Possibility of using foam fillers

Balloon thermal insulation , although better than its analogues in all respects, was not widely used in the past due to its high cost. And the use of such insulation was limited by the need to use special equipment, which, due to its price and complexity of development, is practically inaccessible outside the professional sphere. Much simpler and more profitable, although not always more convenient, was the use of mineral wool and polystyrene boards, which are made by extrusion.

Then manufacturers began to produce sprayed insulation in compact-sized cylinders, which led to a reduction in the cost of the method. To spray such a mixture of steel, complex installations and specialists in thermal insulation finishing are not needed, since the material itself is filled into small containers and the possibility of manual spraying is provided. Each cylinder is designed to cover one square meter of base (layer up to 60 mm thick). One person can process up to one hundred square meters per day.

As a result, calculations showed that working with insulation such as Polyno

r is much more profitable in terms of labor costs , costs for the materials themselves and surface preparation.

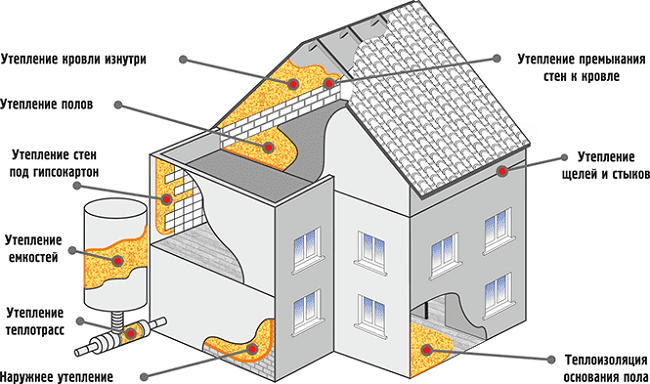

If a professional team of workers charges up to one and a half thousand rubles for insulating one square of wall, then using Polinor insulation with the same amount of material, you need to spend only about 500 rubles. You can work independently, which eliminates the need to look for experienced workers, reduces finishing time, and saves money. The choice of thermal insulation of this type remains the only optimal option that is available to people without special training. Foam can be used to create insulation for foundations, basements, walls inside and outside buildings made of brick, stone, concrete, and blocks. This option is also suitable for thermal insulation of non-load-bearing coatings, including floors on joists, as well as pitched roofs and attic floors.

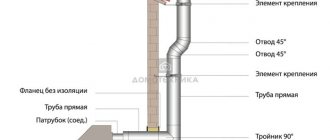

Since Polinor is suitable for application to bases made of almost any material, it can be used as thermal insulation for plumbing fixtures and sewer pipes or fittings. In such cases, foam insulation in cylinders can be used indoors or in open areas. There is only one limitation on the use of balloon thermal insulation, which is that the material cannot be used to foam voids. It can only be applied to a dense base.

Popular manufacturers and prices

The most popular manufacturers of sprayed insulation are the following:

- SEALECTION, intended for interior work;

- HEATLOK SOY, which can be used internally and externally;

- Ecotermix 300 (for external use with 92% cell closeness) and Ecothermix 600 (for internal use with open cells).

Approximate prices for external thermal insulation with a layer of foam of 2.5 cm/m2 can reach up to 500 rubles, for a layer of 5 cm/m2 – up to 800-900 rubles. Internal thermal insulation requires a layer of at least 10 cm/m2 and will require approximately 500-600 rubles at a density of 10 kg/m3. For walls and foundations, the cost calculation will be close to internal insulation. The price should also include the cost of equipment and equipment for work.

Material characteristics

Polyurethane foam (PPU) looks like a homogeneous structure of foam material, consisting of air bubbles filled with gas. Various versions of polyurethane foam are deservedly popular because they can be manufactured directly on the construction site. The most common method is to apply the material to the surface by spraying. Spraying is used for thermal insulation of houses, industrial workshops, pipelines, and in addition, it is actively used in the interior of premises.

Filling is used when it is necessary to fill a cavity between walls or a gap between installed finishing layers.

The thermal conductivity coefficient of the material is 0.023-0.025 W/mS. Teplis heat insulator is lightweight and can be easily applied to surfaces made of any materials (concrete, brick, glass, wood, aluminum, PVC).

Thanks to the optimal ratio of open and closed cells in the structure, the insulation “breathes”. Accordingly, the treated surface always remains clean and dry.

Other product benefits include:

- resistance to temperature changes;

- environmental friendliness;

- duration of operation (at least 20 years);

- seamless application, eliminating the formation of cold bridges;

- good sound insulation;

- low flammability;

- immunity from harmful rodents and insects.

Teplis polyurethane insulation is sold in 1 liter cylinders. Included with this product, the manufacturer offers to purchase a mounting gun with nozzles for uniform spraying.

Basement of a house with sprayed insulation applied

Polinor - insulation in cylinders

The most popular sprayed insulation in small 1 liter containers is Polynor. Its application is carried out using a mounting gun. It has a pink foam color and upon contact with air space a foaming reaction occurs.

Complete hardening occurs within 3 days, although polymerization begins after 40 minutes. After complete drying, the coating has a low level of thermal conductivity. Duration of operation - 35 years. 1 liter capacity is enough for 1 sq. m of surface if the layer thickness does not exceed 4 cm. In this case, there is no need to build a special frame.

Description and characteristics

Polinor is produced in a liquid state and applied to the surface by spraying. This popularity of the material is not caused by chance, because it is characterized by the following advantages:

- Fast drying. The surface becomes hard after 1 hour.

- Unaffected by rodents and insects.

- Does not form cold bridges.

- Does not harm the human body.

- There is no need to buy expensive equipment for application.

- The material is characterized by high efficiency.

- Has a long service life.

- The structure of the material is closed cells that do not allow water or steam to pass through.

- The material is self-extinguishing if there is no direct influence of fire.

In the photo - liquid insulation in cylinders Polinor

Polinor is not without its disadvantages, which include:

- A surface made of Polinor is resistant to direct influence of UV rays and constant contact with water, and the process of applying the material must take place at a temperature of 15-25 degrees.

- When working with insulation, you must adhere to safety rules using a mask and respirator.

Compared to existing analogues of liquid thermal insulation for walls, Polinor insulation is significantly different. First of all, the changes concern the structure, or more precisely, the percentage of open and closed cells in the solid mass. This criterion is very important, as it affects the level of thermal conductivity, moisture absorption and water permeability. Using Polinor, you can get about 70% of the cells, while when using similar sprayed products, the number of closed-type cells will be only 30-40%. However, it cannot be used as a seal for interior doors.

On the video, liquid insulation in cylinders Polinor:

The material in question has the lowest thermal conductivity among all the insulation materials that are available on the domestic market today. For example, mineral wool has a thermal conductivity coefficient of 0.045, expanded polystyrene – 0.033, and Polinor – 0.023 W/m2* °C. Thanks to these properties of the heat insulator, it is possible to reduce its consumption. One cylinder will be enough to treat 1.2-2.0 m2.

Sprayed thermal insulator Polinor can be applied at temperatures from -25 to +125 °C. If it is exposed to a temperature of 450 degrees, then its length will be deformed by 85%, and damage by weight will be 50%. The duration of its independent combustion will be 5 minutes.

Polinor is an environmentally friendly insulation material, thanks to which it can be used when arranging a residential building. The material has high adhesive properties to various surfaces, resistance to moisture, chemicals and aggressive environments.

When spraying polyurethane foam becomes a salvation

A situation often arises when owners buy a house in warm weather, but with the onset of autumn and winter, cold reigns in the premises, drops of water appear on the walls, and the entire building freezes.

Such a house can be made habitable by removing the old insulating material and spraying the outside with polyurethane, which will act as insulation. Then the walls are covered with finishing material, and it becomes convenient and comfortable to live inside.

Another unpleasant situation arises when the owners, having arrived at a country house, discover that the insulation has been practically carried away by mice or has become unusable due to water ingress. In this case, you also have to remove the old insulation material, spray polyurethane foam, and then re-sheath the walls.

Sometimes people build houses from timber, hoping that they will not be cold and without insulation. But in winter, the house becomes uncomfortable, and the wind blows into the walls. The situation is fraught with health problems and astronomical heating bills. As a result, the owners insulate their homes.

The most thoughtful and sensible people immediately build a warm house, inviting a team to spray polyurethane foam onto the timber. And after that they only do interior and exterior decoration.

Liquid foam

This type of insulation includes almost all foam materials based on polymer resins. The quality of the final product, including its environmental friendliness, largely depends on them. There are raw materials whose use is not permissible for residential premises due to the high toxicity of the polymer and its long-term emissions. At the same time, such materials are quite suitable for insulating technical structures or isolated building elements (if there is confidence in their insulation and the conscientiousness of the working specialists).

At the moment, such types of liquid foam as polyurethane foam, penoizol, as well as a number of products in compact cylinders are common.

Polyurethane foam (PPU)

Viscous heterochain polymers in a liquid state are used as the main component of this insulation. During chemical reactions, urethanes foam, which leads to their increase in volume by more than 50 times.

In its frozen state, polyurethane foam resembles ordinary polyurethane foam, the main difference in the structure is less porosity.

Mainly used for:

- Insulation of walls of frame buildings;

- Roofing structures;

- House facades;

- Thermal insulation of basements and lower floors.

To apply polyurethane foam, you need a special unit that first mixes and foams the insulation components, and then delivers the finished mixture under pressure to the surface to be treated.

Final polymerization occurs within 24 hours, after which the finishing can be installed. Polyurethane foam is suitable for treating surfaces made of brick, concrete, wood, metal, cinder blocks and gas silicate blocks.

The average cost of work including material is 1000-1500 rubles per m2 , with a layer thickness of 50 mm.

Penoizol

A budget analogue of polyurethane foam insulation, since it is based on relatively cheap, but more toxic urea-formaldehyde resin. The structure of this insulation is very similar to ordinary foam plastic, but its use is more preferable due to the absence of cold gaps in the insulating layer, characteristic of sheet and roll materials.

The density of penoizol, even in a liquid state, is noticeably lower than its urethane analogues, which does not allow its use in loaded structures. Otherwise, the scope of application is similar to polyurethane foam. Thermal insulation qualities are also not exceptional and are comparable to mineral wool, and two times less than that of the polyurethane foam described above.

Apply under pressure after pre-mixing the components and foaming. Increases in volume by no more than 30 times relative to the original mixture.

Roof insulation with foam insulation

Work together with the material costs approximately 2000 rubles per 1 cubic meter .

Polyurethane foam

The products are mainly used for processing seams between insulation elements. Polyurethane foam is relevant as a means for sealing structures; it is also used for fastening building and finishing materials to the base being constructed. In terms of operational characteristics, the resource has an average level of efficiency. Do-it-yourself polyurethane foam for insulating the walls of a house is produced in small containers; the products are presented in a wide variety of models. When applied, the composition expands 20 times. The material is easy to use independently; even an amateur can handle the job.

Polyurethane foam

Building materials in this category are attractive due to their versatility. Polyurethane foam as thermal insulation demonstrates a high level of efficiency. The PU foam composition has excellent properties of resistance to aggressive environmental influences. After foaming, the primary production volume increases 40 times. The presence of many microbubbles in a two-component compound determines the exceptionally low thermal conductivity coefficient of this foam insulation. The use of polyurethane foam for wall insulation involves significant costs, since the composition is applied using special equipment. The service life of polyurethane foam reaches 50 years.

Polyurethane foam for wall insulation

"Polinor"

This is a liquid insulation based on polyurethanes. A common form of release is small cylinders, similar in appearance to those for polyurethane foam. Using one cylinder you can insulate about 1 m2 of surface with a layer thickness of 6-7 cm.

The strength and thermal insulation qualities are similar to polyurethane foam, but unlike it, “Polinor” is more suitable for household use, since it does not require special equipment for application. The relatively high cost (about 500 rubles per cylinder ) makes its use inappropriate over large areas.

The insulation is applied by spraying, which allows it to be used on almost any surface, for example, for thermal insulation of pipelines located outdoors.

As for filling voids in the walls, this procedure cannot be completed due to insufficient pressure in the cylinder.

"Polinor" has the following technical characteristics:

- Thermal conductivity – 0.025 W/(m*K);

- Moisture absorption coefficient – no more than 0.03;

- No toxicity, non-flammable;

- Solid density – not less than 28 kg per m3;

- Retains all operational properties for 50 years;

- The operating temperature should not exceed +121°C;

In addition, the mixture is quite chemically stable and does not interact with most reagents common in everyday life.

Chloroform, dichloroethane, and high concentration hydrochloric acid have a negative effect (promote swelling) on Polinor. Nitric and sulfuric acids react with polyurethane, thus destroying the insulating mixture as a whole. Current prices for your city:

What are the advantages of insulating the walls of a wooden house with polyurethane foam?

As already noted, the use of polyurethane foam has high thermal insulation properties, and is also one of the most environmentally friendly materials, does not require additional structures that accompany the formation of gaps and cracks for the penetration of unwanted air, simple and quick installation, copes well with the soundproofing function, does not absorb moisture. Also, despite its light weight, polyurethane foam strengthens the supporting structure without creating additional loads. One of the most important advantages of using polyurethane foam is its durability. Even after time, the properties of polyurethane foam are not lost and do not settle. On average, the service life of such insulation reaches 50 years.

When constructing any objects, one of the main tasks is insulation.

For a long time, mineral wool has been the most popular insulation material for wooden houses, not only inside but also outside. However, after a while, significant shortcomings were discovered, including seams, the need for additional fastening, as well as the possible formation of not only mold, but also mildew, which negatively affects human health.

As for polyurethane foam, it eliminates such problems, as well as their possible occurrence. Insulating a wooden house with polyurethane foam not only outside, but also inside is considered very effective on any surface. In addition, it is worth noting such advantages as a high level of sound insulation, preservation of the original properties and shapes, as well as simple application.

Insulation of wooden structures from the outside. As you know, insulation of wooden structures is possible not only inside, but also outside. To retain heat in winter and cold in summer, it is necessary to insulate the surfaces of the house. When performing work outside, polyurethane foam uses a waterproofing function, which results in moisture penetration. If you compare polyurethane foam and mineral wool, you will notice a significant difference in the form of material consumption, as well as money. When insulating the facade, no cavities arise, which means there is no possible occurrence of condensation, which negatively affects other materials used in the construction of the house.

External insulation and finishing of wooden surfaces. The use of polyurethane foam is not limited to just one area, but also includes the use of any type of finish on top of it. Also, it is worth noting the fact that regardless of the area of application of polyurethane foam, it is not subject to any deformation, even after time. Since the service life of polyurethane foam reaches about 50 years, not excluding the effects of high and low temperatures.

Insulation of all surfaces of the room is the key to a comfortable and cozy stay in it

Cold floors not only do not create comfort, but also contribute to the development of human diseases. Also, it is worth considering that “anti-comfort” conditions include not only the presence of cold floors, but also high humidity. Such nuances often appear due to a damp basement in the house. Thus, the application of polyurethane foam when insulating a house should also be used when insulating the floor. Thanks to the latest technological developments, polyurethane foam can be used both during construction and repair work. So, when applying polyurethane foam in the basement on the ceiling, any possible sensation of cold floors is eliminated. Also, a similar method can be used on roofs to avoid any heat loss in the house.

- It is worth noting that by insulating any surfaces of a wooden house, you increase the level of sound insulation, which, of course, is a huge plus.

- A significant advantage of polyurethane foam insulation technology is the absence of additional structures, which greatly simplifies the process of building or renovating a room.

- One of the most important qualities of using polyurethane foam is its environmentally friendly composition. All microparticles that are part of this material contain hypoallergenic substances that eliminate any negative effects on health, including the occurrence of fungus, mold, allergic reactions, etc.

- The longevity of the material means no problems for the owners. As is known, the service life of polyurethane foam reaches about 50 years, which allows owners for many years not to think about the possible occurrence of problems with the coating, as well as heat loss in the house. While in Russia the use of this material is only gaining momentum, in European countries polyurethane foam has secured its leading position in the construction market.

- All-foam polyurethane foam can be applied to any surface, forming a layer that implies the absence of cracks and gaps. Also, it is worth noting that spraying polyurethane foam acts as an excellent protection for building structures from any negative influences that may cause destruction.

- Another advantage of using polyurethane foam for insulating a wooden house is that this material does not deteriorate, is not affected by bacteria, rodents and insects, and is not subject to deformation. Also, a significant advantage between other building materials is long-term use, unlike mineral wool, the service life of which does not exceed several decades.

- One of the unique advantages is ease of installation and the absence of additional structures. It is especially important that such advantages allow you to save not only time, but also money.

As already noted, polyurethane foam is one of the most environmentally friendly materials, since it contains vegetable oils that do not emit harmful substances and eliminate the occurrence of allergic reactions.

Insulation of houses is one of the most important stages in the construction of a residential building

And as practice shows, in order to prevent a significant portion of heat loss, during construction it is important to insulate not only the walls and roof, but also the basement. It is through the basements that moisture enters the house, which significantly aggravates not only the quality of the materials used, but also the microclimate. Thus, insulation in the basement is an equally important step in maintaining heat in the room.

It is worth considering the fact that in the soil the temperature reaches 5-10 degrees up to 2m. With proper installation of thermal insulation, it is possible to maintain this temperature even without heating in the basement. However, installed heating in the basement protects the room from freezing, the formation of dampness and condensation, and also protects from possible destruction.- As practice shows, it is best to insulate basements from the outside. But is there such a possibility in every case? Not always, especially if the house has already been built. In this case, thermal insulation work is carried out indoors. An excellent material in this case is polyurethane foam, which will not allow moisture into the basement, unlike mineral wool, which, on the contrary, most experts do not recommend when insulating basements. Mineral wool does not have the properties that can retain heat, eliminate dampness and not be subject to deformation.

Thus, the application of polyurethane foam has a number of advantages. For example, the service life of the material is 50 years. Polyurethane foam insulation is the most environmentally friendly and hypoallergenic. After all, it contains only vegetable oils that do not emit harmful substances and do not cause an allergic reaction.

As you know, the foundation is the basis of any building structure, which requires special attention

- In most cases, foundation insulation work is carried out from the outside, for which experts give preference to closed-cell material.

- When using polyurethane foam, a fairly serious advantage is the spray method of application, as well as the absence of the need for any additional structures. When applying polyurethane foam, the material is located on the surface in such a way that it eliminates all kinds of gaps, cracks and any existing seams.

- Using this insulation method, you can solve not only the issue of thermal insulation, but also waterproofing, ensuring reliable protection of the construction site from the influence of external factors.

- Also, it should be noted that when using polyurethane foam, any occurrence of dampness in the basement is eliminated, and heat loss is also eliminated.

- This highly effective use of polyurethane foam is due to the fact that the material is made according to European technological standards from high-quality imported raw materials. Thus, these technologies provide for long-term operation.

As you know, the use of polyurethane foam is becoming more relevant

Today, polyurethane foam is used not only for residential construction projects, but also for buildings such as hangars.

Why is polyurethane foam considered the best of its kind? Let's start with the fact that the thermal conductivity of polyurethane foam is significantly different from other insulating building materials, and is also not subject to loss of its properties. Such advantages are very important when choosing a method of insulating industrial premises, for example, a hangar.

Such a characteristic feature as a high environmental composition allows the use of polyurethane foam not only in residential premises, but also in areas such as hangars with animals or vegetable warehouses.

Useful and unique properties of polyurethane foam application, for example, waterproofing, also play a big role when choosing materials.

Insulating a hangar with polyurethane foam is one of the highest quality insulation methods. Since this material is not subject to exploitation, deformation and does not shrink. Also, it is worth noting that insulating a hangar with polyurethane foam by applying a foam composition blocks any penetration of cold, due to which heat loss is reduced by more than 50%.

Polyurethane foam is able to withstand any loads, as well as external influencing factors that do not involve the occurrence of cracks in the structure. If you use any other building materials to insulate a room, there is little chance that after some time you will not notice the occurrence of dampness or cracks.

The method of applying polyurethane foam implies great savings in installation time, as well as the absence of additional structures that will act as fasteners.

Also, it should be noted that insulation with polyurethane foam implies additional high-quality protection for the structure. Since the material is not subject to deformation from all kinds of influences.

The timing of installation and installation of polyurethane foam insulation is also considered a characteristic feature of this material. Since no additional structures are involved, the construction process is accelerated.

The best manufacturers of polyurethane foam

The ranking of well-known manufacturers of polyurethane foam is headed by brands that have earned recognition in the construction industry.

Soudal

The brand has factories in Poland, Belgium and Slovenia. Soudal brand products provide a structure that meets high European standards and a good yield volume. The sealant does not darken or deform over time, and the durability of the product is impressive.

Krimelte

The manufacturer from Estonia (Penosil brand) offers a variety of models of polyurethane foam for various purposes. Krimelte products are known in the professional environment for their decent price-quality ratio.

Titan

The Orion brand, with production facilities in Turkey, Spain and Poland, ranks third in the popularity rating among polyurethane foam suppliers. Products of this brand foam well without secondary expansion.

Moment of installation

The products of a well-known brand are in demand due to their decent quality and availability of solutions.

Ultima

The brand produces good quality polyurethane foam, the products are easy to use. Judging by consumer reviews, the sealant of this brand does not have an acceptable level of efficiency.

Foam for wall insulation

Axton

The company produces a sealant with high odorless polymerization characteristics, while reviews indicate low adhesion and high porosity of the structure.

Titan02

The highly popular mounting foam Titan02 is available in a winter version and with increased fire resistance. The product demonstrates exceptionally high efficiency when installing window and door structures. It is actively used in the repair of utility systems, sealing and thermal insulation of buildings. Titan02 sealant is sold within 230 rubles.

Penosil

The product is distinguished by its density and uniformity of structure with a large output volume. It is used for installation of structures, filling seams and cavities of varying complexity. The model range also includes special versions for foam plastic. The cost varies from 220 rub.

Review of manufacturers

In order for the insulation of the house to go without problems, and for the polyurethane foam to be of high quality, you need to purchase it from well-known manufacturers. There are several most popular companies:

- SYNTHESIA ESPANOLA SA produces different types of polyurethane foam, the materials are of high quality and ease of use;

- Ecotermix produces various thermal insulation systems, sprayed types of polyurethane foam;

- Demilec produces environmentally friendly thermal insulation based on polyurethane foam;

- Bayer is the world's leading chemicals manufacturer.

Receiving PPU

When mixed, polyol and isocyanate produce foam, which increases in volume and then hardens. During the manufacturing process, it is necessary to adhere to a number of requirements: maintain the required temperature and mix all components well, which makes it possible to obtain a polyurethane output that does not have seals and large air cavities.

If you change the production method, you get polyurethane foams that differ in their basic characteristics. Some are better suited for insulating openings for doors and windows, others for brick and panel buildings or pipelines. By changing the proportions of the ingredients, when mixing them, polyurethane foam with different cell sizes is obtained.

The most popular materials in this group are the following:

- Foam rubber. It is widely used in everyday life and is familiar to every person. It is used as an upholstery filler for upholstered furniture and lining material.

- Rigid polyurethane foam is used when performing installation work. It has been noticed that this insulation is negatively affected by acids and solvents.

Polyurethane foam is the best choice for ceiling insulation

Many of you will ask: “Is there such a material, ceiling insulation , which in turn is completely free from all of the above disadvantages?” We can tell you with complete confidence that such heat, hydro and vapor barrier material exists and has existed for a very long time. This material is polyurethane foam or, as many call it, PPU.

Insulation for the ceiling Insulation for the ceiling polyurethane foam Method of insulating the ceiling PPU Insulating the ceiling in a private house with polyurethane foam

This insulation has been used with great success in a wide range of thermal insulation works abroad for many years. Using this material, you can complete all insulation work very quickly, and most importantly, obtain excellent quality in the final result. Also, when using this insulation for the ceiling, there is no need to install vapor and waterproofing, which is a definite advantage.

Polyurethane foam insulation is a high-tech, modern material with the widest capabilities. Using it, you can insulate the ceiling in a private house, brick, wooden house, country house or in any other building. This heat-insulating material has one of the lowest vapor permeability coefficients, which in turn allows for ideal sealing of various junctions and joints. Polyurethane foam is safe, strong and durable.

DIY application technology

Applying liquid insulation does not require any professional skills or expensive equipment (with the exception of liquid foam). To work, you will need a roller (brush or spray). When using a roller, you will also need a container to evenly rub the mixture over its surface. The process itself includes the following steps:

- We prepare the surface (clean the walls from excess mortar, sweep with a brush and wash with water).

- We prepare the material (if necessary, dilute it to the desired consistency).

- Pour paint into the roller container.

- Dip the roller in paint and roll it out on a special area until the mixture evenly saturates the roller.

- We carefully apply the insulation to the wall, no need to press hard. The first layer is applied from bottom to top.

- Subsequent layers are applied after complete polymerization of the first, usually after 24 hours (to find out the exact values, see the instructions for the insulation).

When drying any of the layers, it is necessary to avoid getting them wet, since most liquid thermal insulators are water soluble. Because of this, the impact of water on insulation that has not completely hardened can cause its complete or partial removal from the surface.

Application technology - video instructions:

Consumption per 1 m2

As noted in the advantages, this insulation is quite economical. The consumption of polyurethane foam in cylinders is as follows: 1 liter is enough to cover a wall of 1 m2 with a layer 4 cm thick. For comparison, when working with mineral wool, you will need to spend more. In addition to the material, additional elements are needed for insulation, that is, sheathing, fasteners, etc., which also costs money.

Required layer thickness

It all depends on the region in which the object is located. For clarity, there is a table that indicates how thick the layer should be for a specific element.

Why polyurethane foam is not always good

With all its excellent characteristics, sprayed polyurethane foam is not without its drawbacks:

- Destroyed by exposure to ultraviolet radiation.

- Low vapor permeability requires a forced ventilation device.

- The material is self-extinguishing, but in fire conditions it emits toxic gas; the addition of fire retardants improves the situation by 3...5 years (the service life of the fire retardant).

- To apply insulation, a surface capable of bearing additional load is required.

- Installation of thermal insulation requires expensive equipment and professional skills.

- The cost of the material together with installation significantly exceeds the cost of insulation with traditional materials - polystyrene foam and mineral wool boards.

Features of insulation application technology

The technology for installing sprayed insulation in cylinders involves the following steps:

- the cylinder is equipped with a special tube or gun, having first removed the lid;

- shake the composition thoroughly for at least 60 seconds;

- before applying foam thermal insulation, the surface is treated with water;

- The cylinder is held with the bottom up, the voids are filled to 1/3 of the volume, leaving room for expansion of the composition.

When the foam fills the entire volume of the gap, it is recommended to sprinkle the mass with water to improve the polymerization process. Curing time for foam insulation varies depending on the model and brand, and manufacturers produce products of varying quality. Surface hardening is observed within approximately 20 minutes after spraying. Correction of the mass using a cutting tool begins no earlier than after 4 hours. The full period of polymerization of foam floor insulation in cylinders requires a period of at least 24 hours.

Providing protective equipment

When applying polyurethane foam in cylinders for floor insulation, it is worth considering that the composition is poorly washed off from skin and clothing. You should work in protective clothing; it is also important to use safety glasses and gloves. Manipulations of spraying polyurethane foam with special equipment are performed using professional equipment to completely eliminate contact of the skin and mucous membranes with the substance.

When insulating a floor with foam, you need to use protective equipment

Thermal insulation of the floor by spraying

Installation of polyurethane foam when insulating floors using spraying technology involves the use of special installations. The foam insulator components are contained in separate tanks. The working composition is prepared directly on site before use. Substances enter the mixing device, are then sent to a spray gun and applied under pressure to the surface to be treated.

Features of installation of foam insulation:

- a frame structure is constructed for applying spray-on thermal insulation. Experts recommend lathing depending on the nature of the area being treated. For example, for effective thermal insulation of a wall structure, it is advisable to build a wooden or metal frame with an interval between guides of 30 cm. If you plan to insulate the floor with sprayed polyurethane foam, you should create a sheathing in increments of up to 1 m;

- the foam composition is applied by smoothly moving the jet over the surface to ensure uniform distribution of the mass;

- when processing vertical planes, foam insulator is sprayed from the lower perimeter, gradually filling the openings upward;

- When manipulating, keep the spray gun at a distance of at least 25 cm from the surface to be treated. When moving to another sector, you must release the gun trigger to block the stream.

If you plan to insulate the floor with two-layer spray foam, it is necessary to allow time for complete polymerization of the previous layer. After the mass has hardened, adjustments begin: cut off all protruding fragments with a sharp knife and level out any unevenness.

The flooring is laid after the foam insulation has completely polymerized.

Floor insulation by pouring method

The technology involves creating monolithic thermal insulation in the floor structure by pouring foam into specially made cavities. For example, a rough plank floor is constructed on joists, and small holes are made on the surface in designated areas for pumping polyurethane foam. If thermal protection of walls is planned by pouring polyurethane foam, the cladding is performed with a technical gap between the base and the finishing material. Next, the foam composition is poured through special holes on the facing panel.

Filling is carried out on the basis of the same spraying installations, reconfiguring the equipment parameters. In a professional environment, special units are also used for pouring polyurethane foam, which determines the high-quality level of thermal insulation work. The foam substance exclusively fills all voids down to the slightest cracks, resulting in the formation of a sealed thermal barrier with high performance characteristics.

Briefly about the main thing

Polyurethane foam is a porous polymer material with low thermal conductivity.

To insulate a house, a composition is used that is sold in liquid form: ready-made in cylinders or two separate components for work using special installations.

Two-component polyurethane foam with a high content of closed cells (up to 90%) is considered universal for use. The best in this group is considered to be a composition filled with carbon dioxide.

Polyurethane foam is used locally, has a structure with a small number of closed pores, therefore it is afraid of moisture and allows heat to pass through better.

The higher the density of polyurethane foam, the lower the thermal conductivity, but such material is acceptable for insulating existing roofs and ceilings.

Ratings 0

Which liquid insulation to choose?

As is known, long-term or improper storage significantly worsens the properties of materials, especially liquid insulation. In this regard, when choosing a composition, you should first of all pay attention to the date of its manufacture. In addition, it is recommended to give preference to well-known brands that have proven themselves, because the effectiveness of the entire thermal insulation system depends on the quality of the liquid insulation.

In order to ensure the quality of liquid insulation produced in the form of paint, experts recommend:

- Check the weight of the bucket - the lower the density of the composition, the higher its heat-saving properties. Therefore, if a ten-liter plastic bucket weighs more than 6.5 kilograms, then you should not purchase such a composition.

- Check the paint against light, as light microspheres rise up. Therefore, the thicker the top layer of insulation, the better its thermal insulation characteristics.

- Rub a small amount of paint with your fingertips - a good material should feel a large number of rough microgranules. The absence of such an effect indicates low quality of the product.

- Make sure the composition is white - a change in color indicates gross violations of the technological process. However, this rule does not apply to paints with mineral color additives.

It should be noted that in this case you should not focus on the cost of the product, since some manufacturers deliberately sell low-quality products at inflated prices in the hope that the choice stereotype will be triggered.

Advantages and disadvantages of liquid insulation

Among the positive qualities are the following:

- Possibility of application to surfaces with almost any relief;

- Resistance to atmospheric factors;

- Low cost of installation work;

- Liquid insulation forms a monolithic layer, without joints that occur when using sheet materials.

- There is no need to coordinate the insulation with the supervisory authorities, since after application the appearance of the building remains unchanged;

- The high adhesive properties of liquid insulators eliminate the need for careful surface preparation;

Flaws:

- If storage and transportation rules are not followed, there is a high probability of premature loss of the mixture’s performance qualities;

- Short service life compared to traditional insulation;

- High cost of some products;

- Many foam materials cannot be applied without special equipment;

Where is this material used?

Polyurethane thermal insulation has a very wide range of uses. For the most part, it can be combined with almost any type of surface, even with the floor. However, due to its expensive cost and certain disadvantages, the heat insulator

may not always apply. The material can be of a wide variety of structure types: integral, rigid and plastic. The areas of its use are as follows.

- Roofs. As an insulation material for roofing, it is considered an ideal option, because polyurethane, invisible from sunlight, does not rot, and as a result, the service life will be approximately fifty years.

- Innovative containers. Artificial latex in the form of insulation material will be highly effective, for example, with storage heating devices.

- Walls. Thermal insulation can be used to cover external and internal surfaces. This treatment protects the walls from the adverse effects of winds, rain, temperature changes and other phenomena.

- Floors. The product fits perfectly on horizontal planes. The layer required for good insulation is not very large, thanks to this the distance from the floor to the ceiling surface will not decrease significantly.

- Attics. With the help of insulating sprayed material, thermal insulation of attic walls, which for the most part are of a heavy form, with countless hard-to-reach places and joints, is conveniently performed.

Application

It is allowed to use Polinor insulation both inside and outside the house. At the same time, make sure that it is not directly affected by sunlight and moisture. The installation process is very simple and quick, and even an inexperienced person can cope with the task. All that is required is to install the container on the spray foam gun.

But before this, it is important to properly prepare the surface. It must be cleaned of dust, dirt and moistened with water. The process of applying foam is performed with smooth movements, without jerking. Thanks to this, you can obtain a uniform layer of insulation. Polymerization occurs through reaction with moisture. If you additionally moisten the surface, the composition will be more voluminous. Rubber door seals can provide additional insulation.

Video showing the use of sprayed polyurethane insulation polynor:

In addition, the material becomes lush even at a temperature of 20 degrees. But at a temperature of 15 degrees, the composition becomes dense. The material can be applied both to the frame and to the wall. The choice of a particular method depends on the subsequent cladding.

The following options are provided:

- applying paint;

- applying a layer of plaster;

- use of drywall, OSB, lining, siding.

Polynor insulation is sprayed on in several layers. It can be used not only for thermal insulation of walls, but also floors and roofs. It is often used when insulating various metal tanks and communications.

The sprayed composition is able to pass through all cracks and hard-to-reach places, forming a monolithic seamless layer. It will not allow heat, steam and moisture to pass through. The material should only be applied with gloves and safety glasses, as it has a strong and pungent odor. It is very difficult to be in an unventilated room, but after installation the smell disappears very quickly.

You may also be interested in learning about which insulation for external walls under plaster is best to use.

But this information will help you understand what a wall pie of a frame house with basalt insulation is and in what cases it is used.

What are the characteristics of mineral wool insulation and where can it be used and how exactly. This video explains it in great detail.

And this information will help compare the thermal conductivity of insulation materials.

This article will help you understand what Energoflex water supply pipe insulation is and where it is most often used.

Is polyurethane foam harmful to health?

This question interests many. After all, insulation is most often applied from the inside of the walls. And since it is a polymer substance produced through a chemical reaction, people are afraid that it will release toxic substances.

Indeed, while liquid polyurethane foam is sprayed onto walls, its contact with the skin or inhalation can be dangerous. Therefore, it is recommended to carry out all work wearing a respirator and protective clothing.

But after hardening, polyurethane foam no longer causes harm. And it dries in 20 seconds, so the finished layer of heat-insulating material is absolutely safe.

Sputtering process

Consumer properties

Like any insulating material, Polynor has a number of advantages:

- Features excellent heat conservation. These insulation indicators are higher compared to expanded polystyrene and mineral wool.

- Non-toxic. Consumer reviews about Polinor are quite good, since it is not poisonous and does not require protective equipment when using it.

- Ease of use. When using POLYNOR, a heat-insulating layer is created, which does not require a frame for fastening. Also, no tools or auxiliary materials are required.

- Excellent grip. The composition quickly adheres to any surface - brick, wood, plastic, stone, concrete, which significantly expands the scope of its application.

Polynor insulation is very popular due to the fact that it is applied by spraying. This affects better adhesion of different surfaces, even if they are not very smooth. Very often this insulation is used to finish hard-to-reach places, for example, where pipes or cables are laid.

Since ancient times, people have paid sufficient attention to insulating their baths.

After all, the quality of insulation of a bathhouse or sauna structure is directly related to the quality of the parka.

For quite a long time, mineral wool was used to insulate baths, which lost its importance and lost its competitiveness with the advent of polyurethane foam on the building materials market.

As you know, this material works on the principle of a thermos, retaining heat inside. This principle is achieved by spraying the building material, which eliminates any gaps and air penetration.

Also, it should be noted that a rather important fact is that polyurethane foam has a G2 fire certificate. This guarantees the preservation of the premises even with a high risk of fire.

The main feature that is characteristic only of polyurethane foam is the environmentally friendly materials that are used to create the insulation. And since a bathhouse or sauna requires a high percentage of humidity, as well as high temperature, this quality is extremely necessary.