Houses made of rounded wood or natural timber are rightfully considered the most comfortable. Their high popularity is explained, first of all, by the naturalness of the material and good protective characteristics.

But all types of one-story buildings are characterized by significant losses through ceiling structures. Therefore, you have to fight for warmth and comfort in a wooden private house. The correctly chosen method and a well-thought-out insulation scheme are the main components of success in this fight.

Methods of thermal insulation of wooden ceiling structures

Numerous technologies for insulating ceilings in wooden houses are divided into two groups according to the location of installation of the insulation:

- from the side of residential premises (from the inside);

- from the attic (outside).

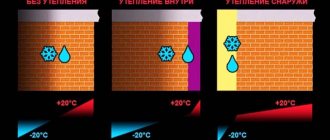

Both approaches have their advantages and disadvantages. Thus, insulating the ceiling in a wooden house from the inside will save money, but will reduce the useful volume of living quarters, and insulation installed outside will require additional protection from mechanical damage and more powerful hydro- and vapor barrier, which will entail an increase in insulation costs.

In the classic version, the thermal insulation layer has the following structure:

- external steam and waterproofing;

- insulation material;

- sheathing;

- internal vapor barrier;

- sheathing

Which insulation is better?

The quality of insulation of a wooden ceiling structure depends on which insulation is chosen and how well its installation is done.

The effectiveness of thermal insulation is best seen in cold weather. Everything is simple here - if it gets warmer, it means the thermal insulation is working.

Doubts can be dispelled with a little snow. It is left in the attic, if after a while it melts, everything is in order with the protection. When the snow has not yet fallen, you can place ice cream or ice from the freezer in the attic.

Based on the price of the material, then the best option for both external and internal insulation is mineral wool. As for the price tag, more economical options are sawdust and expanded clay, which are only suitable for installation outside.

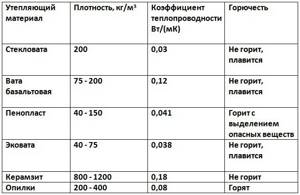

To make your choice easier, you can use the table.

Among the varieties of mineral wool, basalt wool deserves special attention. It contains the least amount of toxic substances. It also has the widest range of permissible temperatures (+)

Polystyrene foam is also a relatively inexpensive material, but it is not entirely reliable from an environmental point of view.

It is also worth worrying in advance about the insulation of the floor in the house to prevent heat leakage through the lower ceiling. Practical recommendations for choosing the optimal thermal insulation material are given in this article.

In addition to using traditional insulation technology, you can use a more progressive and practical solution - installing a heated floor. Such a system can completely replace standard heating or become an effective addition to it.

How to insulate the ceiling?

All materials that can be used to insulate the ceiling in a wooden house are divided into three groups:

- bulk;

- soft;

- solid.

The first group is used only for external insulation. The other two are used in both methods. The most popular representatives of each group, respectively, are:

- sawdust;

- mineral wool;

- Styrofoam.

When to insulate a ceiling

Ceiling insulation will be needed in all cases when there is an unheated room above it, that is:

- The ceiling of the upper floor, above which there is a non-residential attic space.

- In cases where there is an attic space that is used but unheated.

- If in winter only one floor is used, and the upper ones remain without heating.

When installing an attic in the attic with an insulated roof and heating, there is no need for thermal insulation of the ceiling. But even in this case, laying insulation will not be superfluous; it can serve for sound insulation.

Ceiling insulation may be necessary if there is a cold basement. This option will protect the heat of the living space from the cold below if for some reason it is impossible to insulate the floor.

Foam insulation

The easiest way to insulate is to finish the ceiling from the inside with foam plastic. Its advantages include:

- relatively low cost of material;

- light weight;

- unique steam and moisture repellent properties;

- ease of installation;

- environmental friendliness.

Stages of work

First, a waterproofing layer is attached to the false ceiling between the beams. For this you can use glassine or plastic film.

Foam boards are attached on top of the waterproofing using special glue. After applying the adhesive to the insulation, you should wait 1 - 2 minutes and press it tightly to the ceiling. The slabs are mounted end-to-end. If there are gaps between thermal insulation products, they are sealed with polyurethane foam. It is better to additionally fix the insulation on the surface using self-tapping screws with washers of large diameter (10-14 mm).

After installing the slabs, a layer of glassine or other vapor barrier material is laid again. The whole process is completed by cladding and decorative finishing of the ceiling structures.

Modern industry produces foam sheets of various colors and textures. The front surface may contain an abstract pattern, which, if chosen correctly, will enrich the interior of the room.

Causes of condensation

If, after insulation with polystyrene foam it drips from the ceiling , the thermal insulation is made poorly: the low surface temperature collides with steam and warm air rising upward, resulting in the formation of droplets of moisture that settle on the coating.

Drops appear when steam cannot escape, and the higher the humidity in the room, the lower the dew point . The formation of condensation leads to the appearance of mold and fungi and deterioration of thermal insulation.

The most common causes of condensation can be:

- ill-conceived ventilation design;

- lack of an insulating layer or its incomplete protection;

- incorrect placement of insulating layers;

- poor-quality insulation, which leads to freezing of the ceiling covering;

- with temperature changes resulting from different insulation in different areas.

Temperature changes can occur especially often:

- in the cellars on the ceiling;

- in detached garages and sheds;

- on balconies and loggias;

- in poorly ventilated areas;

- when insulating roofs with a large slope, where waterproofing or insulation can roll down, forming cold areas.

How to prevent condensation

To prevent condensation, you must:

- think through the ventilation ducts and air gap in the insulation layer correctly;

- when purchasing, do not skimp on the quality of insulation, waterproofing, vapor barrier;

- when purchasing a premises, pay attention to the design of the ventilation system and the consistency of its operation;

- determine the indicator of importance in the room: at levels above 40%, condensation formation is the norm.

If there is condensation, what can you do?

If there are already deficiencies in thermal insulation, the process of eliminating them is quite labor-intensive:

- insulate the finished coating from the cold ceiling: insulate with mineral wool, cover with expanded clay, apply a layer of brick chips, lay foam insulation;

- you should check the condition of the insulation: disassemble the insulation cake and carefully examine whether there are any breaks or damage, as well as whether there is water absorption;

- if moisture has penetrated to the inner layers of the finish, you need to clear the surface up to the main ceiling (concrete surface), dry the ceiling using a hair dryer, then replace the insulation.

In order for condensation to flow down, it is necessary to create an inclined surface . Depending on the location of the slope, a water drain is adjusted to the outside, under which a container is placed to collect water. Near single buildings, grooves are installed through which water flows into the soil.

To install an inclined condensate drain on the ceiling, you will need: polyethylene film material with a size equal to the area of the ceiling, sheets of galvanized iron, and plastic pipes.

Sawdust

Sawdust is a natural material and has proven itself for thermal protection of wooden houses. This technology is somewhat more complicated than gluing with foam plastic. The main difficulty lies in the preparation, or more precisely, the manufacture of insulation, which is a cement-sawdust mixture.

Preparation of the composition

It is better to use medium-sized shavings. Thyrsa is not suitable for insulation. Its volume contains very little air. The sawdust should not be fresh. The raw materials are treated with antiseptic and antifungal compounds. The simplest solution to this problem is to soak wood chips in a solution of copper sulfate, after which it should be thoroughly dried.

The required volume of sawdust is equal to the planned volume of the insulating layer, the recommended thickness of which is 20 centimeters.

The process of preparing a cement-sawdust mixture consists of the following steps:

- in a spacious container (a trough with sides 25-30 cm), prepare “cement milk” by mixing water with cement in a ratio of ten to one, and mix thoroughly;

- Sawdust is added to the resulting mixture, which during the mixing process should be evenly covered with a layer of solution.

Surface preparation

Before you begin making insulation, you should prepare the area for its application. This preparation includes the following:

- dismantling the attic floor;

- cleaning the space between the joists from debris and other foreign objects;

- treatment of all available wooden floor structures with antifungal and antiseptic agents;

- laying a vapor barrier carpet (as insulation, you can use thick polyethylene film overlapped on the joists).

Application of insulating composition

Next, the prepared cement-sawdust mixture is scattered over the floor area and lightly compacted. The insulation must be evenly distributed between the floor joists. After complete drying, the resulting coating can be walked on.

One of the main advantages of this method of ceiling insulation is the low cost of materials. First of all, this concerns sawdust, which, with some effort, can be purchased for free.

Choosing insulation for a wooden house

Wood itself retains heat very well, which is why wooden log houses with sufficiently thick walls and modern windows are quite warm. However, you should not think that no additional insulation will be required anymore. The greatest heat loss occurs not through walls, windows or doors, but often through the ceiling. After all, according to the laws of physics, heated air rises.

And the temperature in the house depends on how correctly and efficiently the thermal insulation of the ceiling is performed. Don’t forget about sound insulation, which will add comfort to your stay. Let's consider the main types of existing thermal insulation materials. Any insulation must perform the following functions:

- be fireproof;

- do not harm health;

- have little weight;

- have low thermal conductivity and moisture resistance.

The choice of insulation materials is currently quite diverse. Based on their appearance, they are divided into bulk, liquid, tile, roll, block, brick, etc. Based on their composition, they can be classified into inorganic, organic, artificial (polymer) and combined.

Organic insulation materials include sawdust, hay, straw, peat, as well as mixtures made by builders based on cement and these materials. Environmental friendliness, low thermal conductivity, low cost and many years, and sometimes centuries-old experience of use still make them popular in private construction. The main danger is the easy flammability of organic matter; a decrease in thermal insulation qualities over time is also possible. Therefore, work to maintain ceilings in proper condition will have to be carried out much more often than when using more modern types of insulation.

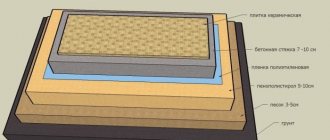

Inorganic ones include expanded clay made from processed clay, expanded vermiculite and perlite, which are obtained by firing rocks of the same name, foam glass, cellular glass obtained by melting ordinary glass waste with coal dust, and mineral wool. Of the above bulk materials, the most popular and in demand is expanded clay, which at a fairly low cost has a thermal conductivity of about 0.1 W/mK.

The only drawback will be its heavy weight, since the optimal layer of this insulation should be from 200 to 400 kg per 1 m3.

Therefore, it is advisable to use it where the ceiling is made of large and thick beams with a continuous roll. If the price issue does not concern you, then the best heat retention properties are inherent in cellular glass, made in the form of individual blocks, a very light and environmentally friendly material.

Mineral wool

A popular method of insulating a wooden ceiling is using mineral wool. In terms of its thermal insulation characteristics, this material is superior to polystyrene foam. The installation process is relatively simple.

Vapor barrier layer

A vapor barrier is laid on the outer surface of the ceiling, freed from the coating and cleared of debris and foreign objects. As with sawdust, thick plastic film will do.

Install it with an overlap of about 10 cm. The seams are taped.

Installation of insulation

Mineral wool is produced in slabs and rolls. When using rolled material, the cotton wool is unrolled along the beams.

The second layer of insulation is laid in the opposite direction, covering the beams and joint areas.

For additional fixation of the insulation strips, you can use nails, the heads of which should be slightly “recessed” into the top layer of the material.

Waterproofing

One of the few disadvantages of mineral wool, but quite significant, is its hygroscopicity. It is very easily saturated with moisture, which has an extremely negative effect on its thermal insulation properties. Therefore, the insulation layer must have reliable external waterproofing.

Lay it on top of the mineral wool, overlapping it and gluing the seams.

Finishing layer

If the attic is not in use, then a cement-sand screed can be placed on top of the insulating structure. When arranging residential attics, floor boards or laminate are installed.

Insulating the ceiling of a private house is a relatively simple technological process. Performing these works does not require special skills. With the desire and knowledge of the main technological aspects, everyone is able to cope with this task independently.

Internal ceiling insulation

It is easier to insulate the ceiling of a wooden house from the outside; internal insulation work is somewhat more complex.

This method is attractive because less materials are consumed, the work can be done together with finishing and at any time. This reduces financial costs.

Although the method of internal insulation of a ceiling structure is effective, it is not worth implementing it if the ceiling has recently been repaired in the house.

Option #1 – insulation from the inside with mineral wool

Rolled mineral wool will be used for insulation.

If the height allows, the insulation can be laid in two layers. Usually mineral wool or polystyrene foam is used for this purpose.

The process consists of 11 sequential steps:

- Marks are placed on the ceiling in the corners. The best solution is to use a laser level for this.

- The marks are transferred to the walls to the desired height, taking into account the height of the profile and the thickness of the roll.

- A line is drawn along the marks using a cord.

- The profile is fastened along the line with self-tapping screws.

- Apply the CD profile to the ceiling, measure the required length, and install it at a distance of 40 cm from each other.

- For each profile, U-shaped hangers are attached at a distance of 70-90 cm.

- Pull the fishing line from the edge of every third profile.

- The profile is screwed to the suspension along the fishing line. The remaining profiles are fixed using a level or rule, based on the previously fixed profile.

- Mineral wool is placed between the profile. The panels are fixed using hangers.

- Using self-tapping screws, screw the sheets of drywall in a checkerboard pattern. A 5 mm gap is left around the perimeter of the ceiling.

- The joints in the places left free are reinforced with a profile, and then covered with pieces of plasterboard.

Metal or wooden frame - additional costs. But this method of attaching insulation opens up wide possibilities for decorative finishing of the ceiling.

Option #2 – insulation with foam plastic

To obtain a perfectly smooth surface layer that retains heat well, polystyrene foam is used for insulation.

Ceiling insulation with polystyrene foam can be done either by frame or by adhesive. The second method is possible when the surface is flat, without drops

Method 1 . To insulate the ceiling using the frame method, you need to prepare: wood screws, washers with a large outer diameter and foam plastic about 300 mm thick.

Sequencing:

- The ceiling is coated over the entire surface with a deep penetration primer and allowed to dry.

- They make markings.

- The foam is secured using self-tapping screws.

- The insulation is puttied with a reinforced mesh with a mesh size of 2.5 mm.

- Apply a layer of finishing putty, then paint the surface.

Method 2 . The foam is not screwed to the ceiling, but glued. For this purpose, use a polymer adhesive mixture or ordinary starting gypsum plaster. The main thing is not to knead a large amount at once, since the latter has a limited time of use.

The mixture is applied to one side of the foam sheet, placing it in slides in the corners, between them and in the center.

The sheet is pressed against the ceiling surface, its spatial position is adjusted using a building level. Having finished laying the first row, begin installing the second. At the same time, they try to avoid continuous seams.

If a full-size sheet is laid at the beginning of the first row, then a half-slab should begin the second row. Next, this entire structure is plastered twice, then covered with finishing.

Instead of polystyrene foam, you can use extruded polystyrene foam - the material is characterized by high thermal efficiency, good strength and resistance to negative influences.

Option #3 – installing penofol on the ceiling

Penofol is an excellent option for insulating the ceiling from the inside of a wooden house. It consists of polyethylene foam and polished foil.

Penofol differs from traditional insulation in that it works on a different principle. While most thermal insulators resist the penetration of heat through themselves, penofol is a reflector of heat flows

The installation sequence is as follows:

- Install a strong sheathing on the wooden ceiling.

- Attach penofol with the foil side facing the room. The material can be fixed with nails.

- Gaps are left on both sides of the insulating layer for ventilation.

- They arrange another crate.

- Attach drywall. Instead, you can use a suspended ceiling.

The thermal resistance of this material with a thickness of 0.3 cm is identical to the corresponding parameter of extruded polyurethane foam, which has a thickness of 3 cm. Penofol is used as an independent insulation and in combination with other insulation.

The two substances included in the structure of penofol are non-flammable, therefore they can be used indoors without any restrictions. It is a good sound absorber and does not allow moisture to pass through, so there is no need for additional moisture protection.

The disadvantages include the lack of rigidity, as well as the fact that it does not stick well. It has to be fixed with nails or staples, which reduces its performance properties. To compensate for this shortcoming, manufacturers began producing self-adhesive foam foam.

If the installation technology is violated, fungal or mold spores may develop in the insulation.

Option #4 – a combination of penofol and mineral wool

In order to perform such double insulation of the ceiling from the inside, a structure is assembled as if under plasterboard. Mineral wool is placed between the profiles. Penofol is fixed on top of the frame and secured to the supporting profile using self-tapping screws.

A thermal insulation option with two layers of penofol is possible. The first is attached to the ceiling with the foil layer down. The second is on top of the mineral wool layer. For mineral wool, penofol will serve as a vapor barrier

The strips are laid without overlap, but end-to-end. The joints are taped with foil tape. At the next stage, the sheathing is done with plasterboard, then the final finishing is performed.