beams. In this case, the film cannot be stretched. It should extend onto the walls to the full height of the insulation layer. The insulation joints are taped with construction tape. It is fixed on the base with staples. Expanded clay can be filled with cement laitance. Before backfilling, clay is laid on the vapor barrier.

It is best to insulate the ceiling of a wooden house with expanded clay/

The process of insulating the ceiling in a private wooden house does not belong to the category of very complex ones - it is not difficult for anyone to carry out, even with minimal construction skills.

Work on insulation using expanded clay should begin with laying hydro- and vapor barriers. To carry out these operations, a layer of material that is intended for vapor barrier must be laid on the prepared wooden ceiling - it will also be a waterproofing agent. For these purposes, it is possible to use both innovative developments of building materials and cheaper analogues, such as polyethylene film, roofing felt, and aluminum foil. The material must be placed on the floor, here it will be more convenient to cut them into strips of the required size - their width should be 10 cm greater than the distance between the ceiling beams.

Backfilling the material is the next stage of work.

Expanded clay will need to be compacted - so it is better to prepare sand and gravel right away. This way it will be possible to compact the material without breaking the granules or deforming them. The surface should be leveled.

Classification of heat insulator by fractions

The variety of material is determined by the size of the fraction, i.e. size of granulates:

- Small. According to the parameters, it is 0.1-5.0 mm. Used as a bulk mixture for backfill. Also used in the production of concrete blocks.

- Average. Reaches sizes of 10-20 mm, called gravel. Construction experts consider this fraction of expanded clay to be better for insulating ceilings, floors and floors of buildings.

- Big. Sizes vary in the range of 20-40 mm. Expanded clay of this fraction is used to insulate roofs, basements and semi-basements, as well as floors in garages and cellars.

Today, the building materials market offers about ten varieties of expanded clay. The distribution of types of material is carried out due to the density of the filling level. Thus, expanded clay of a large fraction has a lower density. Thus, the lower the grade and density of the granulate, the higher the quality.

Insulating a bathhouse using expanded clay

It is no secret that a high-quality insulated bathhouse heats up faster, maintains a consistently high temperature longer, retaining heat throughout the day. Moreover, good thermal insulation of bath rooms largely determines the service life of the entire structure.

Expanded clay is one of the most commonly used materials for thermal insulation of bathhouse floors. It serves as an excellent protection against the development of unfavorable environments and resists heat loss.

As a rule, expanded clay is used to insulate concrete floors. If you plan to lay a wooden floor in the bathhouse, then in this case enhanced waterproofing is required.

Expanded clay is called the most natural thermal insulator, since it is produced on the basis of ordinary clay. Light granules with a porous cellular structure appear during the firing of clay at a very high temperature.

The absolutely environmentally friendly material does not pose any danger to human health and is ideal for use in places that are subject to increased sanitary hygiene requirements. And the floor in the bathhouse is just such a place! In addition, expanded clay is distinguished by good sound insulation and low weight, making it easier to transport and use. The free-flowing nature of the material allows you to smooth out the unevenness of the surface on which it is applied.

The sizes of expanded clay granules vary between 0.5 and 4 cm. It is recommended to take different sizes for the thermal insulation layer. In this case, small granules, penetrating between larger ones, fill the space and make the masonry denser and more efficient.

Check the expanded clay for damage to the integrity of the granules, otherwise damaged elements may cause a decrease in the thermal insulation properties of the material.

What needs to be taken into account when laying expanded clay as a thermal insulation layer is its high moisture absorption rates. That is why, in combination with it, high-quality waterproofing of floors in bathhouses is required.

The procedure for insulating a bathhouse with expanded clay

So, the beginning of work on thermal insulation of floors in a bathhouse begins with the fact that a dense polyethylene film is laid under the expanded clay layer, creating a protective barrier against moisture coming from below. Next, a beacon system is installed to determine the plane of expanded clay backfill. Concrete or asbestos slides, boards secured with mortar, and an angle profile can be used as beacons.

When marking and laying expanded clay, take into account the floor slope required for damp rooms in the bathhouse.

After filling the expanded clay along the intended beacons, it should be leveled and compacted. The thermal insulating properties of expanded clay begin to appear at a thickness of at least 15 cm, so this is the minimum layer thickness. Some builders use a trick that does not affect the efficiency of the work, but speeds up and facilitates its progress. Instead of scattering the material, the expanded clay bags themselves are laid with holes pre-made in them. The same expanded clay is poured into the gaps between the bags.

Next, the expanded clay layer must be poured generously with liquid cement mortar, which is also called “cement laitance.” The composition is simple: cement, sand (3:2), water (20% of the total mass). Filling with the solution is carried out carefully so as not to disturb the structure of the laid granules. By filling the voids, “cement laitance” makes the expanded clay layer stronger and does not sag over time.

After the solution has hardened, work begins with pouring the screed (concrete or polymer floor). The layer is 3-4 cm thick. The screed made of concrete is leveled and reinforced with metal mesh. It takes a long time to harden, about several weeks. The polymer screed, in turn, requires piercing with a needle roller to get rid of air bubbles and dries faster - a week or a little longer.

At this point, work with expanded clay is completed. After the screed has completely dried, a waterproofing layer is fixed on the surface and the finished floor is installed.

Insulating a house with expanded clay: questions and answers

The modern construction market offers many ways to insulate a private home. Our portal has already talked about the most common types of insulation, such as stone and ecowool, extruded polystyrene foam, etc. We also wrote about whether it is profitable to build an energy-efficient house.

Can expanded clay as insulation in a wall compete with modern insulation materials? how and where it is better to use it as insulation; is there any economic benefit from using this material? Let’s look at the experience of FORUMHOUSE users.

What is expanded clay

Expanded clay is a porous granular material of low weight. Low-melting clay is usually used for its production. It is rapidly heated to 1000-1300°C for 25-40 minutes in a thermal chamber. During this process, the raw material “boils” and “swells.” Due to this, voids appear, when they harden, pores are formed in the granules of the material, enclosed in a shell of clay.

Expanded clay is an environmentally friendly and durable material that is widely used in construction.

The scope of application of the material directly depends on its density and the size of the crushed stone fraction. Namely:

- 0-5 – so-called expanded clay sand;

- 5-10;

- 10-20;

- 20-40.

The grade (depending on the bulk density) can vary from 200 to 800 kg/m3.

The most popular brands:

- M350

- M600

The higher the density, the stronger the material, and the worse its thermal insulation qualities as insulation. In addition to density and thermal conductivity, you need to pay attention to the water absorption of expanded clay. This indicator largely determines the durability and possible areas of application of the insulation. Simply put, is the material afraid of water or not, i.e. how much moisture will it absorb (as a percentage of its dry weight) when placed in a moisture-saturated environment. On average, the water absorption of this material (depending on the production technology at the plant) ranges from 8 to 20%.

How to choose and use expanded clay

Most often, the idea to buy expanded clay comes for its use as bulk insulation for thermal insulation of floors, interfloor excavations, external walls in the so-called. well masonry.

Three-layer well masonry is when a layer of expanded clay is poured between the internal main load-bearing wall (made of foam or aerated concrete) and the external decorative brickwork. The material is also used as a filler in the production of lightweight concrete.

Anyone who is planning to build a house from foam blocks will find it useful to read the article, which talks about the features and principles of choosing foam concrete.

Despite the fact that this insulation has been used in construction for a long time, there are many different conjectures and rumors about its properties and methods of use. Some builders scold this material, believing that it is subject to strong moisture accumulation. Others consider it ideal for a do-it-yourself developer. Here is a comment from a member of our portal:

Stupid FORUMHOUSE User

The following experiment came about naturally - expanded clay in bags stood on my street for two years. Recently I opened the bags and saw that there was nothing left of it - the balls had turned into damp dust.

Any building material, be it expanded clay, brick, foam and aerated concrete, etc. If used incorrectly, installed, stored and operated, it will lose its quality.

user343FORUMHOUSE user

I think I just got it “undercooked”. I once had to collect expanded clay that had been lying on the ground for 30-40 years. The granules were even overgrown with moss. I sifted it from the ground, after which there were more whole granules than fragments.

The properties of the material directly depend on the quality of the raw materials and on whether, when making expanded clay, the plant complies with all stages of production. Hence: from different manufacturers, expanded clay of the same fraction and density may differ from each other.

Therefore, you can buy either a “pig in a poke” or a relatively cheap but high-quality product, which, if used correctly, will show all its positive properties.

To choose this material, you first need to decide for what purpose it is needed and what it will be used to insulate.

bagdanovaFORUMHOUSE user

I need it as insulation for walls and as a filler for lightweight concrete. I was wondering which factions to choose.

According to a forum member with the nickname soniikot, it is better to take fractions of 5-10 or 10-20 as a filler for lightweight concrete, because The higher the bulk strength, the higher the grade of expanded clay concrete.

The specific brand is selected depending on the requirements for the wall material. Also, the user of our portal advises, before buying expanded clay in meshes, to study reviews on the Internet about the plant and the supplier company. It happens that careless sellers, offering expanded clay cheaply, mix dirt into the bags or weigh down buyers.

Where to buy expanded clay

FORUMHOUSE is often asked how to choose this material. To get a comprehensive answer from experienced builders, you need to clarify in which region of the Russian Federation the construction is planned, what kind of house is being built, according to what project. This will help you understand why and where the insulation will be used.

A general rule that is useful to everyone: the characteristics of the product (density, brand, frost resistance, etc.) must correspond to the declared technical parameters, which can be found on the manufacturer’s website. When delivering, they should bring “honest” cubes and kilograms, not “air”. It is worth paying attention to where you buy expanded clay - the price from intermediaries and directly from the manufacturer will vary significantly; also look at how long the manufacturer has been on the market and what equipment he has. You shouldn’t throw all your energy into buying expanded clay cheaply; listen to the opinions of those who have already built it, and look for a manufacturer that has proven itself well.

Is insulation with expanded clay beneficial?

When choosing expanded clay as wall or floor insulation, wondering whether a frame wall with expanded clay insulation will withstand Russian frosts, you need to immediately calculate the economic feasibility of this idea. It's all about its thermal conductivity coefficient.

Consider the following examples:

Oleg Lvovich FORUMHOUSE user

Depending on the density, the thermal conductivity coefficient (lambda) of expanded clay varies from 0.11 to 0.23 W/(m*°C). At a density of 400 kg/m3, its thermal conductivity coefficient will be 0.15 W/(m*°C). Insulation thickness 0.15/0.15 W/(m*°C) = heat transfer resistance R=1. Next: 1*0.05 W/(m*°C) (thermal conductivity coefficient (lambda) of PPS polystyrene foam) = 0.05 m.

Hence: according to the thermal characteristics, 15 cm of expanded clay with a density of 400 kg/m3 corresponds to 5 cm of expanded polystyrene grade PSB-25.

If you take and compare expanded clay/stone wool, then the comparisons will again not be in favor of the first. If we take average values (the average thermal conductivity coefficient of expanded clay depending on its density is 0.1-0.14 W/(m*°C), and stone wool is 0.04 W/(m*°C), then in order to obtain a comparable thermal protection effect, Expanded clay will require about 120 mm versus 50 mm of stone wool.You will have to increase the thickness of the expanded clay layer.

44alexFORUMHOUSE user

I thought about using expanded clay instead of extruded polystyrene foam in the foundation of the USP.

The forum member made calculations and found out that such a replacement is unlikely to be justified. The fact is that although the price of expanded clay is approximately three times lower than the price of EPS, its thermal conductivity is five times (or even higher) higher. Therefore, you will have to lay a layer of at least 0.5 m, and in combination with a warm floor system - 0.7-0.8 m.

Although the price for 1 cubic. m of expanded clay is less than the price of 1 cubic. m EPS, but due to the increase in the bedding layer, expanded clay will be required 4-5 times more. Those. the price of a layer of equivalent insulation of the material we are considering will be 2-2.5 times more expensive than EPS, which will negate all the benefits of its use.

This article talks about all the features of the USHP foundation.

If we are talking about a wooden house, then in order to insulate it with expanded clay, you will have to build a strong foundation (since granules weigh more than stone wool), think about how to place a scattering of granules so that they do not spill out, etc. d.

Note: because the cost of insulation in Moscow and different regions can vary significantly; the final price is calculated based on local characteristics and the availability of certain materials.

For the same expanded clay in bags, the price can be blatantly different in different regions; as if the place of sale makes two different materials out of it: “expanded clay Moscow” and “expanded clay region”.

Therefore, for each specific case of insulating a house with expanded clay, a separate calculation is necessary based on the climate zone, the degree of heat loss of the house, the duration of the heating season and the cost of expanded clay must also be taken into account. On our forum there are examples of how to competently approach insulating a house with this material and win.

Spiker99FORUMHOUSE user

I have a house 8x8 meters, built of aerated concrete with a density of D600, block sizes 625x300x200. I spent a long time choosing how to insulate the cottage. After going through several insulation materials, I settled on backfilling with expanded clay as an environmentally friendly and relatively inexpensive material.

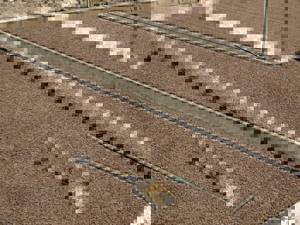

Insulation of walls with expanded clay. Layer thickness

An interesting approach to implementing home insulation. Place of construction - Kirov region. The walls of the house are made in the form of three-layer masonry. Between the blocks of aerated concrete and the external masonry of sand-lime brick, expanded clay is poured; the layer of backfill is not thick - 15 cm. It is spilled with cement laitance. Heated area – 50 sq. m. The second floor is closed. The house is heated by three electric convectors with a total power of 4 kW. Food is cooked on an electric stove, + there are 2 water heaters in the house with a total capacity of 150 liters. Total: heating costs for December amounted to 1.5 thousand rubles. at a tariff of 2 rubles. 7 kopecks for 1 kW*hour. The cost of insulating a house, including delivery and labor, is about 77 thousand rubles.

Insulated blind area made of expanded clay

Builders who use this material are familiar with the expression “expanded clay does not work in the ground.” That is, in structures below ground level (especially in moisture-saturated soils and high groundwater levels), expanded clay insulation has nothing to do. If you neglect this rule, he will “drink” water and lose all his positive properties.

All the more interesting is the method in which the material we are considering can be used as a replacement for extruded polystyrene foam in the construction of an insulated blind area.

TraksFORUMHOUSE User

Expanded clay was used in the blind area as a remedy against frost. Expanded clay of the M450 brand, fraction 5-20, was used. The fragility of this material is very conditional. You need to buy high-quality material, follow the installation technology, and all problems will be solved.

The essence of the method, successfully tested by a forum member, is as follows. Because “burying” expanded clay in the ground is a futile task; in order for it to “work”, it must be isolated from the influence of the external environment, i.e. – waterproof. Which is what was done. The blind area pie (if we consider the layers from bottom to top) has the following structure:

- priming;

- coarse sand, mechanically compacted;

- expanded clay, “wrapped” in a 2x20 m profiled drainage membrane;

- geogrid;

- crushed stone

The backfill width is 1.2 m, the layer thickness is about 15-20 cm.

In the FORUMHOUSE topics you can learn how to insulate the walls of a house with expanded clay, and whether it is worth insulating the foundation with expanded clay.

Do-it-yourselfers will find useful topics with a detailed description of building a house using monolithic expanded clay concrete technology, as well as a detailed report on how to build a cottage from lightweight expanded clay concrete.

In our video, the owners of a house in the forest tell us why they chose expanded clay concrete as a wall material.

Quality checking

How to make sure that the thermal insulation of the ceiling of a private house or bathhouse is done with high quality? The first step is to check the insulated room for heat loss.

To do this, you should warm it up, measure the air temperature, and then close it tightly and leave it for several hours.

If the temperature inside the room quickly drops to the temperature of the other rooms, then there is a heat leak somewhere. We need to find these places and eliminate the cause of the leak.

If there is an attic above the living room, it is necessary to insulate the roof, if this was not done during the construction of the house.